Fruit Vegetable Processing Equipment Market Report

Published Date: 31 January 2026 | Report Code: fruit-vegetable-processing-equipment

Fruit Vegetable Processing Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Fruit Vegetable Processing Equipment market, covering key insights, trends, and forecasts from 2023 to 2033. It includes detailed sections on market size, segmentation, regional analysis, industry dynamics, and technological advancements.

| Metric | Value |

|---|---|

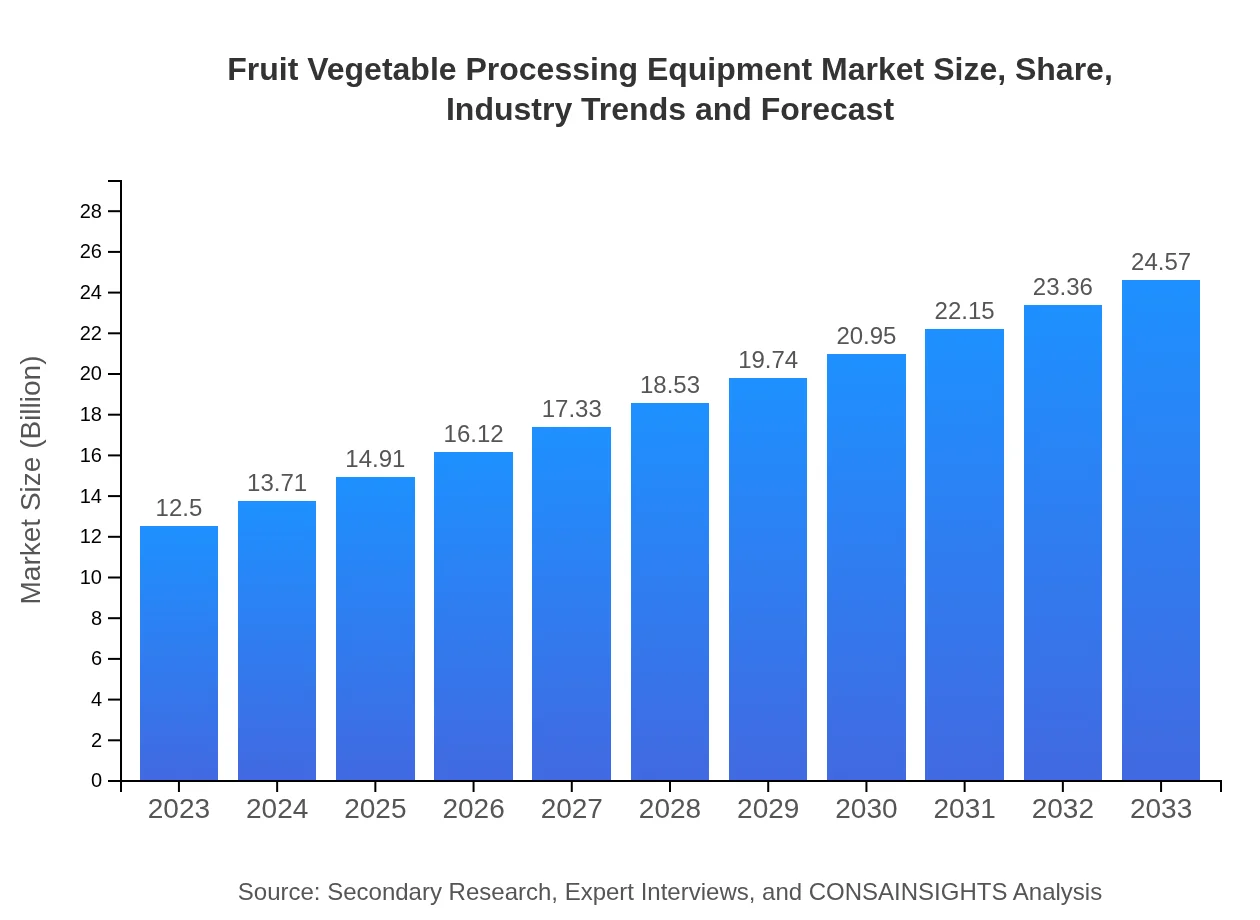

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $24.57 Billion |

| Top Companies | Buhler Group, Marel, GEA Group, Tetra Pak |

| Last Modified Date | 31 January 2026 |

Fruit Vegetable Processing Equipment Market Overview

Customize Fruit Vegetable Processing Equipment Market Report market research report

- ✔ Get in-depth analysis of Fruit Vegetable Processing Equipment market size, growth, and forecasts.

