Flexible Insulation Market Report

Published Date: 22 January 2026 | Report Code: flexible-insulation

Flexible Insulation Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Flexible Insulation market, focusing on current trends, market size, and forecasts from 2023 to 2033. It encompasses industry insights, regional assessments, and competitive landscapes to inform stakeholders and investors.

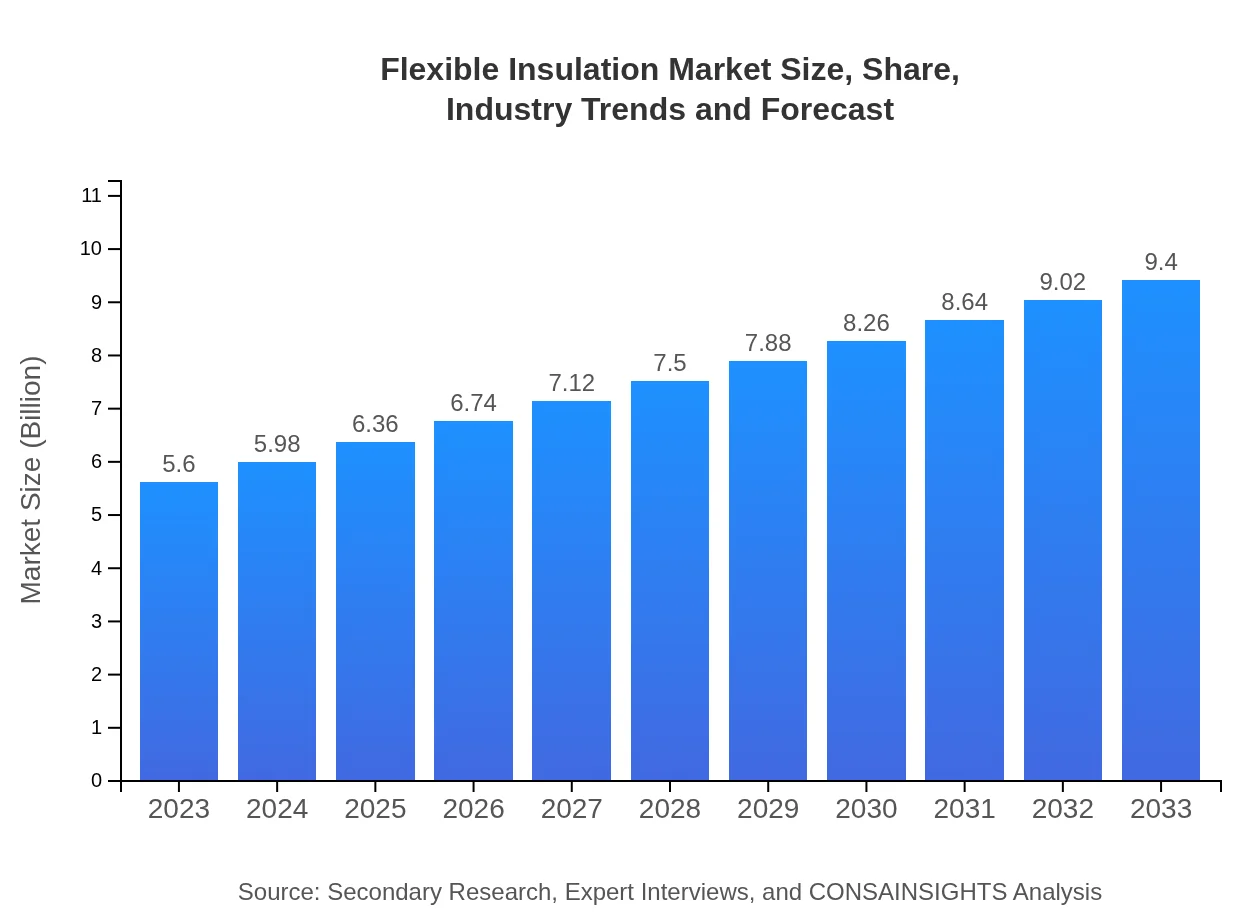

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $9.40 Billion |

| Top Companies | Owens Corning, Johns Manville, BASF SE, Rockwool International |

| Last Modified Date | 22 January 2026 |

Flexible Insulation Market Overview

Customize Flexible Insulation Market Report market research report

- ✔ Get in-depth analysis of Flexible Insulation market size, growth, and forecasts.

