Form Fill Seal Machines Market Report

Published Date: 31 January 2026 | Report Code: form-fill-seal-machines

Form Fill Seal Machines Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Form Fill Seal Machines market, covering market size, growth predictions, regional insights, key players, and trends up to the year 2033.

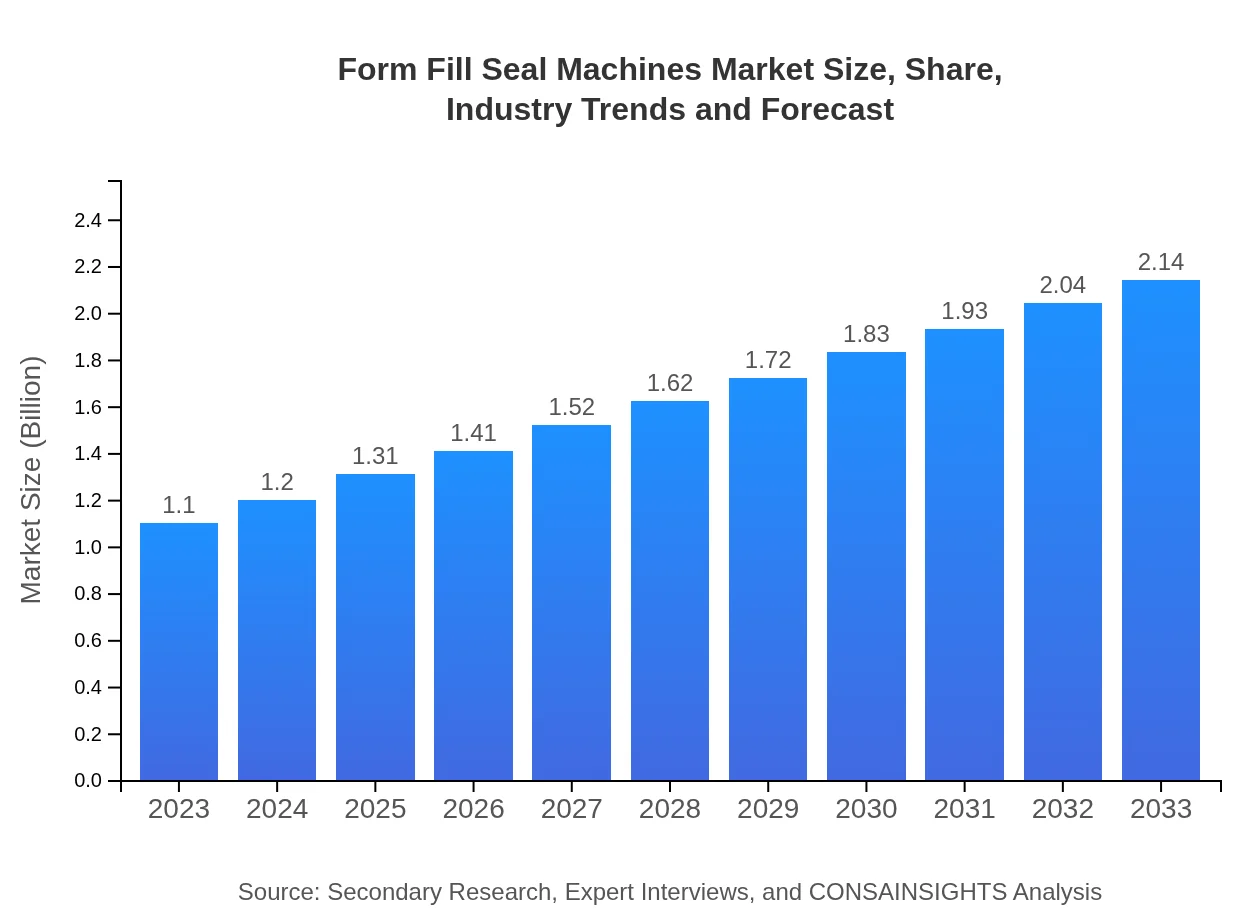

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.10 Billion |

| CAGR (2023-2033) | 6.7% |

| 2033 Market Size | $2.14 Billion |

| Top Companies | Fritz Schur Technical Group, Bosch Packaging Technology, Sealed Air Corporation |

| Last Modified Date | 31 January 2026 |

Form Fill Seal Machines Market Overview

Customize Form Fill Seal Machines Market Report market research report

- ✔ Get in-depth analysis of Form Fill Seal Machines market size, growth, and forecasts.

