Fluid Power Cylinder Market Report

Published Date: 22 January 2026 | Report Code: fluid-power-cylinder

Fluid Power Cylinder Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Fluid Power Cylinder market, covering market dynamics, segmentation, regional insights, technology advancements, and future forecasts for the period 2023 to 2033.

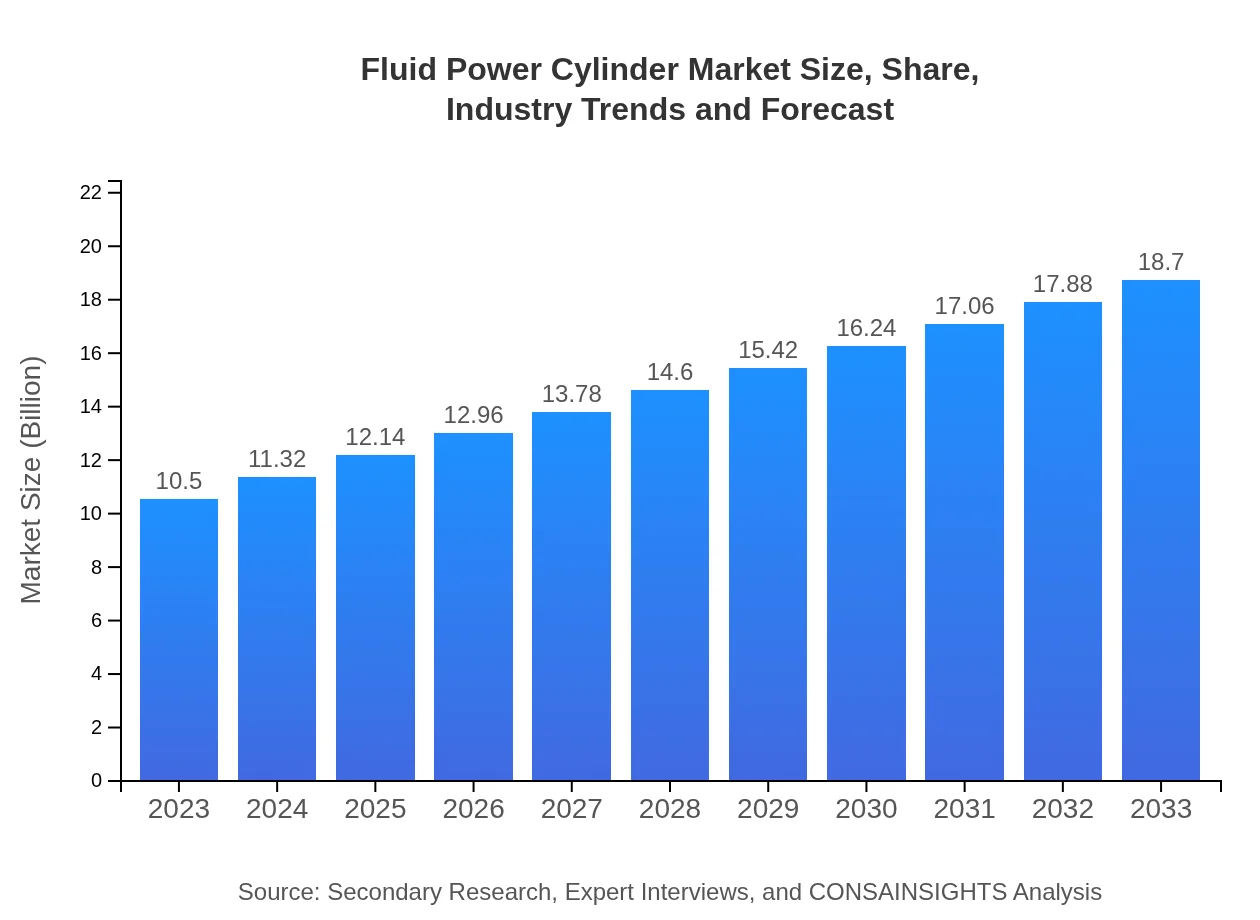

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.50 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $18.70 Billion |

| Top Companies | Parker Hannifin, Bosch Rexroth, Eaton Corporation, Hydac International, Parker Teseo |

| Last Modified Date | 22 January 2026 |

Fluid Power Cylinder Market Overview

Customize Fluid Power Cylinder Market Report market research report

- ✔ Get in-depth analysis of Fluid Power Cylinder market size, growth, and forecasts.