- ✔ Understand Flexible Insulation's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Flexible Insulation

What is the Market Size & CAGR of Flexible Insulation market in 2023?

Flexible Insulation Industry Analysis

Flexible Insulation Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Flexible Insulation Market Analysis Report by Region

Europe Flexible Insulation Market Report:

The European market is expected to grow from $1.68 billion in 2023 to $2.83 billion by 2033. The shift towards sustainable building practices and the growing focus on energy-efficient building renovations are the major factors fueling this growth.Asia Pacific Flexible Insulation Market Report:

The Asia Pacific region is witnessing significant growth, expected to expand from $0.99 billion in 2023 to $1.66 billion by 2033. The rapid industrialization, urbanization, and increasing infrastructure developments in countries like China and India are key drivers of this growth.North America Flexible Insulation Market Report:

North America remains a vital market, projected to increase from $2.16 billion in 2023 to $3.62 billion by 2033. This growth is primarily driven by stringent energy efficiency regulations and the rising demand for advanced insulation solutions across various sectors.South America Flexible Insulation Market Report:

In South America, the market is anticipated to grow modestly from $0.16 billion in 2023 to $0.27 billion by 2033. Investments in residential and commercial construction projects are anticipated to drive this growth.Middle East & Africa Flexible Insulation Market Report:

The Middle East and Africa market is expected to rise from $0.61 billion in 2023 to $1.02 billion by 2033. This growth reflects the ongoing infrastructure projects and increasing awareness of energy conservation in the region.Tell us your focus area and get a customized research report.

