Filling Equipment Market Report

Published Date: 31 January 2026 | Report Code: filling-equipment

Filling Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Filling Equipment market from 2023 to 2033, covering market size, growth trends, segmentation, regional insights, and key players.

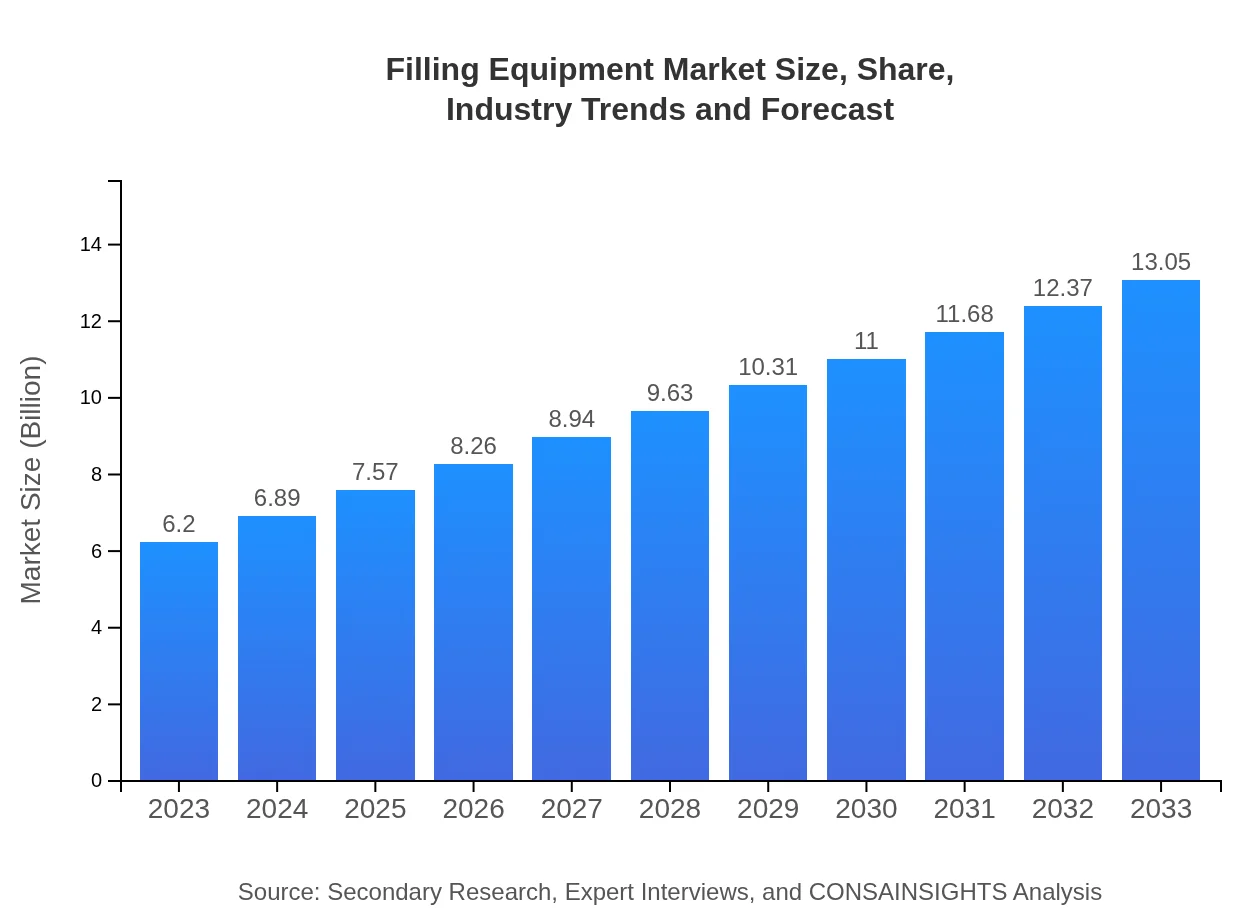

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $6.20 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $13.05 Billion |

| Top Companies | Krones AG, Bosch Packaging Technology, Tetra Pak, Combi-Press, Festo AG |

| Last Modified Date | 31 January 2026 |

Filling Equipment Market Overview

Customize Filling Equipment Market Report market research report

- ✔ Get in-depth analysis of Filling Equipment market size, growth, and forecasts.

