Healthcare-3d Printing Additive Manufacturing Market Report

Published Date: 31 January 2026 | Report Code: healthcare-3d-printing-additive-manufacturing

Healthcare-3d Printing Additive Manufacturing Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Healthcare-3D Printing Additive Manufacturing market, focusing on trends, segmentation, and regional insights from 2023 to 2033, including market size, growth rates, and key players.

| Metric | Value |

|---|---|

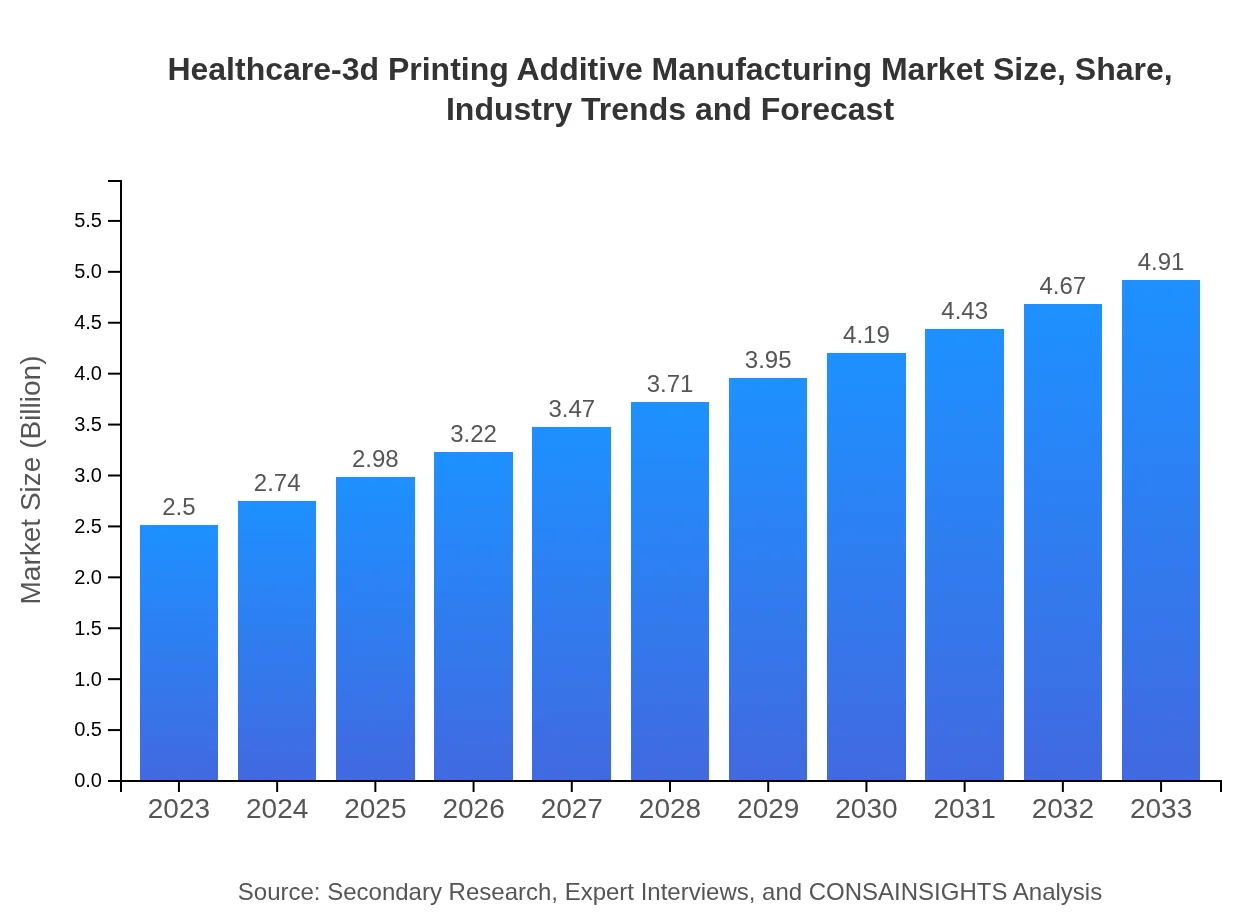

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.91 Billion |

| Top Companies | 3D Systems Corporation, Stratasys Ltd., Materialise NV, HP Inc. |

| Last Modified Date | 31 January 2026 |

Healthcare-3d Printing Additive Manufacturing Market Overview

Customize Healthcare-3d Printing Additive Manufacturing Market Report market research report

- ✔ Get in-depth analysis of Healthcare-3d Printing Additive Manufacturing market size, growth, and forecasts.

