Food-3d Printing Market Report

Published Date: 31 January 2026 | Report Code: food-3d-printing

Food-3d Printing Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Food-3D Printing market from 2023 to 2033, detailing current market conditions, size, segmentation, regional insights, and future trends to offer comprehensive insights for stakeholders and decision-makers.

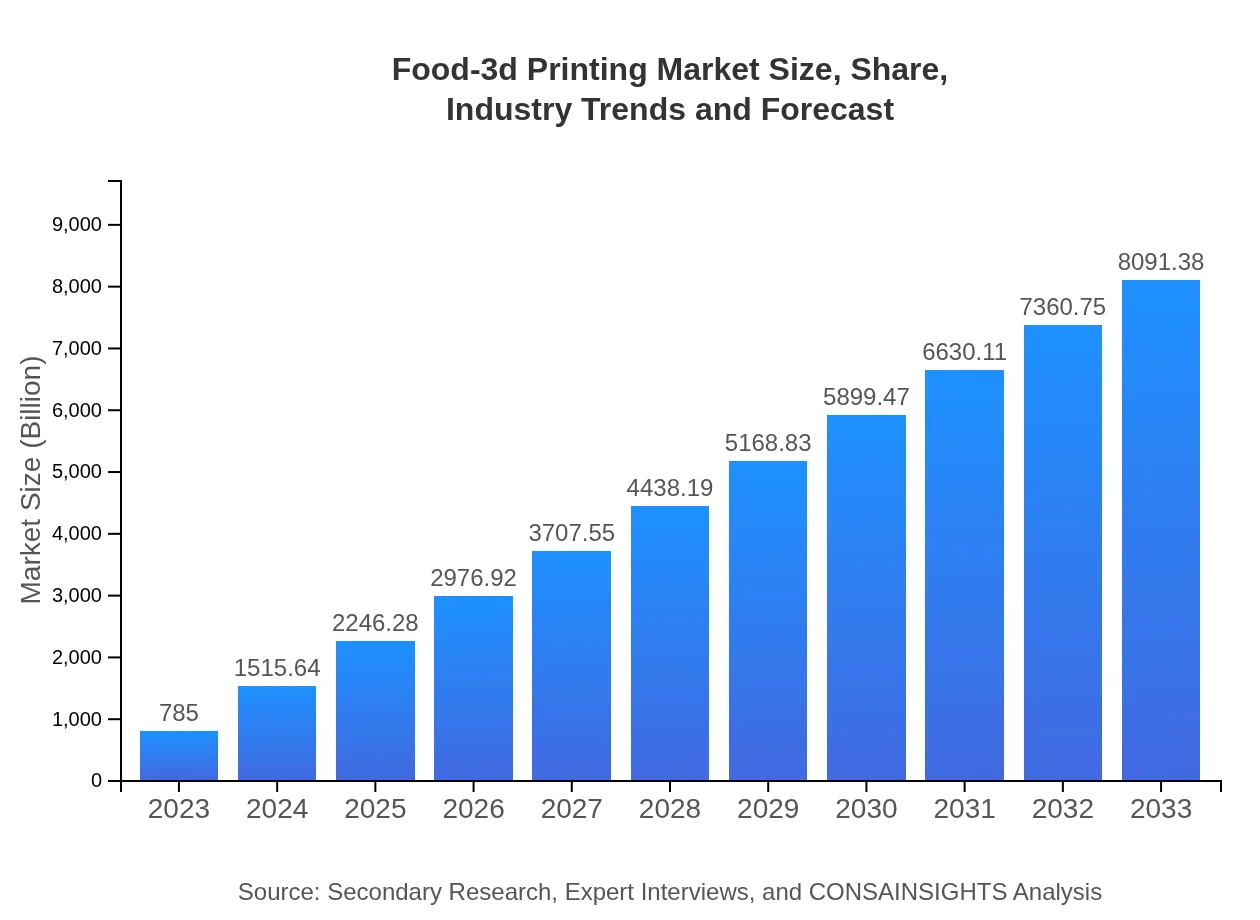

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $785.00 Million |

| CAGR (2023-2033) | 24.6% |

| 2033 Market Size | $8091.38 Million |

| Top Companies | Natural Machines, 3D Food Printing Solutions, BeeHex, CHOC Creator |

| Last Modified Date | 31 January 2026 |

Food-3D Printing Market Overview

Customize Food-3d Printing Market Report market research report

- ✔ Get in-depth analysis of Food-3d Printing market size, growth, and forecasts.

