Flexible Elastomeric Foam Market Report

Published Date: 22 January 2026 | Report Code: flexible-elastomeric-foam

Flexible Elastomeric Foam Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Flexible Elastomeric Foam market, covering current trends, market size forecasts, segmentation, and key players. The insights span from 2023 to 2033, aiming to equip stakeholders with relevant data for informed decision-making.

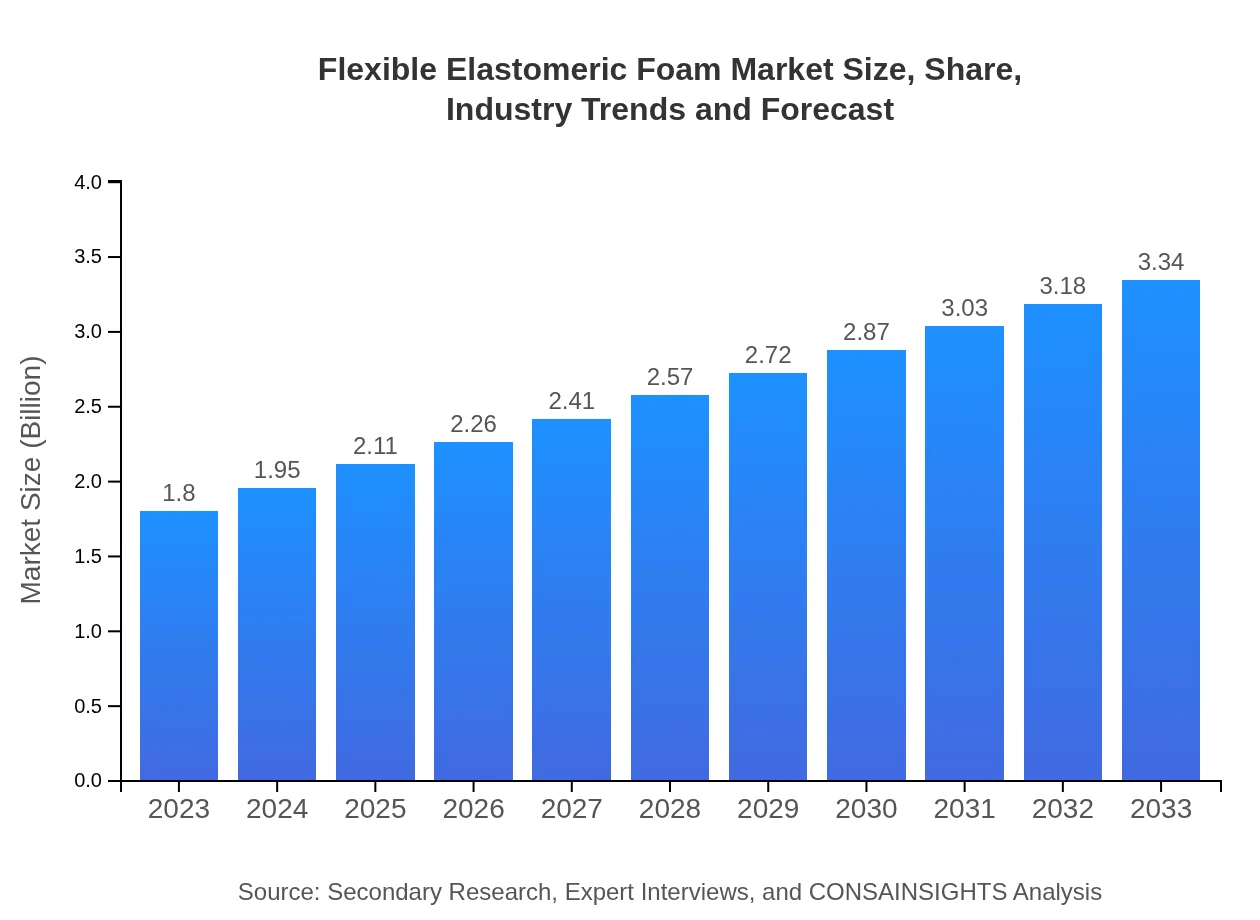

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.80 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $3.34 Billion |

| Top Companies | BASF SE, Nitto Denko Corporation, Rogers Corporation, Huntsman Corporation |

| Last Modified Date | 22 January 2026 |

Flexible Elastomeric Foam Market Overview

Customize Flexible Elastomeric Foam Market Report market research report

- ✔ Get in-depth analysis of Flexible Elastomeric Foam market size, growth, and forecasts.