- ✔ Understand Filling Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Filling Equipment

What is the Market Size & CAGR of Filling Equipment market in 2023?

Filling Equipment Industry Analysis

Filling Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Filling Equipment Market Analysis Report by Region

Europe Filling Equipment Market Report:

Europe's market is expected to grow from $2.04 billion in 2023 to $4.28 billion by 2033. This growth is stimulated by stringent regulations regarding product safety and quality, primarily in the food and beverage and pharmaceutical sectors.Asia Pacific Filling Equipment Market Report:

The Asia Pacific region is poised for significant growth, with a market value of $1.13 billion in 2023, expected to reach $2.38 billion by 2033. This growth is driven by rapid industrialization, a burgeoning consumer base, and an increasing focus on food safety regulations.North America Filling Equipment Market Report:

North America holds a significant share in the Filling Equipment market, valued at $2.17 billion in 2023, projected to rise to $4.57 billion by 2033. The region benefits from advanced manufacturing capabilities and high consumer demand for packaged products.South America Filling Equipment Market Report:

In South America, the Filling Equipment market is projected to grow from $0.45 billion in 2023 to $0.95 billion by 2033. The rise in local manufacturing and demand for packaged goods accelerates the market's expansion.Middle East & Africa Filling Equipment Market Report:

The Middle East and Africa region has a nascent Filling Equipment market valued at $0.41 billion in 2023, forecasted to reach $0.86 billion by 2033. Market growth is driven by rising investments in manufacturing and a burgeoning food and beverage sector.Tell us your focus area and get a customized research report.