- ✔ Understand Fruit Vegetable Processing Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Fruit Vegetable Processing Equipment

What is the Market Size & CAGR of Fruit Vegetable Processing Equipment market in 2023?

Fruit Vegetable Processing Equipment Industry Analysis

Fruit Vegetable Processing Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Fruit Vegetable Processing Equipment Market Analysis Report by Region

Europe Fruit Vegetable Processing Equipment Market Report:

Europe’s Fruit Vegetable Processing Equipment market is projected to grow from $3.85 billion in 2023 to $7.58 billion by 2033. The growth in this region is propelled by a well-established food processing industry, rigorous food safety regulations, and increasing demand for organic products.Asia Pacific Fruit Vegetable Processing Equipment Market Report:

In 2023, the Asia Pacific Fruit Vegetable Processing Equipment market is valued at approximately $2.35 billion and is forecasted to reach $4.61 billion by 2033. The region is characterized by increasing agricultural production and rapid urbanization, driving demand for processed food products, thereby propelling market growth.North America Fruit Vegetable Processing Equipment Market Report:

In North America, the market size is approximately $4.51 billion in 2023, anticipated to grow to $8.86 billion by 2033. The U.S. and Canada are key contributors to this market, driven by technological innovations and rising health consciousness among consumers.South America Fruit Vegetable Processing Equipment Market Report:

The South American market for Fruit Vegetable Processing Equipment was valued at $0.06 billion in 2023, expected to reach $0.12 billion by 2033. The region's growth is attributed primarily to an increase in the consumption of processed food due to changing dietary trends and urbanization.Middle East & Africa Fruit Vegetable Processing Equipment Market Report:

In the Middle East and Africa, the market stands at $1.73 billion in 2023 and is expected to reach $3.39 billion by 2033. The market is witnessing growth thanks to an increase in food security initiatives and investments in the agricultural sector.Tell us your focus area and get a customized research report.

