Frp Grating Market Report

Published Date: 22 January 2026 | Report Code: frp-grating

Frp Grating Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the FRP Grating market from 2023 to 2033, covering market size, growth trends, regional insights, segmentation analysis, and the future outlook of the industry.

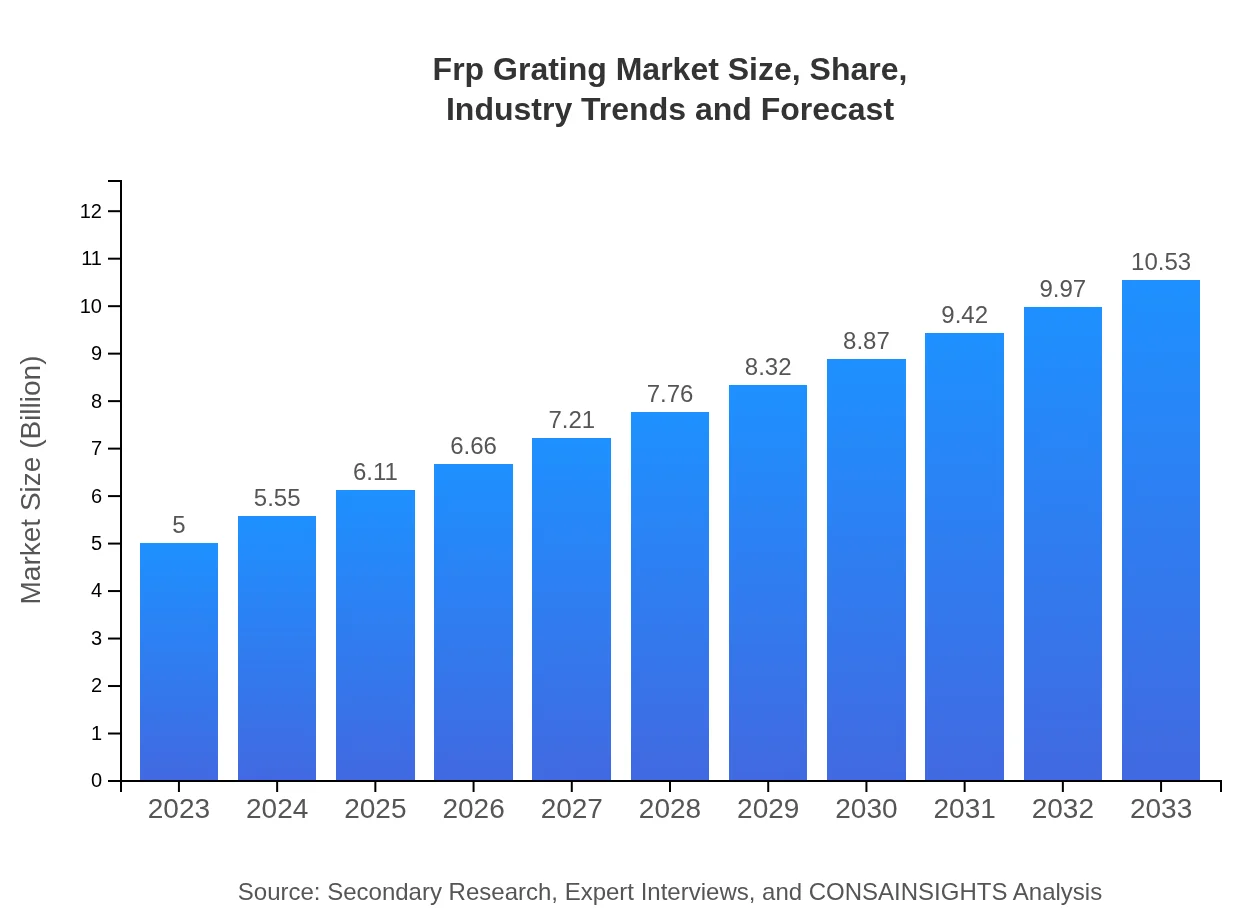

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | FIBERGRATE Composite Structures, Strongwell Corporation, Meridian GRP, DURAGRID |

| Last Modified Date | 22 January 2026 |

FRP Grating Market Overview

Customize Frp Grating Market Report market research report

- ✔ Get in-depth analysis of Frp Grating market size, growth, and forecasts.