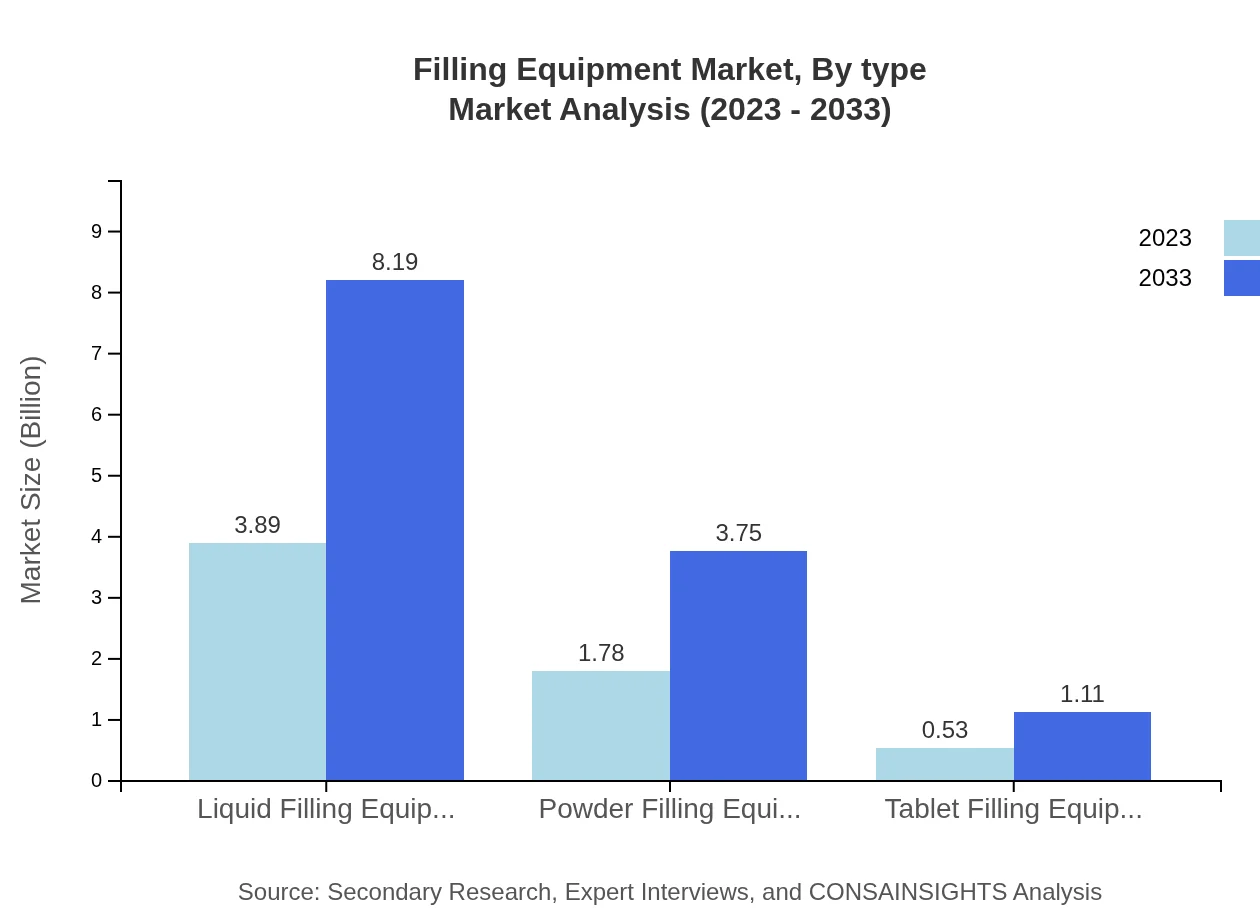

Filling Equipment Market Analysis By Type

The Filling Equipment Market segments include Liquid Filling Equipment, which expected to grow from $3.89 billion in 2023 to $8.19 billion by 2033, holding 62.75% market share. Powder Filling Equipment follows with a growth from $1.78 billion to $3.75 billion, reflecting a 28.77% share. Tablet Filling Equipment, though smaller, is anticipated to expand from $0.53 billion to $1.11 billion, maintaining an 8.48% share.