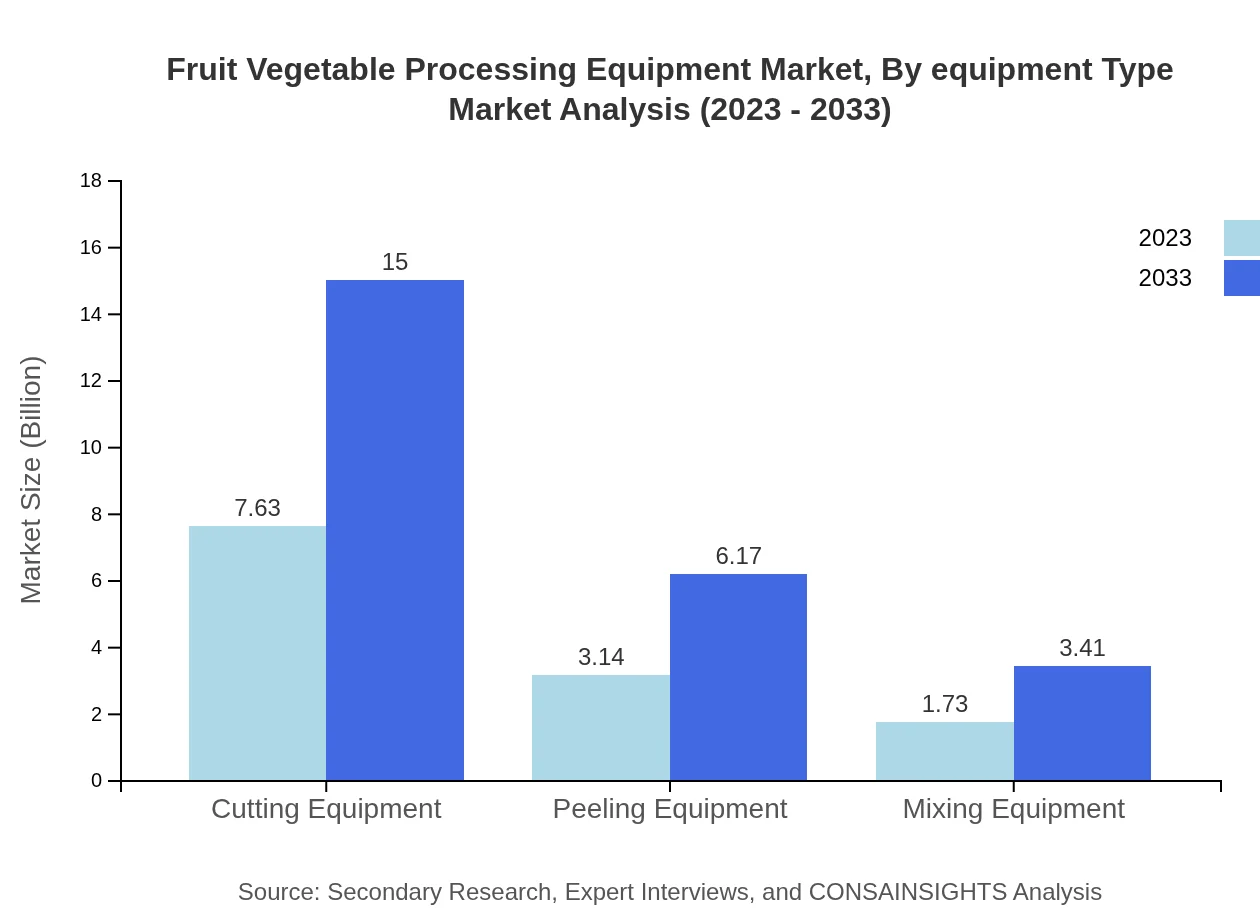

Fruit Vegetable Processing Equipment Market Analysis By Equipment Type

The market for Fruit Vegetable Processing Equipment, categorized by equipment type, encompasses several segments including cutting equipment, peeling equipment, mixing equipment, and packaging. In 2023, cutting equipment commands a market size of $7.63 billion, expected to rise to $15.00 billion by 2033, holding a substantial market share of 61.04%. Peeling and mixing equipment are also vital, contributing $3.14 billion and $1.73 billion, respectively, in 2023, with expected growth mirroring that of cutting equipment.

