Heat Shrink Tubing Market Report

Published Date: 22 January 2026 | Report Code: heat-shrink-tubing

Heat Shrink Tubing Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the Heat Shrink Tubing market, encompassing market size, trends, and forecasts from 2023 to 2033. It provides in-depth insights into regional performances, industry analysis, and the leading players influencing the market landscape.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

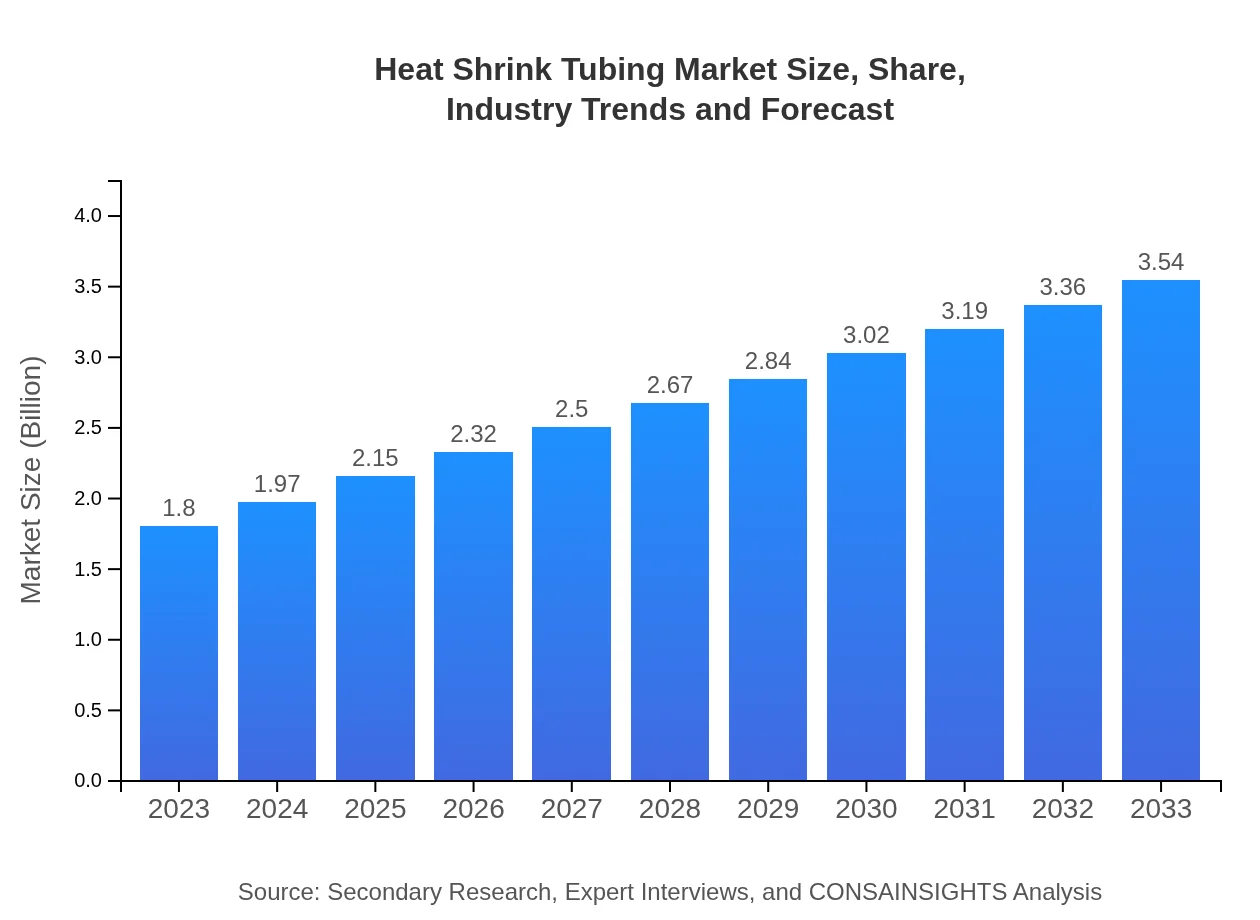

| 2023 Market Size | $1.80 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $3.54 Billion |

| Top Companies | 3M Company, TE Connectivity, Amphenol Corporation, Alpha Wire |

| Last Modified Date | 22 January 2026 |

Heat Shrink Tubing Market Overview

Customize Heat Shrink Tubing Market Report market research report

- ✔ Get in-depth analysis of Heat Shrink Tubing market size, growth, and forecasts.

- ✔ Understand Heat Shrink Tubing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Heat Shrink Tubing

What is the Market Size & CAGR of Heat Shrink Tubing market in 2023?