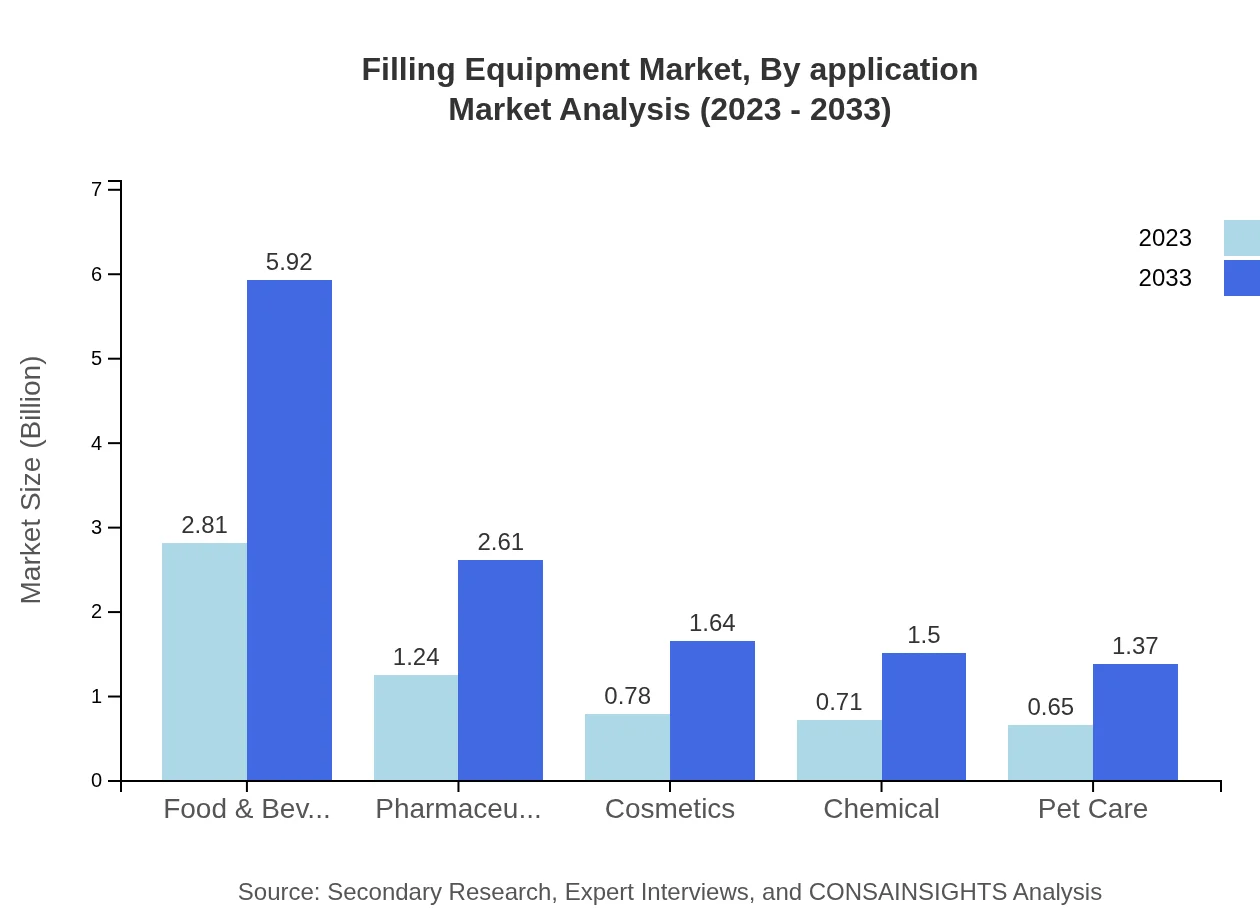

Filling Equipment Market Analysis By Application

By application, the Food & Beverage sector leads with a market size of $2.81 billion in 2023, expected to double to $5.92 billion by 2033, capturing 45.38% of the market. Pharmaceuticals account for $1.24 billion then rising to $2.61 billion, making up 20.02%. The Chemical and Cosmetics industries also play critical roles with respective shares of 11.48% and 12.6%.