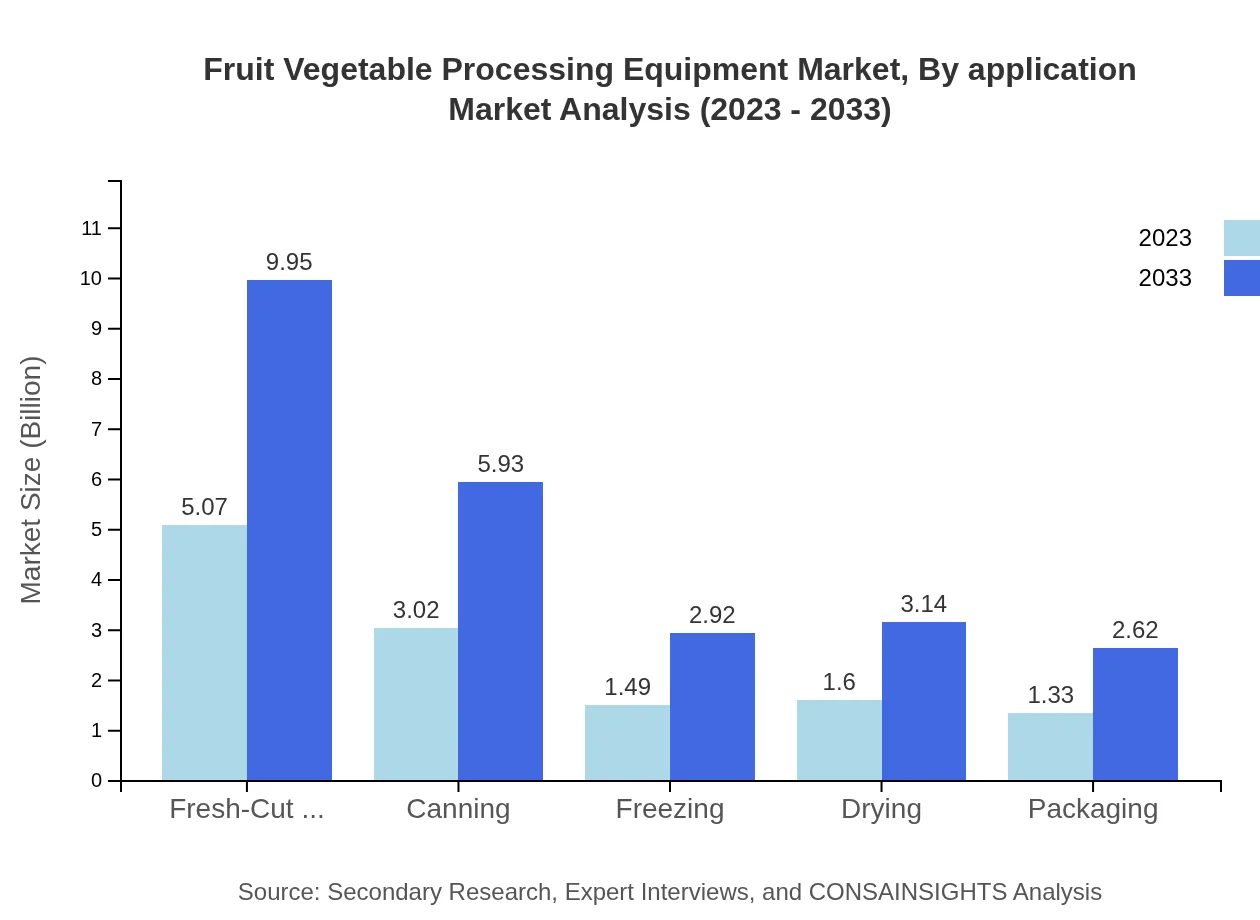

Fruit Vegetable Processing Equipment Market Analysis By Application

When segmented by application, fresh-cut produce processing represents a significant share, valued at $5.07 billion in 2023 and projected to reach $9.95 billion by 2033. Canning, freezing, and drying applications also comprise critical market segments, with canning valued at $3.02 billion and freezing at $1.49 billion in the same year. The share percentages of these applications indicate a robust shift towards fresh and convenient food options.