- ✔ Understand Flexible Elastomeric Foam's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Flexible Elastomeric Foam

What is the Market Size & CAGR of Flexible Elastomeric Foam market in 2023?

Flexible Elastomeric Foam Industry Analysis

Flexible Elastomeric Foam Market Segmentation and Scope

Tell us your focus area and get a customized research report.

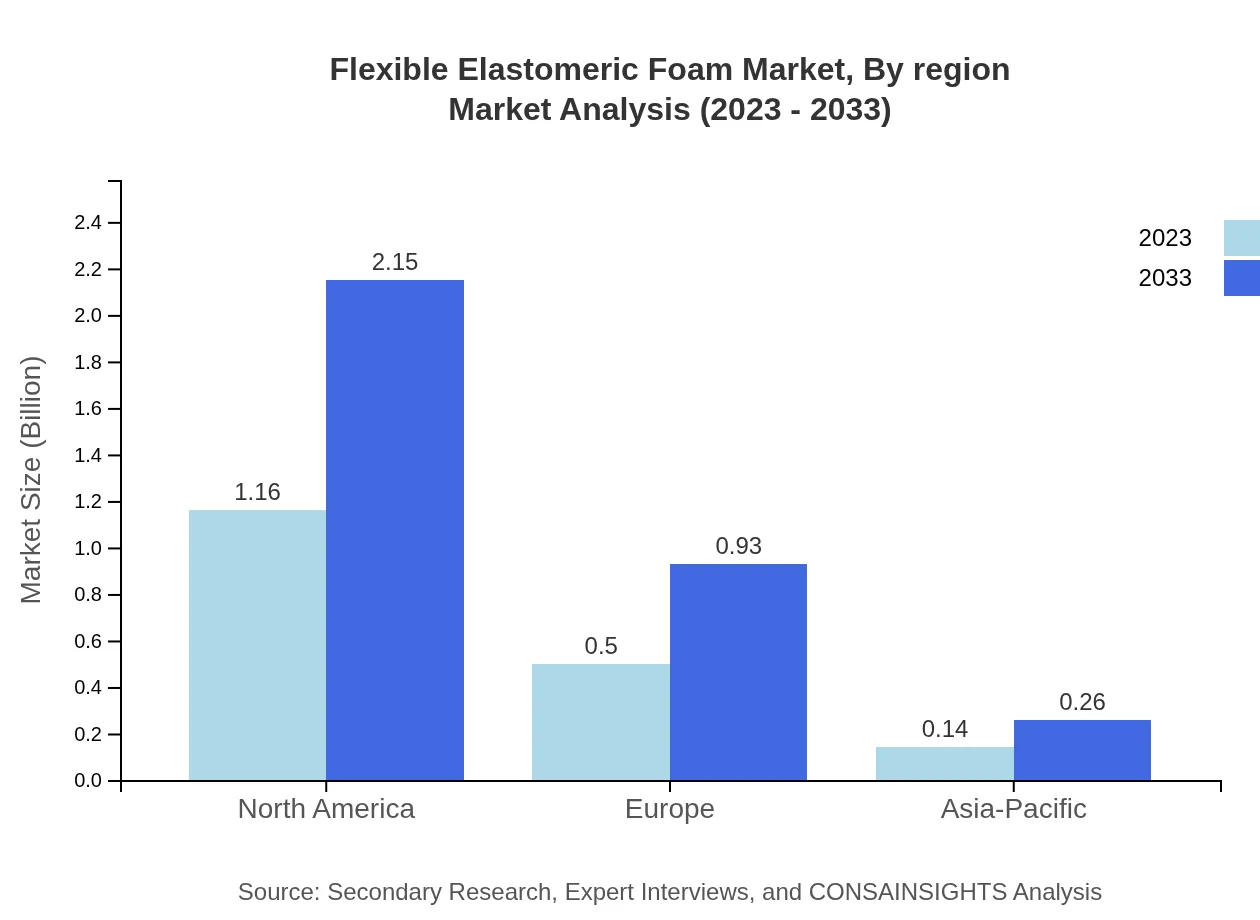

Flexible Elastomeric Foam Market Analysis Report by Region

Europe Flexible Elastomeric Foam Market Report:

