Food Processing Seals Market Report

Published Date: 31 January 2026 | Report Code: food-processing-seals

Food Processing Seals Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the Food Processing Seals market, providing comprehensive insights and data from 2023 to 2033. It includes market size, segmentation, regional analysis, and industry trends that impact the current and future landscape of this vital industry.

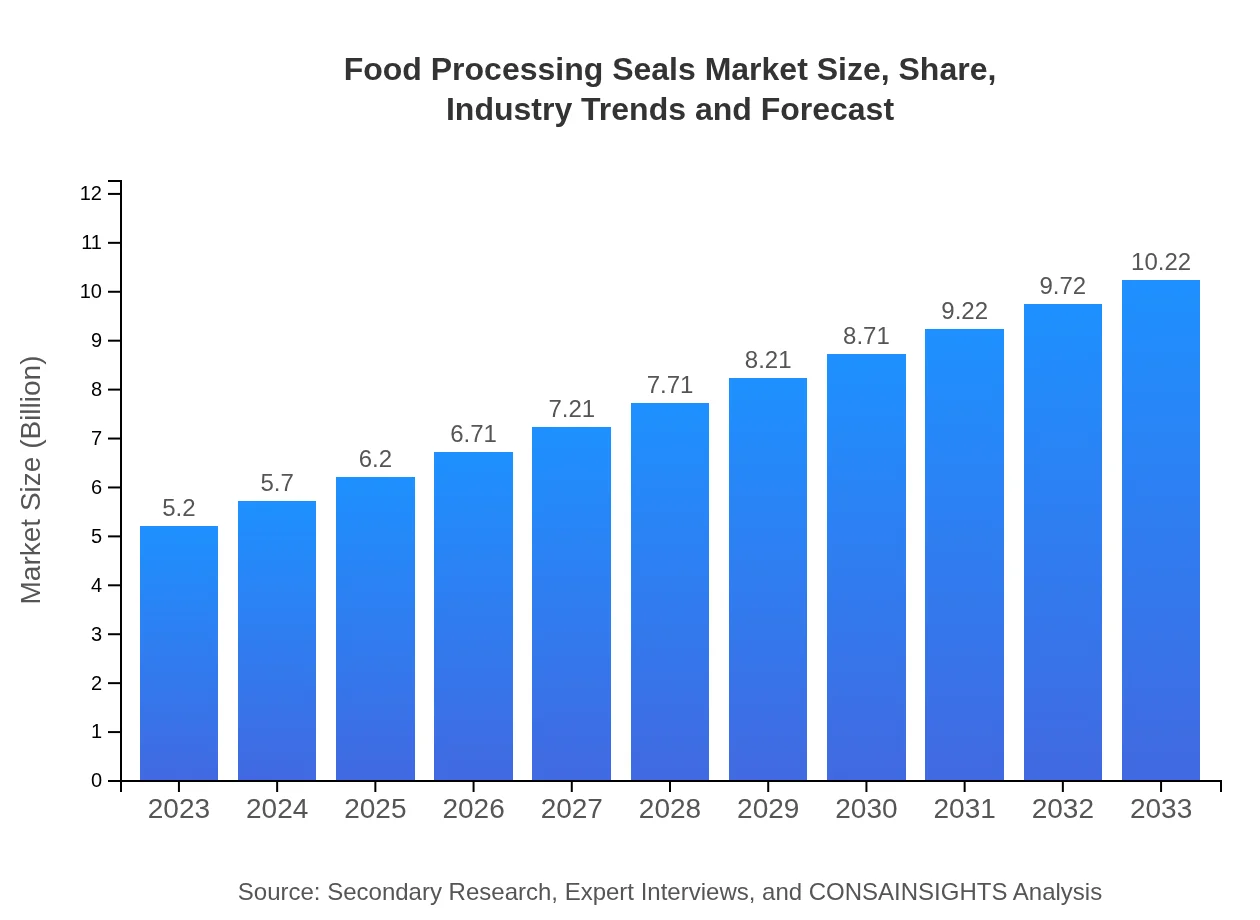

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.20 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $10.22 Billion |

| Top Companies | Parker Hannifin, Saint-Gobain, Plexus Corp., Trelleborg |

| Last Modified Date | 31 January 2026 |

Food Processing Seals Market Overview

Customize Food Processing Seals Market Report market research report

- ✔ Get in-depth analysis of Food Processing Seals market size, growth, and forecasts.

