Gas Spring Market Report

Published Date: 22 January 2026 | Report Code: gas-spring

Gas Spring Market Size, Share, Industry Trends and Forecast to 2033

This comprehensive report delves into the Gas Spring market, providing insights into market trends, size, segmentation, and regional performances over the forecast period from 2023 to 2033.

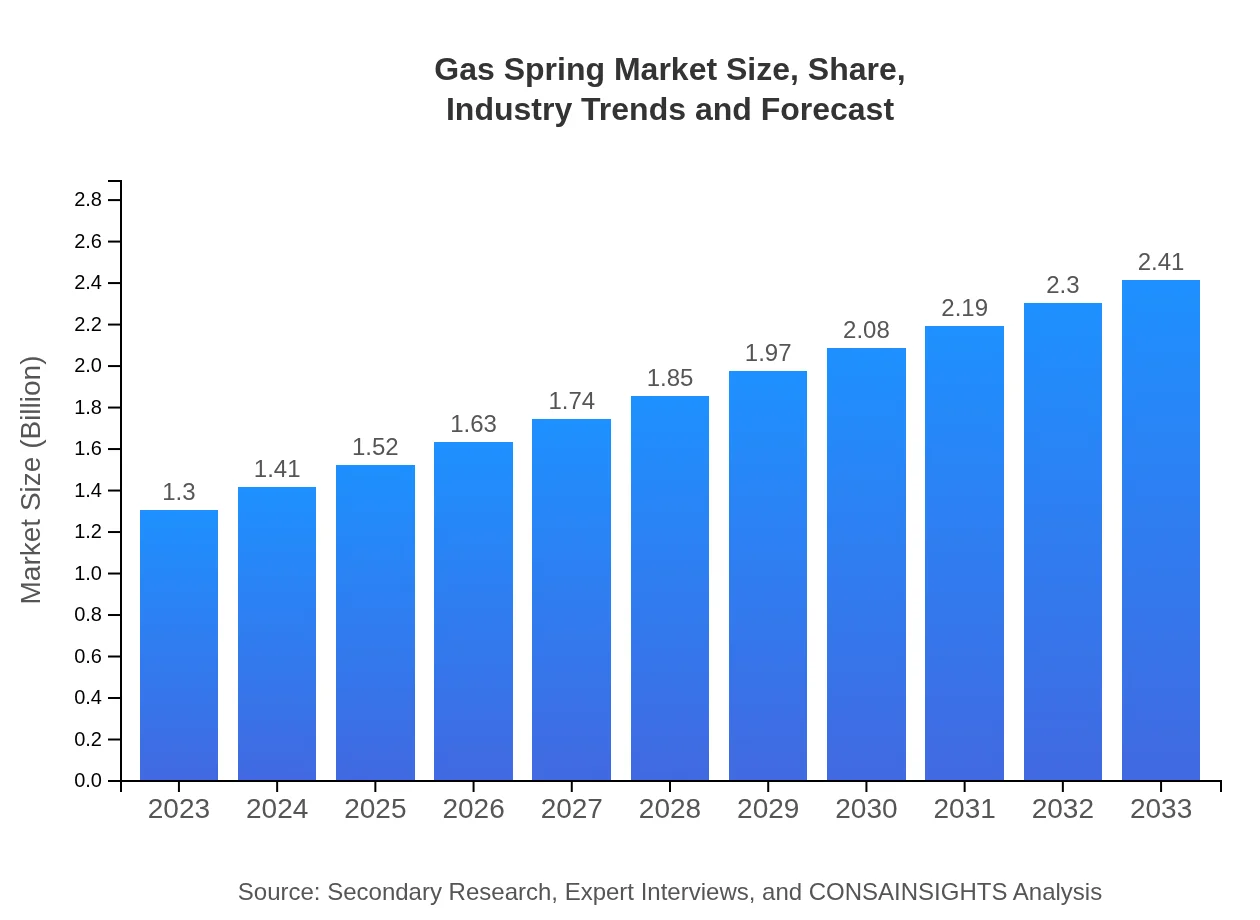

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.30 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $2.41 Billion |

| Top Companies | Suspa, Stabilus, Eibach, Industrial Gas Springs |

| Last Modified Date | 22 January 2026 |

Gas Spring Market Overview

Customize Gas Spring Market Report market research report

- ✔ Get in-depth analysis of Gas Spring market size, growth, and forecasts.

