Feed Processing Machinery Market Report

Published Date: 31 January 2026 | Report Code: feed-processing-machinery

Feed Processing Machinery Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the Feed Processing Machinery market, covering various aspects including market size projections, segmentation, regional insights, and trends from 2023 to 2033. Detailed analyses of key players, technologies, and market forecasts are also included to help stakeholders understand this vibrant industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

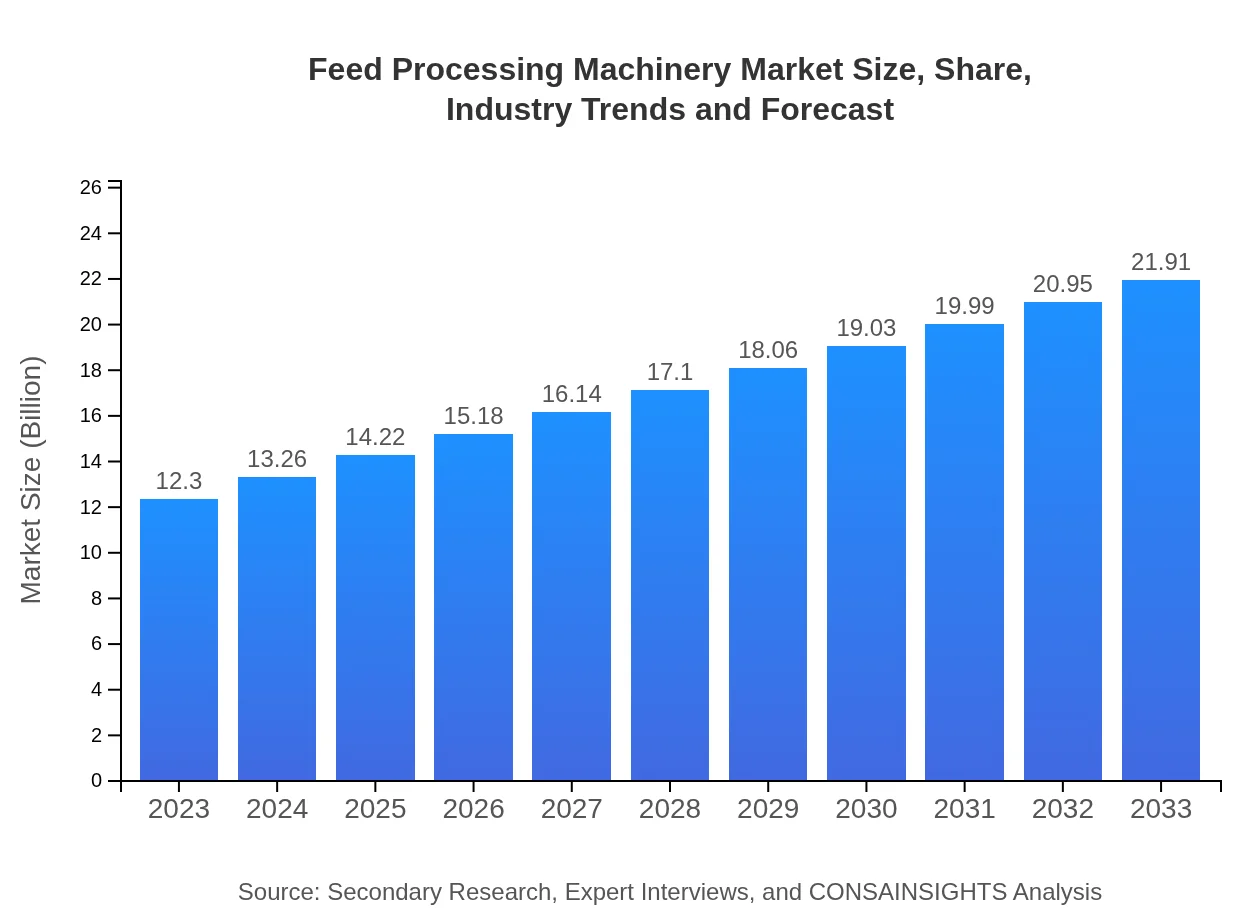

| 2023 Market Size | $12.30 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $21.91 Billion |

| Top Companies | ANDRITZ Group, Bühler Group, CPM Holdings, Inc., Schutte-Buffalo Hammermill |

| Last Modified Date | 31 January 2026 |

Feed Processing Machinery Market Overview

Customize Feed Processing Machinery Market Report market research report

- ✔ Get in-depth analysis of Feed Processing Machinery market size, growth, and forecasts.

