Fiberglass Cutting Robots Market Report

Published Date: 22 January 2026 | Report Code: fiberglass-cutting-robots

Fiberglass Cutting Robots Market Size, Share, Industry Trends and Forecast to 2033

This market report offers a comprehensive analysis of the Fiberglass Cutting Robots industry, detailing market size, trends, forecasts from 2023 to 2033, and insights across various segments and regional markets.

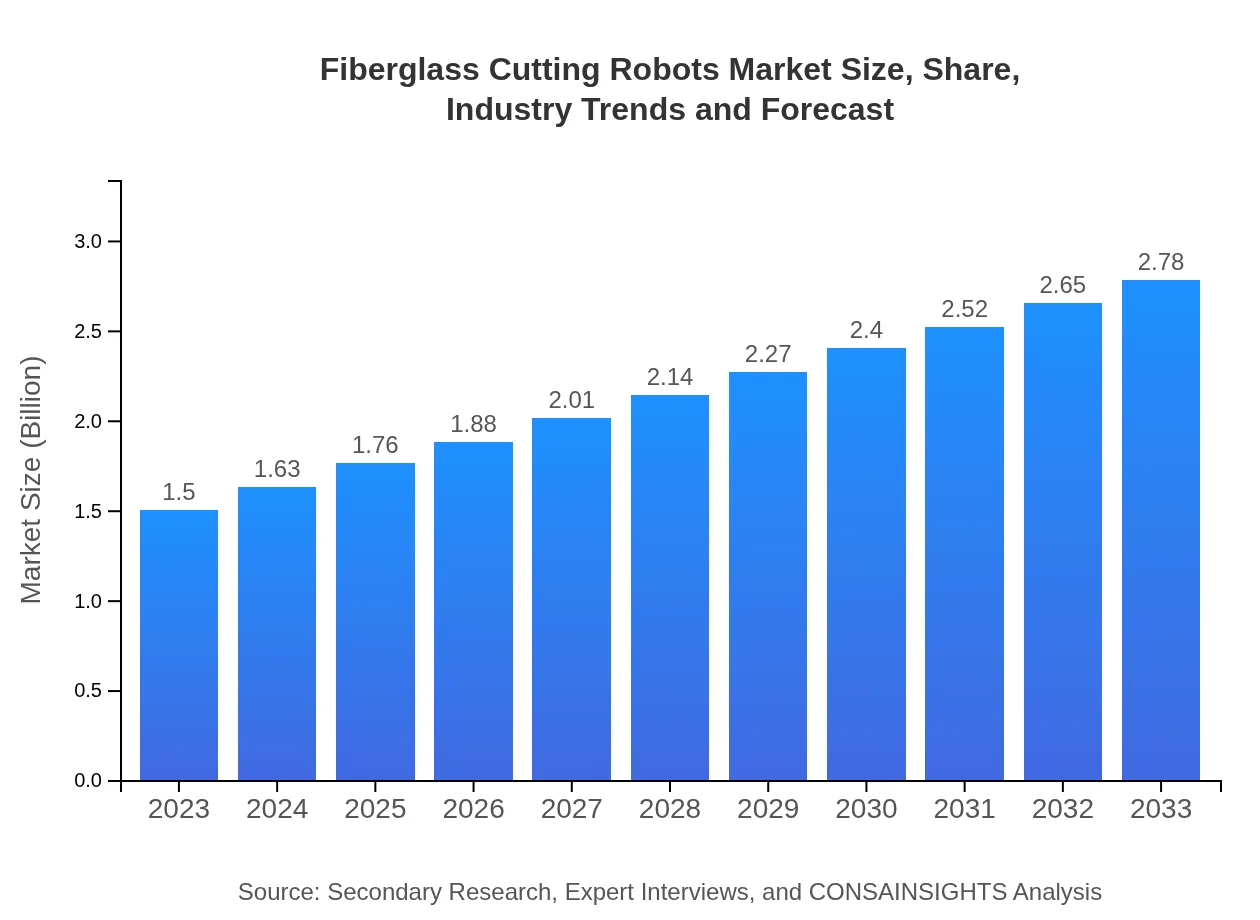

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $2.78 Billion |

| Top Companies | FANUC Corporation, KUKA AG, ABB Ltd, Yaskawa Electric Corporation |

| Last Modified Date | 22 January 2026 |

Fiberglass Cutting Robots Market Overview

Customize Fiberglass Cutting Robots Market Report market research report

- ✔ Get in-depth analysis of Fiberglass Cutting Robots market size, growth, and forecasts.