- ✔ Understand Frp Grating's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Frp Grating

What is the Market Size & CAGR of FRP Grating Market in 2023?

FRP Grating Industry Analysis

FRP Grating Market Segmentation and Scope

Tell us your focus area and get a customized research report.

FRP Grating Market Analysis Report by Region

Europe Frp Grating Market Report:

The European market is projected to see growth from $1.25 billion in 2023 to $2.63 billion by 2033. Europe's emphasis on sustainability and innovation, coupled with regulatory support for high-performance materials, bolsters FRP grating adoption in various sectors.Asia Pacific Frp Grating Market Report:

The Asia Pacific region holds significant potential within the FRP Grating market, projected to grow from $1.03 billion in 2023 to $2.16 billion by 2033. The increasing infrastructure development, particularly in countries like China and India, plays a crucial role in market growth as industries leverage FRP for their lightweight and corrosion-resistant properties.North America Frp Grating Market Report:

In North America, the FRP Grating market is forecasted to grow substantially, from $1.69 billion in 2023 to $3.55 billion by 2033. The region benefits from a well-established manufacturing sector and stringent regulations that drive the adoption of safer and durable materials.South America Frp Grating Market Report:

For South America, the market is expected to expand from $0.48 billion in 2023 to $1.01 billion by 2033. The growth is attributed to rising investments in infrastructure and energy, along with a focus on enhancing safety measures in industrial operations.Middle East & Africa Frp Grating Market Report:

The Middle East and Africa region is also on an upward trajectory, with the market expected to rise from $0.56 billion in 2023 to $1.17 billion by 2033. The need for reliable and cost-effective solutions in projects related to oil and gas is a key driver in this region.Tell us your focus area and get a customized research report.