Europe is projected to see market growth from $0.59 billion in 2023 to $1.10 billion in 2033. The stringent regulations around energy conservation in buildings and eco-friendly materials drive this growth.Asia Pacific Flexible Elastomeric Foam Market Report:

In the Asia-Pacific region, the market size for Flexible Elastomeric Foam is projected to grow from $0.34 billion in 2023 to $0.62 billion by 2033, reflecting a growing demand driven by industrial expansion and increased infrastructure development projects.North America Flexible Elastomeric Foam Market Report:

North America is among the largest markets, with a current size of $0.61 billion in 2023, expected to climb to $1.13 billion by 2033. The region benefits from a strong automotive industry and significant investments in building insulation materials.South America Flexible Elastomeric Foam Market Report:

The South American market remains relatively small, with a projection of $0.01 billion in 2023, increasing to $0.02 billion by 2033. Growth opportunities exist primarily in the automotive and healthcare sectors as they evolve.Middle East & Africa Flexible Elastomeric Foam Market Report:

The Middle East and Africa market is poised to grow from $0.25 billion in 2023 to $0.46 billion by 2033, driven largely by urbanization and infrastructural developments.Tell us your focus area and get a customized research report.

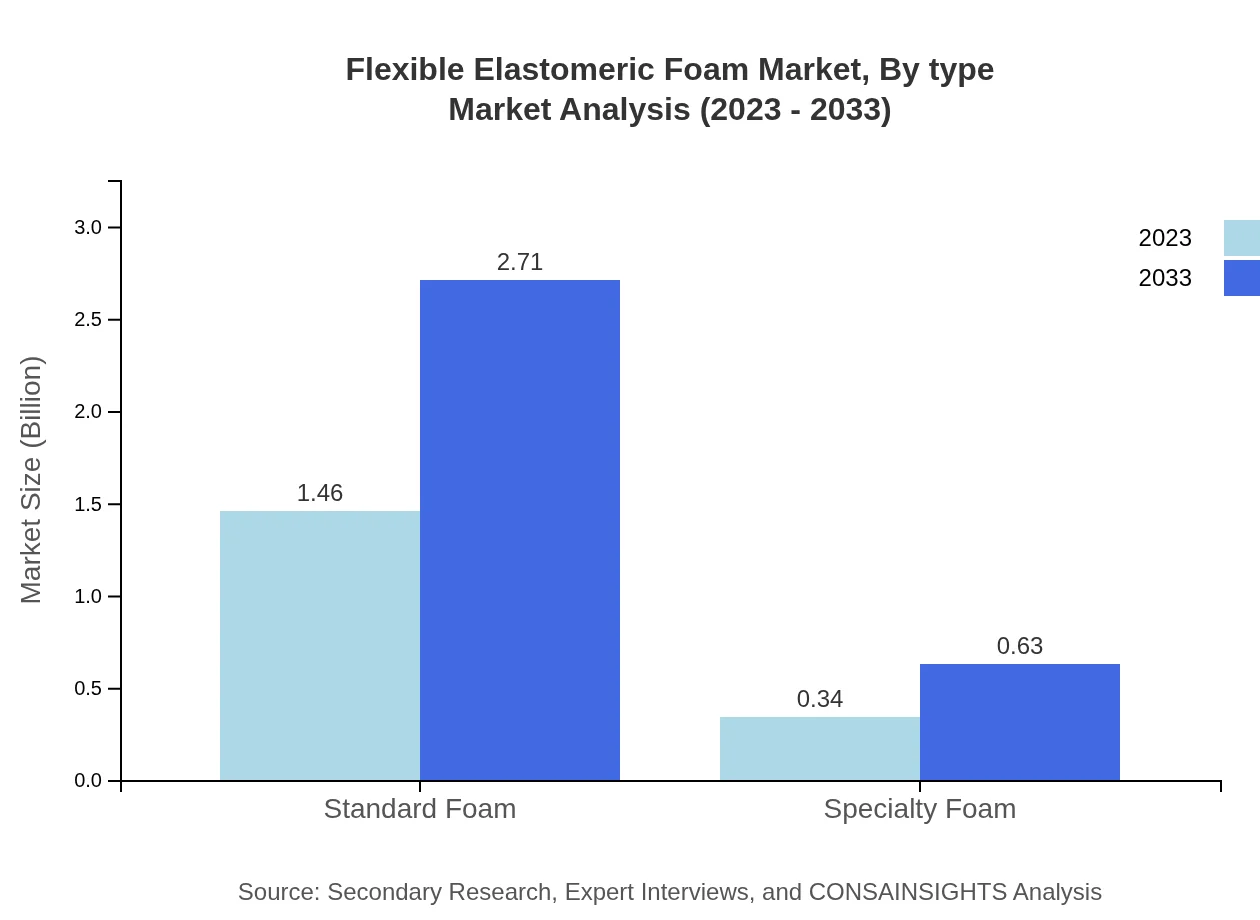

Flexible Elastomeric Foam Market Analysis By Type

Standard Foam and Specialty Foam are the principal types of Flexible Elastomeric Foam. The Standard Foam segment holds a significant market share, providing a market size of $1.46 billion in 2023 and projected to reach $2.71 billion by 2033, maintaining an 81.12% market share throughout this timeline. The Specialty Foam segment, with a market size of $0.34 billion in 2023, is expected to grow to $0.63 billion by 2033, retaining its 18.88% market share.