- ✔ Understand Food Processing Seals's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Food Processing Seals

What is the Market Size & CAGR of Food Processing Seals market in 2023?

Food Processing Seals Industry Analysis

Food Processing Seals Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Food Processing Seals Market Analysis Report by Region

Europe Food Processing Seals Market Report:

The European Food Processing Seals market shows promising growth from 1.28 billion USD in 2023 to 2.51 billion USD by 2033. Stringent food safety regulations and an emphasis on sustainability are driving manufacturers to invest in high-quality sealing solutions, making Europe a vital market for innovation.Asia Pacific Food Processing Seals Market Report:

In the Asia Pacific region, the Food Processing Seals market is anticipated to grow from 1.14 billion USD in 2023 to 2.25 billion USD by 2033. This growth is fueled by increasing urbanization, changing consumer lifestyles, and the rapid adoption of advanced food processing technologies. Countries like China and India are spearheading this growth through significant investments in the food and beverage sectors, ensuring a robust demand for sealing solutions.North America Food Processing Seals Market Report:

North America holds a substantial position in the Food Processing Seals market, projected to rise from 1.86 billion USD in 2023 to 3.65 billion USD by 2033. The United States, being a leader in food processing innovation, invests heavily in robust and hygienic sealing solutions, fostering significant market potential.South America Food Processing Seals Market Report:

The South American market for Food Processing Seals is estimated to increase from 0.48 billion USD in 2023 to approximately 0.94 billion USD in 2033. The expanding agricultural and food processing sectors driven by favorable government policies and consumer trends towards processed foods are key growth factors in this region.Middle East & Africa Food Processing Seals Market Report:

The Middle East and Africa market is expected to witness growth, with projections rising from 0.44 billion USD in 2023 to 0.87 billion USD in 2033. Increasing investments in the food and beverage industry and rising consumer demand for processed products are driving market advancements in this region.Tell us your focus area and get a customized research report.

