Food Ingredients Sterilization Market Report

Published Date: 31 January 2026 | Report Code: food-ingredients-sterilization

Food Ingredients Sterilization Market Size, Share, Industry Trends and Forecast to 2033

This market report delves into the Food Ingredients Sterilization sector, providing insights into market trends, size, and forecasts from 2023 to 2033. It encompasses regional analyses, industry challenges, and competitive landscapes to aid stakeholders' decision-making.

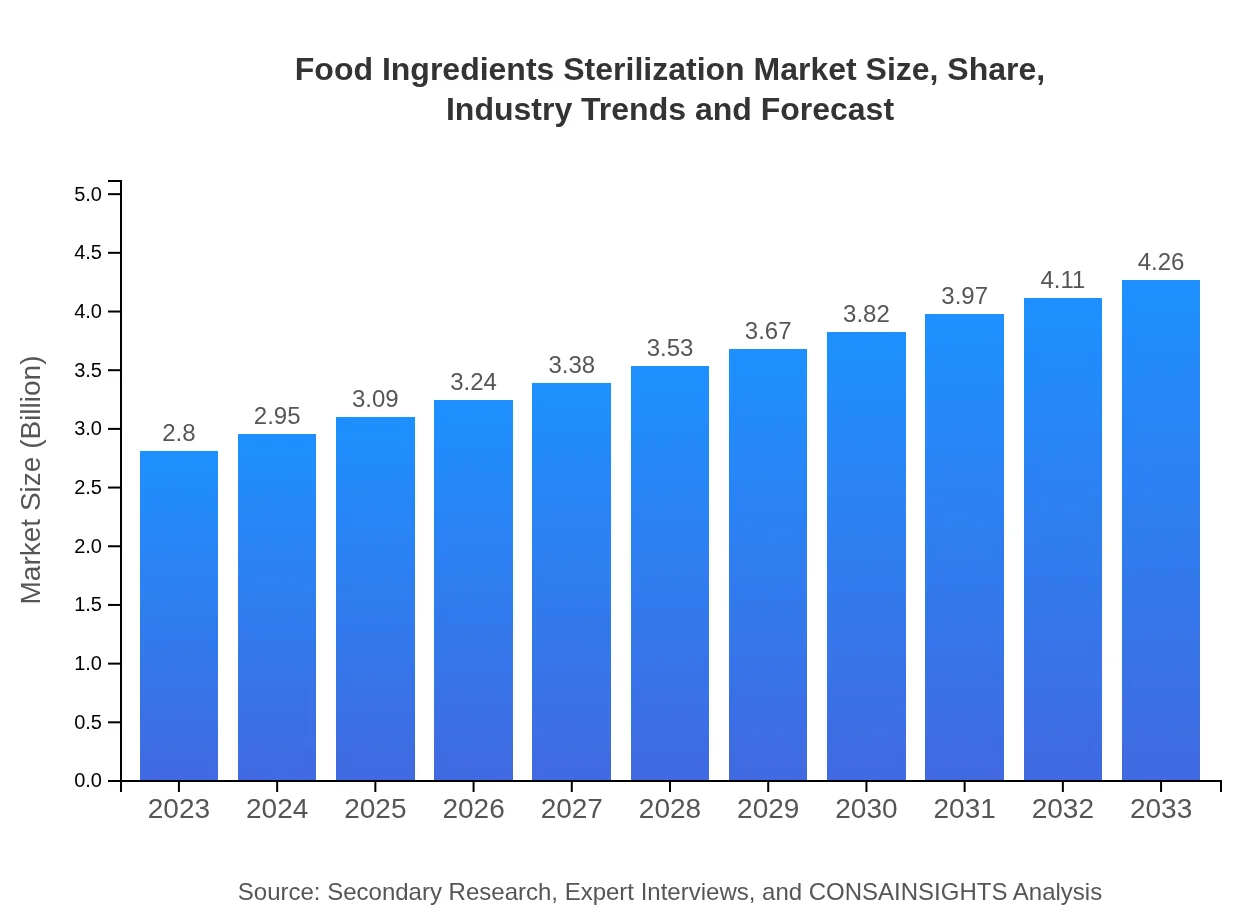

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.80 Billion |

| CAGR (2023-2033) | 4.2% |

| 2033 Market Size | $4.26 Billion |

| Top Companies | Nestlé S.A., Tetra Pak International S.A., Ecolab Inc., Krones AG, GEA Group AG |

| Last Modified Date | 31 January 2026 |

Food Ingredients Sterilization Market Overview

Customize Food Ingredients Sterilization Market Report market research report

- ✔ Get in-depth analysis of Food Ingredients Sterilization market size, growth, and forecasts.

