Gantry Robot Market Report

Published Date: 31 January 2026 | Report Code: gantry-robot

Gantry Robot Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Gantry Robot market from 2023 to 2033, covering market size, growth trends, regional insights, technology advancements, and a breakdown by segments. Detailed insights are supported by data-driven forecasts and industry analysis.

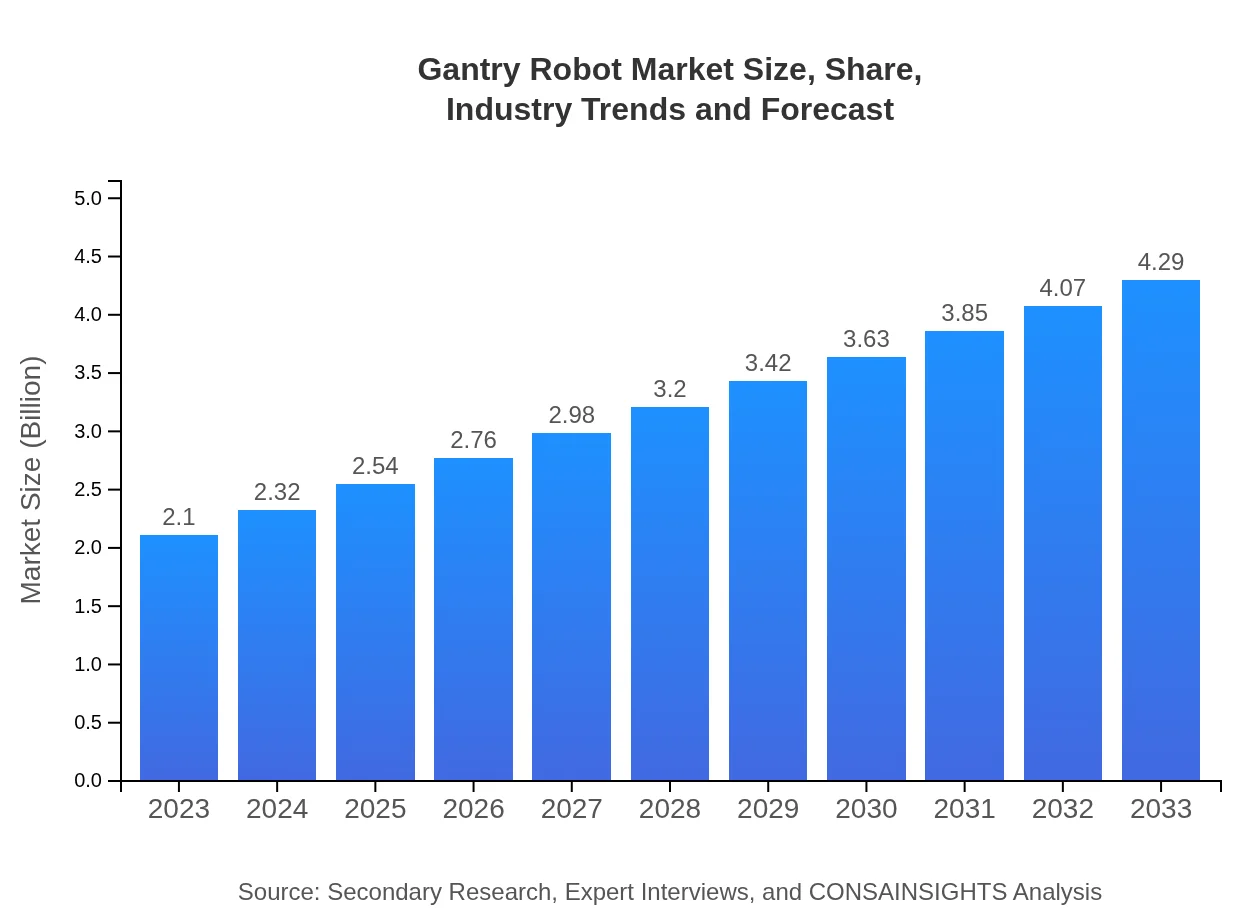

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.10 Billion |

| CAGR (2023-2033) | 7.2% |

| 2033 Market Size | $4.29 Billion |

| Top Companies | KUKA AG, FANUC Corporation, Yaskawa Electric Corporation, ABB Ltd., Universal Robots |

| Last Modified Date | 31 January 2026 |

Gantry Robot Market Overview

Customize Gantry Robot Market Report market research report

- ✔ Get in-depth analysis of Gantry Robot market size, growth, and forecasts.