- ✔ Understand Feed Processing Machinery's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Feed Processing Machinery

What is the Market Size & CAGR of Feed Processing Machinery market in 2023?

Feed Processing Machinery Industry Analysis

Feed Processing Machinery Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Feed Processing Machinery Market Analysis Report by Region

Europe Feed Processing Machinery Market Report:

In Europe, the Feed Processing Machinery market was valued at USD 3.44 billion in 2023, with projections reaching USD 6.12 billion by 2033. The stringent regulations regarding feed quality and safety compel manufacturers to invest significantly in advanced processing technologies.Asia Pacific Feed Processing Machinery Market Report:

In the Asia Pacific, the market was valued at USD 2.67 billion in 2023, projected to grow to USD 4.75 billion by 2033. The growth is primarily driven by increased livestock farming and investments in modern agriculture techniques in countries like China and India. Moreover, rising consumer preferences for high-quality meat and dairy products fuel demand for advanced feed processing solutions.North America Feed Processing Machinery Market Report:

The North American market, valued at USD 3.98 billion in 2023, is forecasted to expand to USD 7.10 billion by 2033. The region's focus on enhancing feed efficiency and sustainability, coupled with technological innovations, drives market growth. The United States remains a key player with advanced livestock production methods.South America Feed Processing Machinery Market Report:

South America, with a market value of USD 0.52 billion in 2023, is expected to reach USD 0.93 billion by 2033. This growth reflects expanding production capacities in Brazilian and Argentinian agriculture, along with a shift towards better feed quality increasing productivity in livestock farming.Middle East & Africa Feed Processing Machinery Market Report:

The Middle East and Africa exhibit a growing market, valued at USD 1.69 billion in 2023, with expectations to rise to USD 3.01 billion by 2033. Rapid urbanization and increased meat consumption propelling demand for feed processing solutions, alongside improvements in agriculture techniques, contribute to this growth.Tell us your focus area and get a customized research report.