- ✔ Understand Healthcare-3d Printing Additive Manufacturing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Healthcare-3d Printing Additive Manufacturing

What is the Market Size & CAGR of Healthcare-3d Printing Additive Manufacturing market in 2023?

Healthcare-3d Printing Additive Manufacturing Industry Analysis

Healthcare-3d Printing Additive Manufacturing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Healthcare-3d Printing Additive Manufacturing Market Analysis Report by Region

Europe Healthcare-3d Printing Additive Manufacturing Market Report:

Europe's Healthcare-3D Printing Additive Manufacturing market is projected to grow from $0.63 billion in 2023 to $1.24 billion by 2033. The European market benefits from strong regulatory support, technological advancements, and high-level investment in healthcare innovations.Asia Pacific Healthcare-3d Printing Additive Manufacturing Market Report:

The Asia-Pacific region is witnessing rapid growth in the Healthcare-3D Printing Additive Manufacturing market, projected to increase from $0.53 billion in 2023 to $1.04 billion by 2033. This growth is attributed to rising healthcare expenditures, the expansion of medical infrastructure, and increasing government support for advanced technologies.North America Healthcare-3d Printing Additive Manufacturing Market Report:

North America remains the largest market, with expectations to grow from $0.92 billion in 2023 to $1.80 billion by 2033. The significant presence of major players, robust healthcare infrastructure, and significant investment in research and development drive this region’s dominance.South America Healthcare-3d Printing Additive Manufacturing Market Report:

In South America, the market is expected to grow from $0.24 billion in 2023 to $0.48 billion in 2033. Factors driving this growth include increasing awareness of advanced medical technologies and a gradual adoption of 3D printing across healthcare settings.Middle East & Africa Healthcare-3d Printing Additive Manufacturing Market Report:

The Middle East and Africa market is anticipated to grow from $0.18 billion in 2023 to $0.35 billion by 2033, with growth driven by increasing healthcare access, investments in healthcare technology, and rising patient awareness.Tell us your focus area and get a customized research report.