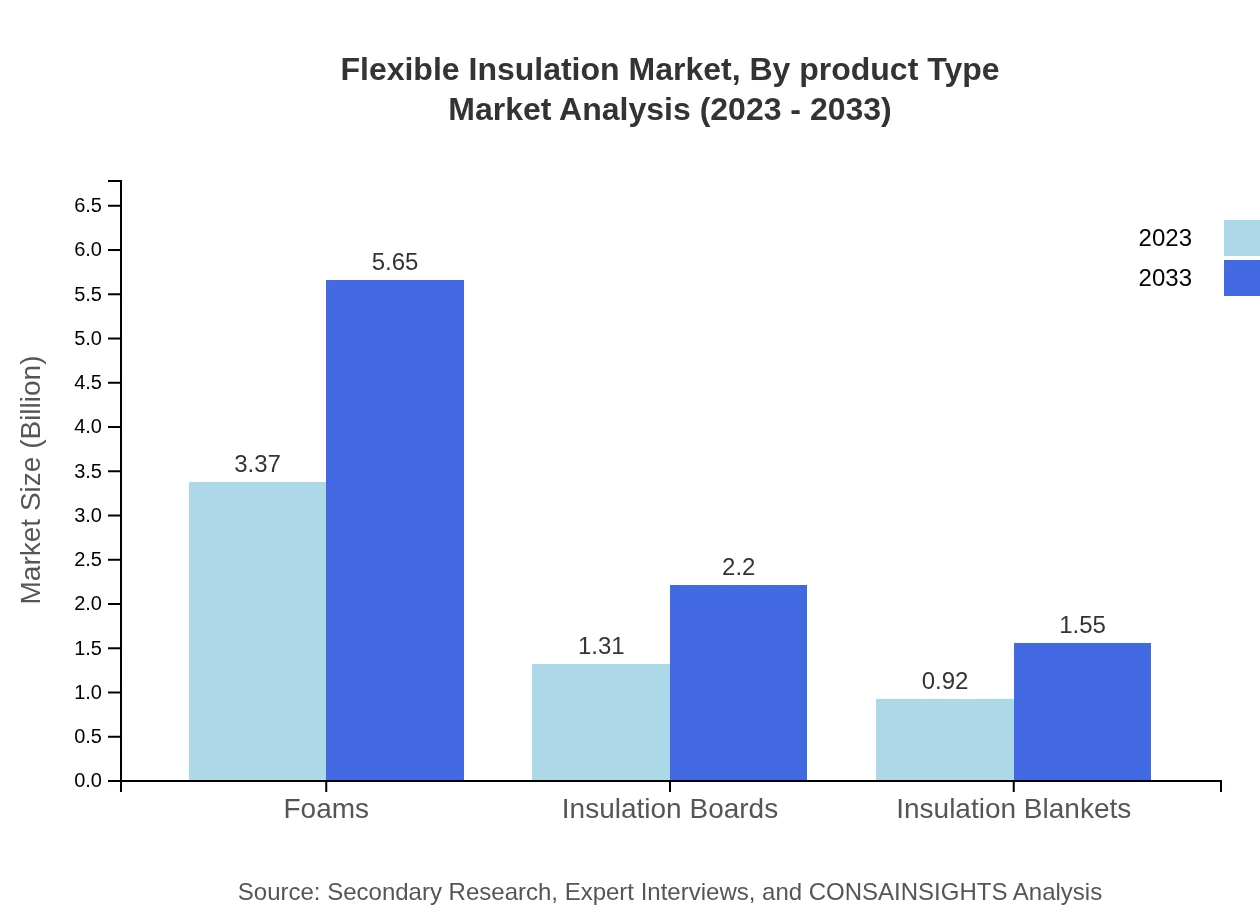

Flexible Insulation Market Analysis By Product Type

The product segmentation reveals that foams account for the largest market share, making up 60.1% in 2023, projected to remain stable as they provide versatility and high thermal efficiency. Insulation boards and blankets follow, contributing 23.44% and 16.46% respectively.