- ✔ Understand Gantry Robot's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Gantry Robot

What is the Market Size & CAGR of Gantry Robot market in 2023?

Gantry Robot Industry Analysis

Gantry Robot Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Gantry Robot Market Analysis Report by Region

Europe Gantry Robot Market Report:

The European market for Gantry Robots is poised to grow from $0.59 billion in 2023 to $1.20 billion by 2033, driven by strict regulations promoting automation in manufacturing sectors. A strong push for sustainability and innovation within industries helps bolster this demand.Asia Pacific Gantry Robot Market Report:

The Asia Pacific region is projected to witness significant growth in the Gantry Robot market, expanding from $0.40 billion in 2023 to $0.81 billion by 2033. Countries like China, Japan, and South Korea are leading the adoption of automation technologies across various sectors, including manufacturing and logistics, spurred by government initiatives and investments in Industry 4.0.North America Gantry Robot Market Report:

North America holds a significant share in the Gantry Robot market, with projections moving from $0.80 billion in 2023 to approximately $1.64 billion by 2033. The emphasis on improving operational efficiency and minimizing production costs among industries, particularly automotive and electronics, contributes to this growth.South America Gantry Robot Market Report:

In South America, the market is expected to double from $0.19 billion in 2023 to $0.38 billion by 2033. This growth is driven by increasing investments in infrastructural development and a growing awareness of automation benefits in manufacturing processes amid economic challenges.Middle East & Africa Gantry Robot Market Report:

The Middle East and Africa are emerging markets for Gantry Robots, too, with forecasts indicating growth from $0.12 billion in 2023 to $0.25 billion by 2033. The development of local infrastructure and the increasing adoption of technological solutions in sectors like oil & gas and manufacturing drive this upward trend.Tell us your focus area and get a customized research report.