- ✔ Understand Fluid Power Cylinder's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Fluid Power Cylinder

What is the Market Size & CAGR of Fluid Power Cylinder market in 2023?

Fluid Power Cylinder Industry Analysis

Fluid Power Cylinder Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Fluid Power Cylinder Market Analysis Report by Region

Europe Fluid Power Cylinder Market Report:

The European market is expected to experience growth from 2.92 billion USD in 2023 to 5.20 billion USD by 2033. Innovation in energy-efficient products and stringent regulations on energy consumption support this growth.Asia Pacific Fluid Power Cylinder Market Report:

The Asia Pacific region, with a market value of approximately 1.99 billion USD in 2023, is expected to grow to 3.55 billion USD by 2033. This growth is driven by rapid industrialization in countries like China and India, increasing investments in infrastructure, and rising demand in sectors such as automotive and manufacturing.North America Fluid Power Cylinder Market Report:

North America's market, starting at 4.02 billion USD in 2023 and projected to reach 7.16 billion USD by 2033, benefits from strong industrial bases in the U.S. and Canada, alongside growing emphasis on automation and smart manufacturing technologies.South America Fluid Power Cylinder Market Report:

In South America, the Fluid Power Cylinder market is anticipated to increase from 0.16 billion USD in 2023 to 0.28 billion USD by 2033. Despite smaller market size, growth opportunities arise from rising sectors such as mining and transportation.Middle East & Africa Fluid Power Cylinder Market Report:

The Middle East and Africa region is projected to grow from 1.41 billion USD in 2023 to 2.52 billion USD by 2033, spurred by investments in oil and gas and construction industries, enhancing demand for fluid power solutions.Tell us your focus area and get a customized research report.

