Food Extrusion Market Report

Published Date: 22 January 2026 | Report Code: food-extrusion

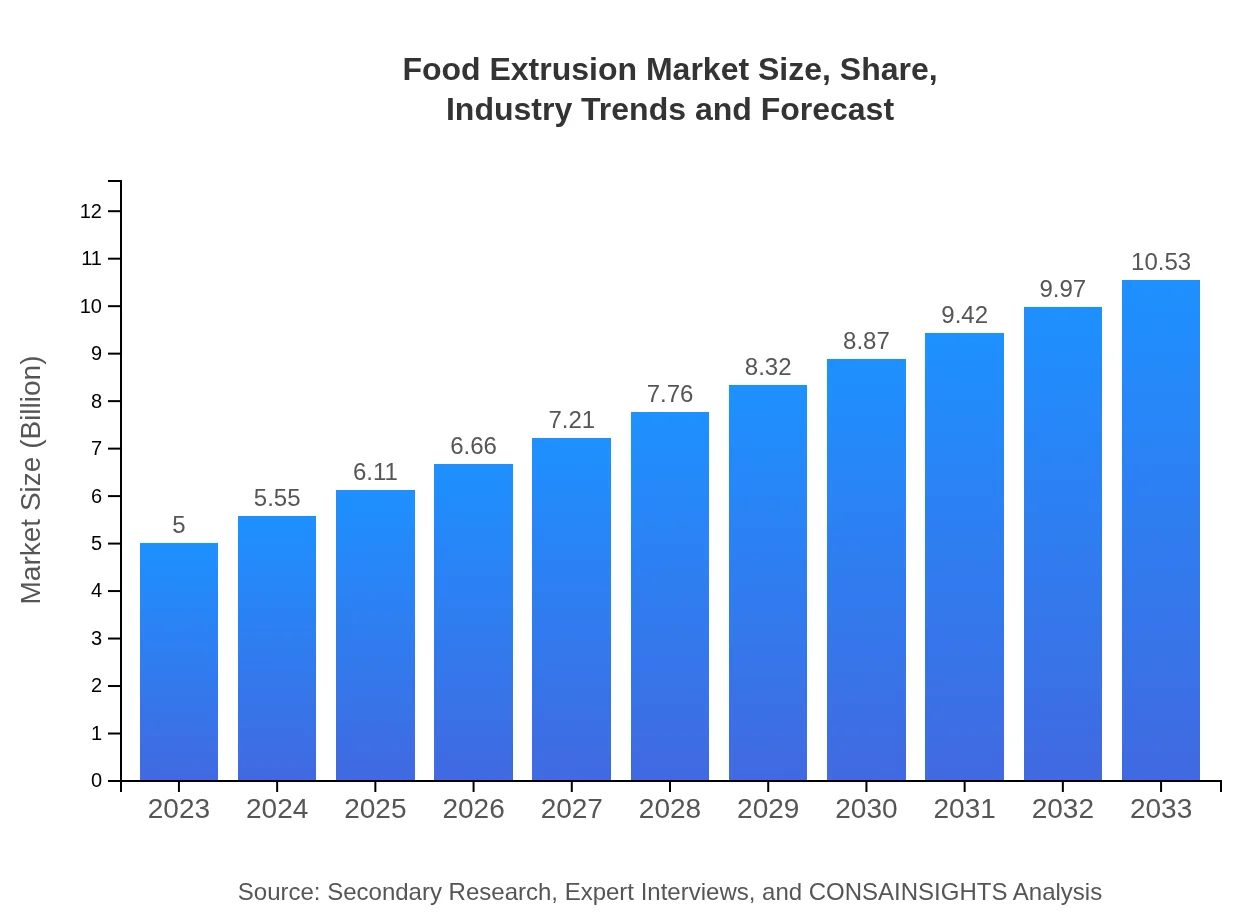

Food Extrusion Market Size, Share, Industry Trends and Forecast to 2033

This market report provides a comprehensive analysis of the Food Extrusion industry from 2023 to 2033, covering key insights, trends, market size, and competitive landscape to guide stakeholders in making informed decisions.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Clextral, Bühler Group, Andritz AG, Heat and Control, Inc., Schneider Electric |

| Last Modified Date | 22 January 2026 |

Food Extrusion Market Overview

Customize Food Extrusion Market Report market research report

- ✔ Get in-depth analysis of Food Extrusion market size, growth, and forecasts.

- ✔ Understand Food Extrusion's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Food Extrusion

What is the Market Size & CAGR of Food Extrusion market in 2023?