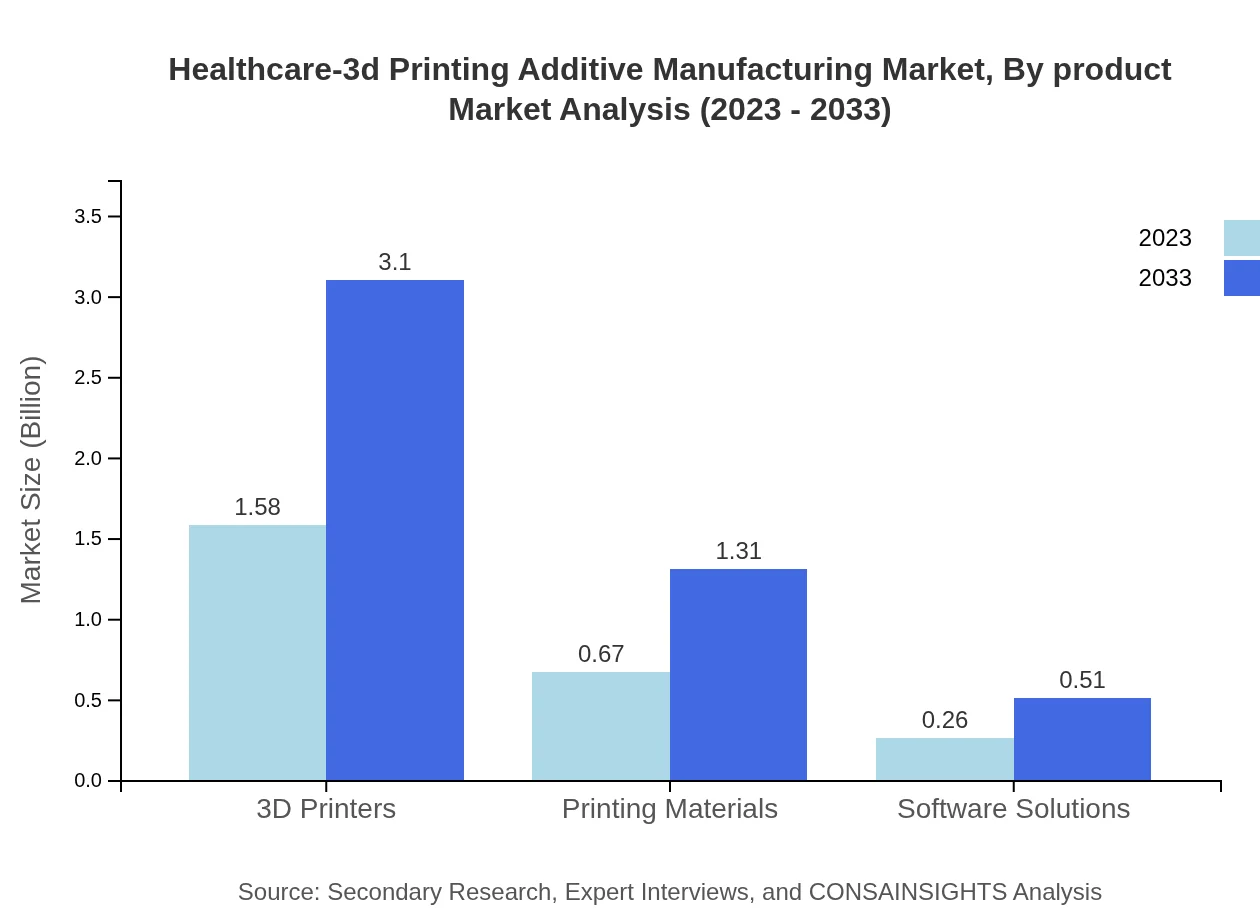

Healthcare-3d Printing Additive Manufacturing Market Analysis By Product

In 2023, the 3D printers segment is valued at $1.58 billion, and it is anticipated to reach $3.10 billion by 2033. The market share for 3D printers is projected to remain stable at 63.04% throughout this period. The materials segment will also see growth from $0.67 billion to $1.31 billion with a 26.6% market share, while software solutions will grow from $0.26 billion to $0.51 billion, maintaining a 10.36% share.