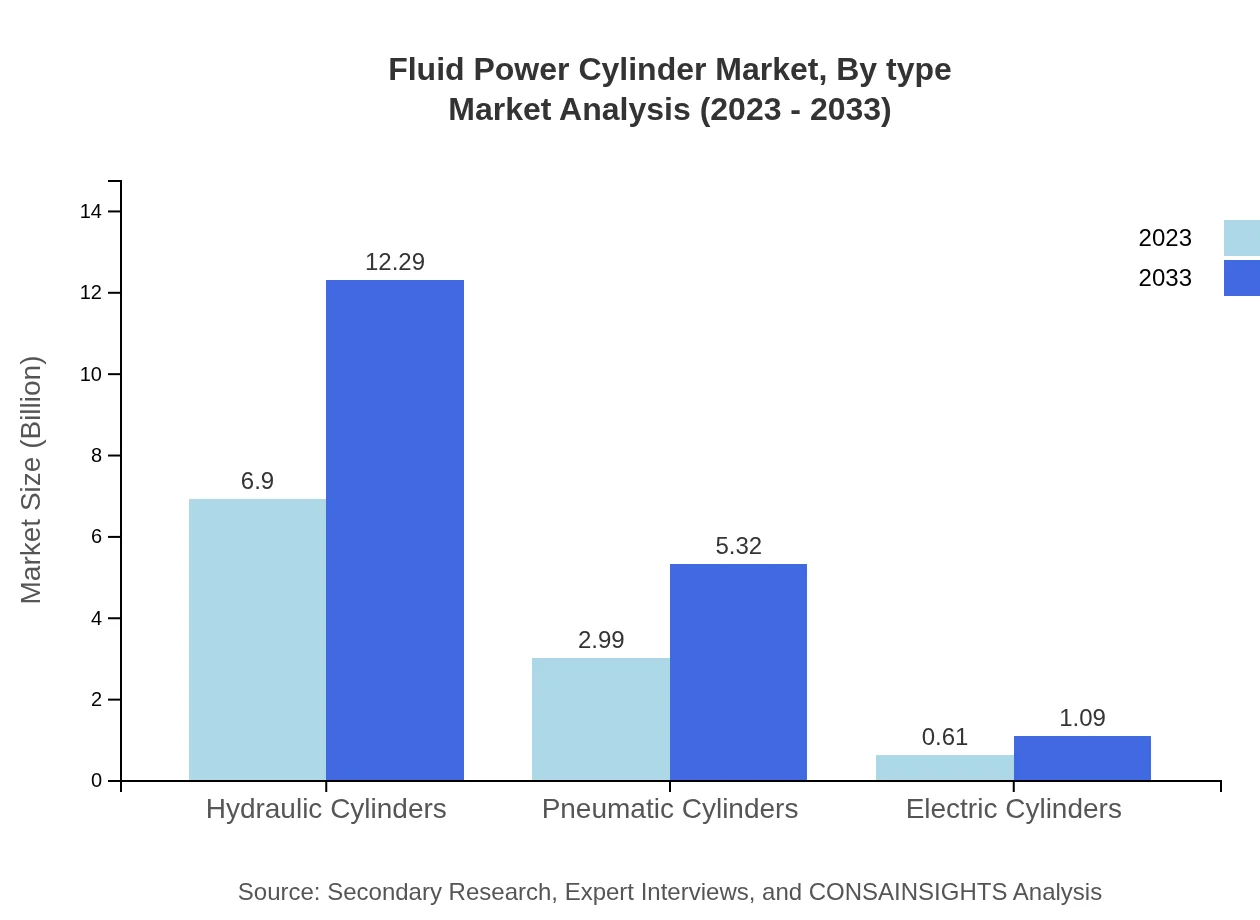

Fluid Power Cylinder Market Analysis By Type

Hydraulic Cylinders, dominating the market, are valued at 6.90 billion USD in 2023, and growth is projected to reach 12.29 billion USD by 2033, holding a substantial market share of 65.72%. Pneumatic Cylinders are estimated at 2.99 billion USD in 2023, expected to grow to 5.32 billion USD, contributing to a share of 28.43%. Electric Cylinders represent a smaller segment with a value of 0.61 billion USD, growing to 1.09 billion USD, holding 5.85% of the market.