- ✔ Understand Fiberglass Cutting Robots's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Fiberglass Cutting Robots

What is the Market Size & CAGR of Fiberglass Cutting Robots market in 2023?

Fiberglass Cutting Robots Industry Analysis

Fiberglass Cutting Robots Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Fiberglass Cutting Robots Market Analysis Report by Region

Europe Fiberglass Cutting Robots Market Report:

In Europe, the market size is estimated at $0.43 billion in 2023, projected to grow to $0.80 billion by 2033. European countries are actively adopting automation technologies to enhance their manufacturing efficiency. The aerospace sector in particular contributes significantly to this growth, signaling a robust transitional phase towards greater precision in production.Asia Pacific Fiberglass Cutting Robots Market Report:

In 2023, the Asia Pacific region holds a market size of $0.31 billion, projected to grow to $0.57 billion by 2033. The rapid industrialization in countries like China and Japan, coupled with increasing investments in advanced manufacturing technologies, is fueling this growth. Additionally, a strong demand from the automotive and aerospace sectors supports the expansion of fiberglass cutting robots in this region.North America Fiberglass Cutting Robots Market Report:

North America represents a significant market for fiberglass cutting robots, with a size of $0.52 billion in 2023, projected to reach $0.96 billion by 2033. The USA’s focus on advanced manufacturing and robotics adoption in the automotive and aerospace industries is driving the growth. Furthermore, the presence of key robotics manufacturers supports regional expansion.South America Fiberglass Cutting Robots Market Report:

The South American market for fiberglass cutting robots is comparatively smaller, estimated at $0.12 billion in 2023, expected to grow to $0.22 billion by 2033. Growth is limited due to economic volatility; however, expansion in manufacturing capabilities and investments in infrastructure are paving the way for gradual market development. Countries such as Brazil and Argentina are leading the charge.Middle East & Africa Fiberglass Cutting Robots Market Report:

The Middle East and Africa market is growing gradually, with a 2023 valuation of $0.12 billion and growth expected to $0.22 billion by 2033. Investments in green technology and infrastructure development are critical to market growth. While the market is nascent, increasing interest in manufacturing capabilities is a positive sign for future expansion.Tell us your focus area and get a customized research report.