- ✔ Understand Food Ingredients Sterilization's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Food Ingredients Sterilization

What is the Market Size & CAGR of Food Ingredients Sterilization market in 2023?

Food Ingredients Sterilization Industry Analysis

Food Ingredients Sterilization Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Food Ingredients Sterilization Market Analysis Report by Region

Europe Food Ingredients Sterilization Market Report:

Europe, with a market size increasing from $0.85 billion in 2023 to $1.29 billion in 2033, benefits from high-quality standards for food products. The growing demand for convenience and healthy foods among consumers reinforces the importance of effective sterilization methods.Asia Pacific Food Ingredients Sterilization Market Report:

The Asia Pacific region is projected to grow from $0.52 billion in 2023 to $0.79 billion in 2033, driven by increasing disposable income and changing consumer preferences toward processed foods. Countries like China and India are significant contributors, backed by expanding urban populations and innovative food safety regulations.North America Food Ingredients Sterilization Market Report:

North America is set to grow from $1.05 billion in 2023 to $1.60 billion in 2033, largely due to stringent food safety regulations and advancements in sterilization technology. The presence of key market players significantly contributes to this growth and innovative advancements.South America Food Ingredients Sterilization Market Report:

In South America, the market is expected to experience growth from $0.12 billion in 2023 to $0.19 billion in 2033. The region’s focus on improving food safety standards and rising exports of agricultural products are key growth drivers.Middle East & Africa Food Ingredients Sterilization Market Report:

The Middle East and Africa region is forecasted to grow from $0.26 billion in 2023 to $0.40 billion in 2033, fueled by increasing awareness of food safety and enhanced distribution channels. Investment in food processing infrastructure is also expected to rise.Tell us your focus area and get a customized research report.