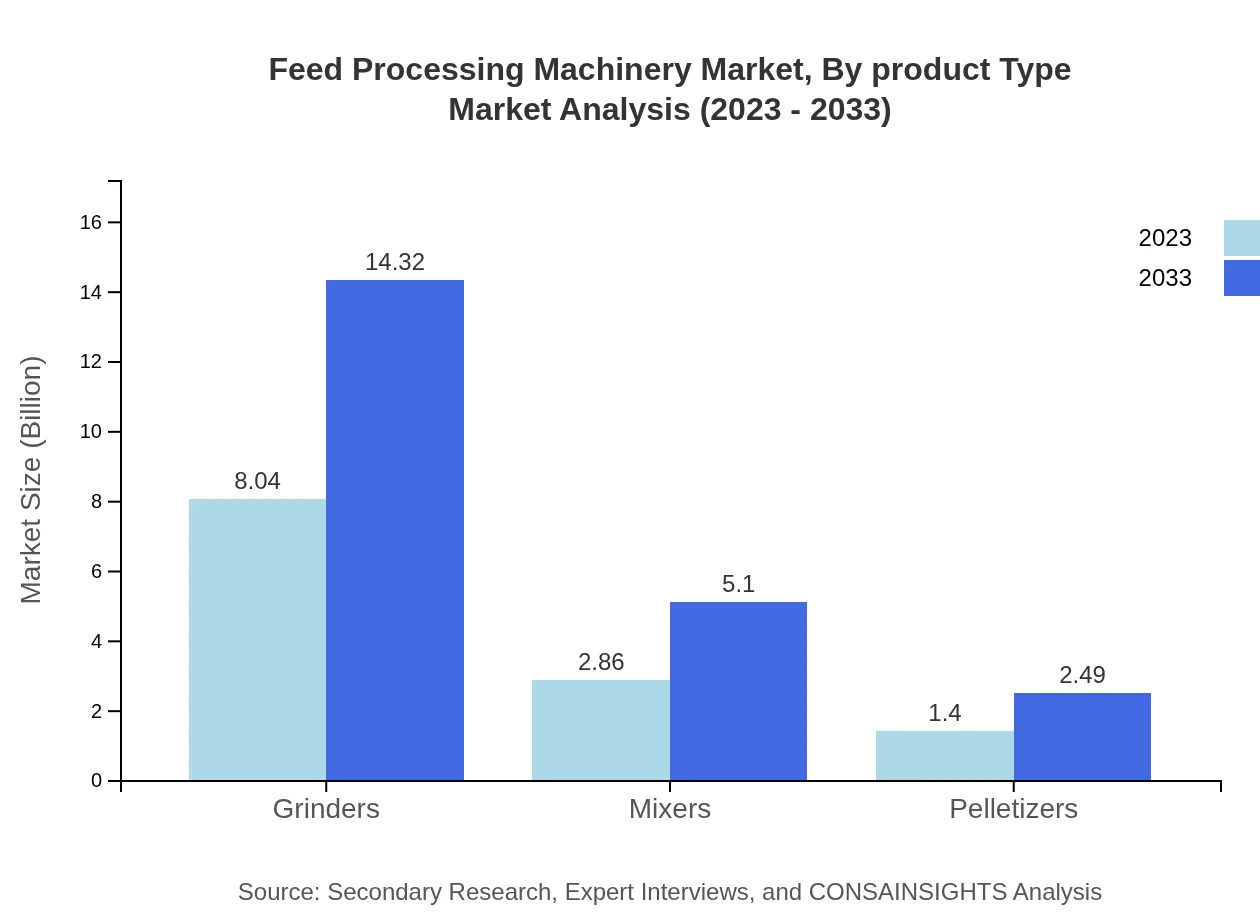

Feed Processing Machinery Market Analysis By Product Type

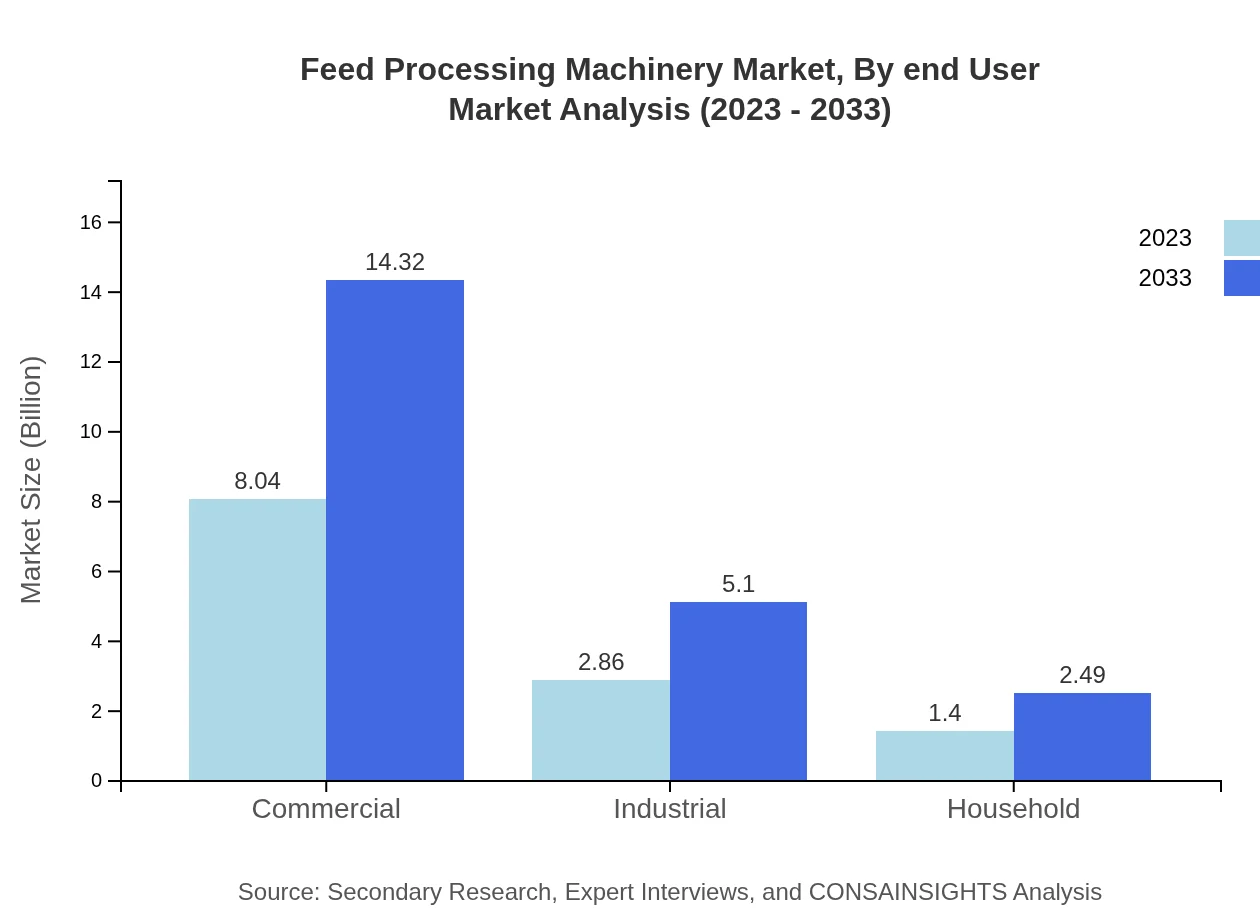

The Feed Processing Machinery market by product type is notably segmented into grinders, mixers, and pelletizers. Grinders dominate the market with a size of USD 8.04 billion in 2023, projected to grow to USD 14.32 billion by 2033, representing 65.36% of market share. Mixers and pelletizers follow, with sizes projected at USD 2.86 billion and USD 1.40 billion respectively in the same period.