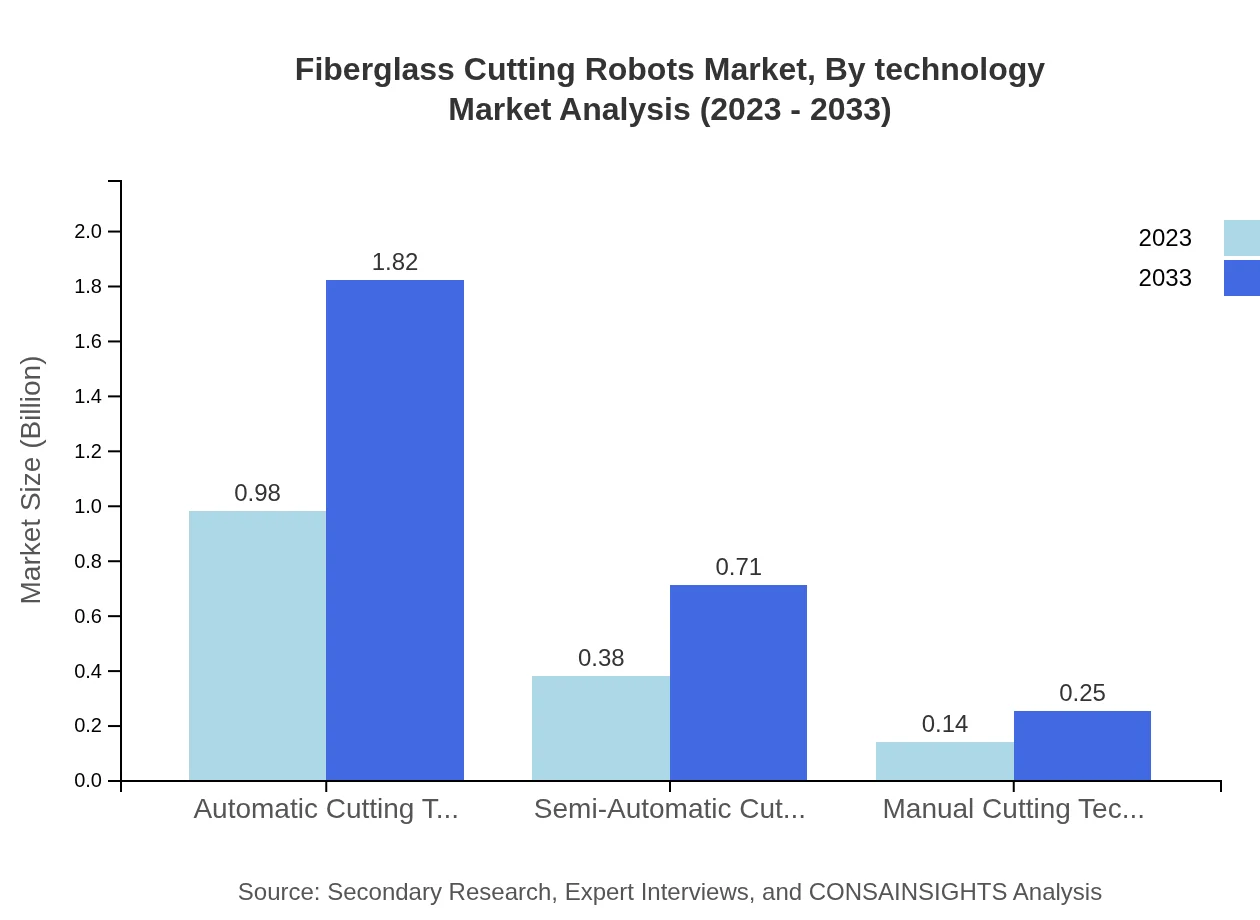

Fiberglass Cutting Robots Market Analysis By Technology

The technology segment is divided into automatic, semi-automatic, and manual cutting technologies. Automatic cutting technology dominates the market, representing a size of $0.98 billion in 2023, expected to rise to $1.82 billion by 2033, accounting for over 65% market share. Semi-automatic and manual technologies, although smaller, play a crucial role in niche applications, retaining significant share in specific manufacturing setups.