- ✔ Understand Gas Spring's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Gas Spring

What is the Market Size & CAGR of Gas Spring market in 2023?

Gas Spring Industry Analysis

Gas Spring Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Gas Spring Market Analysis Report by Region

Europe Gas Spring Market Report:

Europe is a key player as well, with high demand for advanced manufacturing solutions. The Gas Spring market is forecasted to grow from $0.36 billion in 2023 to $0.67 billion by 2033.Asia Pacific Gas Spring Market Report:

The Asia-Pacific region is witnessing significant growth in the Gas Spring market due to rapid industrialization and increasing automotive manufacturing, with market size expected to grow from $0.25 billion in 2023 to $0.47 billion in 2033.North America Gas Spring Market Report:

North America leads in market size, driven by technological advancements and a mature automotive industry. The market size is expected to increase from $0.45 billion in 2023 to $0.83 billion in 2033.South America Gas Spring Market Report:

In South America, the Gas Spring market is gradually evolving, fueled by infrastructural development and automotive growth, with projections showing a rise from $0.10 billion in 2023 to $0.19 billion in 2033.Middle East & Africa Gas Spring Market Report:

The Middle East and Africa show emerging opportunities for market growth, particularly in the automotive sector, projecting growth from $0.13 billion in 2023 to $0.24 billion in 2033.Tell us your focus area and get a customized research report.