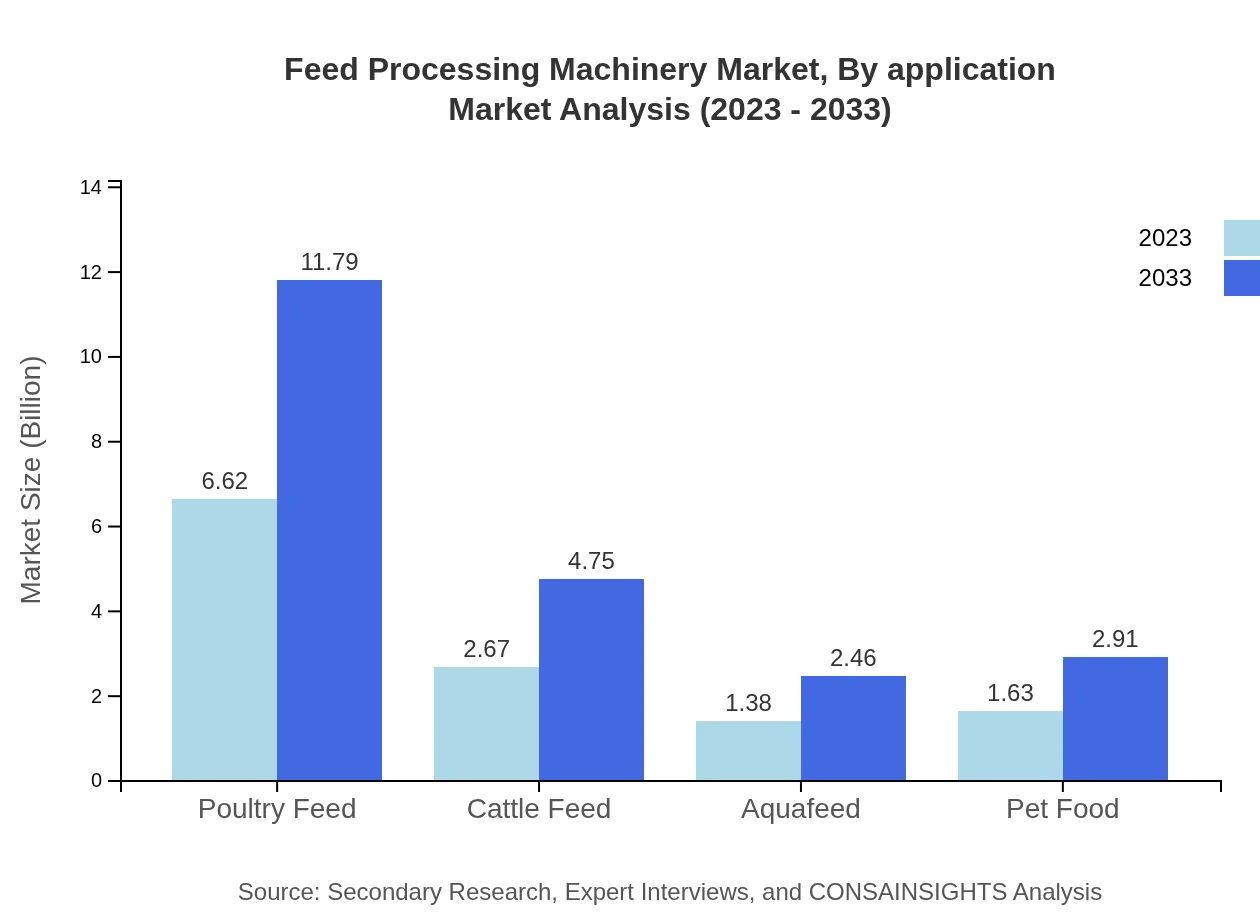

Feed Processing Machinery Market Analysis By Application

By application, poultry feed leads the way with a size of USD 6.62 billion in 2023 and expected to reach USD 11.79 billion by 2033, holding 53.82% market share. However, cattle feed, aquafeed, and pet food are also significant contributors, reflecting a diverse application landscape.