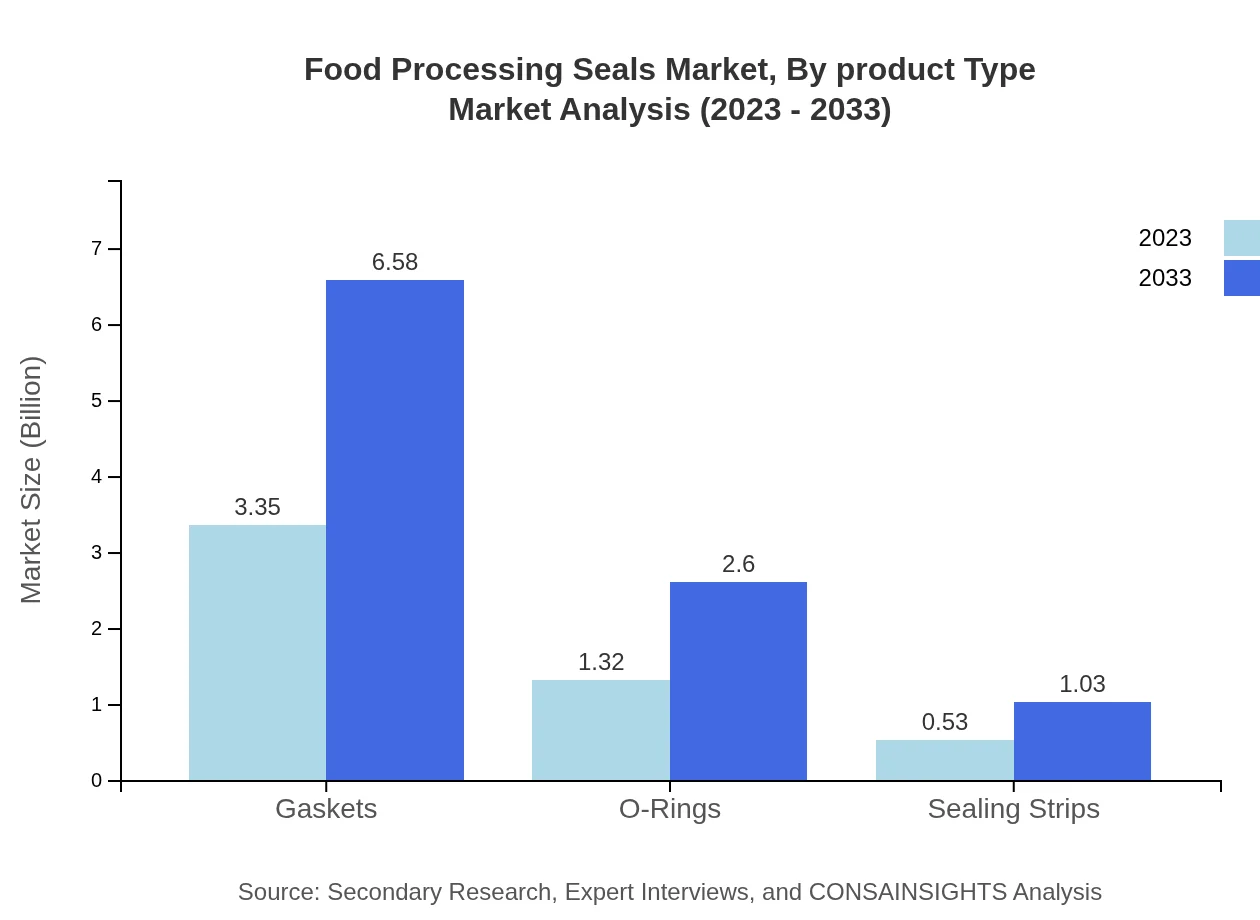

Food Processing Seals Market Analysis By Product Type

The Food Processing Seals market, by product type, demonstrates significant growth, particularly in the gaskets segment, which dominates with an estimated size of 3.35 billion USD in 2023 and projected growth to 6.58 billion USD by 2033.