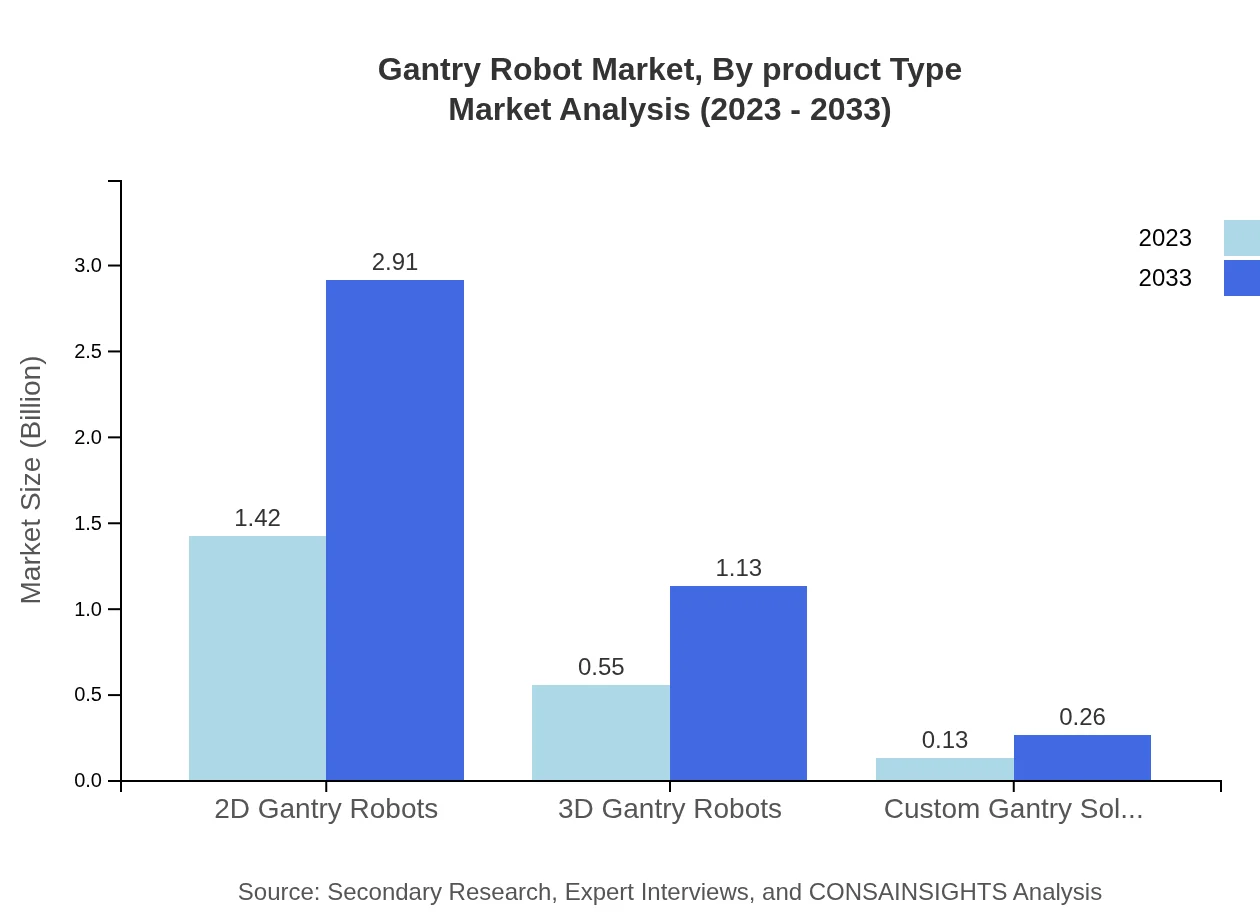

Gantry Robot Market Analysis By Product Type

The market is segmented by product types between 2D and 3D Gantry Robots, which takes dominant shares due to their diverse applications in various industries. In 2023, the 2D Gantry Robots constitute roughly 67.73% of the market share, amounting to $1.42 billion, while 3D solutions account for 26.27%. The need for custom gantry solutions is on the rise, particularly in complex applications requiring specialized configurations.