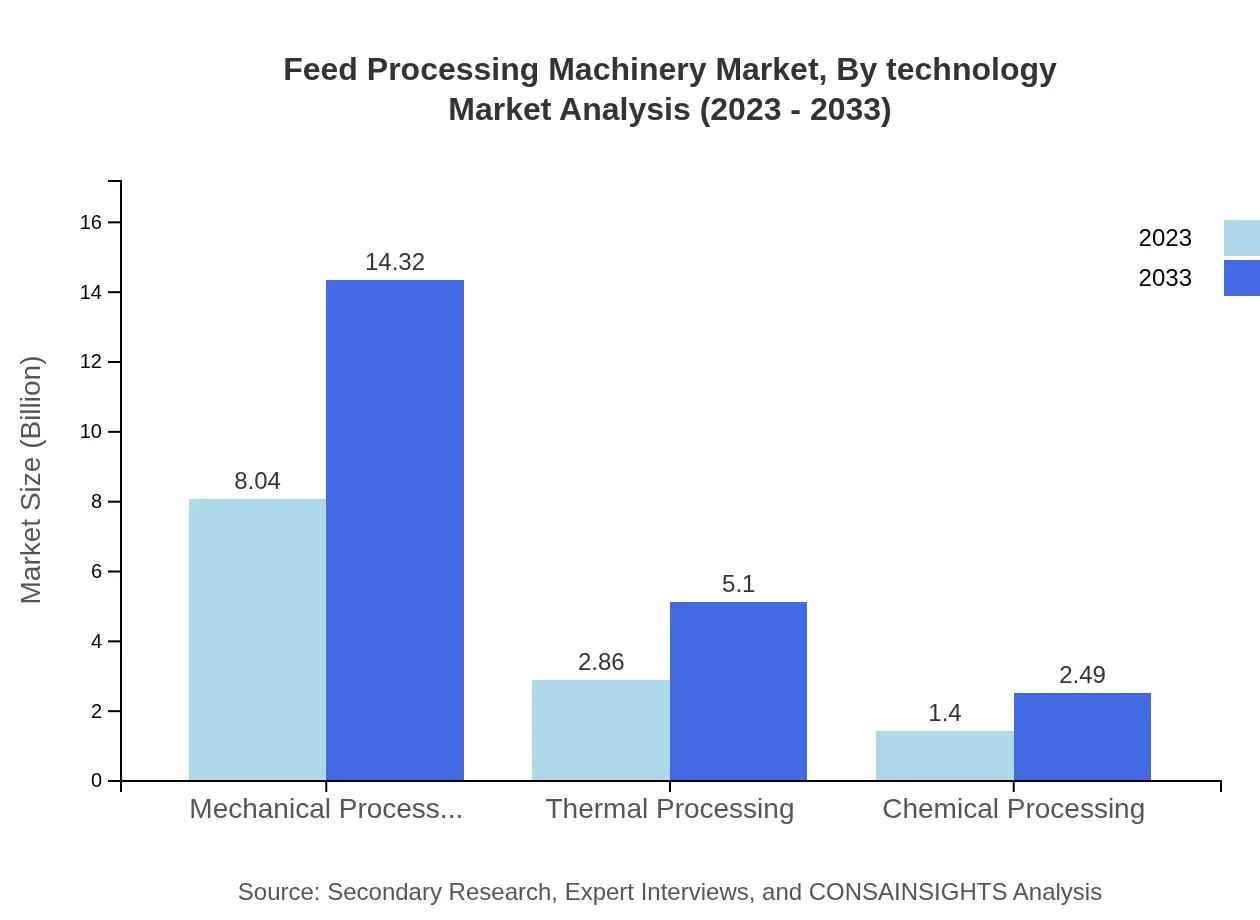

Feed Processing Machinery Market Analysis By Technology

Technology plays a vital role in the Feed Processing Machinery sector, with a shift towards automation and smart technologies. Processing advancements, particularly in thermal and mechanical methods, have influenced market growth, signaling a trend towards energy-efficient and user-friendly machinery.