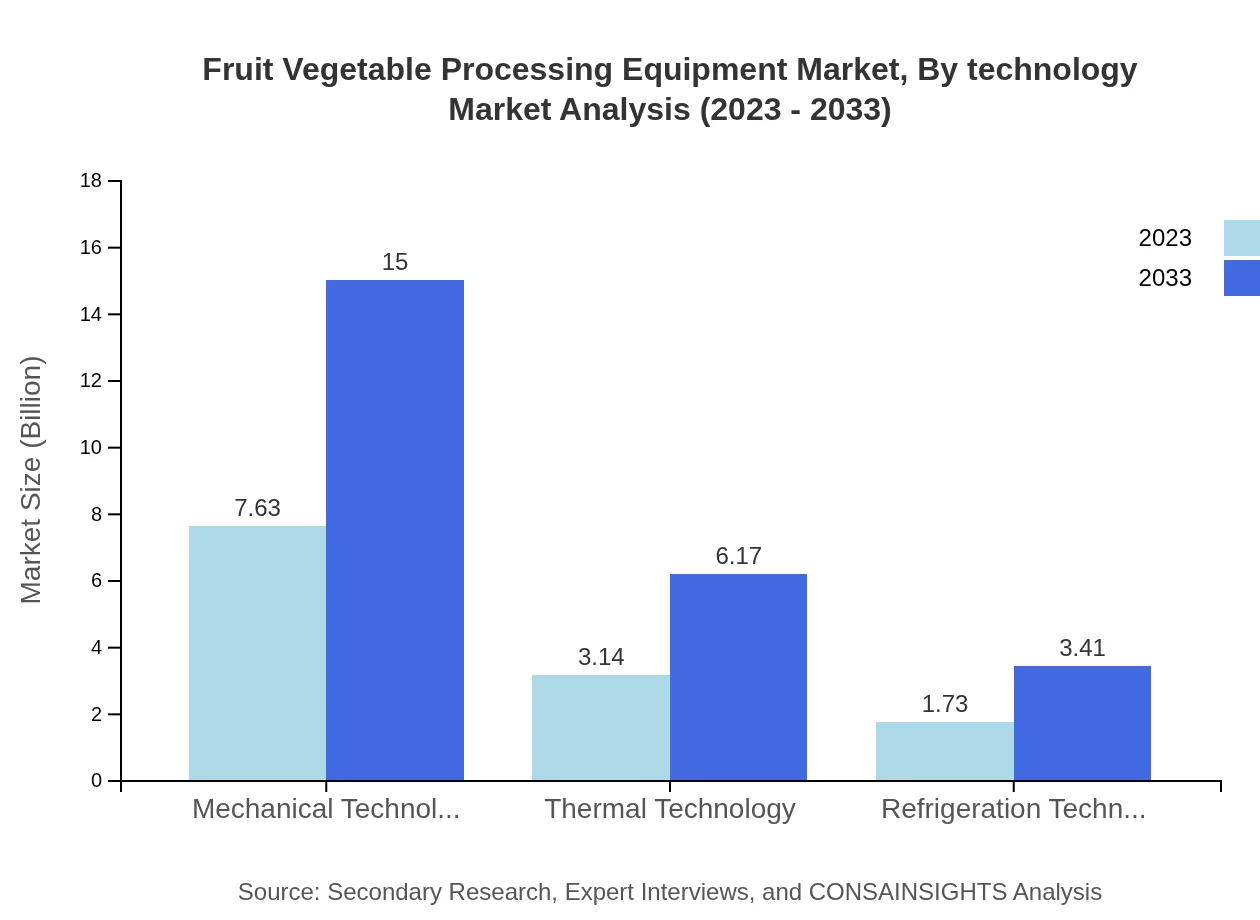

Fruit Vegetable Processing Equipment Market Analysis By Technology

The technological segmentation of the market reveals a strong preference for mechanical technology, accounting for $7.63 billion in 2023 and projected to maintain a 61.04% market share by 2033. Thermal technology follows with $3.14 billion, as consumers demand processed products that retain high organoleptic qualities. Refrigeration technology, though smaller, also plays a significant role, valued at $1.73 billion.