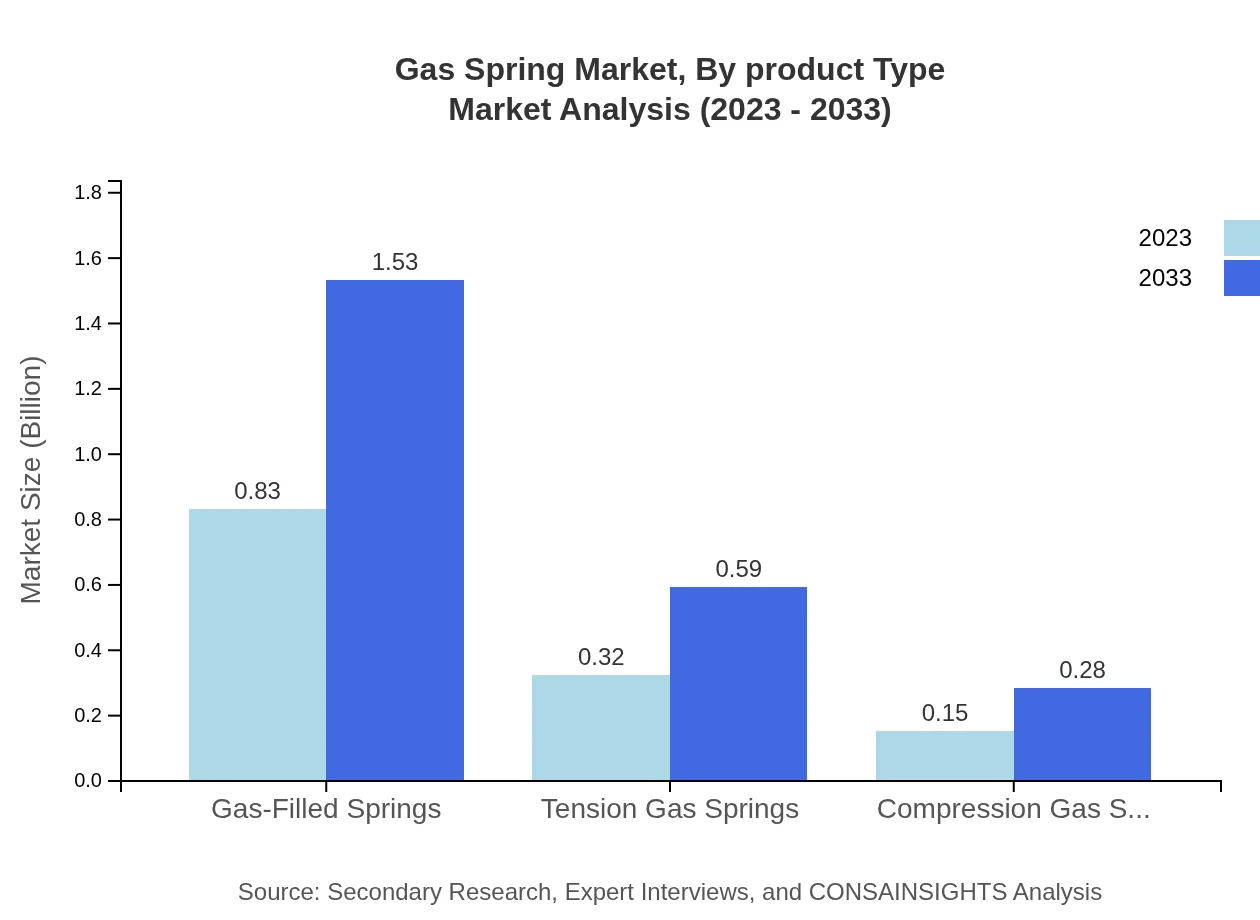

Gas Spring Market Analysis By Product Type

The product type segmentation reflects diverse applications of Gas Springs. Gas-Filled Springs dominate the market, anticipated to grow from $0.83 billion in 2023 to $1.53 billion in 2033, maintaining a market share of 63.63%. Tension Gas Springs, significant in automotive applications, project growth from $0.32 billion to $0.59 billion, holding 24.64% market share. Compression Gas Springs represent a smaller segment, growing from $0.15 billion to $0.28 billion, capturing 11.73% of the market.