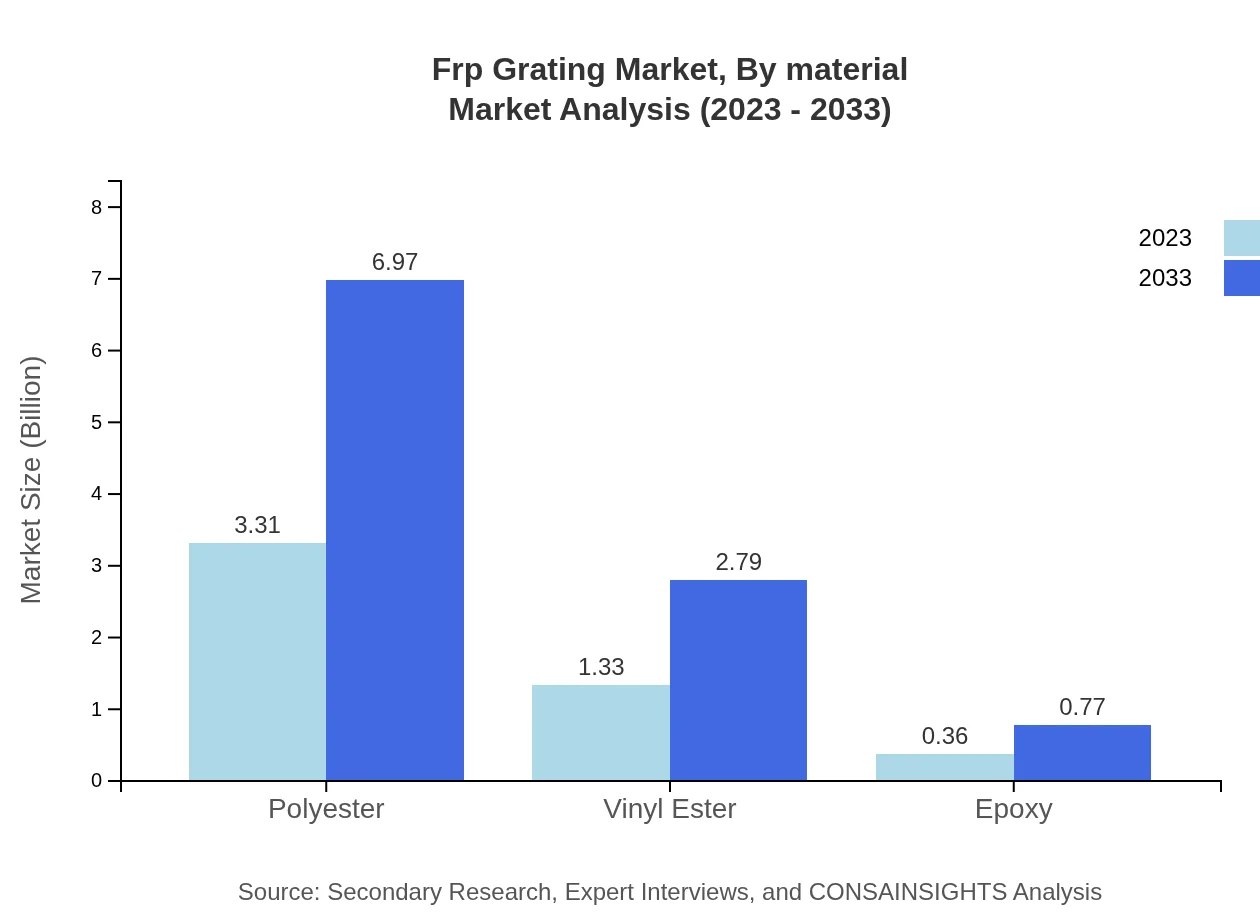

Frp Grating Market Analysis By Material

The FRP grating market is primarily segmented into four material types: Polyester, Vinyl Ester, Epoxy, and others. Polyester dominates the market, holding a significant share due to its cost-effectiveness and wide applicability across industries. Vinyl Ester follows, known for its superior chemical resistance, especially in harsh environments. The Epoxy segment, while smaller, shows promise due to its strength and durability in specialized applications.