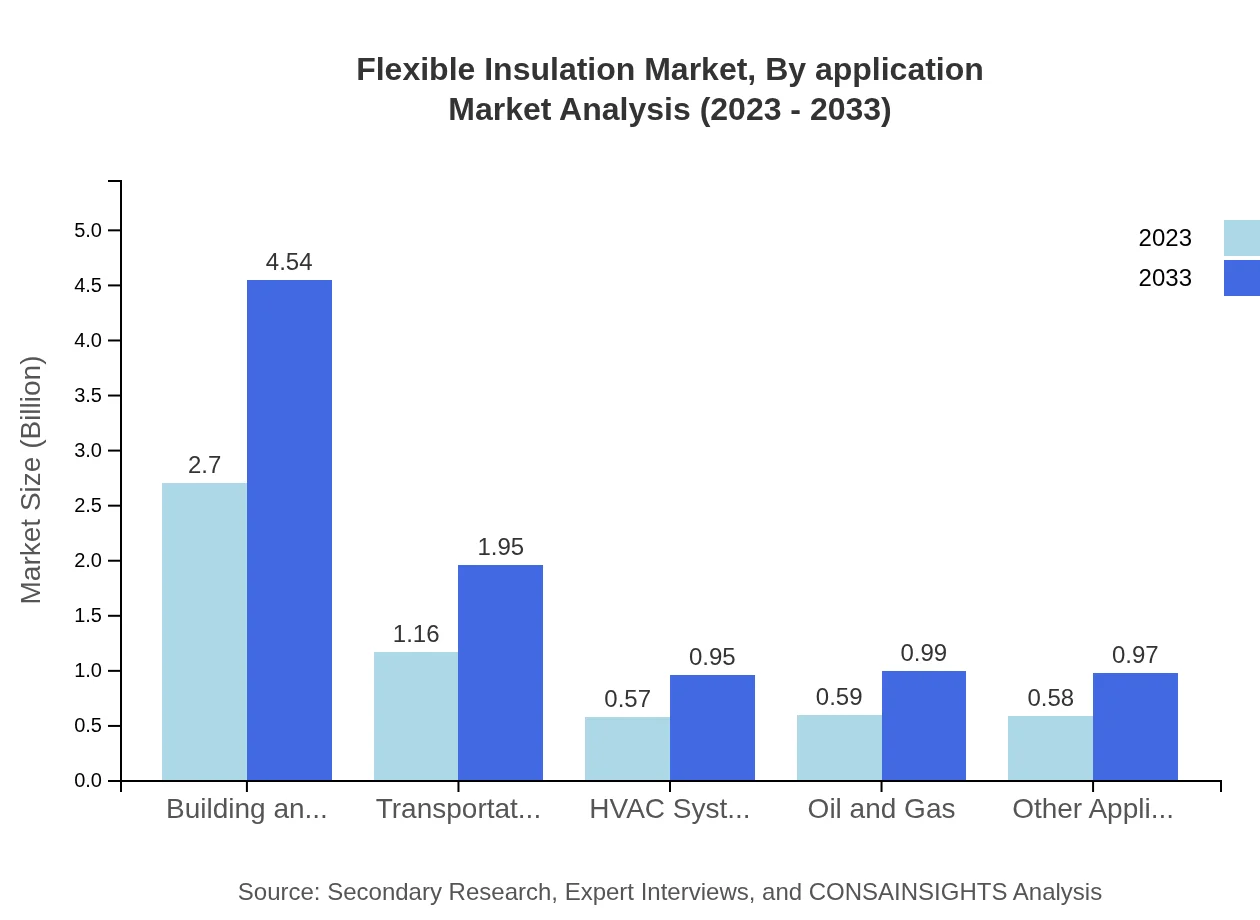

Flexible Insulation Market Analysis By Application

The building and construction sector is the largest application area, representing 48.3% of the market in 2023. Other significant applications include automotive (20.78%) and aerospace (10.1%). These sectors continue to expand, driving overall market growth.