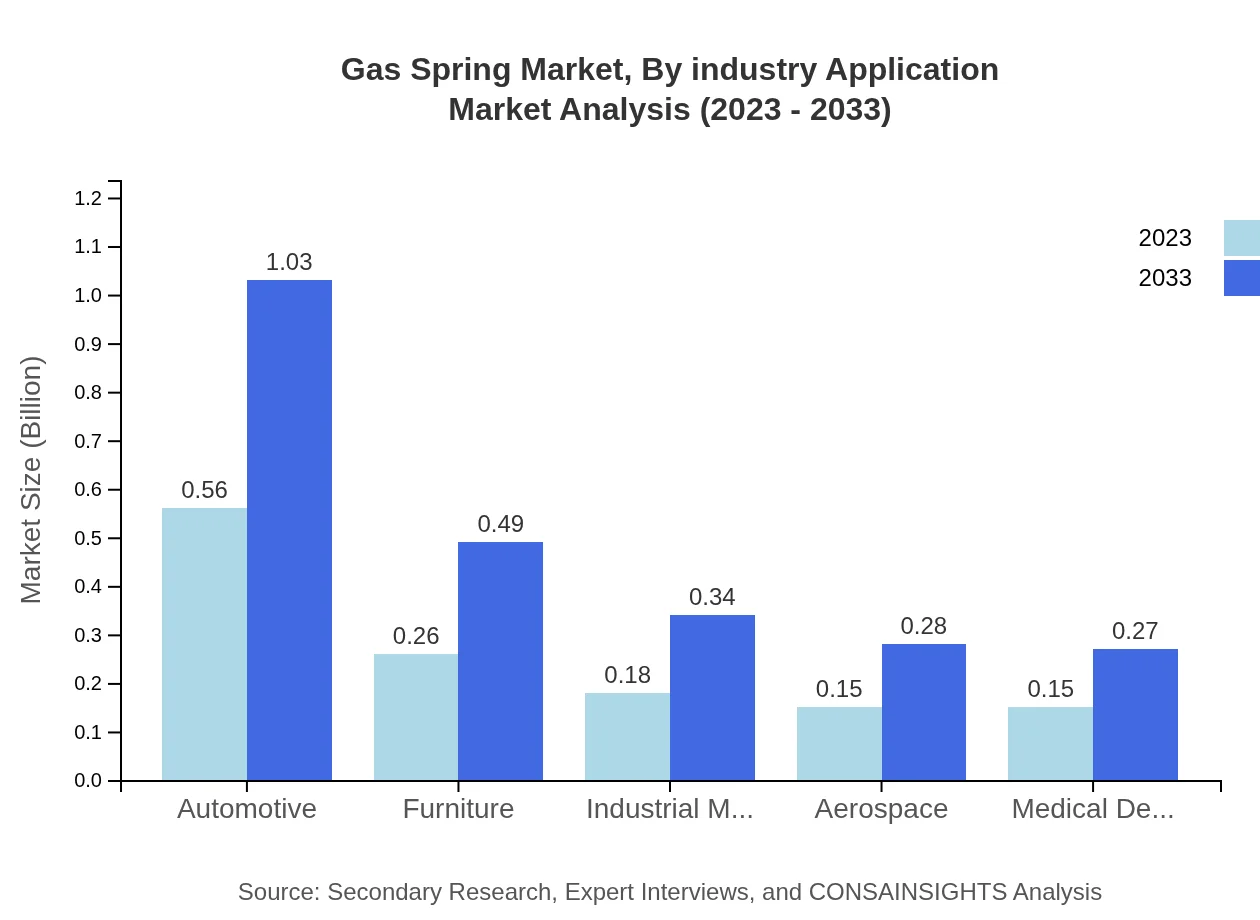

Gas Spring Market Analysis By Industry Application

The automotive sector leads in Gas Spring adoption, reflecting growth from $0.56 billion in 2023 to $1.03 billion in 2033, representing 42.97% share. Furniture applications follow, expanding from $0.26 billion to $0.49 billion, comprising 20.15%. Industrial Machinery and Aerospace show a steady increase, with sizes growing to $0.34 billion and $0.28 billion, respectively, at shares of 14.05% and 11.65%.