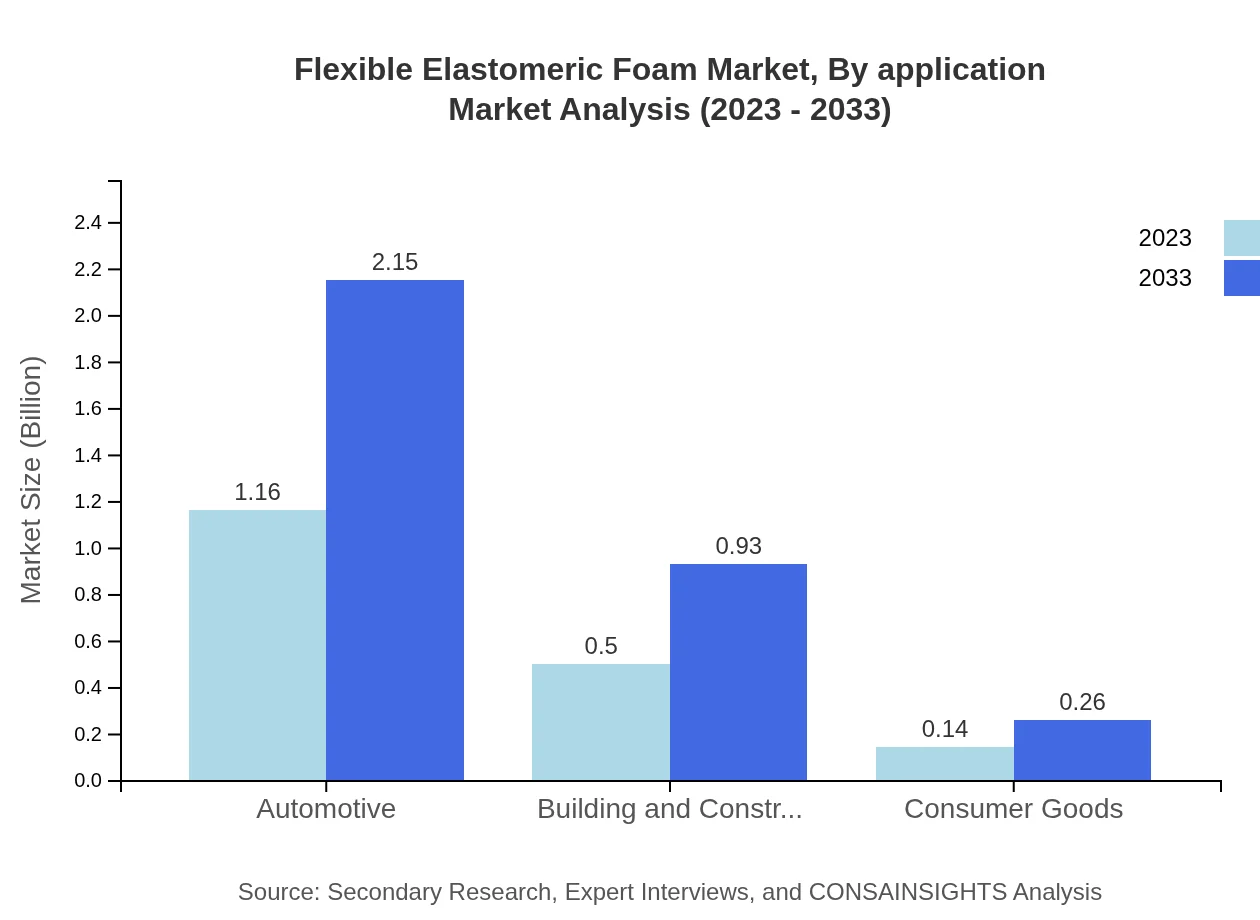

Flexible Elastomeric Foam Market Analysis By Application

Applications for Flexible Elastomeric Foam include construction, automotive, healthcare, and consumer goods. The construction segment is the largest, with $1.16 billion in 2023, projected to grow to $2.15 billion by 2033, accounting for approximately 64.45% of the market. The automotive segment follows with $0.50 billion currently, expanding to $0.93 billion by 2033, capturing 27.79% of market share. Healthcare and consumer goods are smaller segments, reflecting a combined total of $0.28 billion by 2033, representing 7.76% market share.