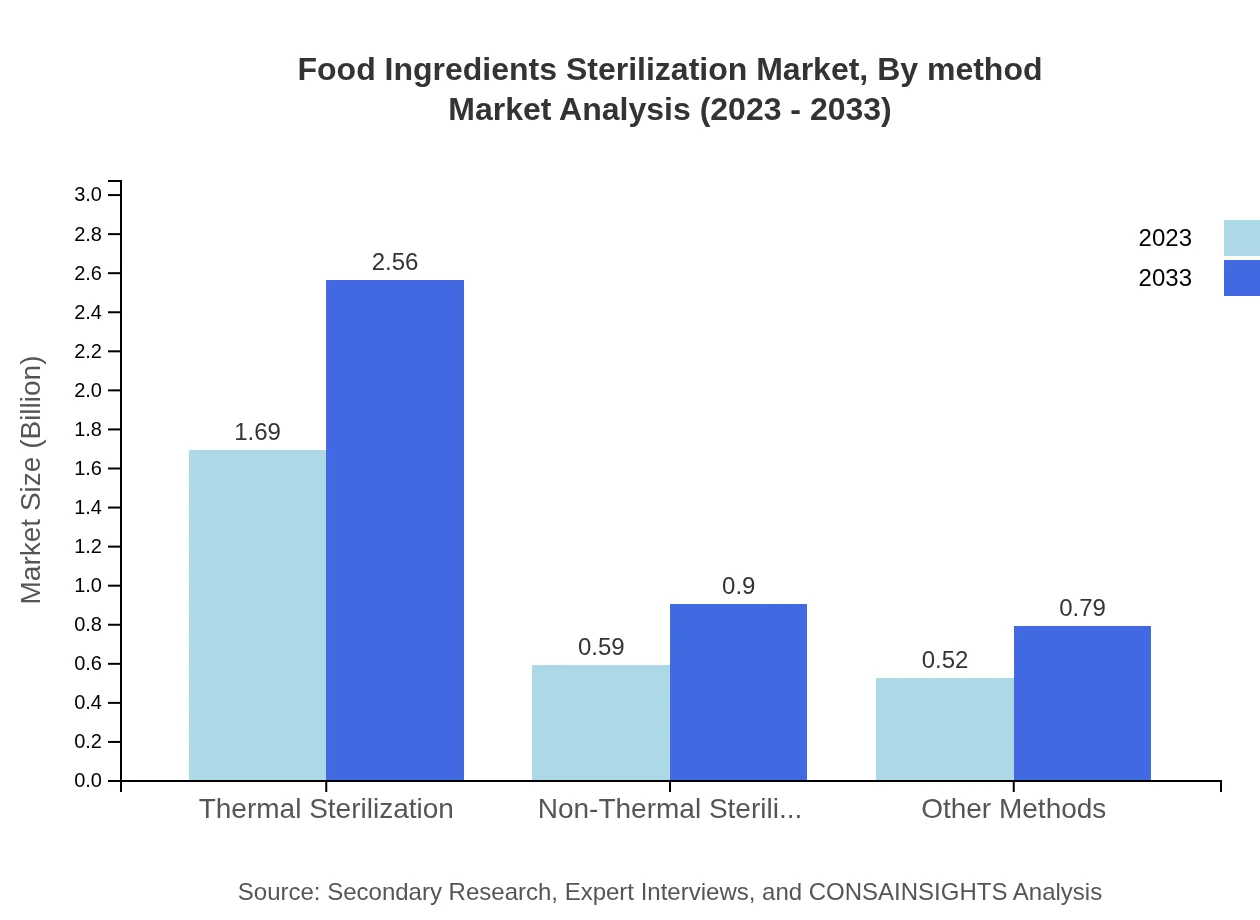

Food Ingredients Sterilization Market Analysis By Method

The method segment is divided into Thermal Sterilization and Non-Thermal Sterilization. Thermal Sterilization dominates with a market size of $1.69 billion in 2023, projected to reach $2.56 billion by 2033, capturing approximately 60.24% of the market share. Non-Thermal Sterilization is anticipated to grow from $0.59 billion to $0.90 billion during the same period, holding 21.12% market share.