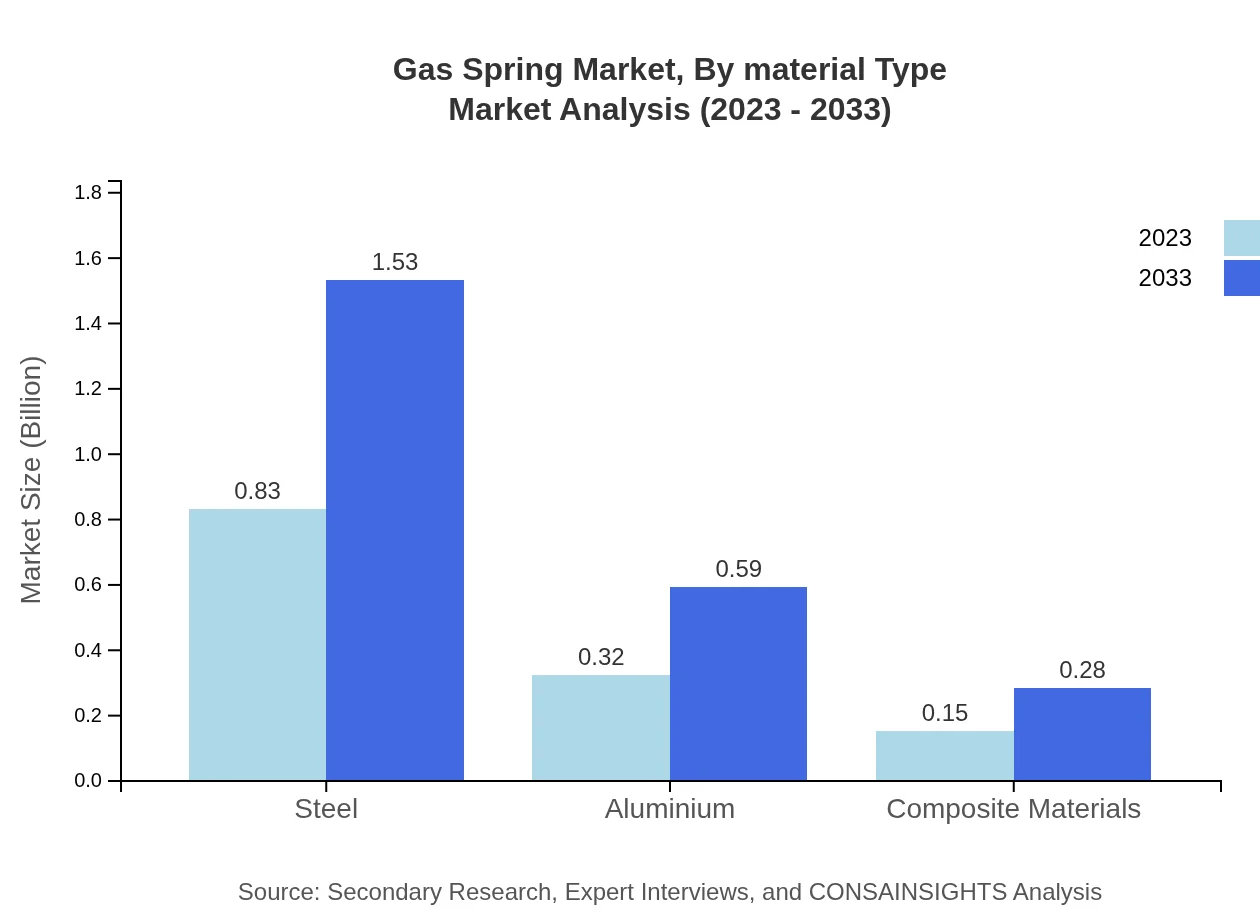

Gas Spring Market Analysis By Material Type

Steel predominates the material segment, projecting growth from $0.83 billion to $1.53 billion, with a share of 63.63%. Aluminium gas springs are gaining traction, expanding from $0.32 billion to $0.59 billion (24.64%), while composite materials, though smaller, are expected to grow from $0.15 billion to $0.28 billion, holding a share of 11.73%, mostly in specialized applications.