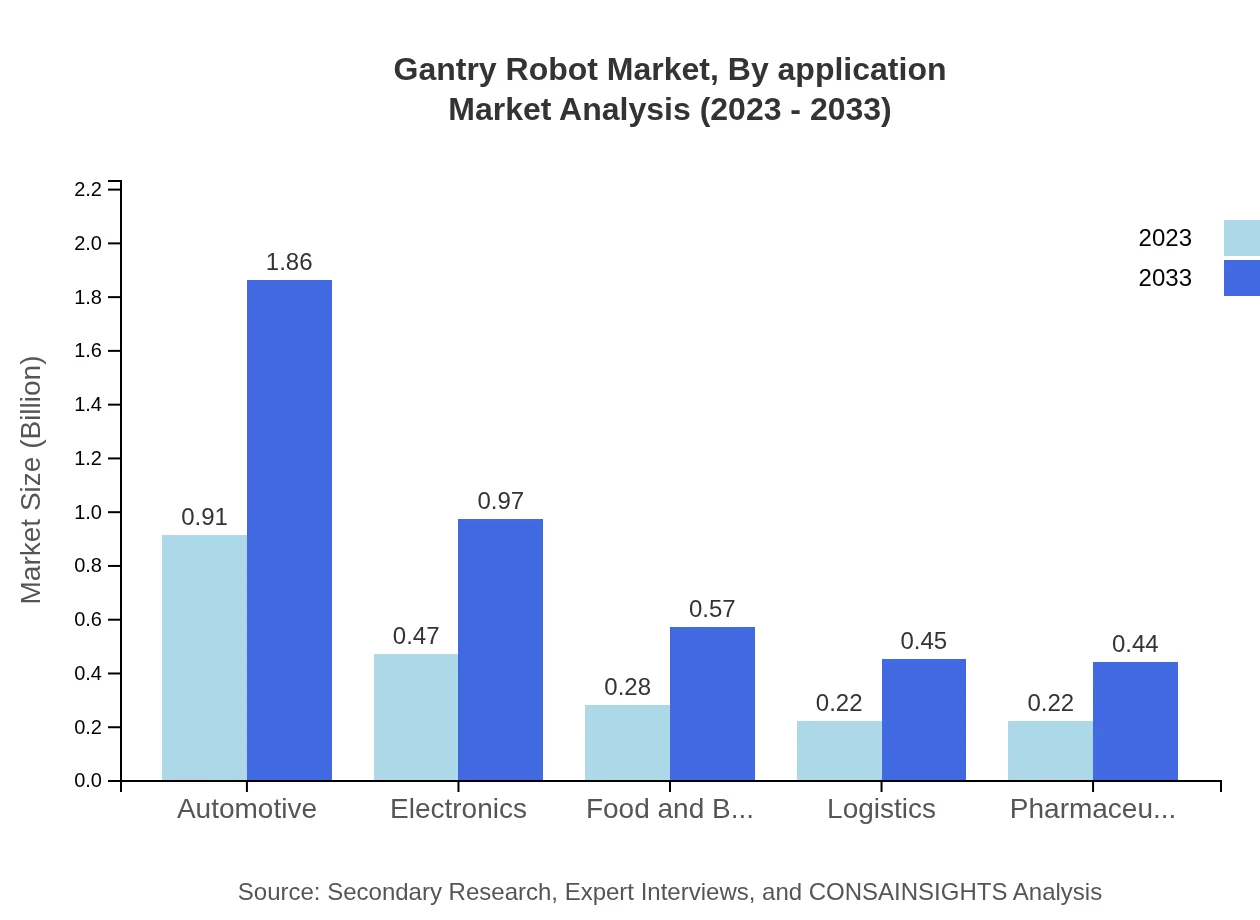

Gantry Robot Market Analysis By Application

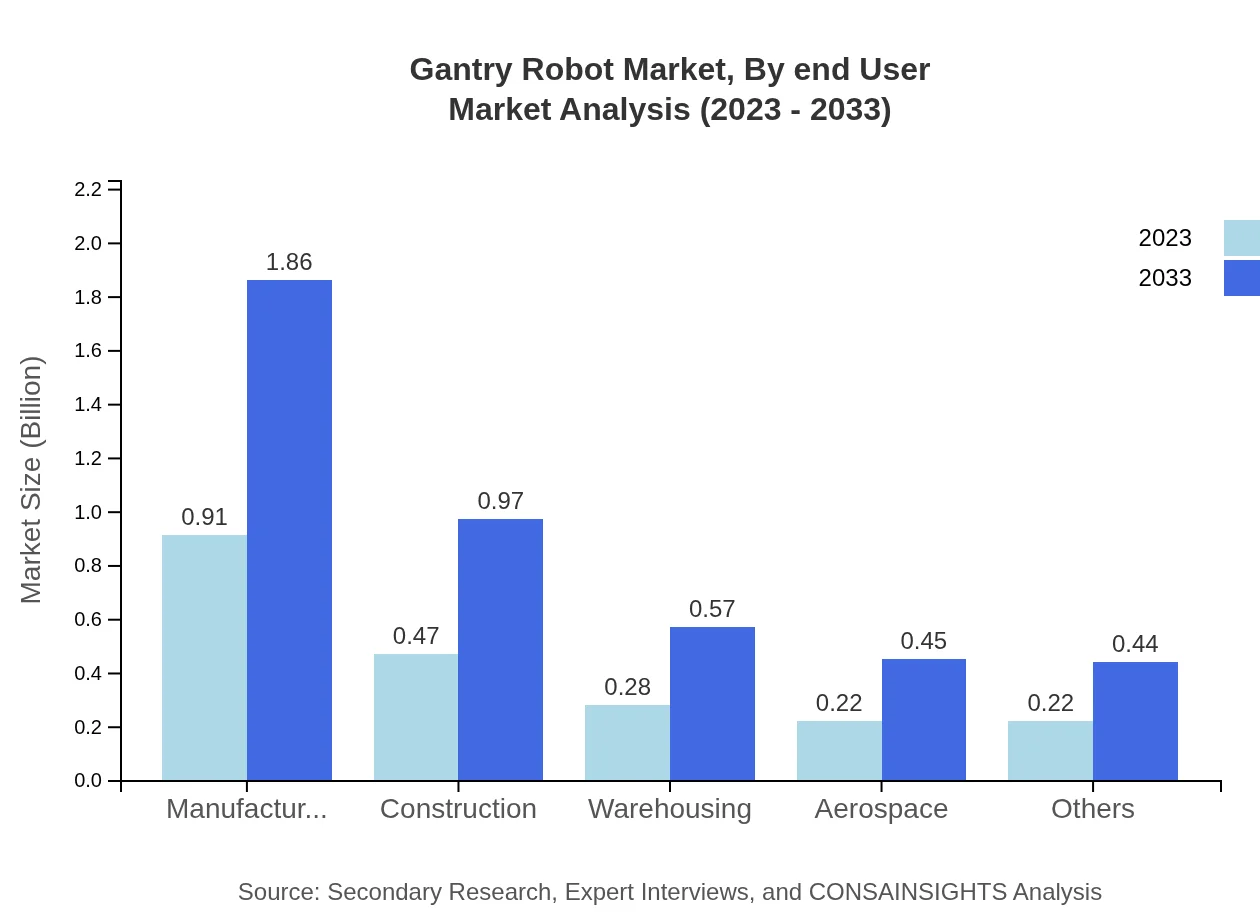

In terms of application, manufacturing remains the leading segment, capturing 43.3% market share in 2023, valued at $0.91 billion. The automotive sector significantly contributes to this with similar shares. Other crucial applications include warehousing (13.38%), food and beverage (13.38%), and pharmaceuticals (10.36%), all indicating substantial growth potential as automated solutions become more integrated into production lines.