- ✔ Understand Form Fill Seal Machines's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Form Fill Seal Machines

What is the Market Size & CAGR of Form Fill Seal Machines market in 2023?

Form Fill Seal Machines Industry Analysis

Form Fill Seal Machines Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Form Fill Seal Machines Market Analysis Report by Region

Europe Form Fill Seal Machines Market Report:

In Europe, the market was approximately $0.39 billion in 2023 and expected to reach $0.77 billion by 2033, supported by stringent regulations on packaging waste and an increasing focus on sustainable practices.Asia Pacific Form Fill Seal Machines Market Report:

In the Asia Pacific region, the market is valued at approximately $0.18 billion in 2023, projected to reach $0.36 billion by 2033, driven by increasing food processing industries and demand for packaged foods.North America Form Fill Seal Machines Market Report:

North America reported a market size of $0.37 billion in 2023, anticipated to grow to $0.72 billion by 2033, attributed to the technological advancements and demand for automation in packaging.South America Form Fill Seal Machines Market Report:

South America’s market was valued at $0.09 billion in 2023, reaching $0.17 billion by 2033. The expanding consumer base and rising demand for convenience foods are key growth drivers.Middle East & Africa Form Fill Seal Machines Market Report:

The Middle East and Africa market size was $0.06 billion in 2023, projected to reach $0.12 billion by 2033, as the region witnesses growth in the food and beverage sector driven by population growth and urbanization.Tell us your focus area and get a customized research report.