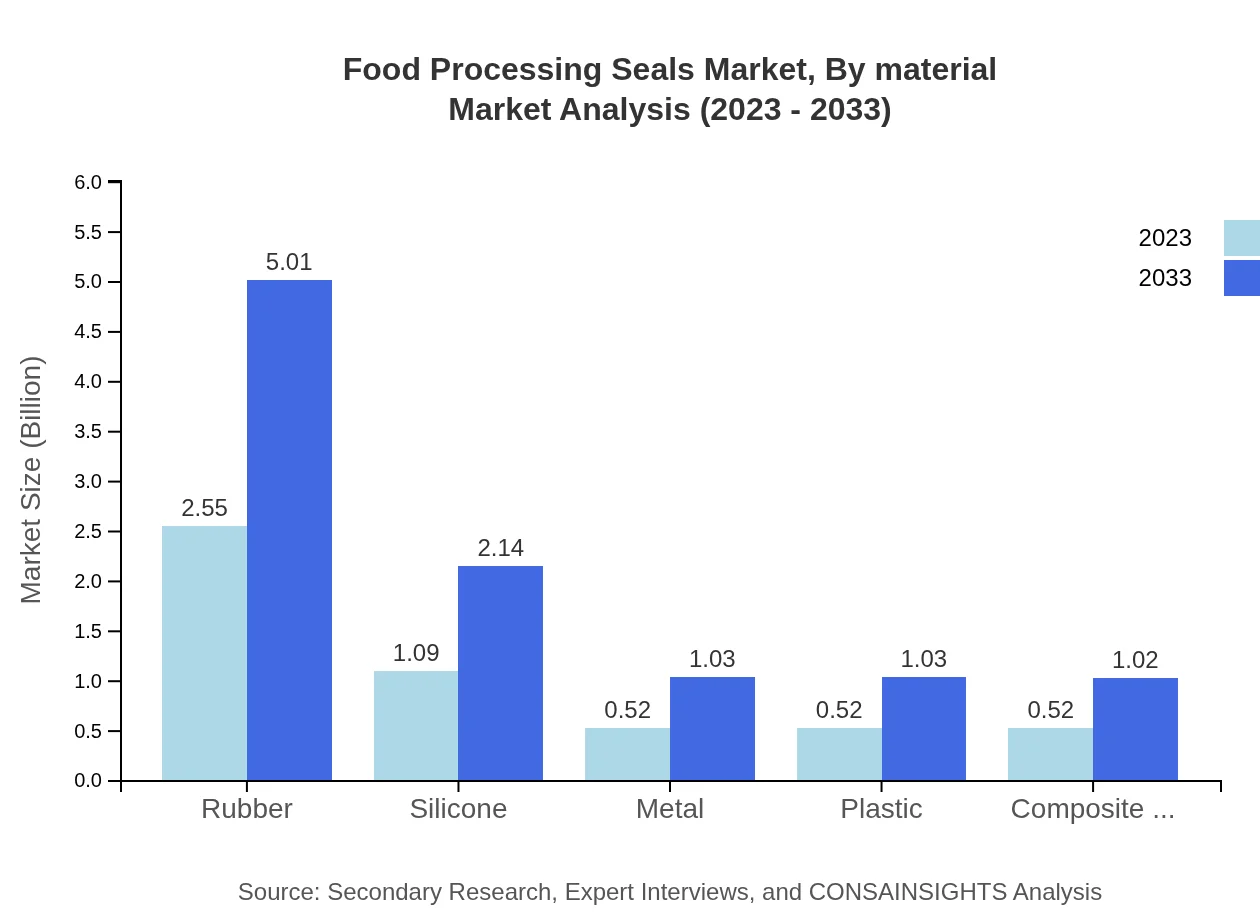

Food Processing Seals Market Analysis By Material

Rubber remains the leading material for food processing seals, accounting for 2.55 billion USD in 2023 and forecasted to reach 5.01 billion USD by 2033. The versatility and durability of rubber make it ideal for various applications in the food industry.