- ✔ Understand Food-3d Printing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Food-3d Printing

What is the Market Size & CAGR of Food-3D Printing market in 2023?

Food-3D Printing Industry Analysis

Food-3D Printing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Food-3D Printing Market Analysis Report by Region

Europe Food-3d Printing Market Report:

Europe's market is significantly thriving, having a size of USD 262.35 million in 2023 and an expected reach of USD 2,704.14 million by 2033, propelled by increasing sustainability goals and technological innovations.Asia Pacific Food-3d Printing Market Report:

The Asia Pacific region is poised for substantial growth, with a market size of approximately USD 140.75 million in 2023, projected to reach USD 1,450.79 million by 2033. The growing adoption of food technology and increasing culinary tourism are key drivers.North America Food-3d Printing Market Report:

North America exhibits a robust Food-3D Printing market, sized at USD 267.92 million in 2023 and projected to attain USD 2,761.59 million by 2033, heavily influenced by advancements in nutritional science and food personalization.South America Food-3d Printing Market Report:

In South America, the market was estimated at USD 40.98 million in 2023, expected to increase to USD 422.37 million by 2033. The region's unique culinary heritage accentuates the demand for innovative food solutions.Middle East & Africa Food-3d Printing Market Report:

The Middle East and Africa report a market size of USD 73.01 million in 2023, anticipated to reach USD 752.50 million by 2033, influenced by growing urbanization and changing dietary habits.Tell us your focus area and get a customized research report.