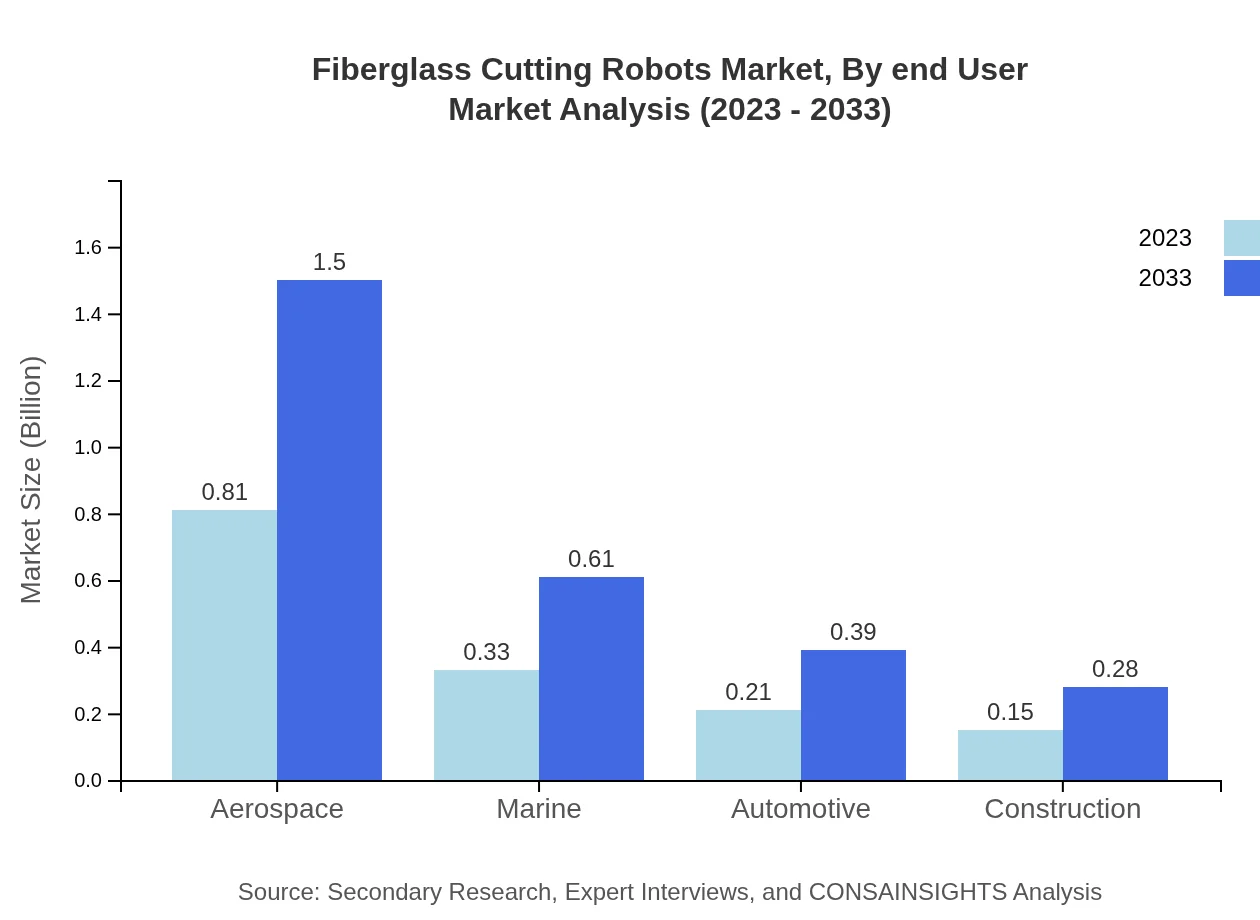

Fiberglass Cutting Robots Market Analysis By End User

The end-user segment highlights diverse applications in industries such as aerospace, automotive, marine, and construction. Aerospace is the leading sector, with a market share of 53.96% in 2023, expected to grow significantly as the demand for lightweight materials increases. Automotive follows, accounting for 14.03% share, with growing automation trends driving the need. Other sectors, while smaller, are also expected to increase their adoption of fiberglass cutting robots.