Food Extrusion Industry Analysis

Food Extrusion Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Food Extrusion Market Analysis Report by Region

Europe Food Extrusion Market Report:

Europe's Food Extrusion market is projected to rise from USD 1.30 billion in 2023 to USD 2.74 billion by 2033. The region's emphasis on health and wellness, alongside stringent regulations on food safety, drives the demand for high-quality extruded products. European consumers’ inclination towards organic and natural food ingredients is also a major factor contributing to market growth.Asia Pacific Food Extrusion Market Report:

The Asia Pacific region is anticipated to witness significant growth in the Food Extrusion market, projected to increase from USD 1.02 billion in 2023 to USD 2.14 billion by 2033. The rising urban population, shifting dietary habits towards convenience foods, and increased investments in food processing technologies are key factors fueling market expansion in this region.North America Food Extrusion Market Report:

North America remains a significant player in the Food Extrusion market, with a market value projected to grow from USD 1.86 billion in 2023 to USD 3.92 billion by 2033. The demand for innovative and functional food products, coupled with a robust retail sector, facilitates this growth trend. Key manufacturers are leveraging advanced extrusion technologies to meet changing consumer preferences.South America Food Extrusion Market Report:

In South America, the Food Extrusion market is expected to grow from USD 0.37 billion in 2023 to USD 0.77 billion by 2033. The growth is driven primarily by rising consumer awareness about health and nutrition, alongside the burgeoning snack food sector. The region's growing middle class is boosting demand for diversified food options, including snacks and convenience foods.Middle East & Africa Food Extrusion Market Report:

The Middle Eastern and African Food Extrusion market is anticipated to grow from USD 0.45 billion in 2023 to USD 0.95 billion by 2033, propelled by increasing urbanization and changing dietary patterns. Advancements in food technology and rising investments from foreign firms to enhance local production capabilities are key to this region’s market development.Tell us your focus area and get a customized research report.

Food Extrusion Market Analysis Snacks

Global Food Extrusion Market, By Product: Snacks (2023 - 2033)

The snacks segment dominates the Food Extrusion market, with a size of USD 3.42 billion in 2023 expected to grow to USD 7.19 billion by 2033, maintaining a 68.33% market share. The rise in health consciousness among consumers has significantly influenced product offerings in this category, leading to an increased preference for healthier snack alternatives.

Food Extrusion Market Analysis Pellets_and_granules

Global Food Extrusion Market, By Product: Pellets and Granules (2023 - 2033)

Pellets and granules represent a significant portion of the market, projected to increase from USD 1.36 billion in 2023 to USD 2.87 billion by 2033, holding a 27.29% market share. Their applications in various food processing sectors contribute to strong demand, driven by innovations that enhance their functional properties.

Food Extrusion Market Analysis Textured_vegetable_proteins

Global Food Extrusion Market, By Product: Textured Vegetable Proteins (2023 - 2033)

This segment is expected to grow from USD 0.22 billion in 2023 to USD 0.46 billion by 2033, maintaining a share of 4.38%. The increasing consumer inclination toward plant-based proteins for health and environmental considerations is a crucial factor driving this segment.

Food Extrusion Market Analysis Household

Global Food Extrusion Market, By Application: Household (2023 - 2033)

The household application contributes significantly, with a market size projected to rise from USD 2.89 billion in 2023 to USD 6.07 billion by 2033. Households are increasingly utilizing extruded products due to convenience and nutritional benefits.

Food Extrusion Market Analysis Food_industry

Global Food Extrusion Market, By Application: Food Industry (2023 - 2033)

The Food Industry segment is anticipated to grow from USD 1.05 billion in 2023 to USD 2.21 billion by 2033, accounting for 20.98% of the market. The growing demand for processed and convenient food items has bolstered this segment's growth.

Food Extrusion Market Analysis Pet_food_industry

Global Food Extrusion Market, By Application: Pet Food Industry (2023 - 2033)

With a projected increase from USD 0.53 billion in 2023 to USD 1.12 billion by 2033, this segment maintains a 10.6% share. The rising trend of pet humanization is driving higher demand for high-quality extruded pet food products.

Food Extrusion Market Analysis Commercial

Global Food Extrusion Market, By Application: Commercial (2023 - 2033)

This segment is set to grow from USD 0.54 billion in 2023 to USD 1.13 billion by 2033 with a 10.71% market share, influenced by increasing commercial use of extruded products.

Food Extrusion Market Analysis Single_screw_extrusion

Global Food Extrusion Market, By Technology: Single Screw Extrusion (2023 - 2033)

This technology holds a market size of USD 3.42 billion in 2023 and is expected to rise to USD 7.19 billion by 2033, maintaining a 68.33% share. It is the most commonly used technology due to its simplicity and efficiency.