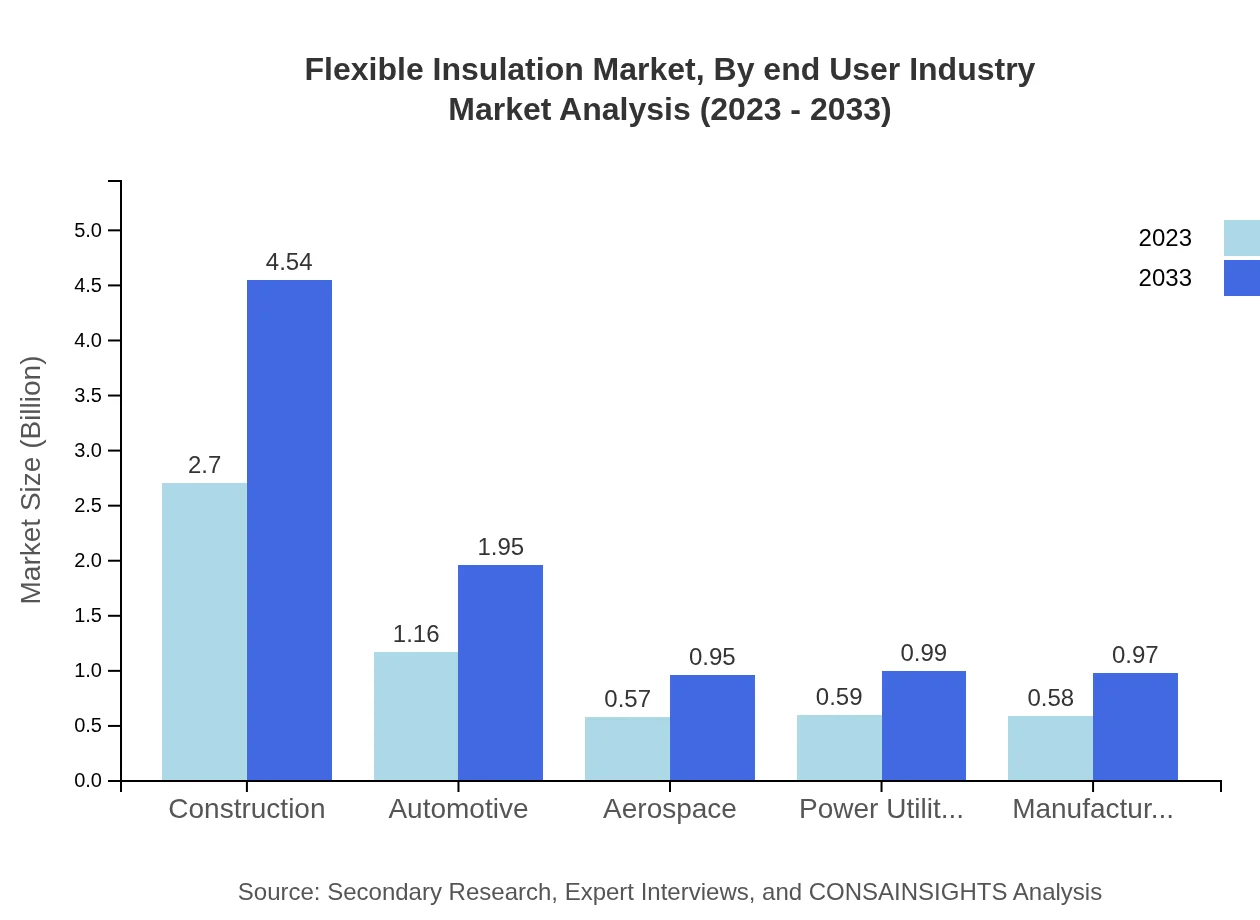

Flexible Insulation Market Analysis By End User Industry

The end-user industries are diverse, with key sectors including construction, transportation, and power utilities. The construction industry leads with a major market share, emphasizing the critical need for insulation in energy efficiency.