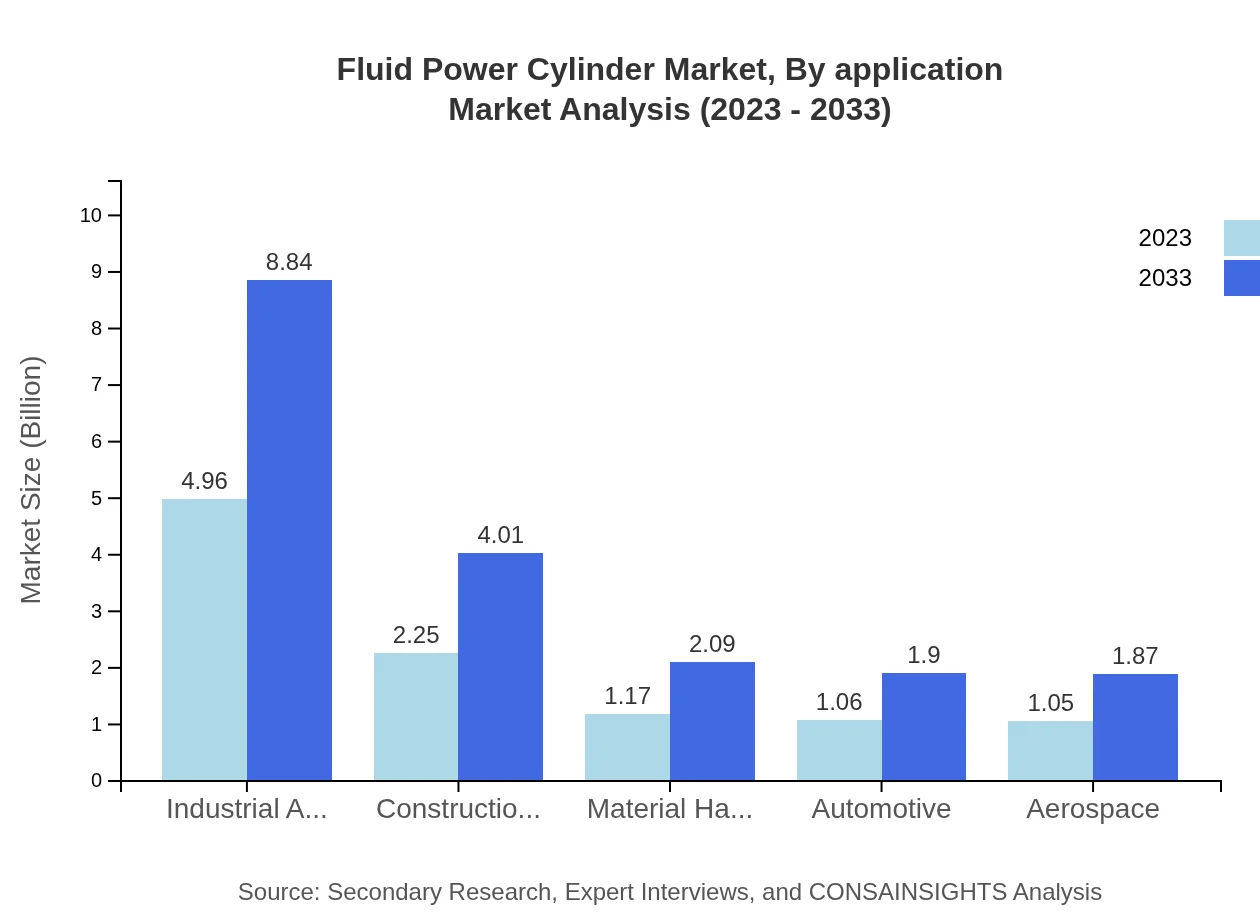

Fluid Power Cylinder Market Analysis By Application

Applications in manufacturing and industrial automation account for approximately 4.96 billion USD in 2023 and are expected to reach 8.84 billion USD by 2033 (47.25% share). Oil & Gas contributes about 2.25 billion USD, projected to grow to 4.01 billion USD (21.45% share). Other notable applications include food & beverage, pharmaceuticals, and construction equipment, with growth trajectories similarly mirroring industrial demand sustainability.