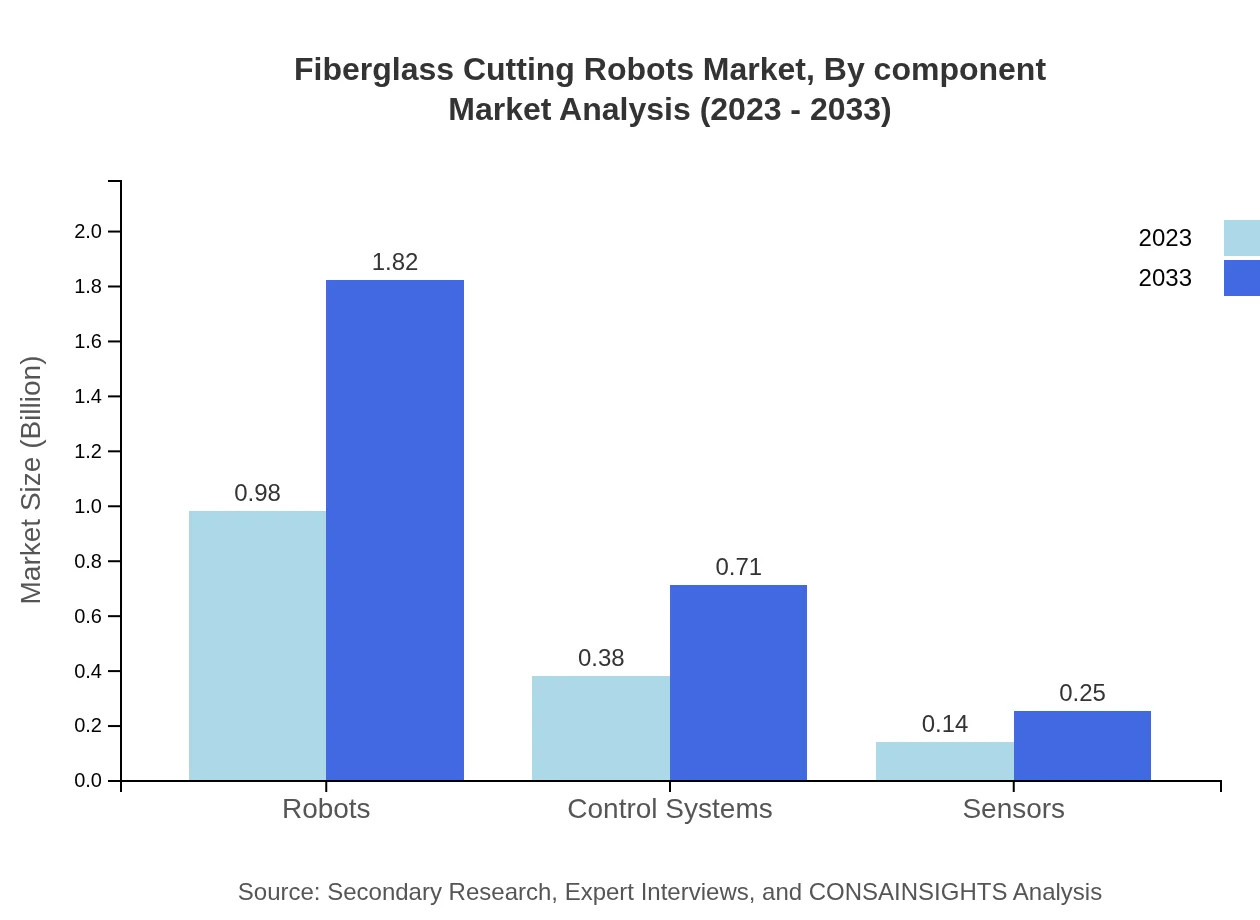

Fiberglass Cutting Robots Market Analysis By Component

In the component analysis, control systems and sensors are critical for the functionality of fiberglass cutting robots. Control systems represent a market size of $0.38 billion in 2023 and are projected to grow to $0.71 billion by 2033, with a 25.63% share. Sensors are also essential, albeit smaller, represented by a size of $0.14 billion, expected to grow to $0.25 billion by 2033.