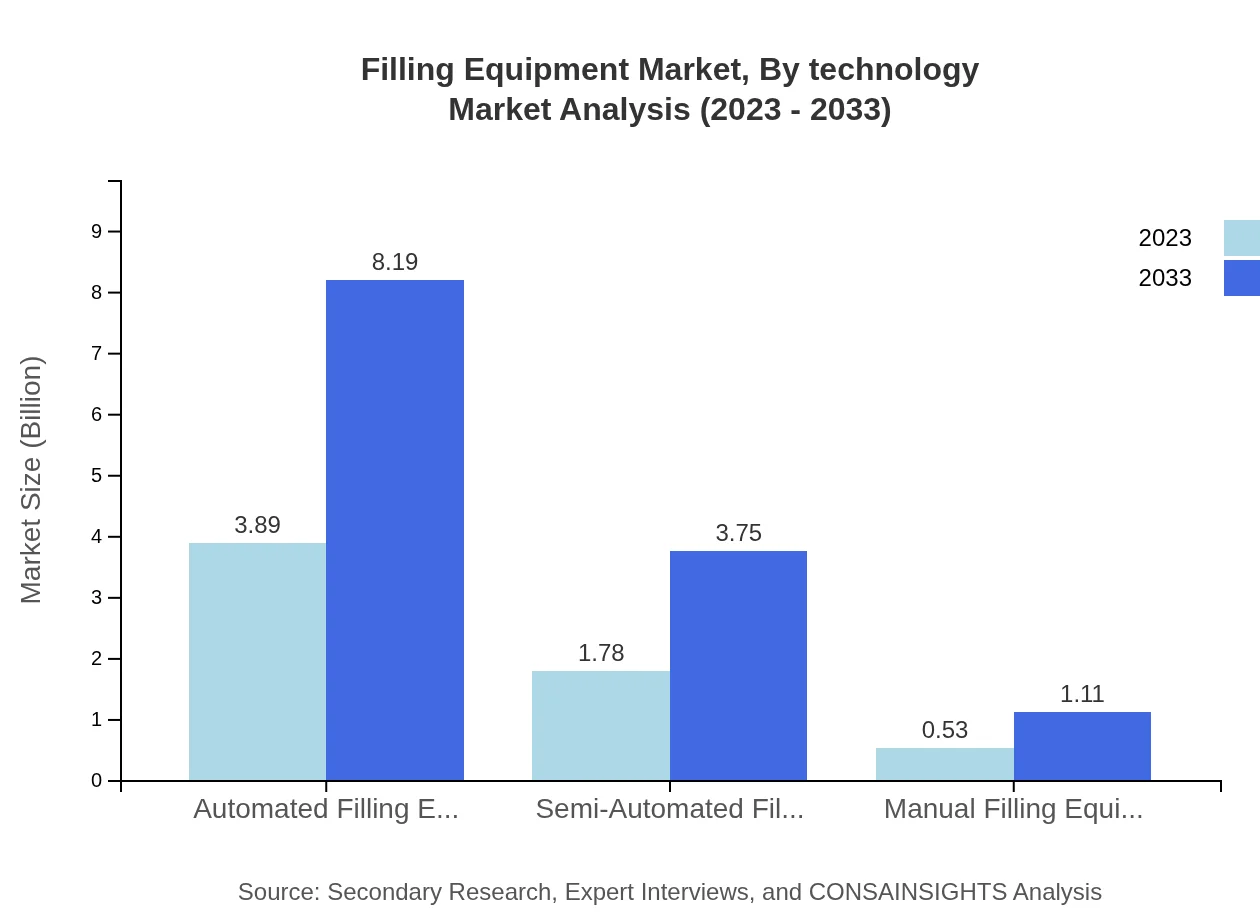

Filling Equipment Market Analysis By Technology

The technology segment highlights a significant preference for Automated Filling Equipment, which will grow from $3.89 billion in 2023 to $8.19 billion by 2033, offering 62.75% market share. Semi-Automated and Manual Filling Equipment follows with expected sizes of $1.78 billion to $3.75 billion, and $0.53 billion to $1.11 billion, respectively.