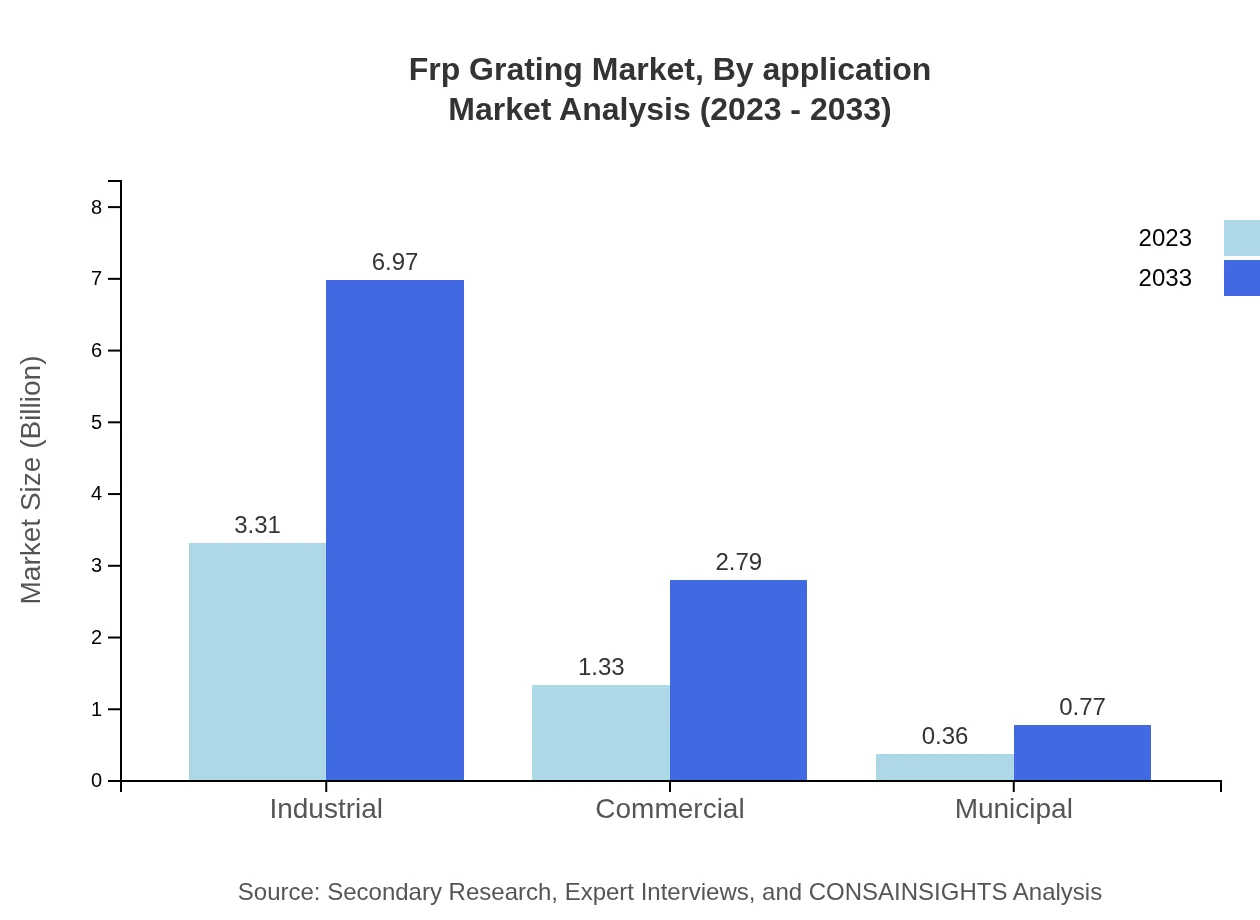

Frp Grating Market Analysis By Application

The applications of FRP grating include construction, oil and gas, power generation, and others. The construction sector leads the market, attributed to the increasing demand for lightweight, durable materials that enhance safety and reduce maintenance. Oil and gas applications are also significant due to the requirement for corrosion-resistant materials in challenging environments. Power generation applications are growing as industries prioritize sustainable and efficient solutions.