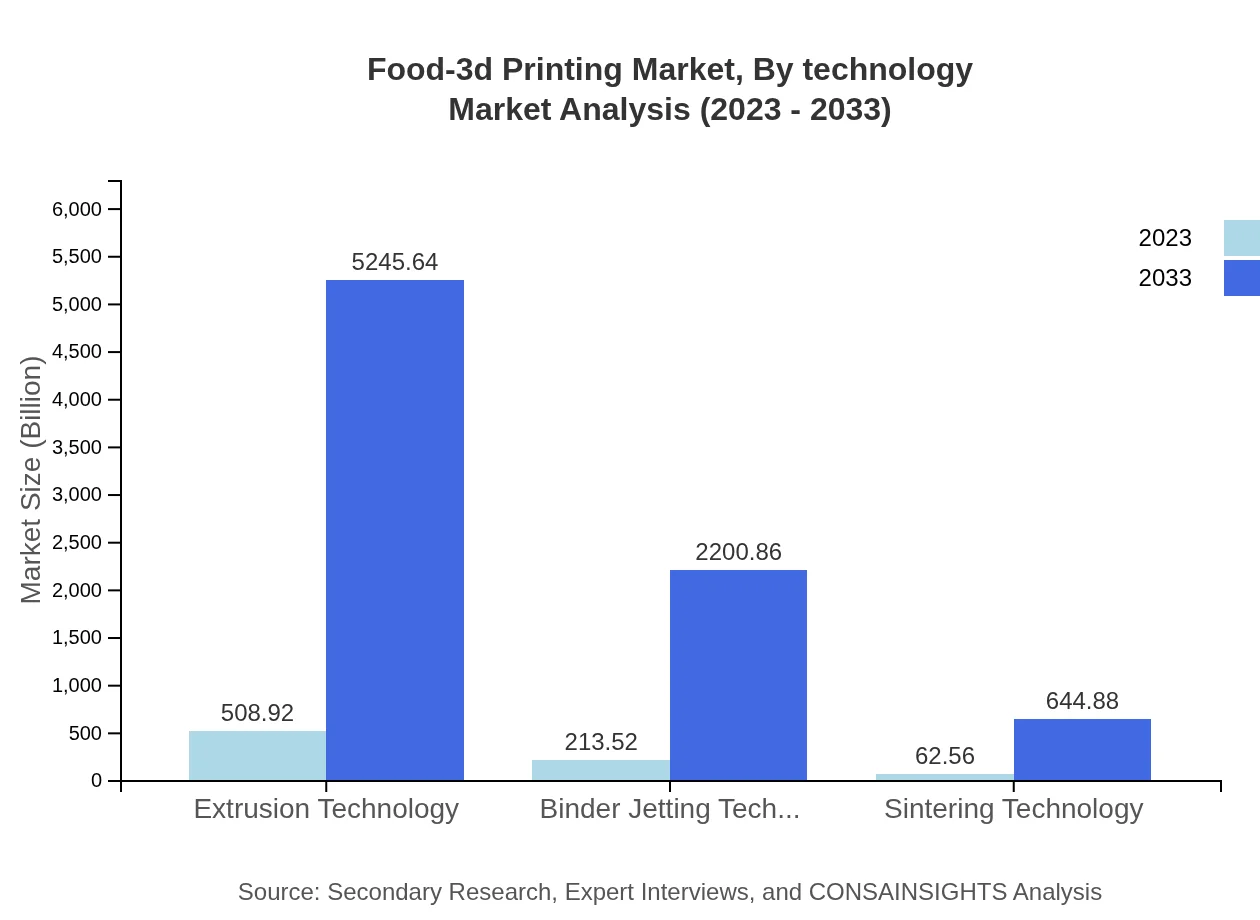

Food-3d Printing Market Analysis By Technology

The Food 3D Printing market by technology includes Extrusion, Binder Jetting, and Sintering technologies. Notably, Extrusion Technology leads the segment with a market size of USD 508.92 million in 2023 and expected growth to USD 5,245.64 million by 2033, accounting for 64.83% of the overall market share.