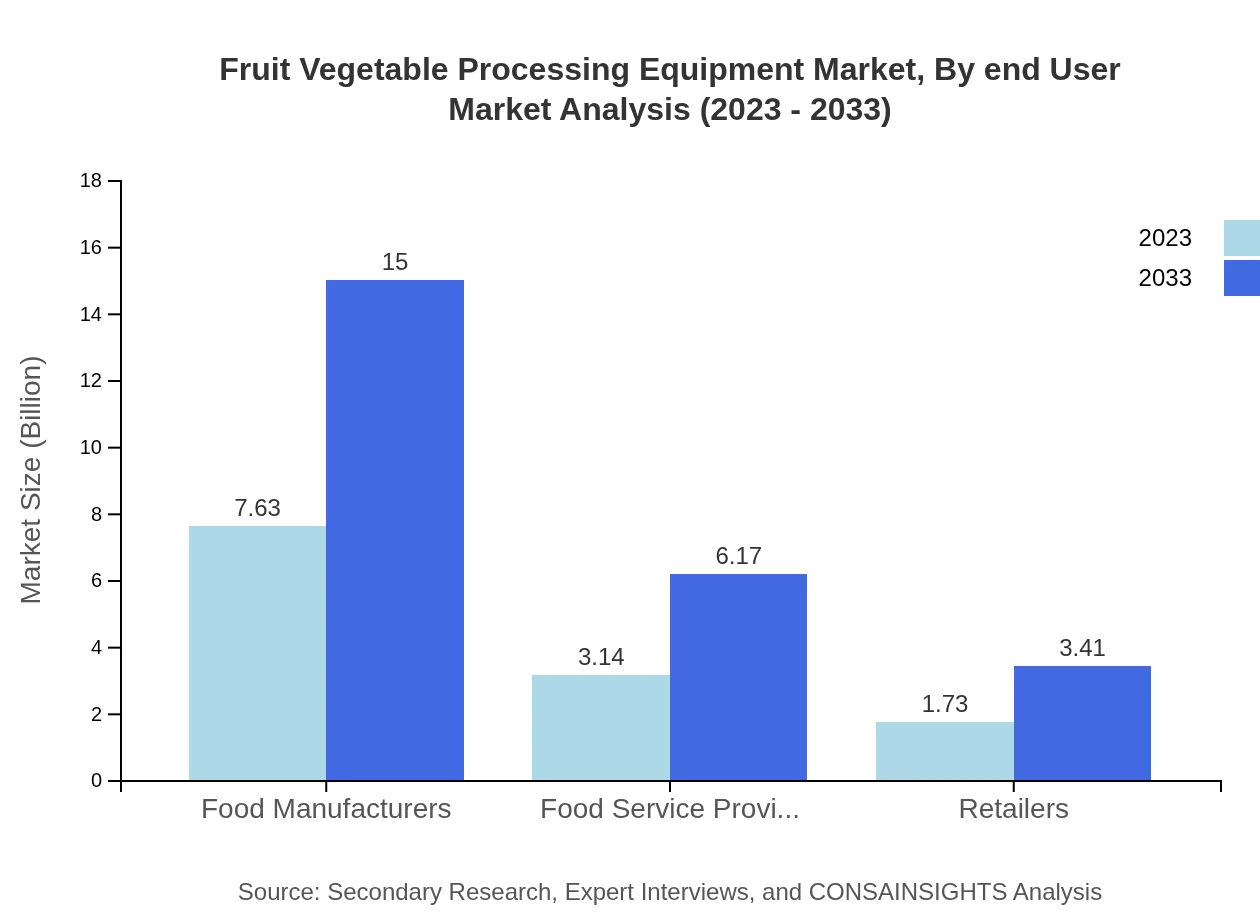

Fruit Vegetable Processing Equipment Market Analysis By End User

The three primary end-user segments—food manufacturers, food service providers, and retailers—capture significant portions of the market. Food manufacturers hold a dominant position, with a size of $7.63 billion in 2023, maintaining a stable 61.04% market share. Food service providers and retailers present promising growth opportunities, currently valued at $3.14 billion and $1.73 billion, respectively, showcasing their crucial role within the industry's ecosystem.

Fruit Vegetable Processing Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Fruit Vegetable Processing Equipment Industry

Buhler Group:

A global leader in technology and services for the food processing industry, Buhler Group specializes in providing solutions for the grain, bakery, and feed industry, including advanced fruit and vegetable processing equipment.Marel:

Marel is a leading global provider of advanced processing systems and services for the poultry, fish, meat, and dairy industries, including fruit and vegetable processing technologies that enhance efficiency and sustainability in food processing.GEA Group:

GEA Group focuses on the food processing industry with innovative equipment for transforming raw materials into high-quality processed foods, emphasizing sustainability and efficiency.Tetra Pak:

Tetra Pak is known for its food processing and packaging solutions, including advanced technologies for the processing of fruits and vegetables, ensuring food safety while extending shelf life.We're grateful to work with incredible clients.

FAQs

What is the market size of fruit Vegetable Processing Equipment?

The global fruit and vegetable processing equipment market is valued at approximately $12.5 billion in 2023, with a compound annual growth rate (CAGR) of 6.8% projected through 2033.

What are the key market players or companies in this fruit Vegetable Processing Equipment industry?

Key players in the fruit and vegetable processing equipment market include well-established manufacturers and technology providers. These firms leverage advancements in technology to enhance processing efficiency and quality in the industry.

What are the primary factors driving the growth in the fruit Vegetable Processing Equipment industry?

Growth in the fruit and vegetable processing equipment market is driven by rising health consciousness among consumers, increased demand for processed food, and technological innovations that enhance processing capacities and efficiency.

Which region is the fastest Growing in the fruit Vegetable Processing Equipment?

The Asia Pacific region is projected to be the fastest-growing market for fruit and vegetable processing equipment, with growth anticipated from $2.35 billion in 2023 to $4.61 billion by 2033.

Does ConsaInsights provide customized market report data for the fruit Vegetable Processing Equipment industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the fruit-vegetable processing equipment industry, ensuring comprehensive insights relevant to market demands.

What deliverables can I expect from this fruit Vegetable Processing Equipment market research project?

Deliverables from the fruit and vegetable processing equipment market research project include detailed market analysis, trend forecasting, competitive landscape assessments, and segmented data insights.

What are the market trends of fruit Vegetable Processing Equipment?

Current trends in the fruit and vegetable processing equipment market include increasing automation, demand for energy-efficient machinery, and a focus on sustainable and organic processing practices across the industry.