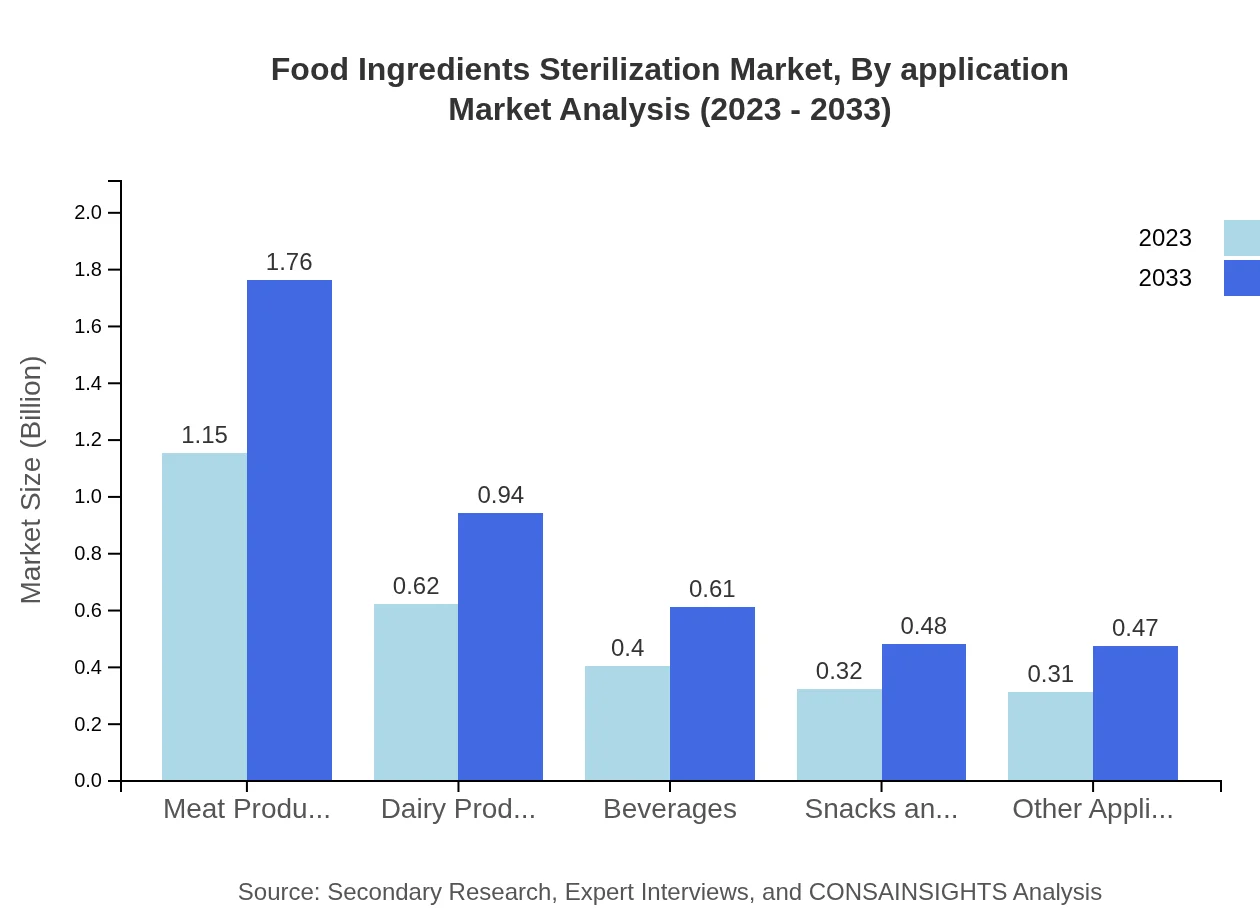

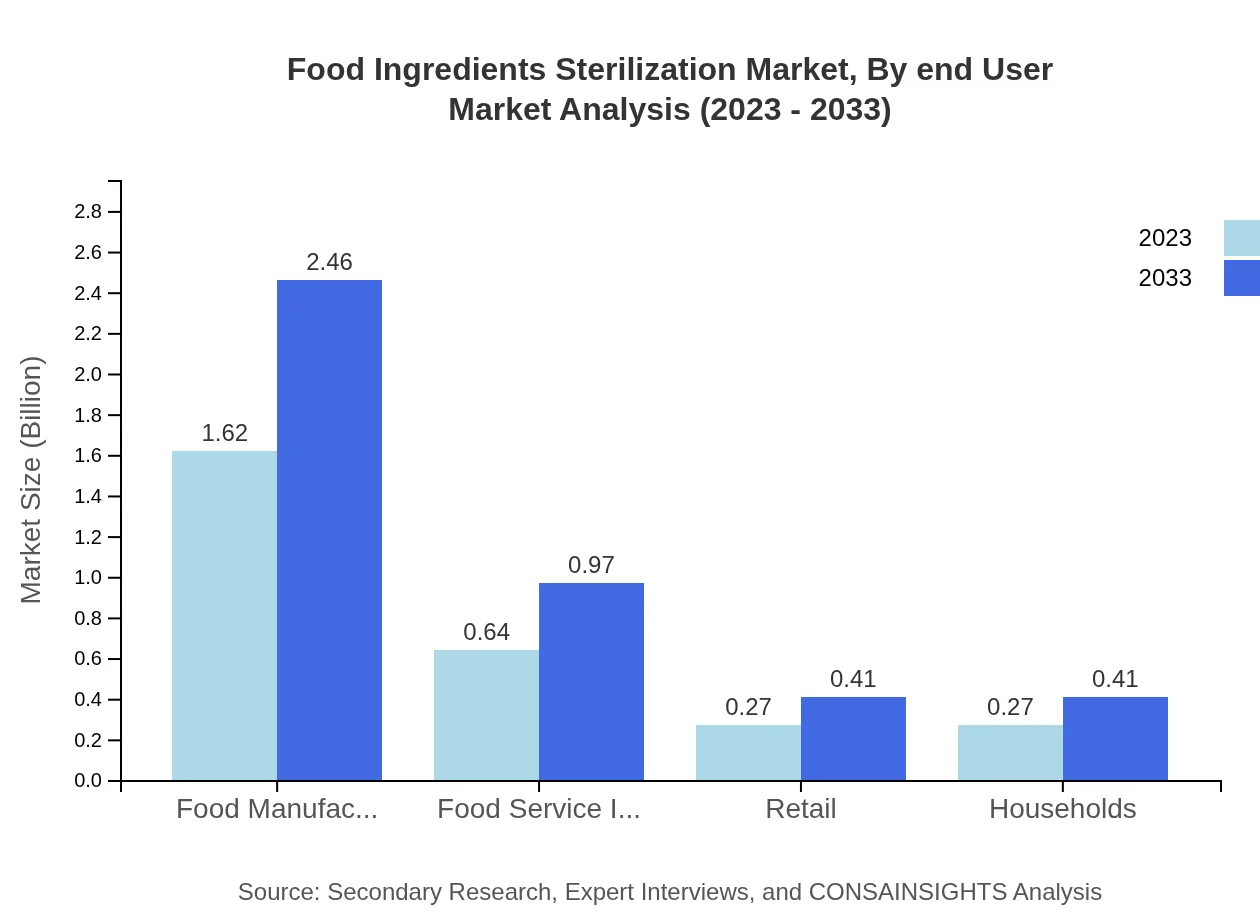

Food Ingredients Sterilization Market Analysis By Application

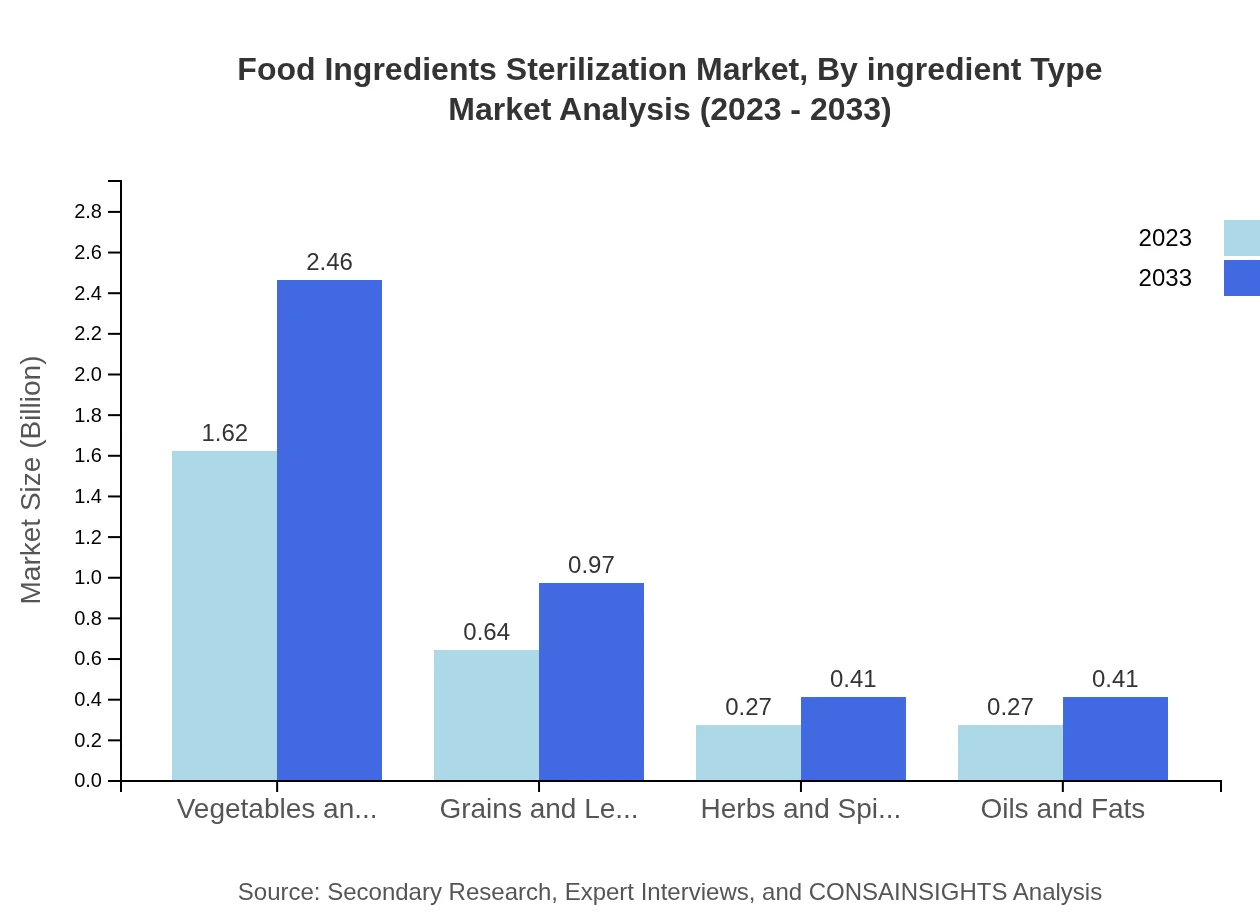

The market is segmented by application into Food Manufacturers, Food Service Industry, Retail, and Households. Food Manufacturers lead with a size of $1.62 billion in 2023, expected to grow to $2.46 billion by 2033, representing 57.85% market share. The Food Service Industry follows with a growth from $0.64 billion to $0.97 billion, showcasing a 22.87% share.

Food Ingredients Sterilization Market Analysis By Ingredient Type

The ingredient type segment includes Meat Products, Dairy Products, Beverages, Snacks and Confectionery, and Vegetables and Fruits. Meat Products dominate with a market size of $1.15 billion in 2023, expected to reach $1.76 billion by 2033. Vegetables and Fruits represent the largest market share at 57.85%.