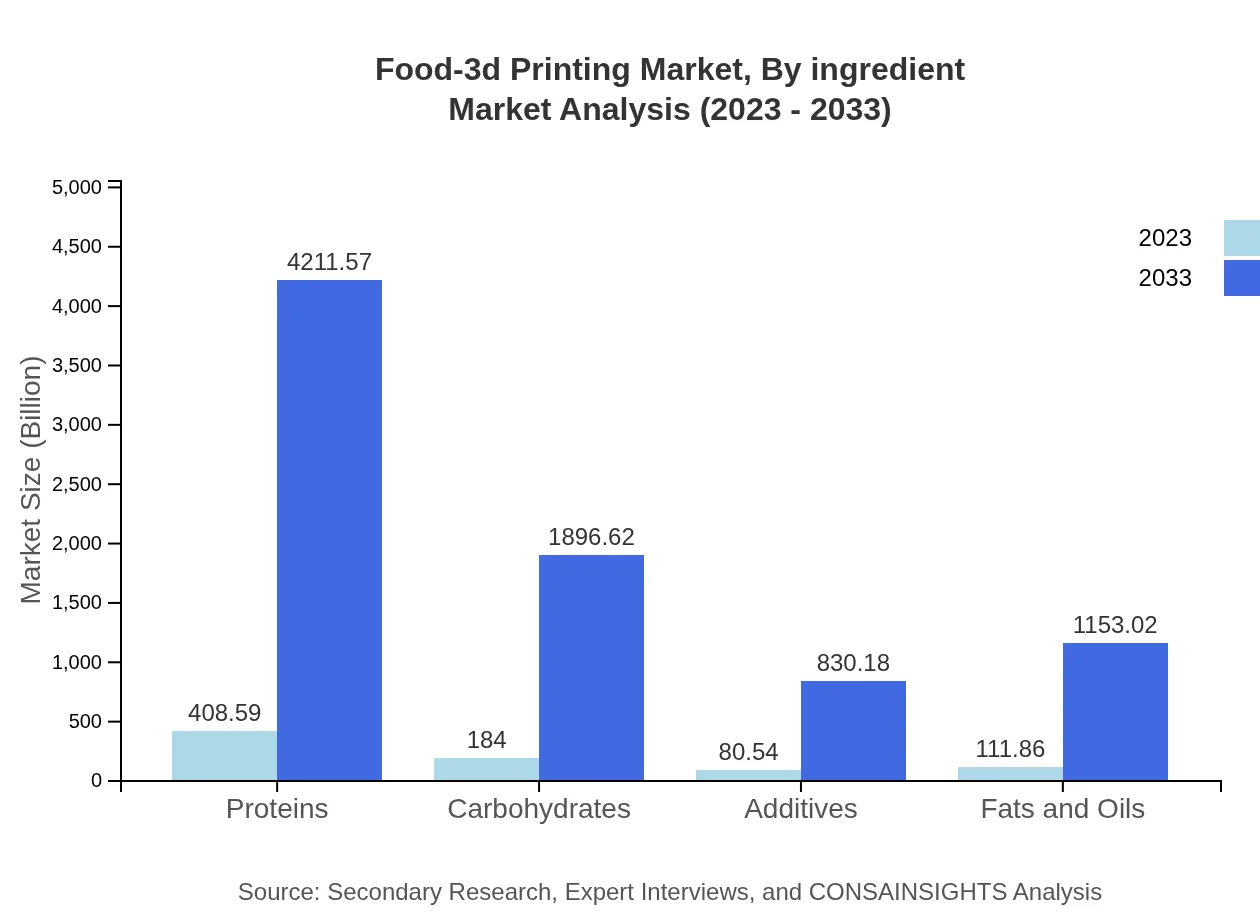

Food-3d Printing Market Analysis By Ingredient

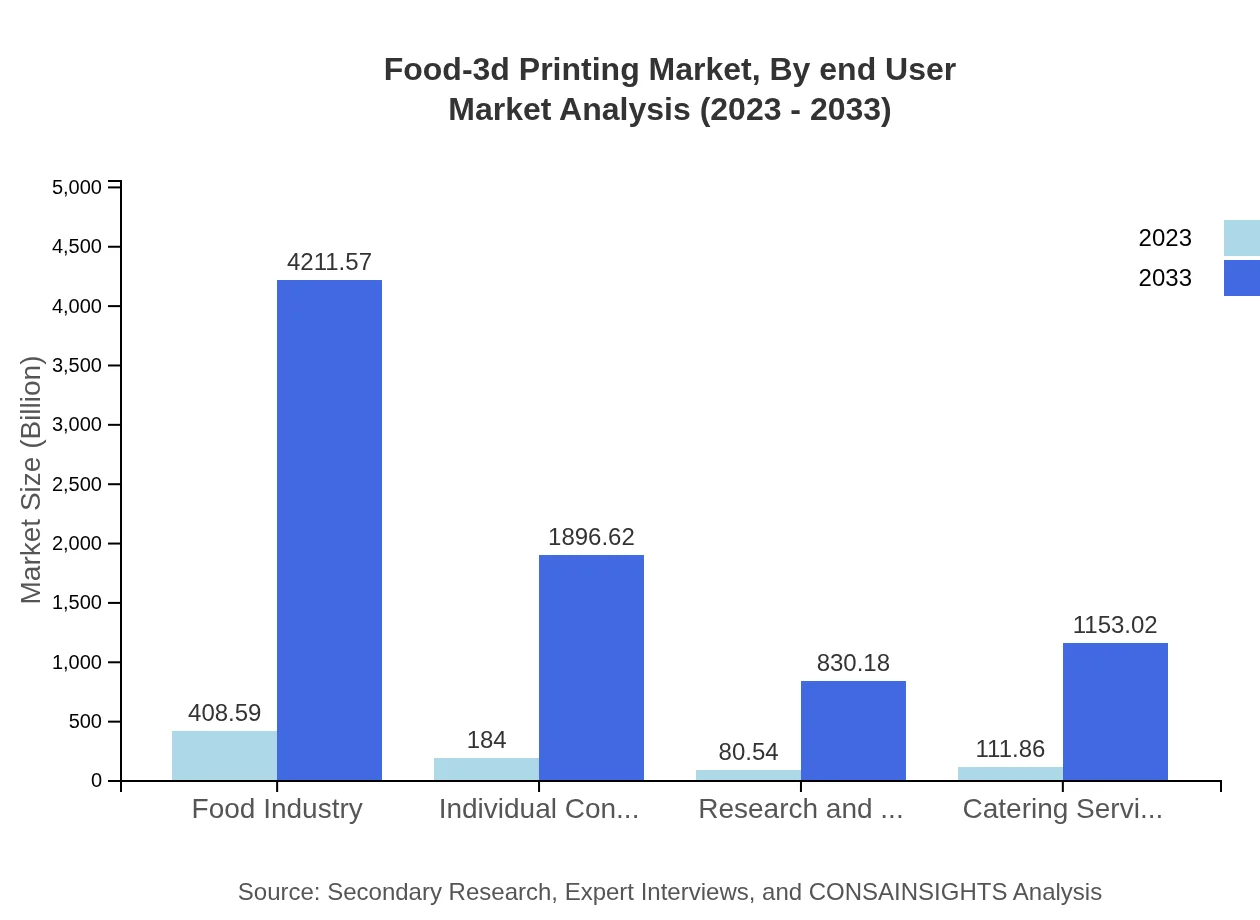

Segments by ingredient are dominated by proteins, carbohydrates, additives, and fats and oils. The protein segment holds a significant market of USD 408.59 million in 2023, which is projected to reach USD 4,211.57 million by 2033, aligning with trends in personalized nutrition.