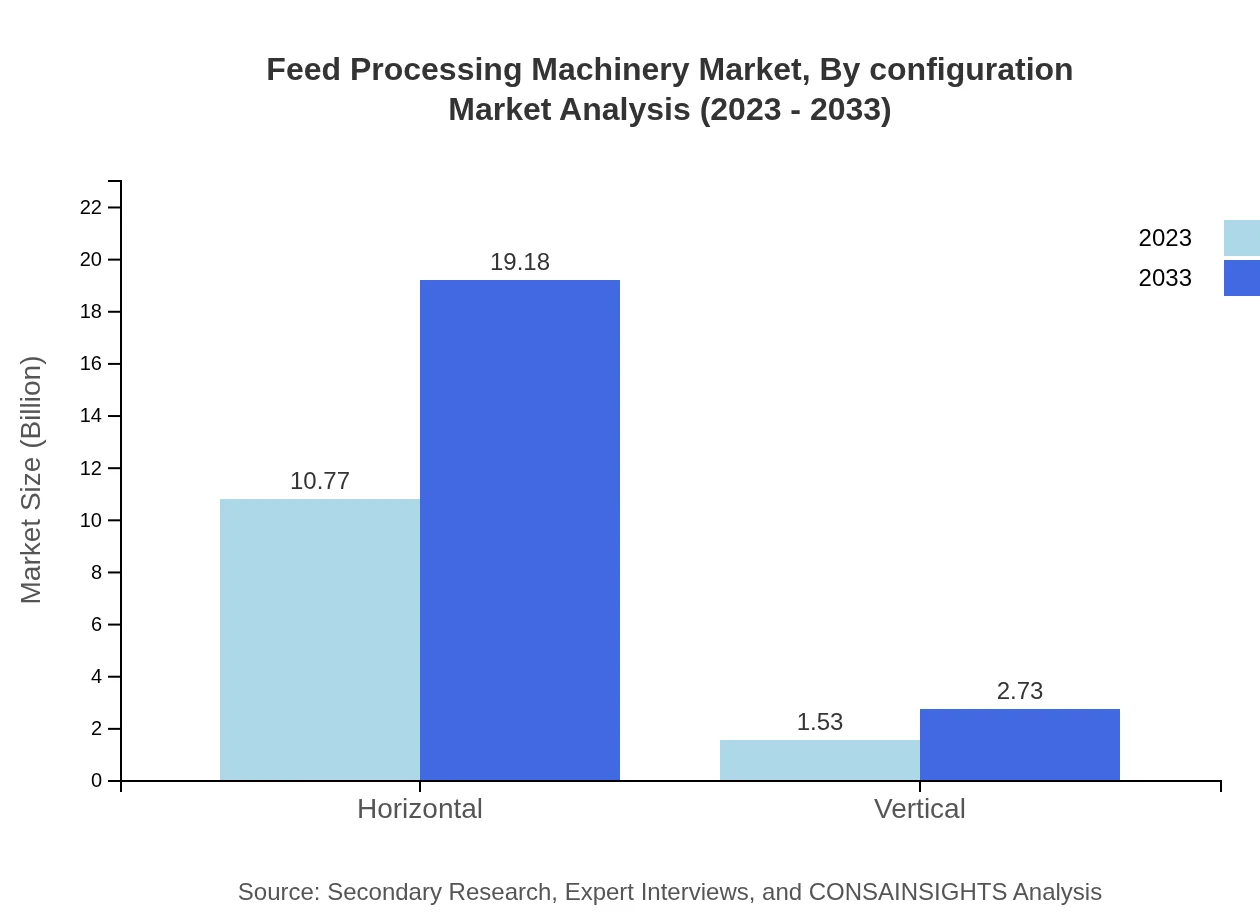

Feed Processing Machinery Market Analysis By Configuration

Configuration analysis reveals strong demand for horizontal feed processing machinery, valued at USD 10.77 billion in 2023 and set to increase to USD 19.18 billion by 2033, taking a significant market share of 87.55%. Vertical configurations are emerging but hold a smaller segment of the market.

Feed Processing Machinery Market Analysis By End User

End-user segmentation indicates that commercial entities are the largest consumers, valued at USD 8.04 billion in 2023 and projected at USD 14.32 billion by 2033, covering 65.36% of the market, followed by industrial and household users, which are gradually gaining prominence.

Feed Processing Machinery Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Feed Processing Machinery Industry

ANDRITZ Group:

ANDRITZ Group specializes in industrial machinery and is a leader in the feed and biofuel sectors, developing advanced processing systems for higher efficiency and productivity.Bühler Group:

Bühler Group is renowned for its innovative technologies in feed processing and is committed to sustainability, helping clients improve output through modern solutions.CPM Holdings, Inc.:

A major player in production equipment, CPM focuses on processing machinery for various industries, including premium solutions for animal feeds.Schutte-Buffalo Hammermill:

Schutte-Buffalo is known for manufacturing high-quality hammer mills and pulverizers that cater to the feed processing market.We're grateful to work with incredible clients.

FAQs

What is the market size of feed Processing Machinery?

The global feed processing machinery market was valued at approximately $12.3 billion in 2023, with a projected CAGR of 5.8% from 2023 to 2033, indicating robust growth prospects over the next decade.

What are the key market players or companies in this feed Processing Machinery industry?

Key players in the feed processing machinery market include prominent manufacturers such as Buhler AG, Andritz AG, AGICO Group, and Clextral. These companies lead the industry with innovative solutions and advanced technologies.

What are the primary factors driving the growth in the feed Processing Machinery industry?

Growth in the feed processing machinery market is driven by increasing demand for high-quality animal feed, advancements in technology, the rise of livestock population, and the need for improved feed quality and nutritional value.

Which region is the fastest Growing in the feed Processing Machinery?

The Asia Pacific region is the fastest-growing market for feed processing machinery, showing significant growth from $2.67 billion in 2023 to approximately $4.75 billion by 2033, reflecting the rising need for sustainable feed solutions.

Does ConsaInsights provide customized market report data for the feed Processing Machinery industry?

Yes, ConsaInsights offers customized market report data to cater to specific industry needs. This tailored approach ensures access to the most relevant and actionable insights for clients.

What deliverables can I expect from this feed Processing Machinery market research project?

Deliverables from the feed processing machinery market research project include comprehensive market analysis, detailed segmentation insights, competitive landscape evaluation, regional market data, and growth forecasting over the next decade.

What are the market trends of feed Processing Machinery?

Current trends in the feed processing machinery market include a shift towards automation, increased use of eco-friendly materials, growth in nutritional feed additives, and advancements in processing equipment technology, enhancing efficiency and output.