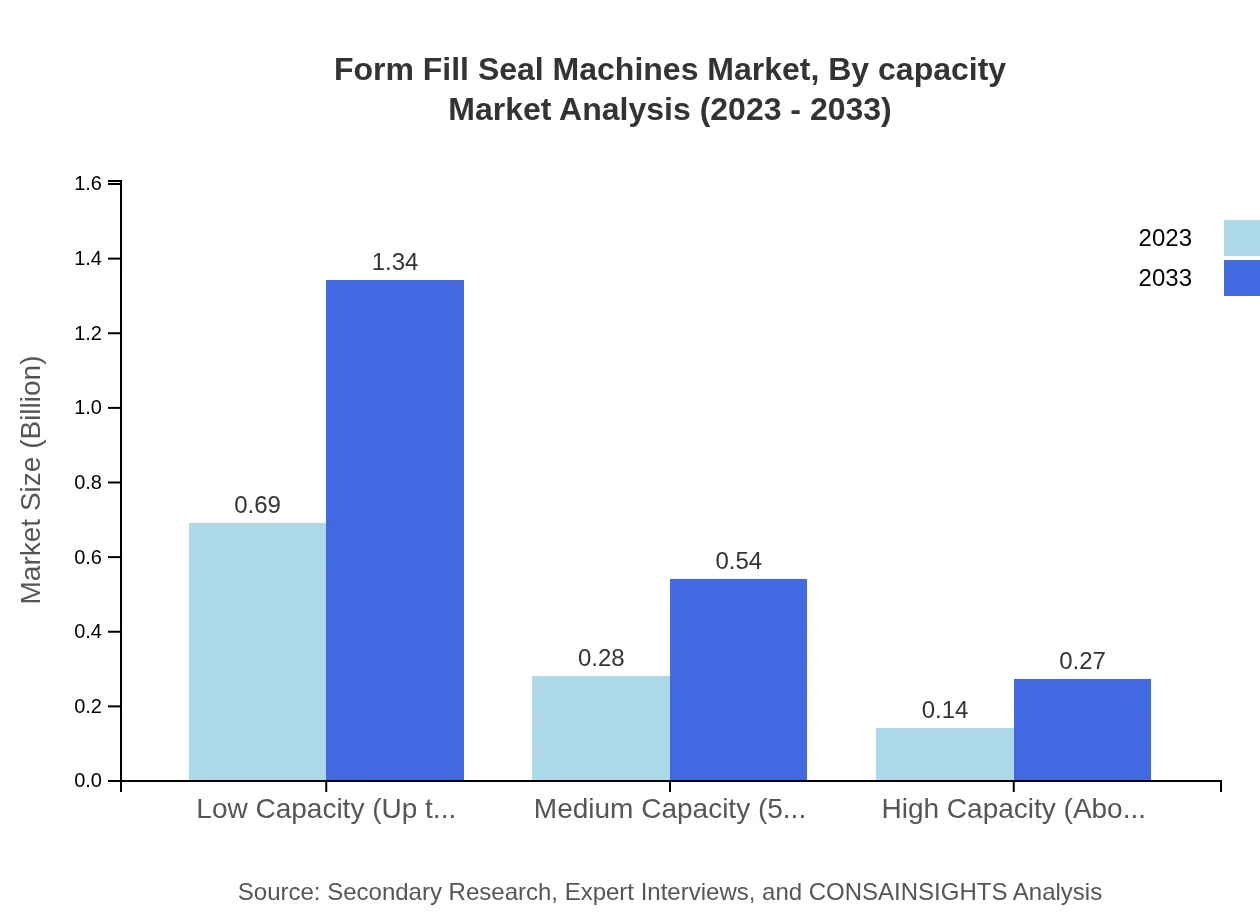

Form Fill Seal Machines Market Analysis By Capacity

The market analysis indicates that low capacity (up to 50 containers/min) dominates with a market size of $0.69 billion in 2023 and projected to grow to $1.34 billion by 2033, maintaining a significant market share of 62.36%. Medium capacity (50-200 containers/min) shows a moderate market size of $0.28 billion in 2023, expected to increase to $0.54 billion by 2033, with a share of 25.14%. High capacity (above 200 containers/min) accounts for $0.14 billion in 2023, aiming to double to $0.27 billion by 2033, covering 12.5% of the market share.