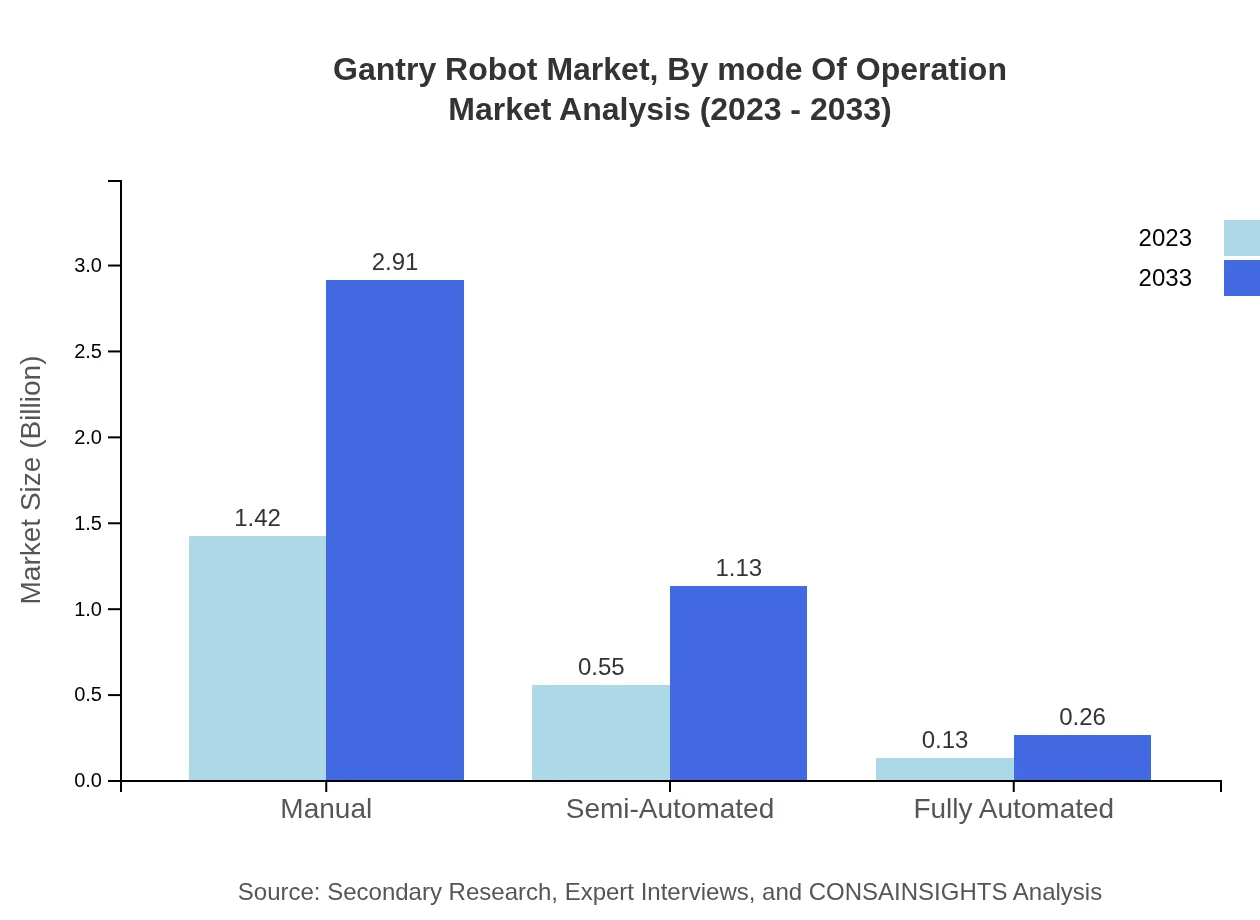

Gantry Robot Market Analysis By Mode Of Operation

The market can also be broken down into modes of operation: manual, semi-automated, and fully automated. Manual robots hold a significant share of approximately 67.73%, indicating a preference in certain sectors for human intervention complemented by robotics. As industry trends lean towards automation, semi-automated and fully automated solutions are anticipated to grow, especially in manufacturing and logistics.

Gantry Robot Market Analysis By End User

Key end-user industries driving the Gantry Robot market are automotive, manufacturing, and electronics, collectively dominating the landscape. The automotive sector alone represents 43.3% of the market share in 2023. Industries like aerospace and healthcare are expected to see increased adoption of gantry robots as they seek improved efficiency and precision in operations.