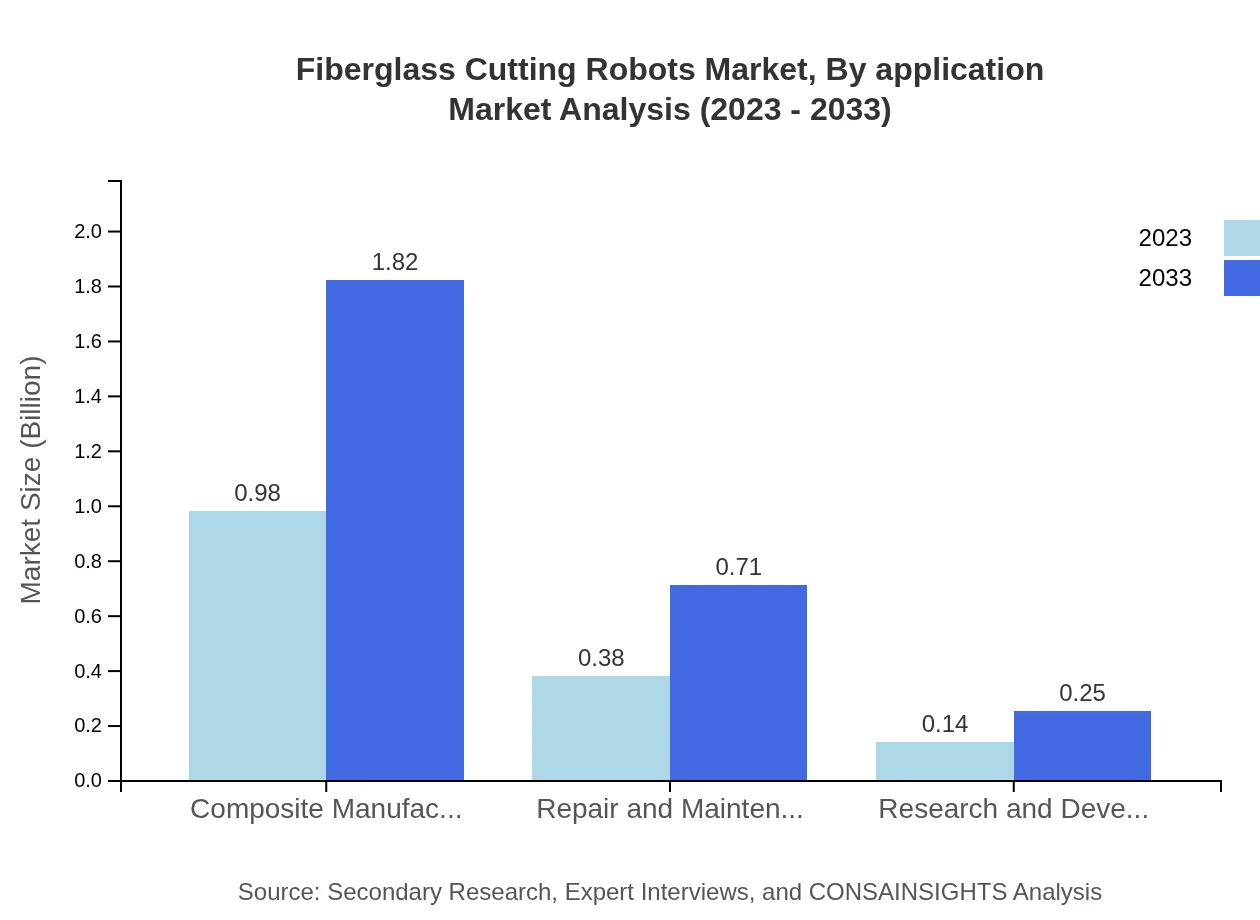

Fiberglass Cutting Robots Market Analysis By Application

The application segment includes uses in composite manufacturing, maintenance, and research and development. Composite manufacturing leads with a market size of $0.98 billion and a market share of 65.36%, rapidly growing as new materials are developed. Repair and maintenance applications show significant potential, valued at $0.38 billion in 2023 and projected to grow steadily.

Fiberglass Cutting Robots Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Fiberglass Cutting Robots Industry

FANUC Corporation:

A global leader in robotics and automation, FANUC specializes in manufacturing high-performance robots for various applications, including fiberglass cutting.KUKA AG:

KUKA is known for its innovative robotic solutions and automation technologies, playing a pivotal role in the fiberglass cutting sector.ABB Ltd:

ABB provides advanced robotic solutions, particularly in manufacturing and integration of cutting-edge systems in various industries.Yaskawa Electric Corporation:

Yaskawa focuses on industrial robotics and automation solutions, offering advanced cutting technologies for fiberglass and composite materials.We're grateful to work with incredible clients.

FAQs

What is the market size of fiberglass Cutting Robots?

The fiberglass-cutting robots market is projected to reach approximately $1.5 billion by 2033, growing at a CAGR of 6.2% from the current year.

What are the key market players or companies in the fiberglass Cutting Robots industry?

Key players in the fiberglass-cutting robots industry include companies such as ABB Ltd, KUKA AG, and Yaskawa Electric Corporation, which provide advanced robotic solutions for composite cutting.

What are the primary factors driving the growth in the fiberglass Cutting robots industry?

Growth in the fiberglass-cutting robots industry is driven by increasing demand for automation, advancements in robotics technology, and the rising need for precision in manufacturing processes across sectors such as aerospace and automotive.

Which region is the fastest Growing in the fiberglass Cutting robots?

The fastest-growing region in the fiberglass-cutting robots market is North America, expected to grow from $0.52 billion in 2023 to $0.96 billion by 2033, fueled by advancements in robotic technologies.

Does ConsaInsights provide customized market report data for the fiberglass Cutting robots industry?

Yes, ConsaInsights offers customized market report data to cater to specific needs in the fiberglass-cutting robots industry, allowing clients to obtain targeted insights and analysis.

What deliverables can I expect from this fiberglass Cutting robots market research project?

Expect to receive detailed market analysis, segmentation breakdown, trend insights, forecasts, and competitive landscape evaluations in the fiberglass-cutting robots market research project.

What are the market trends of fiberglass Cutting robots?

Current market trends for fiberglass-cutting robots include a shift towards automation, increased application in aerospace and automotive, and growing interest in eco-friendly composite materials.