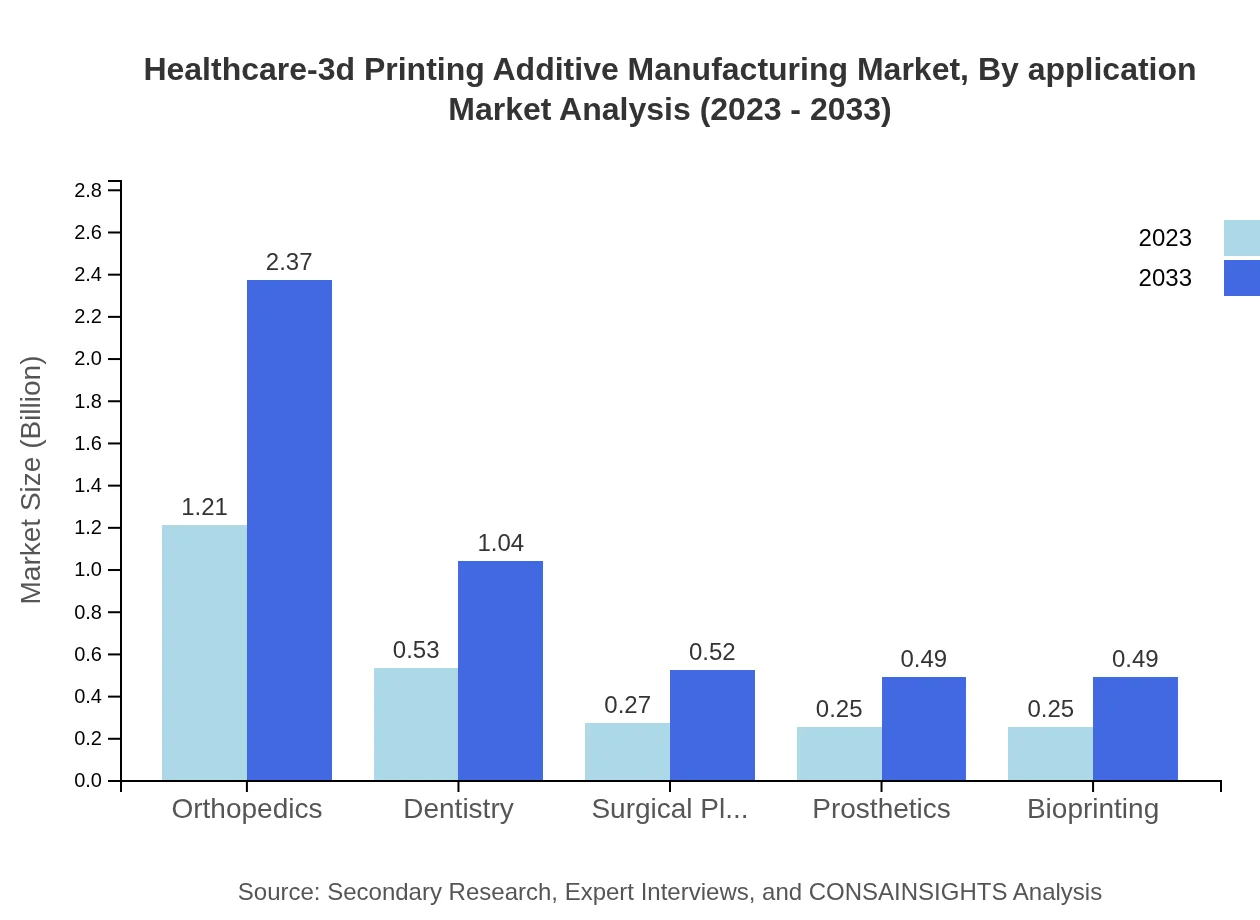

Healthcare-3d Printing Additive Manufacturing Market Analysis By Application

The application of 3D printing in orthopedics is expected to grow significantly, expanding from $1.21 billion in 2023 to $2.37 billion by 2033, with a consistent market share of 48.22%. The dentistry application is projected to grow from $0.53 billion to $1.04 billion, maintaining a 21.15% share. Other applications like surgical planning and prosthetics exhibit steady growth trends as well.