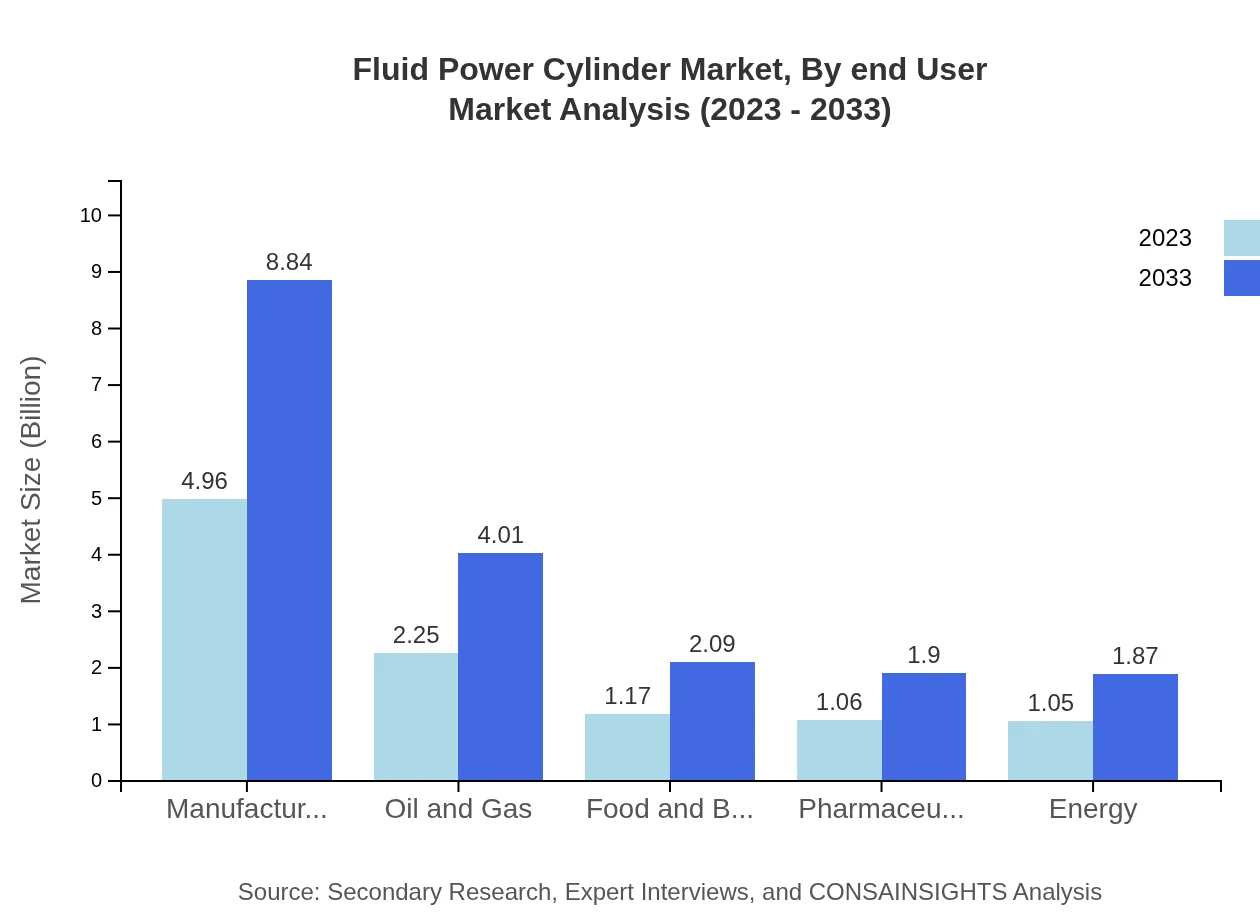

Fluid Power Cylinder Market Analysis By End User

The automotive industry's demand for fluid power cylinders is on the rise, projected to grow from 1.06 billion USD in 2023 to 1.90 billion USD by 2033 (10.14% share). The aerospace sector, while smaller, remains vital, forecasted to increase from 1.05 billion USD to 1.87 billion USD over the same period (10% share). Other end-user industries include energy, construction, and material handling, collectively supporting market stability.