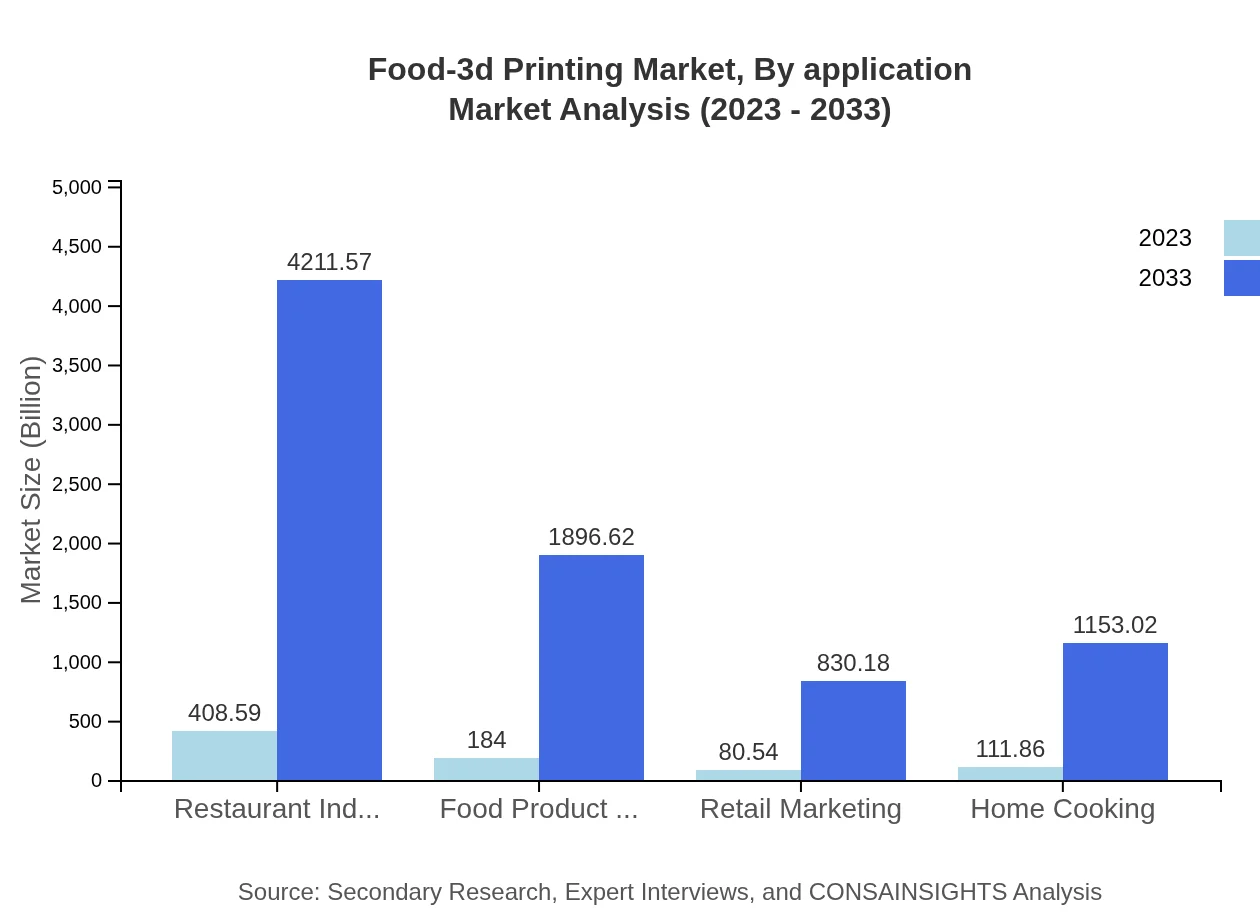

Food-3d Printing Market Analysis By Application

Applications in the Food-3D Printing market include catering services, home cooking, and food product development. The catering segment is projected to grow from USD 111.86 million to USD 1,153.02 million by 2033, highlighting the demand for customized culinary solutions.

Food-3d Printing Market Analysis By End User

End-user segments range from individual consumers to research and development sectors. The market for individual consumers is expected to grow from USD 184.00 million to USD 1,896.62 million by 2033, emphasizing the trend towards personalized cooking experiences.

Food-3D Printing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Food-3D Printing Industry

Natural Machines:

Natural Machines is recognized for its innovative Foodini 3D food printer, fostering creativity in culinary applications by allowing chefs and home cooks to create customized meals.3D Food Printing Solutions:

3D Food Printing Solutions specializes in providing advanced printing technology that caters to the catering and restaurant sectors, pushing the boundaries of food design.BeeHex:

BeeHex is notable for its work with NASA in developing pizza printing technologies for space missions, showcasing how 3D food printing can serve future ventures.CHOC Creator:

CHOC Creator focuses on 3D printing chocolate, enhancing the creativity of culinary arts, especially in dessert preparation.We're grateful to work with incredible clients.

FAQs

What is the market size of food-3d Printing?

The food-3D printing market is projected to reach approximately $785 million by 2033, with a remarkable CAGR of 24.6%. This substantial growth indicates a rapidly evolving sector poised for innovation.

What are the key market players or companies in the food-3d Printing industry?

Key players in the food-3D printing sector include major firms like 3D Systems Corporation, Naturalmachines, and BeeHex. These companies lead the industry by developing advanced 3D printing technologies tailored for food applications.

What are the primary factors driving the growth in the food-3d Printing industry?

The growth in food-3D printing is driven by rising consumer demand for personalized nutrition, technological advancements in printing materials, and the increasing trend towards sustainable food production methods.

Which region is the fastest Growing in the food-3d Printing market?

The Asia Pacific region is projected to experience significant growth, increasing from $140.75 million in 2023 to approximately $1450.79 million by 2033, showcasing a rapidly expanding market for food-3D printing technologies.

Does ConsaInsights provide customized market report data for the food-3d Printing industry?

Yes, ConsaInsights offers customized market report data tailored to client specifications, ensuring comprehensive insights into the food-3D printing industry, including market trends, growth projections, and competitive analysis.

What deliverables can I expect from this food-3d Printing market research project?

Deliverables from the food-3D printing market research project typically include a detailed report, market forecasts, segmentation analysis, competitive landscape overview, and actionable insights tailored to strategic decisions.

What are the market trends of food-3d Printing?

Key trends in the food-3D printing market include the rise of plant-based ingredients, advancements in food safety technologies, increasing investment in R&D, and the growing popularity of custom food experiences among consumers.