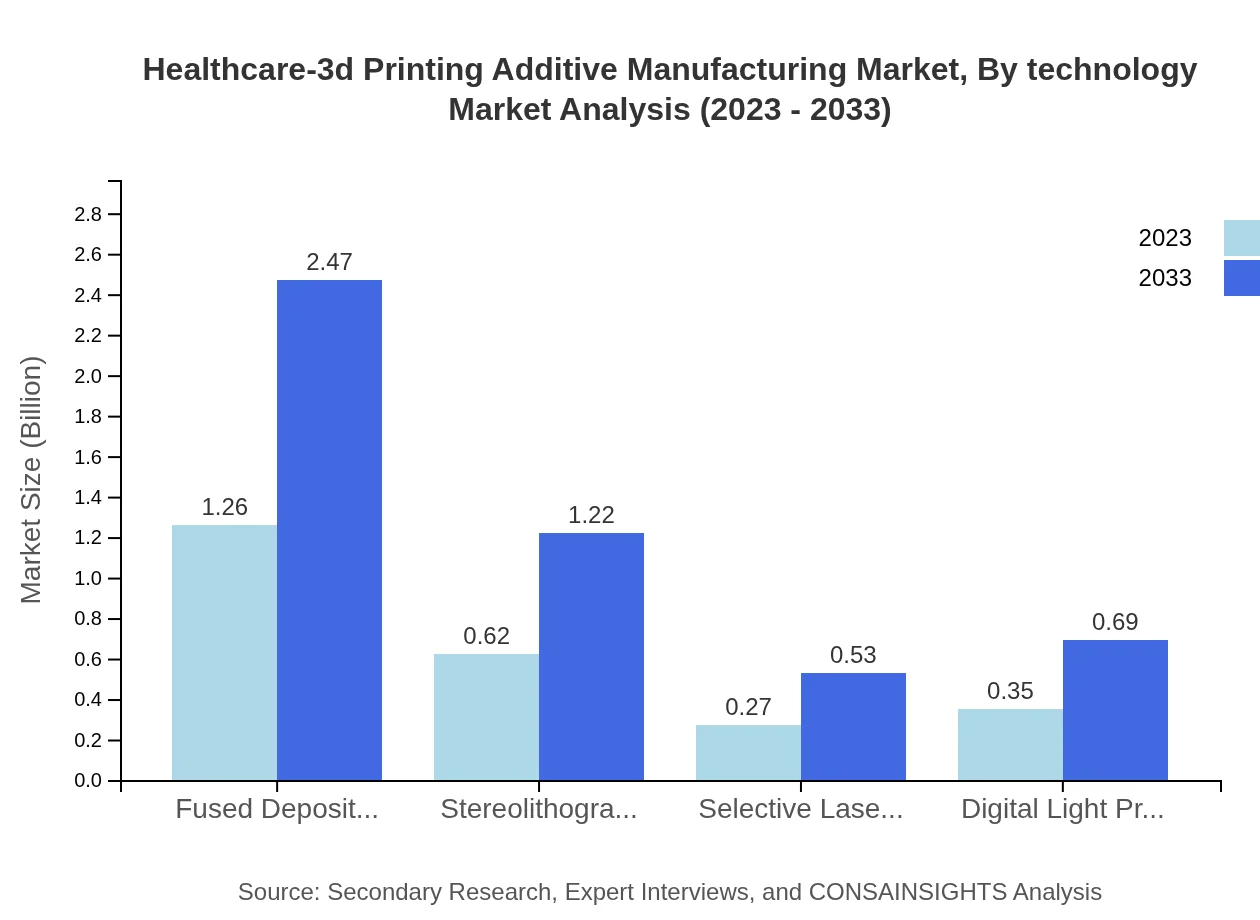

Healthcare-3d Printing Additive Manufacturing Market Analysis By Technology

Technologies such as Fused Deposition Modeling (FDM) will dominate the market, growing from $1.26 billion to $2.47 billion, sustaining a 50.34% market share. Stereolithography (SLA) will also maintain its relevance, expanding from $0.62 billion to $1.22 billion at a 24.85% share. Emerging technologies like Selective Laser Sintering (SLS) and Digital Light Processing (DLP) will contribute to the diversification of applications in healthcare, focusing on biocompatibility and precision.