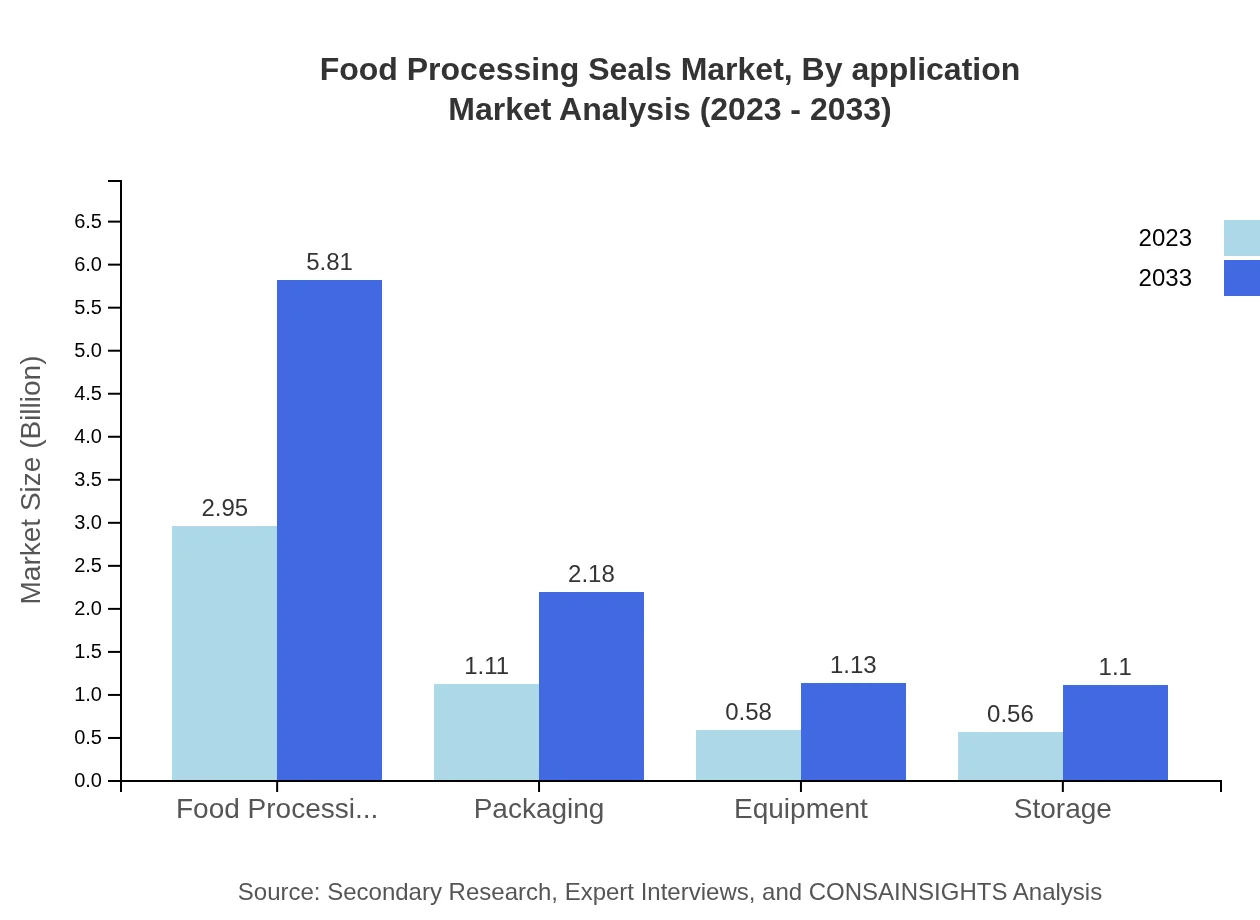

Food Processing Seals Market Analysis By Application

In terms of application, the food processing segment is the highest contributor, with a value of 2.95 billion USD in 2023 and expected growth to 5.81 billion USD by 2033, highlighting the critical need for effective sealing solutions in food manufacturing processes.