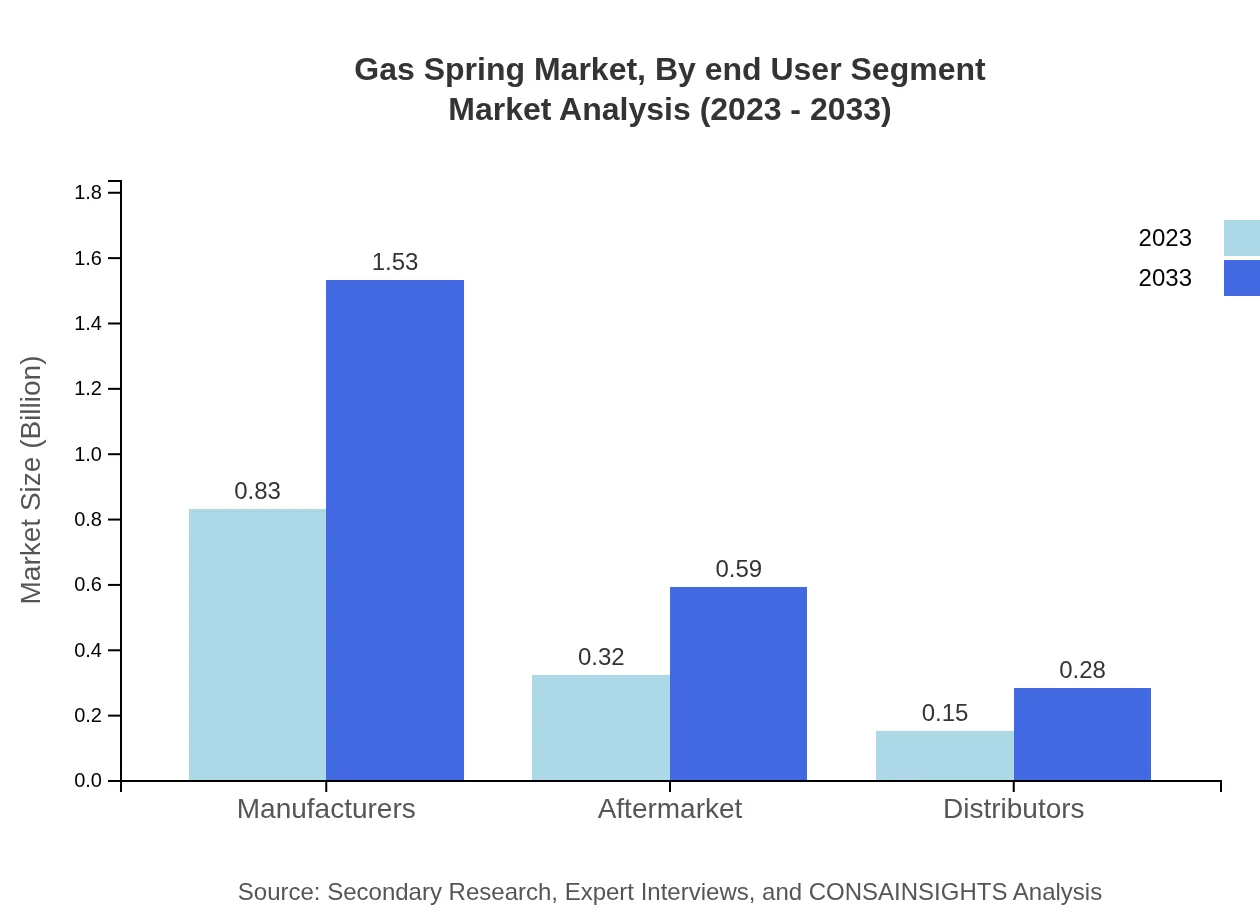

Gas Spring Market Analysis By End User Segment

The market reveals varying significance across end-user segments, with manufacturers holding a considerable share of 63.63% and growing from $0.83 billion to $1.53 billion. The aftermarket segment also sees a steady increase, moving from $0.32 billion to $0.59 billion (24.64%), while distributors account for 11.73% of the market, reflecting growth from $0.15 billion to $0.28 billion.

Gas Spring Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Gas Spring Industry

Suspa:

A leading manufacturer in the Gas Spring industry, known for innovative engineering solutions and a robust product portfolio for a variety of applications.Stabilus:

A global player recognized for its high-quality gas springs and dampers, offering tailored solutions for the automotive and industrial sectors.Eibach:

Famed for performance and application springs, providing gas spring solutions catering to automotive and specialty machinery markets.Industrial Gas Springs:

Specializes in custom gas spring solutions for various industries, committed to quality and reliability.We're grateful to work with incredible clients.

FAQs

What is the market size of gas Spring?

The global gas spring market is projected to reach approximately $1.3 billion by 2033, with a steady CAGR of 6.2%. This growth is largely driven by rising demand in sectors like automotive and industrial machinery.

What are the key market players or companies in this gas Spring industry?

Key players in the gas spring industry include companies leading in manufacturing and innovation, such as Stabilus, Suspa, and Bansbach. These firms are notable for their extensive product offerings and global reach.

What are the primary factors driving the growth in the gas spring industry?

The gas spring industry is being propelled by increasing automation in industries such as automotive, furniture, and aerospace. Additionally, advancements in technology and rising consumer preferences for efficient lifting solutions are crucial growth drivers.

Which region is the fastest Growing in the gas spring?

The Asia Pacific region is the fastest-growing market for gas springs, anticipated to expand from $0.25 billion in 2023 to $0.47 billion by 2033, fueled by rapid industrialization and robust automotive demand in countries like China and India.

Does ConsaInsights provide customized market report data for the gas spring industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the gas spring industry. This service ensures clients receive detailed insights and analytics relevant to their business goals.

What deliverables can I expect from this gas spring market research project?

From the gas spring market research project, you can expect comprehensive reports including market size data, trend analysis, competitor profiling, regional breakdown, and segment-specific insights for better strategic decision-making.

What are the market trends of gas spring?

Current market trends indicate a shift towards lightweight materials and sustainability, with an increasing share of gas-filled springs dominating the market. Innovations and enhanced functionalities are also shaping product development strategies.