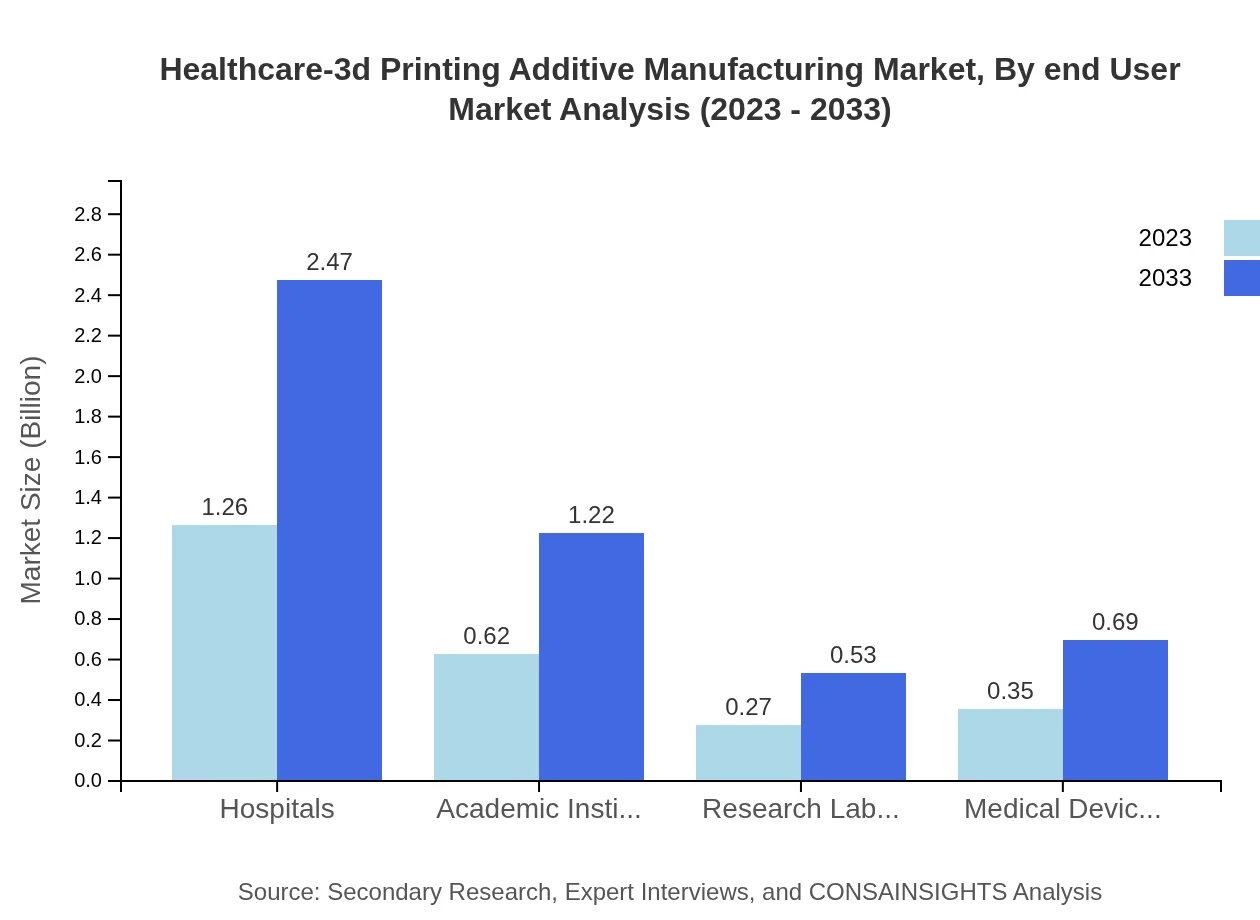

Healthcare-3d Printing Additive Manufacturing Market Analysis By End User

The demand for healthcare 3D printing is robust in hospitals, projected to surge from $1.26 billion to $2.47 billion, capturing a 50.34% share. Academic institutions will grow from $0.62 billion to $1.22 billion, maintaining 24.85% share, while research laboratories and medical device manufacturers are also significant contributors to market expansion, reflecting growing investments in innovative healthcare solutions.

Healthcare-3d Printing Additive Manufacturing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Healthcare-3d Printing Additive Manufacturing Industry

3D Systems Corporation:

A pioneer in 3D printing technologies, 3D Systems Corporation provides comprehensive 3D printing solutions and materials designed for healthcare applications.Stratasys Ltd.:

Stratasys is known for its innovative 3D printing solutions aimed at healthcare providers, helping in the production of custom medical devices and prototypes.Materialise NV:

Materialise specializes in 3D printing software and medical applications, providing solutions that empower healthcare professionals with personalized print options.HP Inc.:

HP offers advanced 3D printing technologies that cater to the healthcare sector, focusing on the production of durable, high-quality medical devices.We're grateful to work with incredible clients.

FAQs

What is the market size of healthcare-3d Printing Additive Manufacturing?

The healthcare 3D printing additive manufacturing market was valued at $2.5 billion in 2023, with a projected CAGR of 6.8% from 2023 to 2033, indicating strong future growth in this innovative industry.

What are the key market players or companies in this healthcare-3d Printing Additive Manufacturing industry?

Key players in the healthcare 3D printing additive manufacturing industry include Stratasys, 3D Systems, Materialise, Stryker, and Siemens, all contributing to advancements in medical applications and technologies.

What are the primary factors driving the growth in the healthcare-3d Printing Additive Manufacturing industry?

Growth in this industry is driven by advancements in technology, increased adoption of 3D printing for customized medical solutions, and the demand for cost-effective and efficient production methods in healthcare.

Which region is the fastest Growing in the healthcare-3d Printing Additive Manufacturing?

The Asia Pacific region is projected to be the fastest-growing market for healthcare 3D printing, growing from $0.53 billion in 2023 to $1.04 billion by 2033, fueled by investments and innovation in medical technologies.

Does ConsaInsights provide customized market report data for the healthcare-3d Printing Additive Manufacturing industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the healthcare 3D printing additive manufacturing industry, providing insights and analysis relevant to particular business objectives.

What deliverables can I expect from this healthcare-3d Printing Additive Manufacturing market research project?

Deliverables typically include a comprehensive report outlining market size, growth forecasts, competitive analysis, regional insights, and strategic recommendations tailored to the healthcare 3D printing additive manufacturing sector.

What are the market trends of healthcare-3d Printing Additive Manufacturing?

Current trends include increased integration of AI in 3D printing processes, customized patient solutions, rise of bioprinting technologies, and enhanced regulatory frameworks encouraging the adoption of these advanced manufacturing techniques.