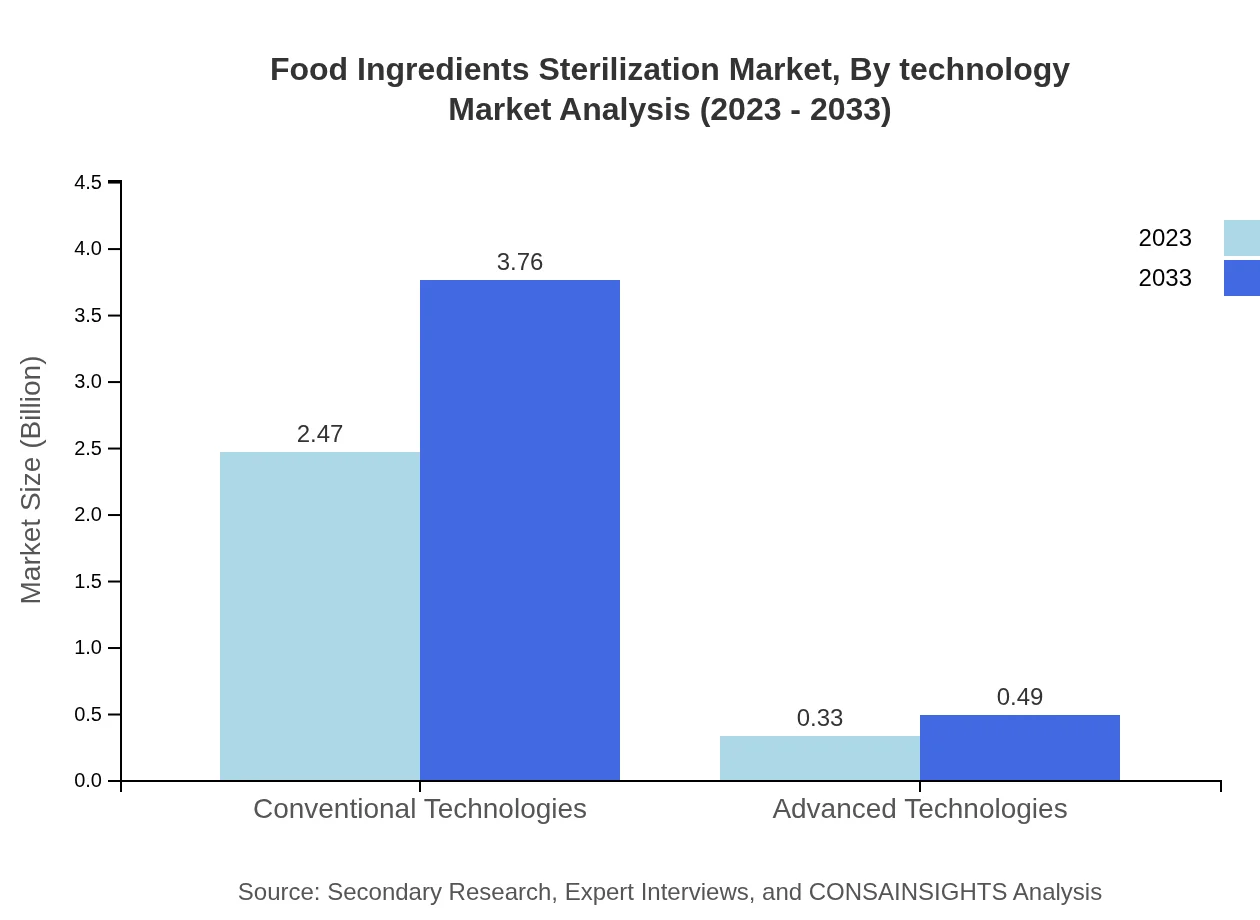

Food Ingredients Sterilization Market Analysis By Technology

The technology segment comprises Conventional and Advanced Technologies. Conventional Technologies account for a majority share, sized at $2.47 billion in 2023, increasing to $3.76 billion by 2033 (88.38% share), while Advanced Technologies, expected to grow from $0.33 billion to $0.49 billion (11.62%), gain momentum with innovative solutions.

Food Ingredients Sterilization Market Analysis By End User

End-users include various sectors such as Pharmaceutical and Food Industries. Both sectors increasingly emphasize food safety standards and adopting sterilization processes, showcasing expected growth across all end-users reflective of overall market trends.

Food Ingredients Sterilization Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Food Ingredients Sterilization Industry

Nestlé S.A.:

Nestlé is a leading player in the food industry, actively integrating advanced sterilization technologies in its production processes to ensure food safety and quality.Tetra Pak International S.A.:

Tetra Pak specializes in food processing and packaging technology, providing solutions that enhance food safety through effective sterilization methods.Ecolab Inc.:

Ecolab is recognized for its innovative solutions in cleaning and sanitation, contributing to the food industry's sterilization efforts.Krones AG:

Krones AG delivers systems for beverage production and bottling, focusing on sterilization technologies to ensure product quality in the beverage sector.GEA Group AG:

GEA Group provides processing and packaging equipment that incorporates effective sterilization solutions in various food and beverage applications.We're grateful to work with incredible clients.

FAQs

What is the market size of food Ingredients Sterilization?

The global food ingredients sterilization market is currently valued at $2.8 billion in 2023, with a projected CAGR of 4.2%. By 2033, the market is expected to expand significantly, driven by rising demand for food safety and preservation.

What are the key market players or companies in this food Ingredients Sterilization industry?

Key players in the food ingredients sterilization market include major food manufacturing companies and specialized sterilization service providers. These companies lead innovations and implement advanced technologies, shaping industry standards in food safety and quality.

What are the primary factors driving the growth in the food Ingredients Sterilization industry?

Several factors are fueling growth in this industry, including increasing consumer awareness of food safety, stringent regulatory policies, and advancements in sterilization technologies. The growing demand for processed and packaged foods also significantly contributes to market expansion.

Which region is the fastest Growing in the food Ingredients Sterilization?

The fastest-growing region in the food ingredients sterilization market is projected to be Europe, which is expected to grow from $0.85 billion in 2023 to $1.29 billion by 2033. North America and Asia Pacific also show robust growth dynamics.

Does ConsaInsights provide customized market report data for the food Ingredients Sterilization industry?

Yes, ConsaInsights offers customized market report data tailored to clients' specific needs within the food-ingredients-sterilization industry. This includes detailed analyses of trends, competitive landscaping, and regional insights.

What deliverables can I expect from this food Ingredients Sterilization market research project?

Deliverables include comprehensive reports detailing market size, growth forecasts, competitive analysis, regional breakdowns, and insights into key segments. Clients will also receive visual representations of data for better understanding.

What are the market trends of food Ingredients Sterilization?

Current trends in the food ingredients sterilization market include a shift towards non-thermal sterilization methods and increased application of advanced technologies. Companies are also focusing on sustainability and clean label products to attract health-conscious consumers.