Food Extrusion Market Analysis Twin_screw_extrusion

Global Food Extrusion Market, By Technology: Twin Screw Extrusion (2023 - 2033)

Holding a market size that is projected to grow from USD 1.36 billion in 2023 to USD 2.87 billion by 2033, this segment accounts for 27.29% of the market, favored for its ability to handle complex formulations.

Food Extrusion Market Analysis Other_extrusion_technologies

Global Food Extrusion Market, By Technology: Other Extrusion Technologies (2023 - 2033)

This segment includes various proprietary technologies and is expected to grow from USD 0.22 billion in 2023 to USD 0.46 billion by 2033, holding a 4.38% share, primarily benefiting from niche applications.

Food Extrusion Market Analysis High_moisture_extrusion

Global Food Extrusion Market, By Formulation: High Moisture Extrusion (2023 - 2033)

This sector is anticipated to grow from USD 3.42 billion in 2023 to USD 7.19 billion by 2033, maintaining a 68.33% market share, favored for its capability to create meat analogs.

Food Extrusion Market Analysis Low_moisture_extrusion

Global Food Extrusion Market, By Formulation: Low Moisture Extrusion (2023 - 2033)

Projected to rise from USD 1.36 billion in 2023 to USD 2.87 billion by 2033, this segment holds a 27.29% share, essential for producing crisp, dry snacks.

Food Extrusion Market Analysis Feed_extrusion

Global Food Extrusion Market, By Formulation: Feed Extrusion (2023 - 2033)

This niche segment is poised for growth from USD 0.22 billion in 2023 to USD 0.46 billion by 2033, representing a 4.38% share, essential for producing animal feed and aquafeeds.

Food Extrusion Market Analysis Meat_substitutes

Global Food Extrusion Market, By End-User: Meat Substitutes (2023 - 2033)

The meat substitutes segment is growing steadily, expected to reach USD 1.16 billion by 2033. The increasing demand for alternative protein sources has led to the development of various products within this category.

Food Extrusion Market Analysis Other_applications

Global Food Extrusion Market, By End-User: Other Applications (2023 - 2033)

This segment projects variations depending on emerging food applications, anticipated to grow in alignment with trends towards specialty health foods.

Food Extrusion Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Food Extrusion Industry

Clextral:

A leading player specializing in extrusion solutions for food and feed industries, providing innovative technologies and complete processing lines.Bühler Group:

Bühler is renowned for its advanced food processing technology, supplying extrusion solutions that enhance productivity and product quality.Andritz AG:

An established industrial equipment supplier known for its extruders and processing technologies serving the food, feed, and biomass sectors.Heat and Control, Inc.:

Heat and Control provides custom processing and packaging equipment, specializing in extrusion systems for food applications.Schneider Electric:

They offer automation solutions for the food industry, contributing to operational efficiency and smart manufacturing in extrusion processes.We're grateful to work with incredible clients.

FAQs

What is the market size of food Extrusion?

The food extrusion market is projected to reach $5 billion by 2033, growing at a CAGR of 7.5% from a current size of approximately $3.30 billion in 2023. This growth reflects increasing demand across snack and pet food sectors.

What are the key market players or companies in this food Extrusion industry?

Key players in the food-extrusion industry include Cargill, Bühler AG, and Texan Food Innovations. These companies are at the forefront of technology innovation and market expansion, contributing significantly to market dynamics and competition.

What are the primary factors driving the growth in the food Extrusion industry?

Growth factors for food extrusion include rising consumer demand for convenient snacks, increased investments in food technology, and a shift toward plant-based diets, highlighting sustainable practices and novel food processing techniques in the industry.

Which region is the fastest Growing in the food Extrusion?

The fastest-growing region in the food extrusion market is North America, with market size increasing from $1.86 billion in 2023 to an estimated $3.92 billion by 2033, driven by innovation and demand for processed food products.

Does ConsaInsights provide customized market report data for the food Extrusion industry?

Yes, ConsaInsights offers tailored market report data for the food-extrusion industry, enabling clients to receive insights specific to their interests, including detailed analysis on regional markets, segments, and future trends.

What deliverables can I expect from this food Extrusion market research project?

Deliverables include a comprehensive report detailing market size, forecasts up to 2033, key segments, regional analysis, competitive landscape, and actionable insights to support strategic decision-making for stakeholders in the food extrusion sector.

What are the market trends of food Extrusion?

Current trends in the food-extrusion market include the rise of high moisture extrusion technologies, increased health-conscious snack options, and innovations in plant-based proteins, reflecting consumer preferences for healthier, sustainable food choices.