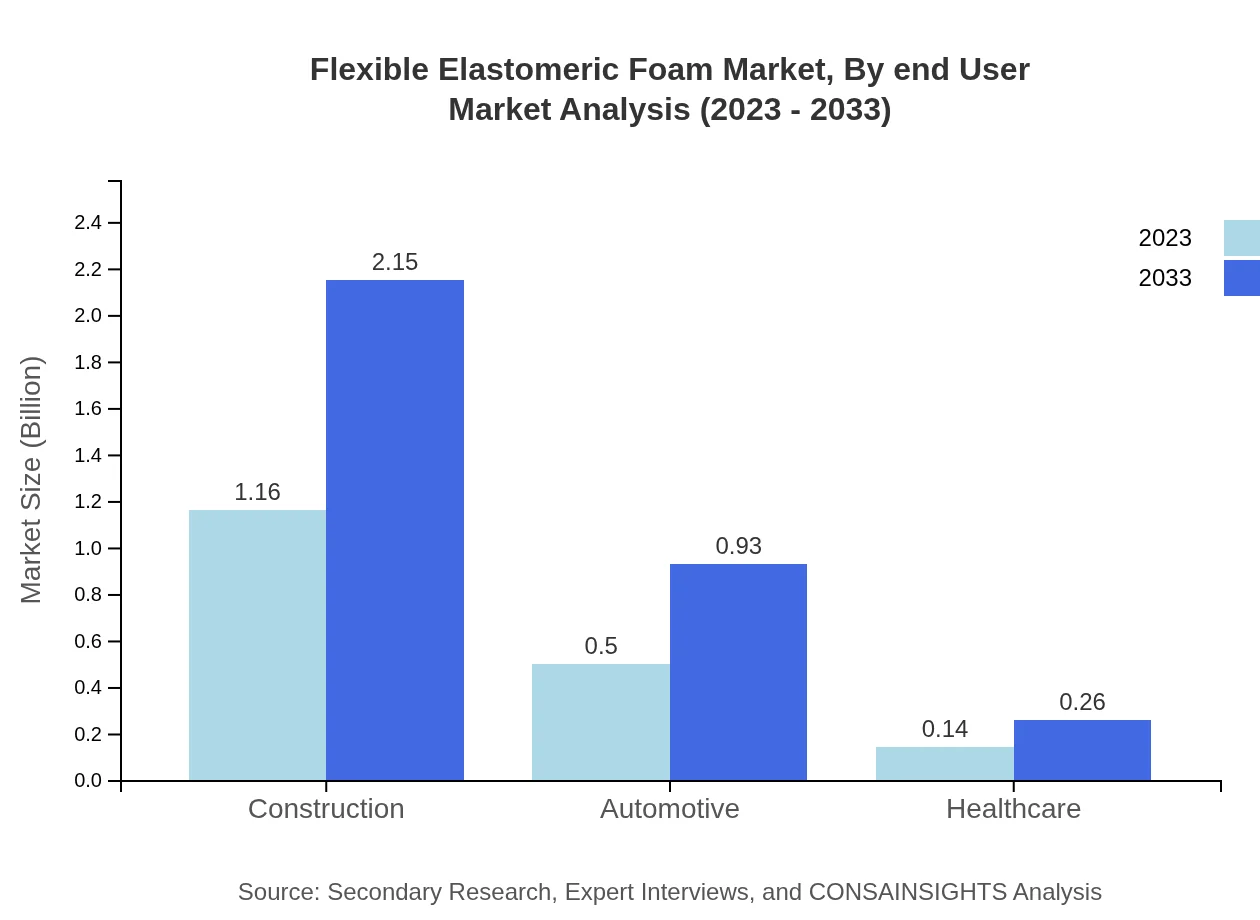

Flexible Elastomeric Foam Market Analysis By End User

End-user industries for Flexible Elastomeric Foam include building & construction, automotive, and consumer goods. Each end-user segment contributes distinctively, with building & construction being the dominant end user. Automotive needs are anticipated to keep rising due to innovations in vehicle design and manufacturing technologies.

Flexible Elastomeric Foam Market Analysis By Region

Regionally, North America takes the lead, followed closely by Europe and Asia-Pacific. Each region displays unique demand drivers, regulatory frameworks, and industry challenges, underlining the importance of tailored approaches for market engagement and growth.

Flexible Elastomeric Foam Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Flexible Elastomeric Foam Industry

BASF SE:

A global leader in chemical manufacturing, BASF produces a wide range of elastomeric foam products known for their quality and innovative applications across several industries.Nitto Denko Corporation:

Specializing in flexible materials, Nitto Denko focuses heavily on adhesive products, including elastomeric foams that cater to automotive and electronic applications.Rogers Corporation:

Known for high-performance materials, Rogers Corporation develops specialized elastomeric foams that are critical for electronic and telecommunications sectors.Huntsman Corporation:

Engaged in developing advanced materials, Huntsman offers a variety of elastomeric foams utilized in industrial markets with emphasis on sustainability and efficiency.We're grateful to work with incredible clients.

FAQs

What is the market size of flexible Elastomeric Foam?

The global market size for flexible elastomeric foam was valued at approximately $1.8 billion in 2023, with a projected CAGR of 6.2% from 2023 to 2033, indicating robust demand and growth in applications across various sectors.

What are the key market players or companies in this flexible Elastomeric Foam industry?