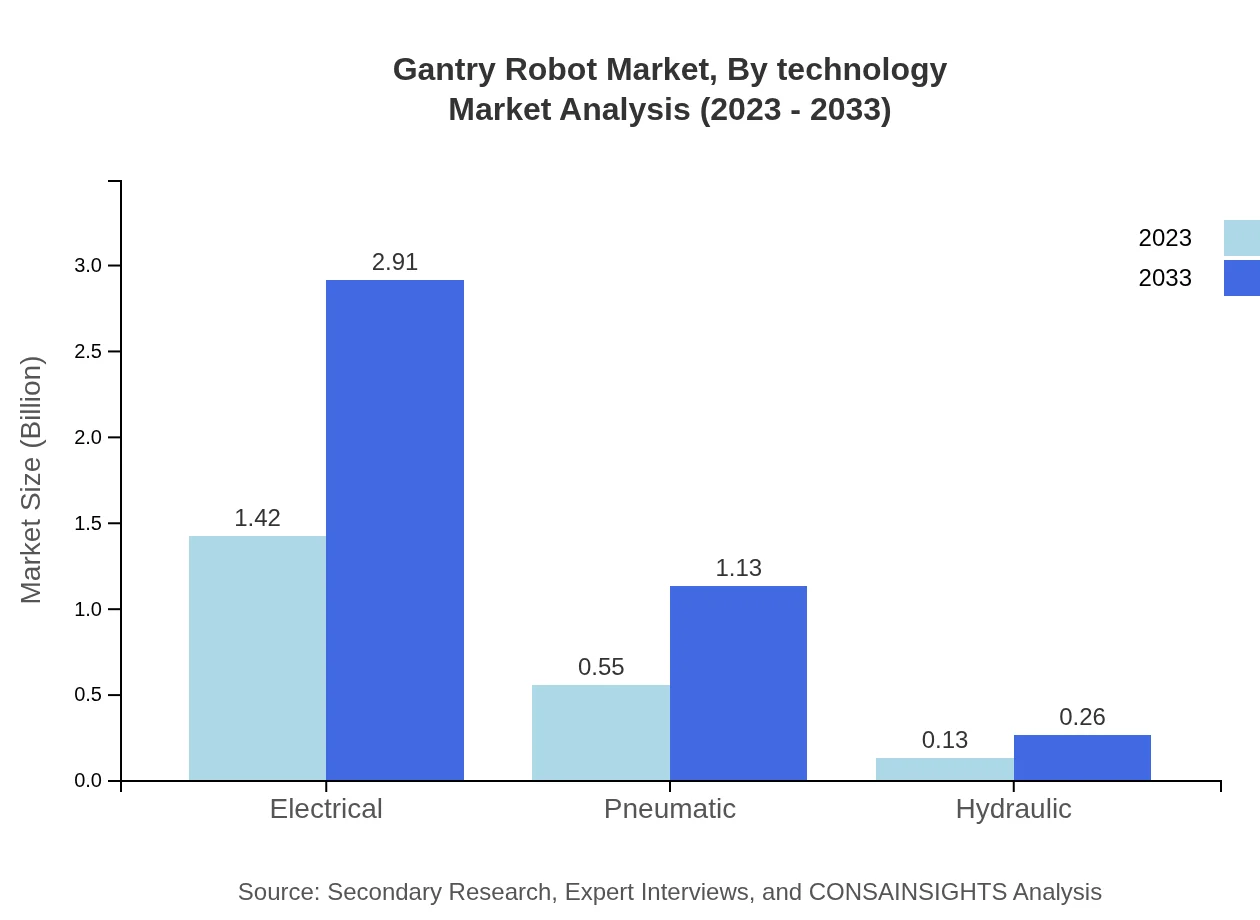

Gantry Robot Market Analysis By Technology

Technological advancements are influencing the Gantry Robot market, with innovations in AI and machine learning enhancing functionalities. Electrical systems dominate, comprising 67.73% of the market, while pneumatic and hydraulic systems account for 26.27% and 6% respectively. Future developments will likely bring forth even more sophisticated technologies, including collaborative and next-gen robotics.

Gantry Robot Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Gantry Robot Industry

KUKA AG:

KUKA AG is a leading automation technology company, providing advanced robotic systems and solutions to various industries, with a strong focus on innovation and efficiency.FANUC Corporation:

FANUC is known for its wide range of industrial robots and automation solutions, specializing in robotics for manufacturing and heavy industries.Yaskawa Electric Corporation:

Yaskawa Electric is a pioneer in motion control and robotics, providing high-quality solutions and services vital to enhancing productivity in various sectors.ABB Ltd.:

As a prominent player in the automation field, ABB Ltd. offers extensive robotic solutions focusing on industry-specific applications and services.Universal Robots:

Universal Robots specializes in collaborative robots (cobots), emphasizing ease of use and integration in diverse applications, enhancing the efficiency of operations.We're grateful to work with incredible clients.

FAQs

What is the market size of Gantry Robot?

The Gantry Robot market is projected to reach approximately $2.1 billion by 2033, growing at a CAGR of 7.2% from 2023. This growth indicates increasing demand across various industries for efficient automation solutions.

What are the key market players or companies in the Gantry Robot industry?

Key players in the Gantry Robot market include manufacturers like FANUC Corporation, ABB Ltd., KUKA AG, Yaskawa Electric Corporation, and Mitsubishi Electric Corporation. These companies are driving innovation and setting trends in automation technology.

What are the primary factors driving the growth in the Gantry Robot industry?

Several factors are propelling the Gantry Robot market, including the need for improved efficiency, reduced labor costs, technological advancements in robotics, and increased adoption in sectors like manufacturing and logistics.

Which region is the fastest Growing in the Gantry Robot?

The North American region is currently the fastest-growing market for Gantry Robots, expected to grow from $0.80 billion in 2023 to $1.64 billion by 2033, driven by rapid industrial automation and technological advancements.

Does ConsaInsights provide customized market report data for the Gantry Robot industry?

Yes, ConsaInsights offers customized market report data tailored to specific requirements in the Gantry Robot industry. Clients can receive insights based on unique parameters, facilitating informed decision-making.

What deliverables can I expect from this Gantry Robot market research project?

Deliverables from the Gantry Robot market research project will typically include detailed market analysis reports, segmentation studies, growth forecasts, competitive landscape evaluations, and regional opportunity assessments.

What are the market trends of Gantry Robot?

Current trends in the Gantry Robot market involve the rising use of 2D and 3D robotic models in various applications, an increased focus on automation in manufacturing, and innovations in technology enhancing productivity and safety.