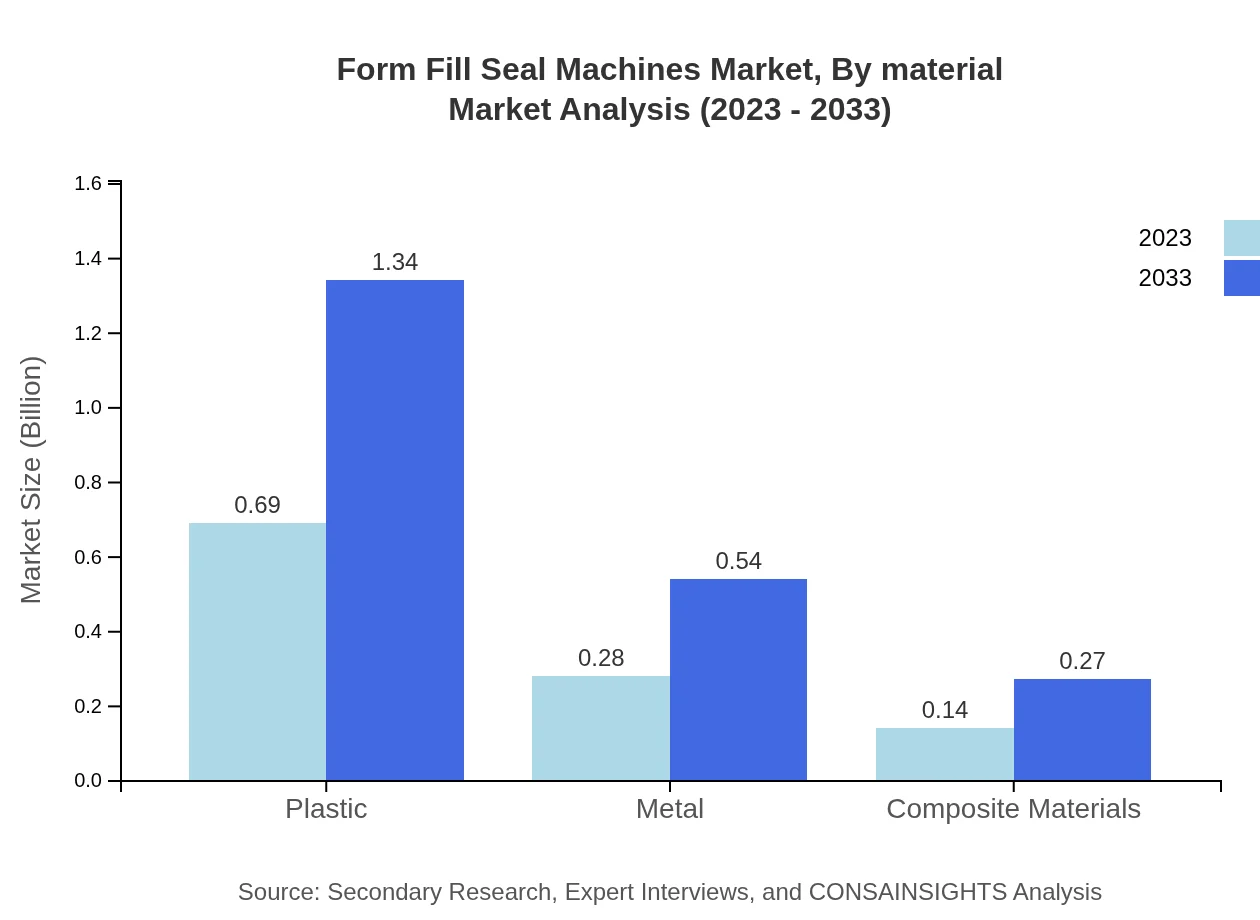

Form Fill Seal Machines Market Analysis By Material

Market segmentation by material reveals that plastic remains the leading segment at $0.69 billion in 2023 and forecasted to reach $1.34 billion by 2033. Metal machines currently hold $0.28 billion, expected to grow to $0.54 billion, while composite materials show an emerging trend with $0.14 billion in 2023, indicating advancements in sustainable packaging applications.