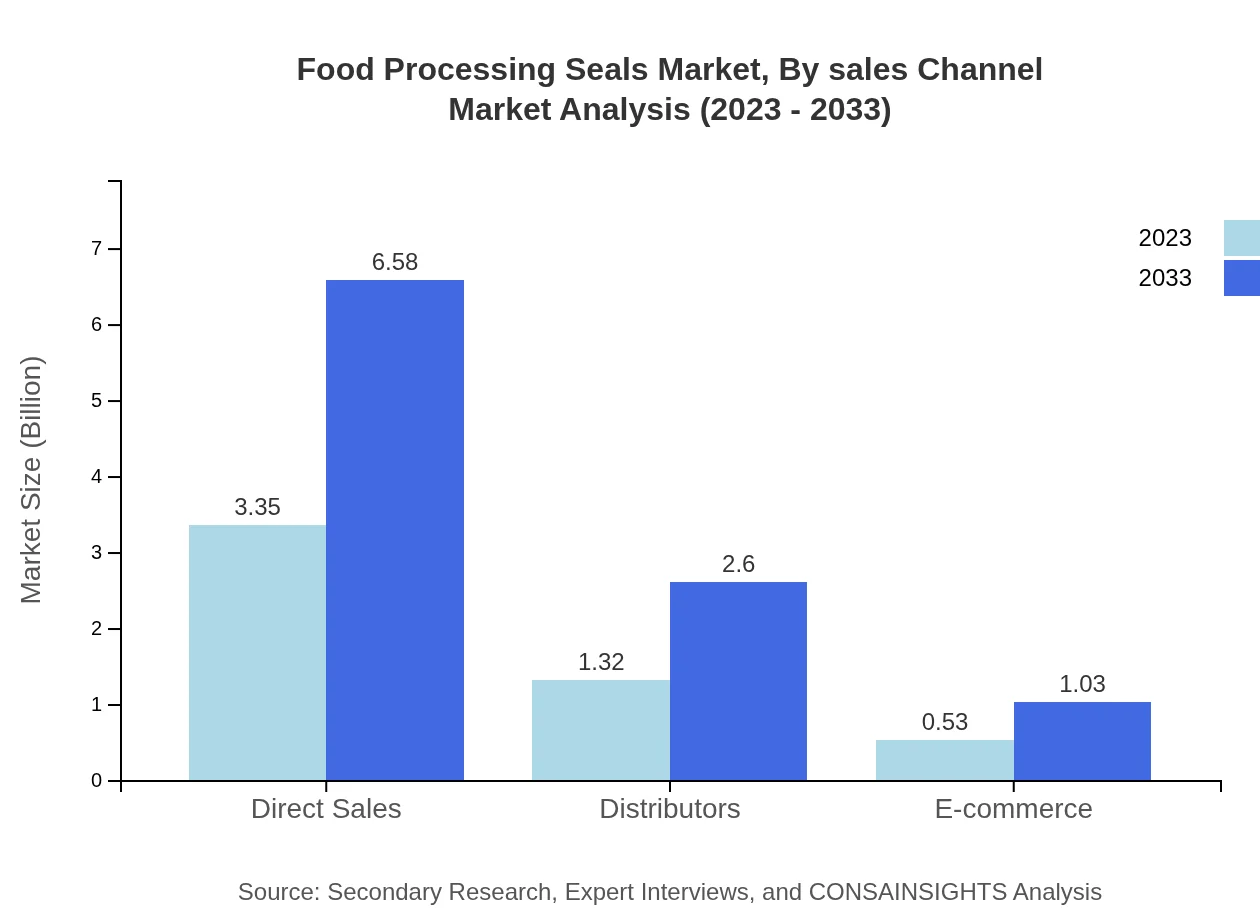

Food Processing Seals Market Analysis By Sales Channel

Direct sales channels have shown substantial performance, initially valued at 3.35 billion USD in 2023 and forecasted to grow to 6.58 billion USD by 2033, underscoring the importance of building direct relationships with customers.