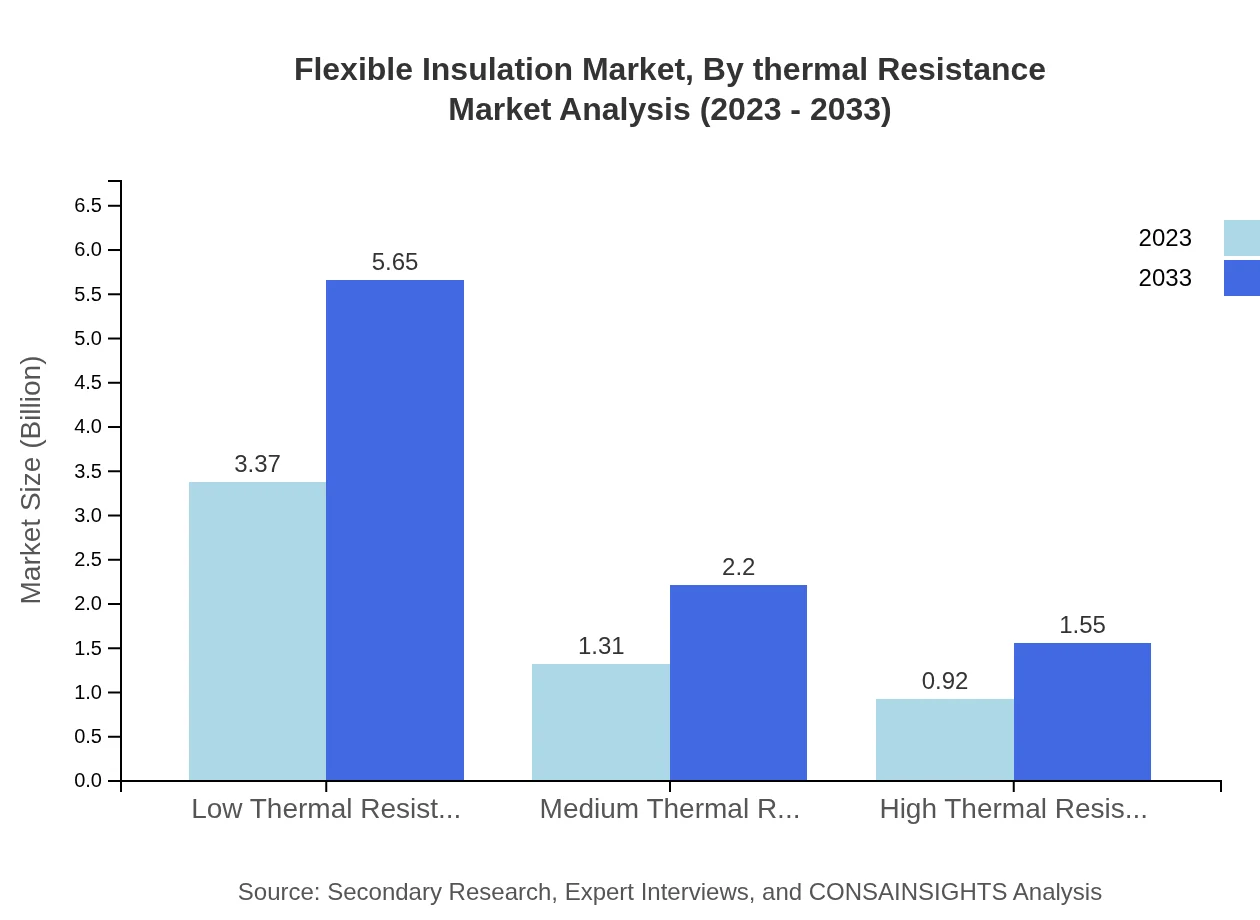

Flexible Insulation Market Analysis By Thermal Resistance

Low thermal resistance products dominate the market, capturing 60.1% in 2023. They are followed by medium (23.44%) and high thermal resistance products (16.46%), each serving distinct insulation needs across various applications.