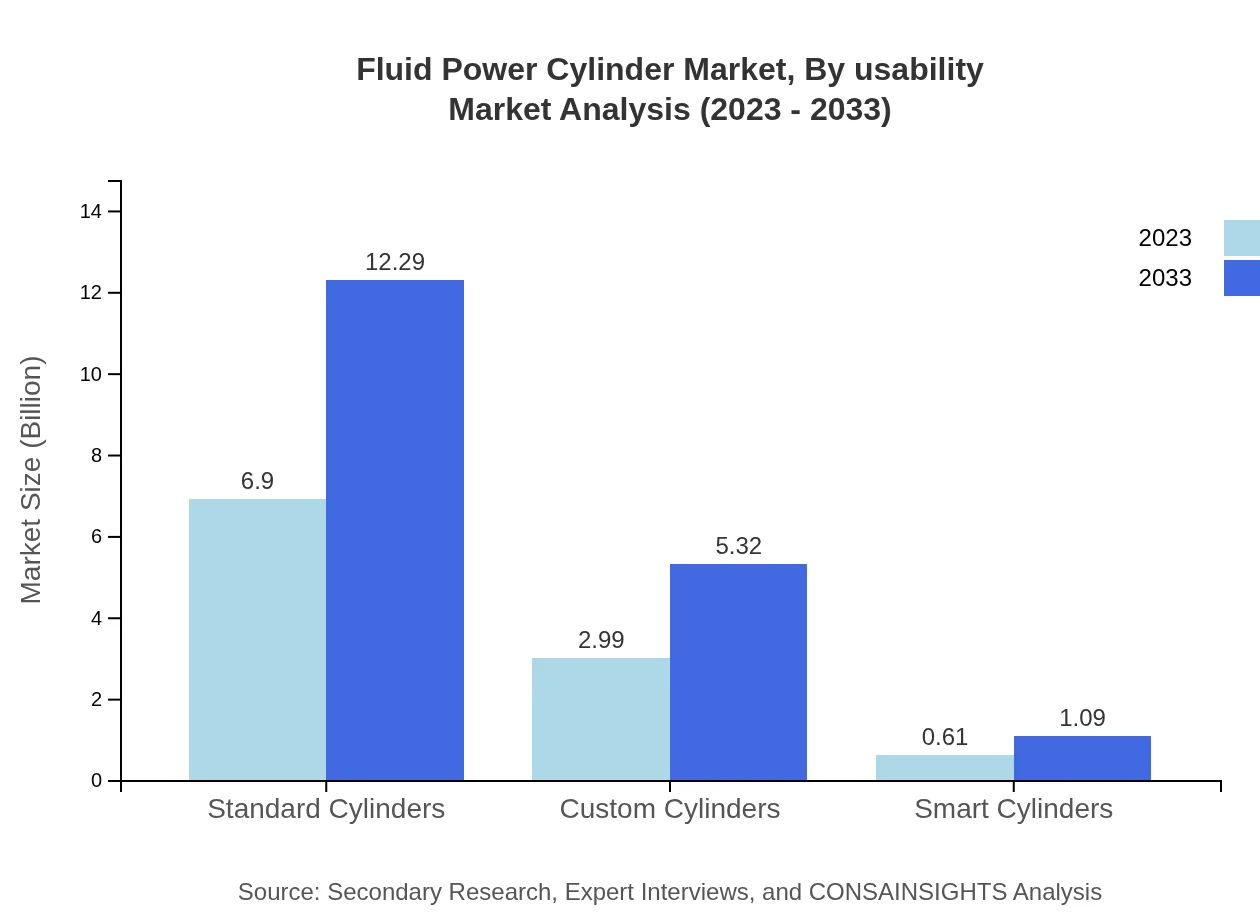

Fluid Power Cylinder Market Analysis By Usability

Standard Cylinders currently dominate the overall market at 6.90 billion USD and show steady growth to 12.29 billion USD by 2033 (65.72% share). Custom Cylinders, although representing a smaller segment at approx 2.99 billion USD currently, forecasted growth to 5.32 billion USD reflects increasing demand for tailored solutions (28.43% share). Smart Cylinders are also emerging, raising interest with innovative features, projected to grow from 0.61 billion USD to 1.09 billion USD (5.85% share).

Fluid Power Cylinder Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Fluid Power Cylinder Industry

Parker Hannifin:

A leader in motion and control technologies, Parker Hannifin offers a diverse range of fluid power products and solutions for numerous industries globally.Bosch Rexroth:

Bosch Rexroth provides innovative fluid power solutions and is known for its sophisticated hydraulic components and systems, contributing extensively to industrial automation.Eaton Corporation:

With a strong presence in fluid power, Eaton Corporation focuses on sustainability and efficiency in designing hydraulic and pneumatic technologies for various market sectors.Hydac International:

Known for hydraulic systems and components, Hydac International emphasizes technological advancements and customer-specific solutions in fluid power systems.Parker Teseo:

Parker Teseo specializes in hydraulic and pneumatic solutions, particularly in sectors demanding high reliability and efficiency.We're grateful to work with incredible clients.

FAQs

What is the market size of fluid Power Cylinder?

The global fluid power cylinder market is projected to reach approximately $10.5 billion by 2033, growing at a CAGR of 5.8%. The growth reflects the rising demand across various sectors such as manufacturing and construction.

What are the key market players or companies in this fluid Power Cylinder industry?

Key players in the fluid power cylinder market include Parker Hannifin Corporation, Bosch Rexroth AG, and SMC Corporation. These companies are recognized for their innovations and extensive product portfolios, contributing significantly to market development.

What are the primary factors driving the growth in the fluid Power Cylinder industry?

Key growth drivers include the increasing demand for automation in manufacturing, advancements in hydraulic technology, and the rising need in sectors like construction and automotive. These factors drive investments and innovations in fluid power cylinders.

Which region is the fastest Growing in the fluid Power Cylinder?

The Asia Pacific region is expected to exhibit significant growth in the fluid power cylinder market, with sales projected to increase from $1.99 billion in 2023 to $3.55 billion by 2033, primarily due to industrial expansion.

Does ConsaInsights provide customized market report data for the fluid Power Cylinder industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the fluid power cylinder industry, enabling clients to gain insights relevant to their unique strategies and goals.

What deliverables can I expect from this fluid Power Cylinder market research project?

Deliverables typically include comprehensive reports with market size data, growth forecasts, trend analyses, and competitive landscape insights across various segments and regions for the fluid power cylinder market.

What are the market trends of fluid Power Cylinder?

Current trends include a shift towards smart cylinders and increased adoption of automation technologies. The market is seeing innovations in energy efficiency improvements and enhanced performance capabilities across hydraulic and pneumatic segments.