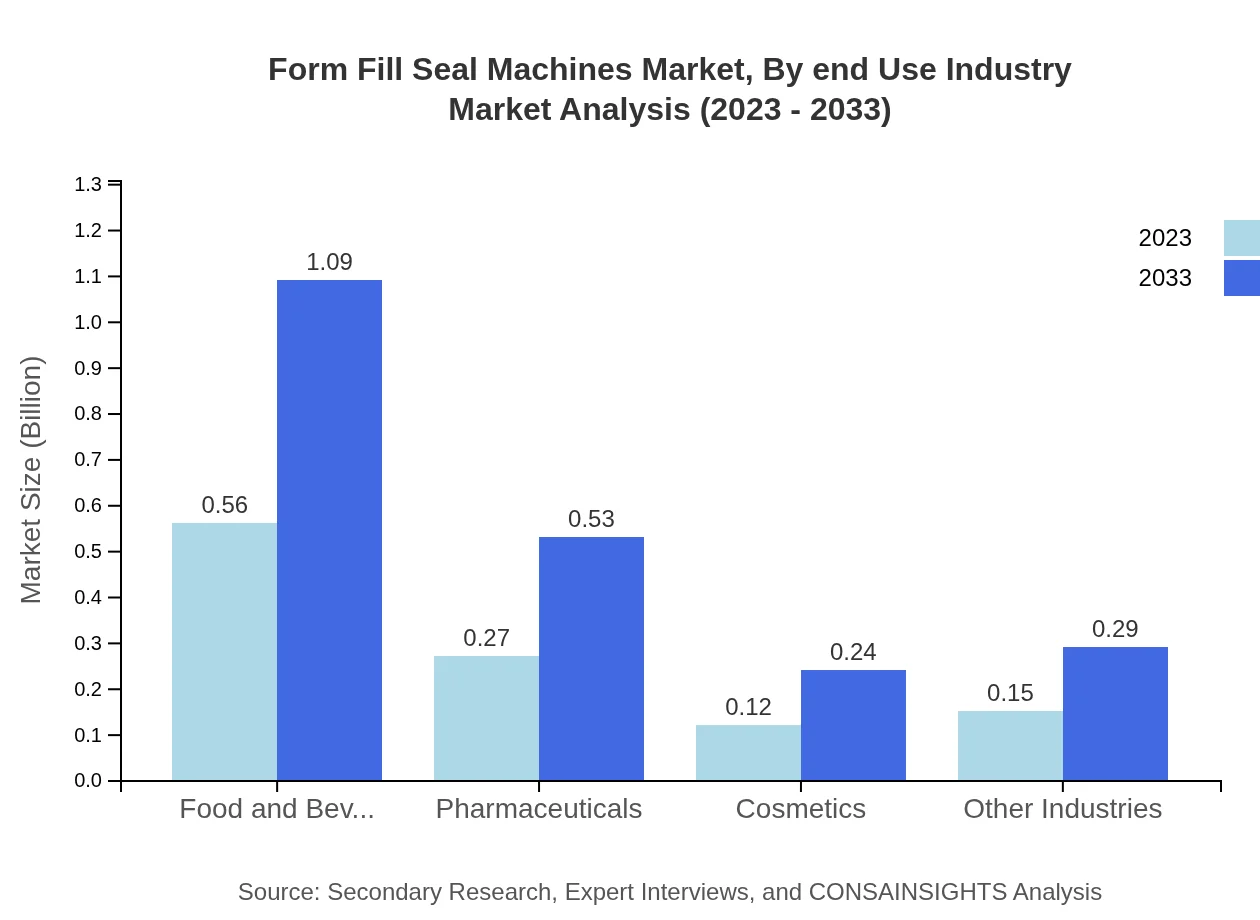

Form Fill Seal Machines Market Analysis By End Use Industry

An analysis of end-use industries places food and beverage at the forefront, accounting for $0.56 billion in 2023, anticipated to hit $1.09 billion by 2033 due to the demand for ready-to-eat meals. Pharmaceuticals accounts for $0.27 billion, predicted to grow to $0.53 billion, while the cosmetics sector shows potential growth from $0.12 billion to $0.24 billion in the coming decade.