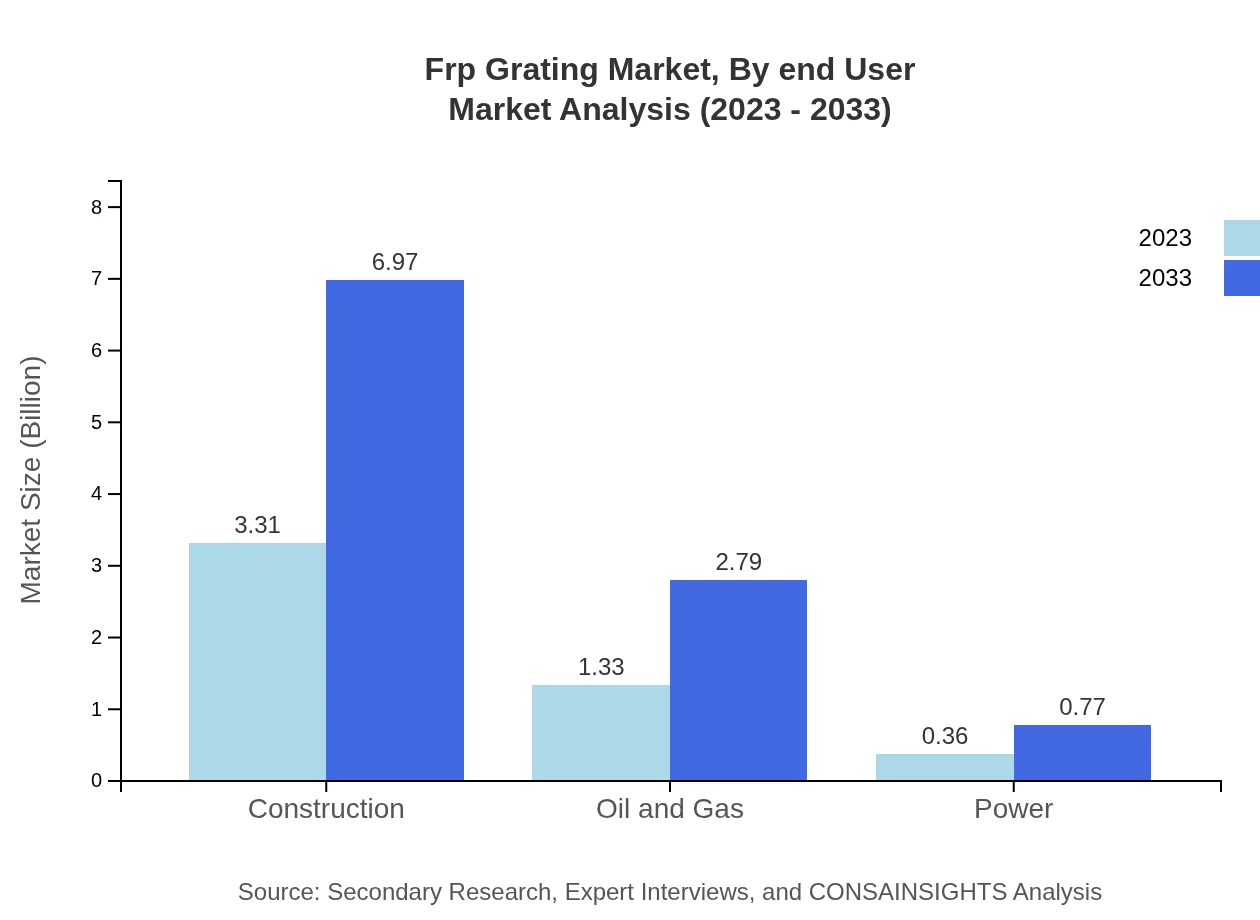

Frp Grating Market Analysis By End User

Key end-user industries for FRP grating include industrial, commercial, and municipal sectors. The industrial sector holds a large share of the market as industries look for materials that provide safety in hazardous conditions. Commercial applications are steadily growing with an emphasis on providing safe, attractive environments for businesses. Municipal projects are increasingly adopting FRP gratings in infrastructure maintenance and development.