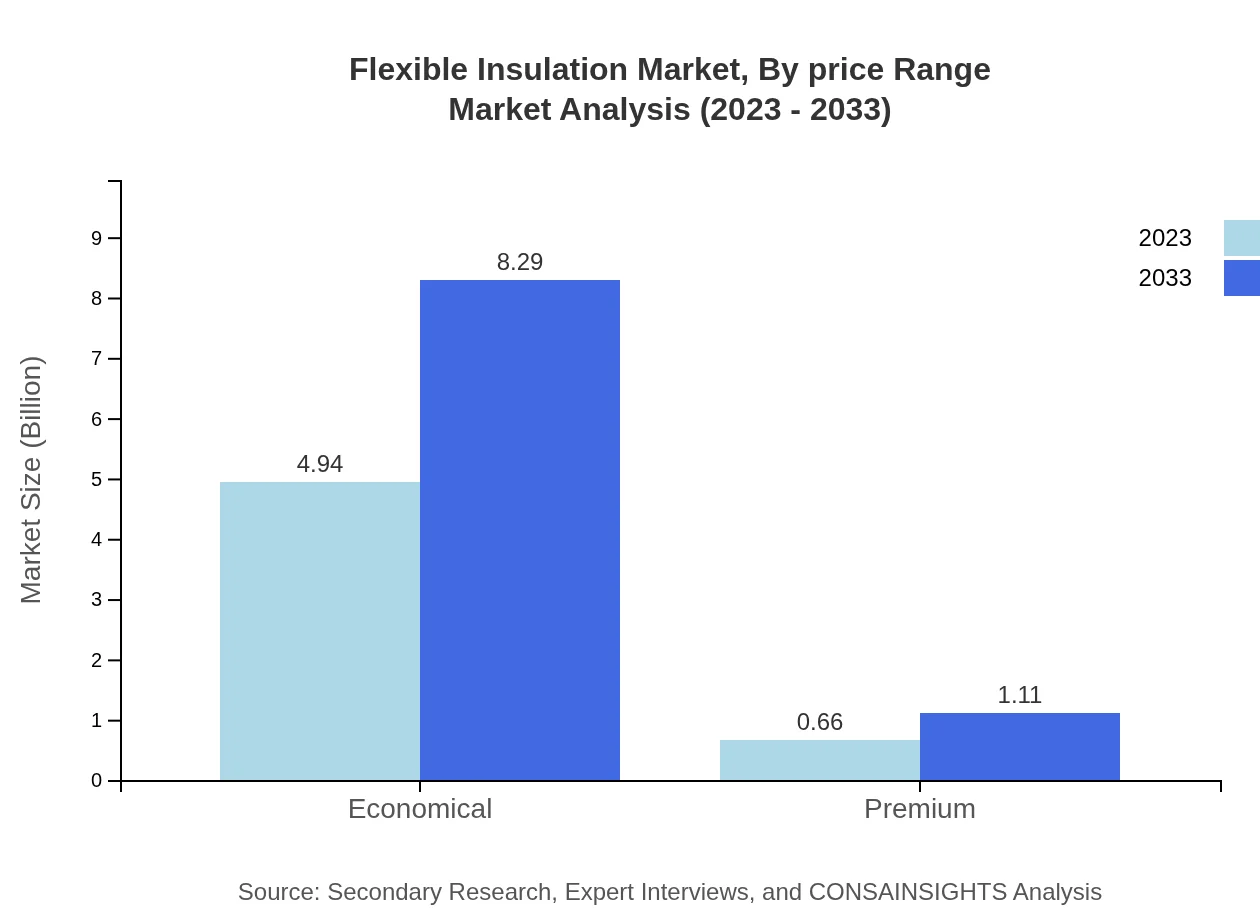

Flexible Insulation Market Analysis By Price Range

The market is primarily segmented into economical and premium price ranges, with economical products leading at 88.22%. Premium products are growing in demand as they offer enhanced performance, currently capturing 11.78% of the market share.

Flexible Insulation Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Flexible Insulation Industry

Owens Corning:

A leader in insulation, roofing, and fiberglass composites, Owens Corning focuses on sustainability and energy efficiency innovations.Johns Manville:

A subsidiary of Berkshire Hathaway, Johns Manville is a producer of insulation and roofing materials with a strong commitment to green building practices.BASF SE:

BASF SE offers a broad range of insulation materials, emphasizing energy efficiency and eco-friendliness in its product lines.Rockwool International:

Specializing in stone wool insulation, Rockwool International is recognized for its sustainability practices and high-performance products.We're grateful to work with incredible clients.

FAQs

What is the market size of flexible insulation?

The flexible insulation market is projected to reach a size of approximately $5.6 billion by 2033, growing at a compound annual growth rate (CAGR) of 5.2% from 2023. This indicates robust demand across various sectors, reflecting significant market potential.

What are the key market players or companies in the flexible insulation industry?

Key players in the flexible insulation industry include renowned companies like Owens Corning, Johns Manville, and Rockwool. These companies are instrumental in driving innovation and advancements in insulation technology, ensuring products meet stringent performance standards.

What are the primary factors driving the growth in the flexible insulation industry?

Factors such as increasing energy efficiency regulations, growing construction activities, and rising awareness regarding thermal insulation benefits are propelling growth in the flexible insulation industry. The shift towards sustainable buildings further contributes to market expansion.

Which region is the fastest Growing in the flexible insulation market?

North America is currently the fastest-growing region in the flexible insulation market, projected to increase from $2.16 billion in 2023 to $3.62 billion by 2033. This growth is driven by heightened construction activities and stringent energy regulations.

Does ConsaInsights provide customized market report data for the flexible insulation industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the flexible insulation industry. Clients can access detailed insights that align with their strategic goals, enhancing decision-making capabilities.

What deliverables can I expect from this flexible insulation market research project?

Deliverables include comprehensive market analysis, segmentation insights, growth forecasts, and regional breakdowns. Custom reports featuring strategic recommendations tailored to your business needs will also be provided to aid in informed decision-making.

What are the market trends of flexible insulation?

Current trends in the flexible insulation market focus on the adoption of eco-friendly materials and advanced manufacturing techniques. Additionally, technological innovations and increased demand for energy conservation continue to shape the market landscape.