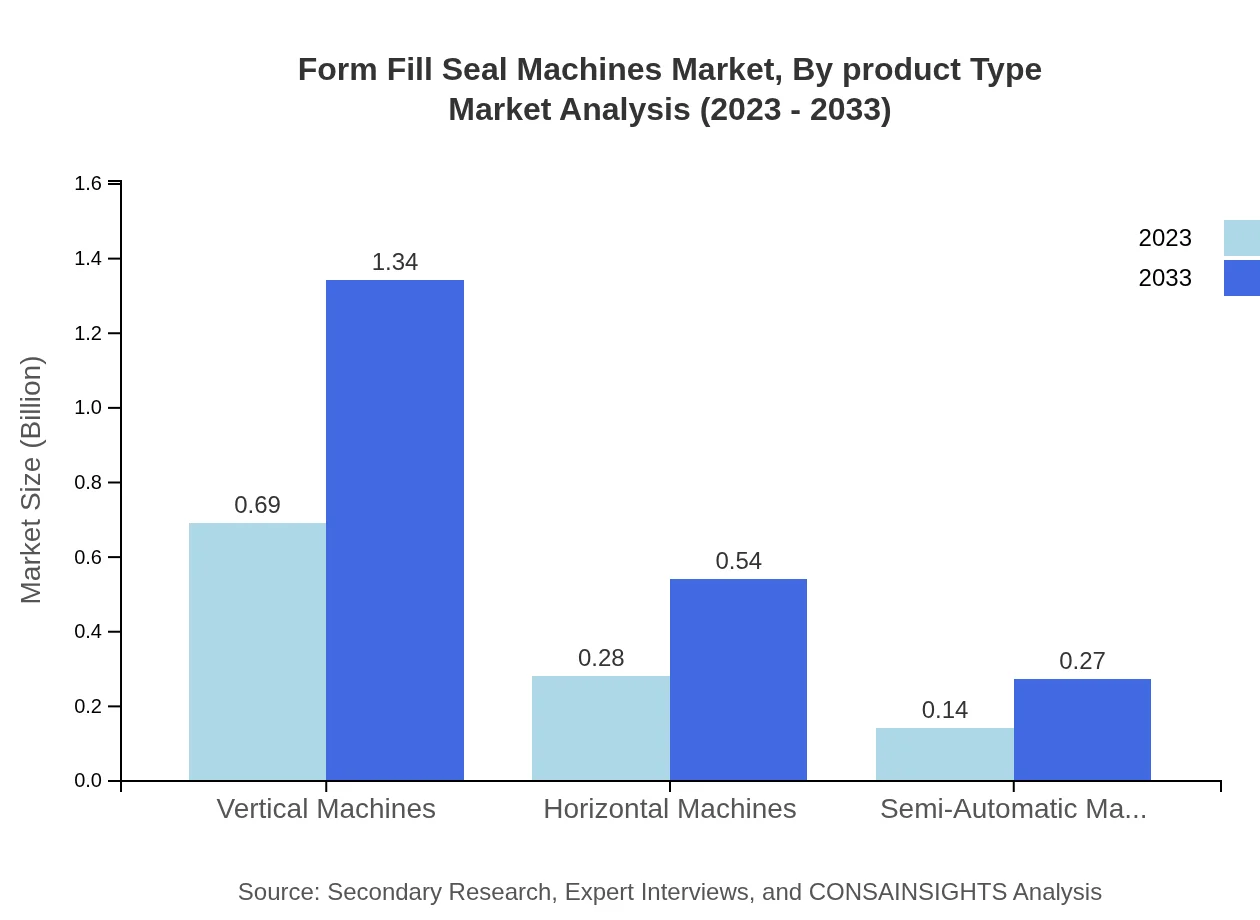

Form Fill Seal Machines Market Analysis By Product Type

The product type market indicates dominance from vertical machines, valued at $0.69 billion in 2023, expected to grow to $1.34 billion by 2033, maintaining a share of 62.36%. Horizontal machines show steady growth, moving from $0.28 billion to $0.54 billion, and semi-automatic machines are projected to reach $0.27 billion from $0.14 billion.

Form Fill Seal Machines Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Form Fill Seal Machines Industry

Fritz Schur Technical Group:

A leading provider in the manufacturing of FFS machines, renowned for their high-speed and automated solutions that enhance operational efficiency.Bosch Packaging Technology:

A key player in the packaging machinery industry, Bosch specializes in advanced Form Fill Seal machines that integrate cutting-edge technology for diverse applications.Sealed Air Corporation:

Offers innovative packaging solutions, focusing on protecting products and improving sustainability with their FFS machine offerings.We're grateful to work with incredible clients.

FAQs

What is the market size of form Fill Seal machines?

The global market size for form-fill-seal machines is estimated at $1.1 billion in 2023, with a projected compound annual growth rate (CAGR) of 6.7% through 2033.

What are the key market players or companies in the form Fill Seal machines industry?

Key players in the form-fill-seal machines industry include leading manufacturers such as Bosch Packaging Technology, ILAPAK, and Adco Manufacturing. Their innovations and strong market presence drive competition and advancements within the sector.

What are the primary factors driving the growth in the form Fill Seal machines industry?

The growth of the form-fill-seal machines industry is driven by increasing demand for packaged goods, advancements in automation technology, and rising consumer preferences for convenience. Additionally, the growth of e-commerce and sustainability initiatives are influential factors.

Which region is the fastest Growing in the form Fill Seal machines market?

The Asia Pacific region is emerging as the fastest-growing market for form-fill-seal machines, with growth projections from $0.18 billion in 2023 to $0.36 billion by 2033, driven by industrialization and rising manufacturing capabilities.

Does ConsaInsights provide customized market report data for the form Fill Seal machines industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs and queries in the form-fill-seal machines industry. Clients can leverage insights based on their operational requirements for strategic decision-making.

What deliverables can I expect from this form Fill Seal machines market research project?

Deliverables from the form-fill-seal machines market research project include a detailed market analysis report, trend evaluations, competitive landscape assessment, regional insights, and actionable recommendations for market entry or expansion.

What are the market trends of form Fill Seal machines?

Market trends in form-fill-seal machines highlight a shift towards automation, increased adoption of sustainable packaging materials, and innovations in machine technology enhancing speed and efficiency. Additionally, customization to meet specific industry needs is on the rise.