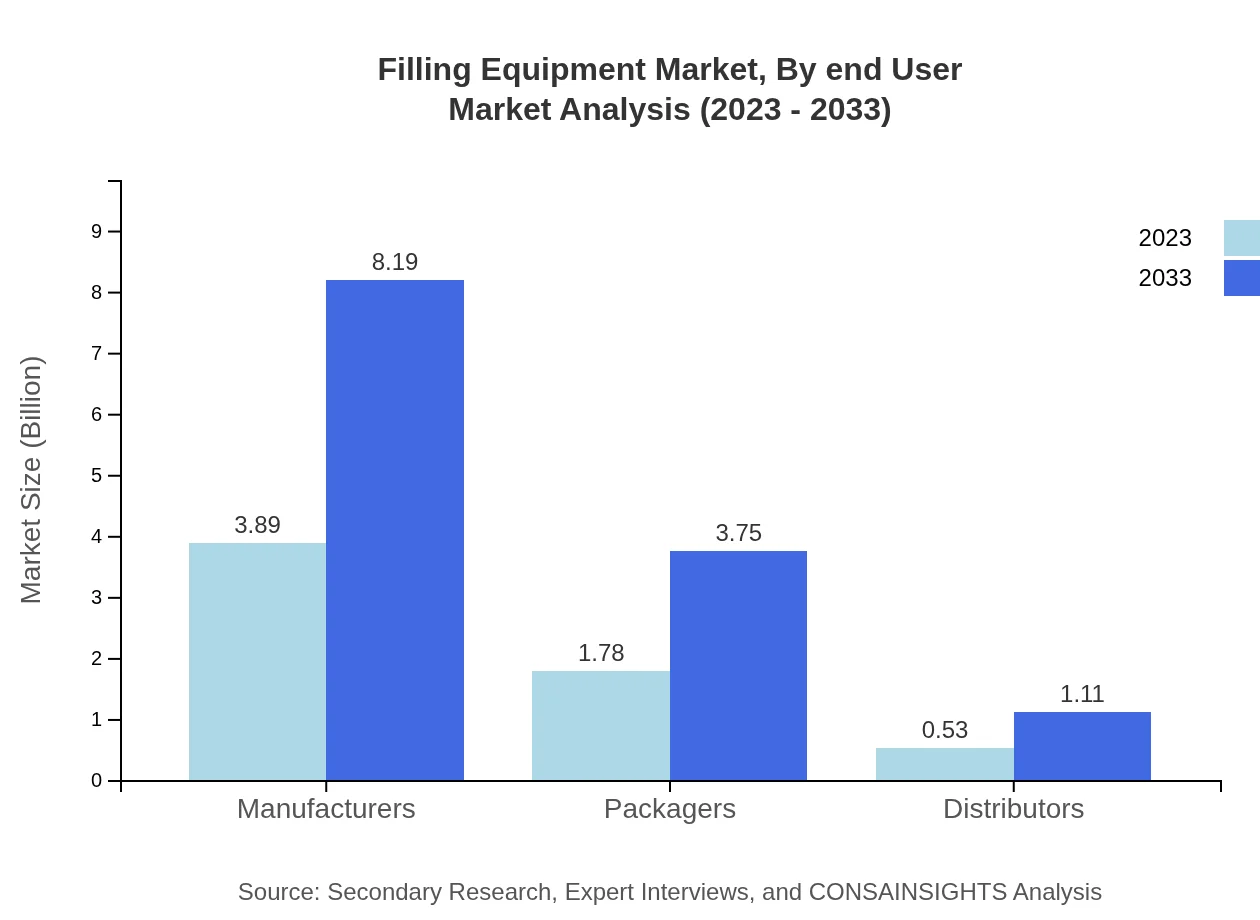

Filling Equipment Market Analysis By End User

The end-user segments reveal that manufacturers command the largest share of the Filling Equipment market, valued at $3.89 billion in 2023, with anticipated growth to $8.19 billion by 2033. Following this, Packagers garner $1.78 billion to reach $3.75 billion, whereas Distributors expand from $0.53 billion to $1.11 billion.