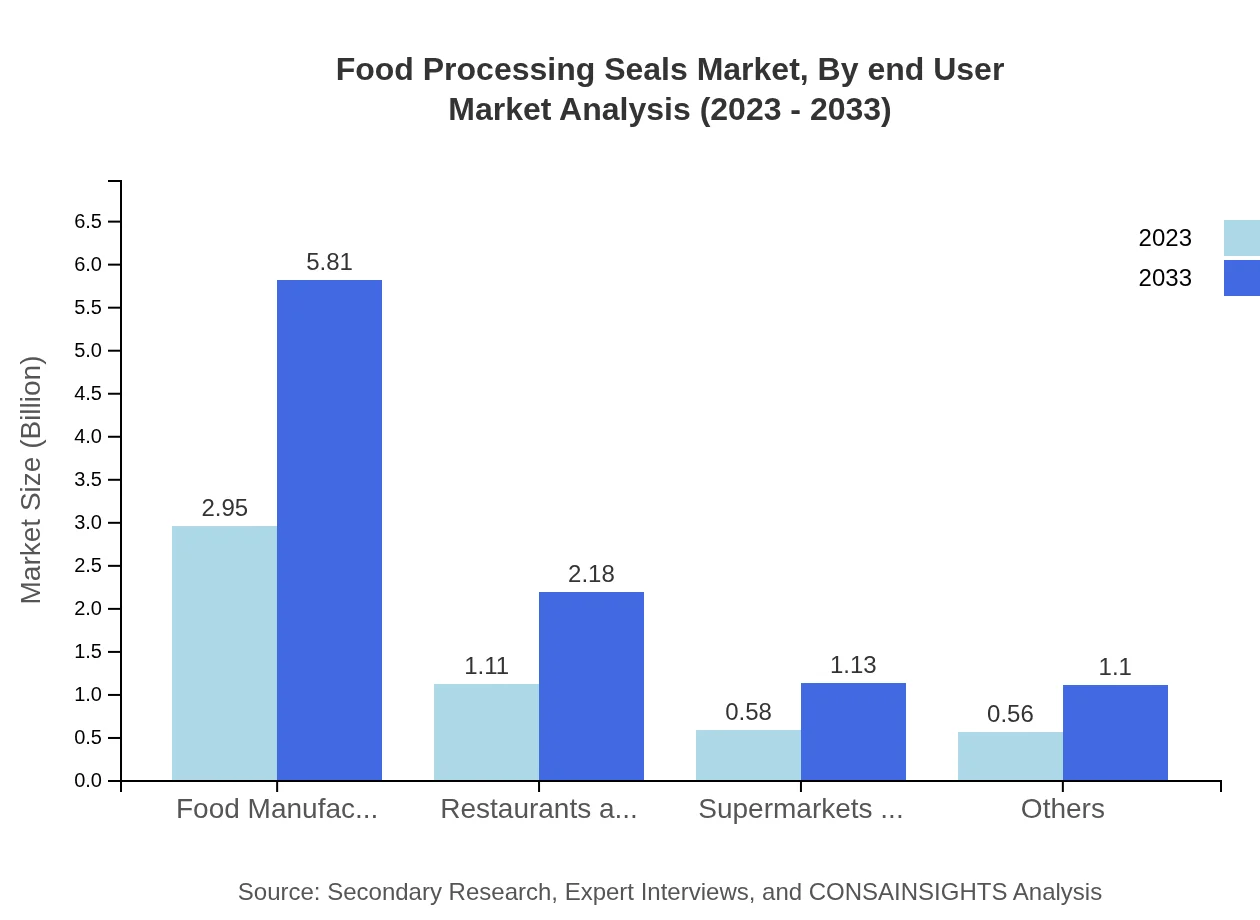

Food Processing Seals Market Analysis By End User

Food manufacturers dominate the end-user segment, controlling a market size of 2.95 billion USD in 2023 and projected growth to 5.81 billion USD by 2033, emphasizing the central role they play in the food processing ecosystem.

Food Processing Seals Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Food Processing Seals Industry

Parker Hannifin:

A leader in motion and control technologies, Parker Hannifin specializes in sealing solutions for various industries, including food and beverage, ensuring compliance with rigorous health standards.Saint-Gobain:

Saint-Gobain is known for high-performance materials and sealing solutions that cater to the needs of the food processing industry, focusing on innovation and sustainability.Plexus Corp.:

Plexus Corp. provides comprehensive sealing solutions tailored for the food sector, emphasizing quality and efficiency to meet rising consumer expectations.Trelleborg:

Trelleborg specializes in engineered polymer solutions and offers an extensive range of seals and gaskets for the food processing industry.We're grateful to work with incredible clients.

FAQs

What is the market size of food Processing Seals?

The global food processing seals market is valued at approximately $5.2 billion in 2023 with a projected CAGR of 6.8% from 2023 to 2033, indicating significant growth over the decade.

What are the key market players or companies in the food Processing Seals industry?

Key players in the food processing seals industry include companies such as Trelleborg, Parker Hannifin, and SKF, which dominate the market with their innovative sealing solutions and strong distribution networks.

What are the primary factors driving the growth in the food Processing Seals industry?

The growth of the food processing seals industry is driven by increasing food safety regulations, rising demand for processed food, and advancements in sealing technologies that enhance product efficiency and maintain hygiene.

Which region is the fastest Growing in the food Processing Seals?

The North American region is the fastest-growing market for food processing seals, expected to grow from $1.86 billion in 2023 to $3.65 billion by 2033, showcasing robust expansion due to its booming food industry.

Does ConsaInsights provide customized market report data for the food Processing Seals industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the food processing seals industry, ensuring clients receive relevant insights aligned with their strategic objectives.

What deliverables can I expect from this food Processing Seals market research project?

Clients can expect comprehensive deliverables including in-depth market analysis, competitive landscape insights, segment performance data, and regional growth forecasts within the food processing seals market.

What are the market trends of food Processing Seals?

Current trends in the food processing seals market include increasing adoption of advanced materials like silicone and composite materials, a focus on sustainability, and the rising trend of automation in food processing.