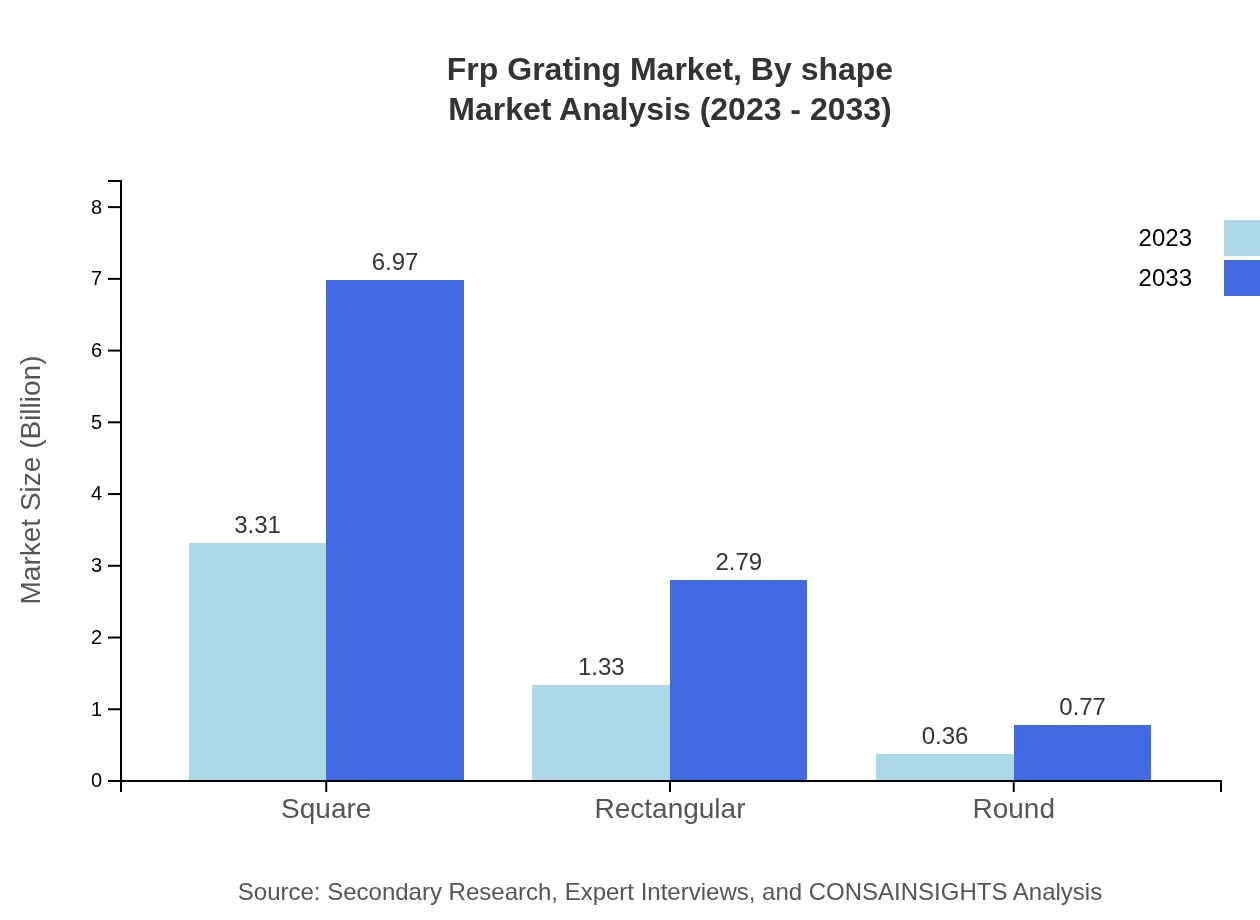

Frp Grating Market Analysis By Shape

FRP grating comes in various shapes, with square, rectangular, and round being the primary formats. Square shaped gratings dominate the segment, accounting for a large portion of the market due to their versatility in various applications. Rectangular gratings are preferred in specific projects requiring customized dimensions, while round gratings serve specialized applications.