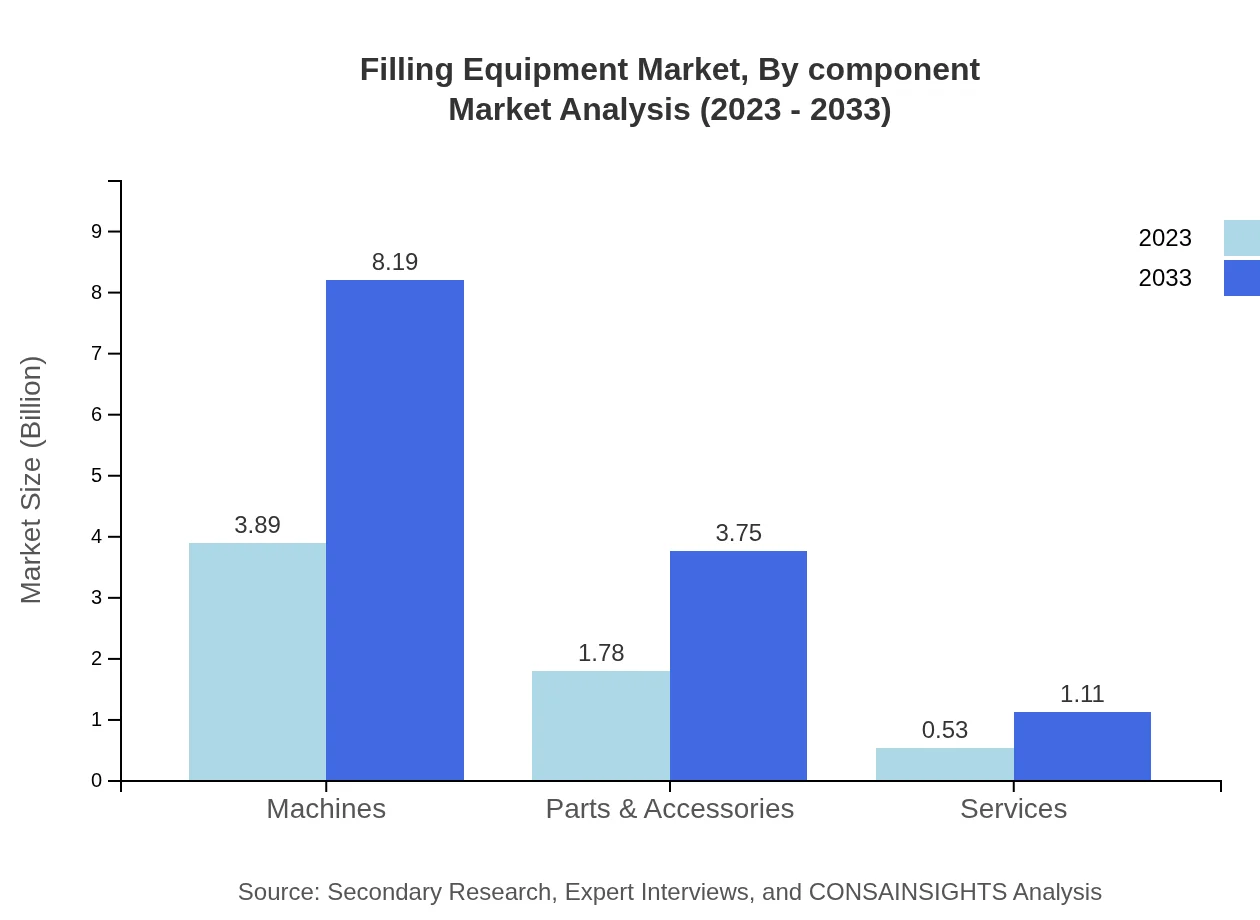

Filling Equipment Market Analysis By Component

Parts & Accessories contribute significantly, projected to grow from $1.78 billion in 2023 to $3.75 billion by 2033. In contrast, Services in the market will see growth from $0.53 billion to $1.11 billion.

Filling Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Filling Equipment Industry

Krones AG:

Krones AG is a leading manufacturer of filling and packaging equipment, known for its innovative technologies that enhance production efficiency across various industries.Bosch Packaging Technology:

Bosch is recognized for its cutting-edge filling technologies and comprehensive systems, particularly in the food and beverage sector.Tetra Pak:

Tetra Pak specialized in processing and packaging solutions for food products, is renowned for its sustainable practices and advanced filling equipment.Combi-Press:

Combi-Press provides versatile filling solutions that cater to various industries, emphasizing automation and efficiency.Festo AG:

Festo AG delivers innovative automation solutions, significantly improving the performance of filling equipment in manufacturing processes.We're grateful to work with incredible clients.

FAQs

What is the market size of Filling Equipment?

The Filling Equipment market is currently valued at approximately $6.2 billion as of 2023, with a projected compound annual growth rate (CAGR) of 7.5% through 2033. This growth reflects increasing demand across various sectors.

What are the key market players or companies in the Filling Equipment industry?

Key players in the Filling Equipment market include leading manufacturers and technology providers that offer diverse filling machinery and solutions. Their innovation and market strategies significantly influence industry dynamics.

What are the primary factors driving the growth in the Filling Equipment industry?

The growth in the Filling Equipment industry is primarily driven by advancements in technology, increased automation in manufacturing processes, and rising demand from sectors such as food and beverage, pharmaceuticals, and cosmetics.

Which region is the fastest Growing in the Filling Equipment market?

The fastest-growing region in the Filling Equipment market is expected to be North America, with market growth projected to increase from $2.17 billion in 2023 to $4.57 billion by 2033, driven by industrial advancements and rising consumer demand.

Does ConsaInsights provide customized market report data for the Filling Equipment industry?

Yes, ConsaInsights offers customized market report data tailored specifically to the Filling Equipment industry, helping clients gain deeper insights into market trends and competitive landscapes.

What deliverables can I expect from this Filling Equipment market research project?

Clients can expect a comprehensive market research report detailing market size, growth trends, competitive analysis, and segmented data across regions and product categories specific to the Filling Equipment industry.

What are the market trends of Filling Equipment?

Current trends in the Filling Equipment market include the rise of automated solutions, increased focus on sustainability in packaging processes, and the growing preference for customized filling solutions catering to niche markets.