Key players in the flexible elastomeric foam market include major chemical manufacturers and suppliers. Their competitive strategies often involve product innovation, partnerships, mergers, and acquisitions aimed at enhancing market presence and improving product offerings.

What are the primary factors driving the growth in the flexible Elastomeric Foam industry?

The primary growth drivers in the flexible elastomeric foam industry include the rising demand from the construction and automotive sectors, technological advancements in production, and the increasing adoption of insulation materials due to energy efficiency regulations.

Which region is the fastest Growing in the flexible Elastomeric Foam?

North America is anticipated to be the fastest-growing region, with market growth projected from $0.61 billion in 2023 to $1.13 billion in 2033. Europe is also significant, expected to grow from $0.59 billion to $1.10 billion over the same period.

Does ConsaInsights provide customized market report data for the flexible Elastomeric Foam industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the flexible elastomeric foam industry. This includes market size estimates, forecasts, competitive analysis, and detailed segment insights designed for strategic planning.

What deliverables can I expect from this flexible Elastomeric Foam market research project?

Expect comprehensive market research deliverables including detailed reports on market size, growth projections, competitive landscape evaluations, and analysis of market segments, along with actionable insights that inform business strategies.

What are the market trends of flexible Elastomeric Foam?

Current trends in the flexible elastomeric foam market include a shift toward eco-friendly materials, increased use of foams in HVAC applications, and advancements in manufacturing technologies. These trends are being driven by heightened environmental awareness and safety regulations.