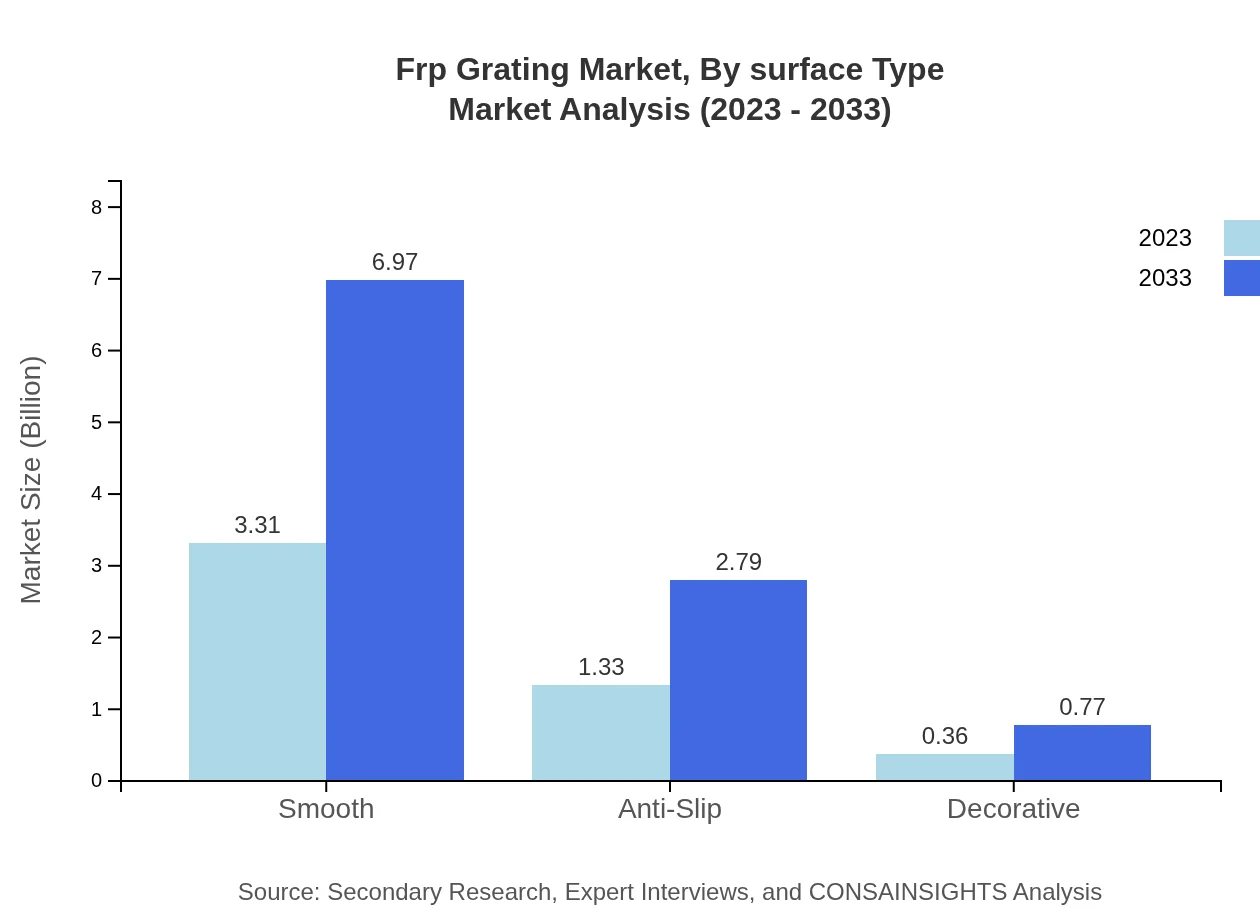

Frp Grating Market Analysis By Surface Type

Surface types in FRP grating include smooth, anti-slip, and decorative options. Anti-slip surfaces are increasingly popular in environments that prioritize safety, such as walkways or industrial settings. Smooth types are commonly used in spaces where easy cleaning is essential, while decorative types see use in aesthetic applications.

FRP Grating Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in FRP Grating Industry

FIBERGRATE Composite Structures:

A leading manufacturer known for its range of FRP grating products but also offers solutions addressing safety and maintenance issues in various industries.Strongwell Corporation:

Recognized for pioneering high-performance composite products, Strongwell’s FRP grating solutions are utilized in various sectors from industrial to architectural applications.Meridian GRP:

Specializes in FRP products for sectors such as energy and infrastructure, maintaining a strong focus on sustainability and design innovation.DURAGRID:

Provides a wide range of grating solutions designed for demanding industrial applications, including anti-slip surfaces suited for worker safety.We're grateful to work with incredible clients.

FAQs

What is the market size of frp Grating?

The global frp-grating market is currently valued at approximately $5 billion. With a projected compound annual growth rate (CAGR) of 7.5%, this market is set to significant growth in the coming years, enhancing its size in various applications.

What are the key market players or companies in this frp Grating industry?

Key players in the global frp-grating market include companies focusing on manufacturing and innovating composite materials. Some notable names are Strongwell Corporation, FRPGrating.com, and Plastics & Graphics, who have built strong reputations in quality and performance.

What are the primary factors driving the growth in the frp Grating industry?

The frp-grating industry is driven by rising demand for lightweight, corrosion-resistant materials in construction, oil and gas, and industrial applications. Additionally, the growing focus on safety and environmental sustainability continues to fuel the adoption of frp-gratings.

Which region is the fastest Growing in the frp Grating?

The North America region is currently the fastest-growing market for frp-grating, projected to expand from $1.69 billion in 2023 to $3.55 billion by 2033. This growth is attributed to increased investments in infrastructure and industrial sectors.

Does ConsaInsights provide customized market report data for the frp Grating industry?

Yes, ConsaInsights offers customized market report data tailored to specific client needs in the frp-grating industry. This includes detailed analyses of market trends, forecasts, and competitive landscapes to support strategic decision-making.

What deliverables can I expect from this frp Grating market research project?

From the frp-grating market research project, clients can expect comprehensive reports including market size, segment analysis, growth forecasts, competitive landscape insights, and strategic recommendations customized to their business requirements.

What are the market trends of frp Grating?

Current trends in the frp-grating market include the rising adoption of composite materials for enhanced durability and safety. Furthermore, innovations in manufacturing techniques and increasing regulations on safety standards are significantly influencing market dynamics.