Heat Shrink Tubing Industry Analysis

Heat Shrink Tubing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Heat Shrink Tubing Market Analysis Report by Region

Europe Heat Shrink Tubing Market Report:

Europe's market is projected to grow from $0.48 billion in 2023 to $0.94 billion by 2033. Growth factors include technological innovations and increasing regulations regarding cable management and protection in electric vehicles and infrastructure.Asia Pacific Heat Shrink Tubing Market Report:

The Asia Pacific region is projected to grow from $0.38 billion in 2023 to $0.74 billion by 2033, driven by increased manufacturing activities and the growing automotive sector. China and India are major contributors due to their vast electronics and automotive industries.North America Heat Shrink Tubing Market Report:

North America leads with a market size of $0.63 billion in 2023, anticipated to reach $1.23 billion by 2033. Strong growth is spurred by the high demand in the automotive and medical industries, coupled with stringent safety standards.South America Heat Shrink Tubing Market Report:

In South America, the market is expected to climb from $0.13 billion in 2023 to $0.25 billion in 2033. The growth is supported by rising investments in infrastructure and advancements in telecommunications.Middle East & Africa Heat Shrink Tubing Market Report:

The Middle East and Africa region shows potential growth from $0.19 billion in 2023 to $0.37 billion by 2033, stemming from an increased focus on renewable energy projects and expanding telecommunications infrastructure.Tell us your focus area and get a customized research report.

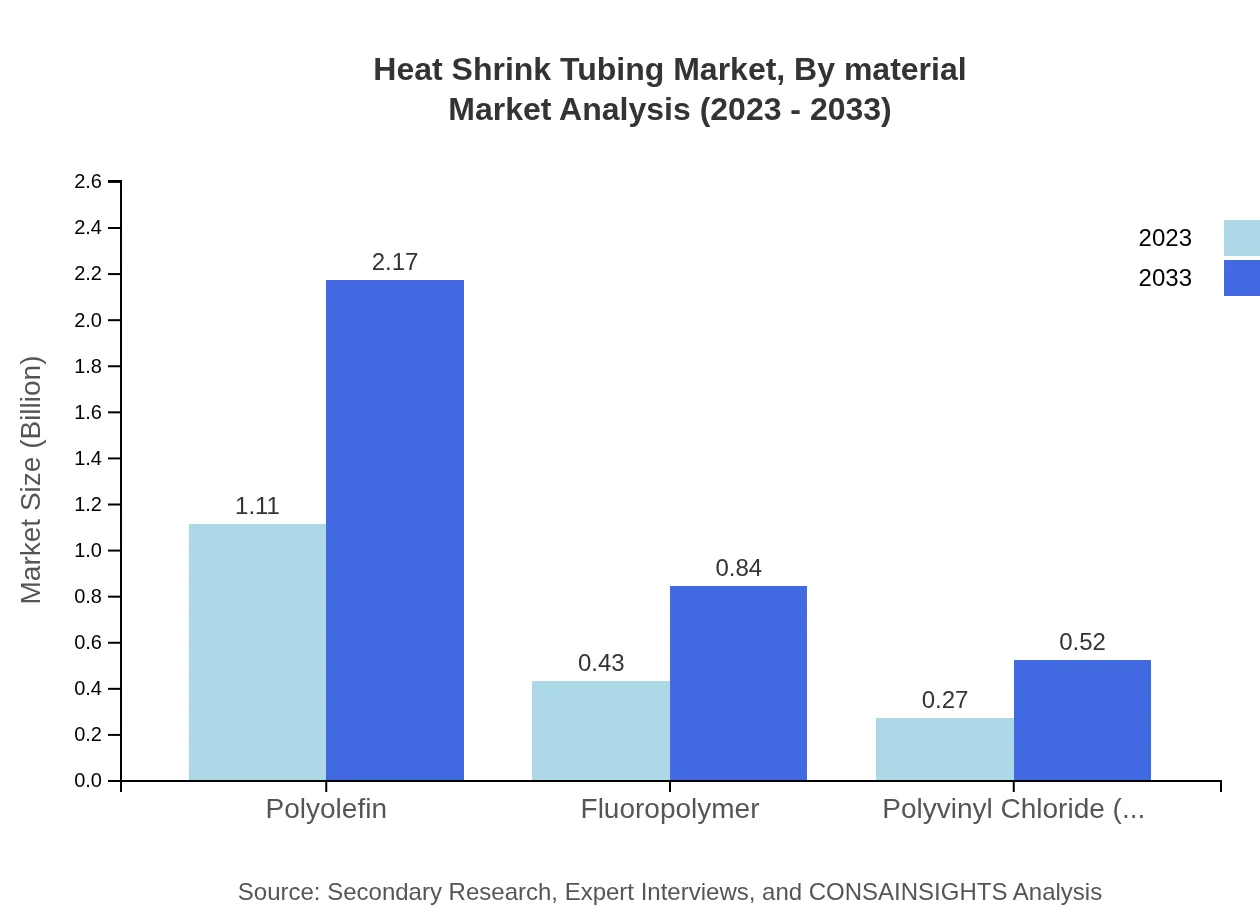

Heat Shrink Tubing Market Analysis By Material

In terms of materials, polyolefin dominates the market with a share of 61.47% in 2023, growing from a market size of $1.11 billion to $2.17 billion by 2033. Fluoropolymer follows, with significant applications in high-performance environments. Standard tubing represents a substantial segment with projected growth that emphasizes the strengths of traditional materials against evolving demands.

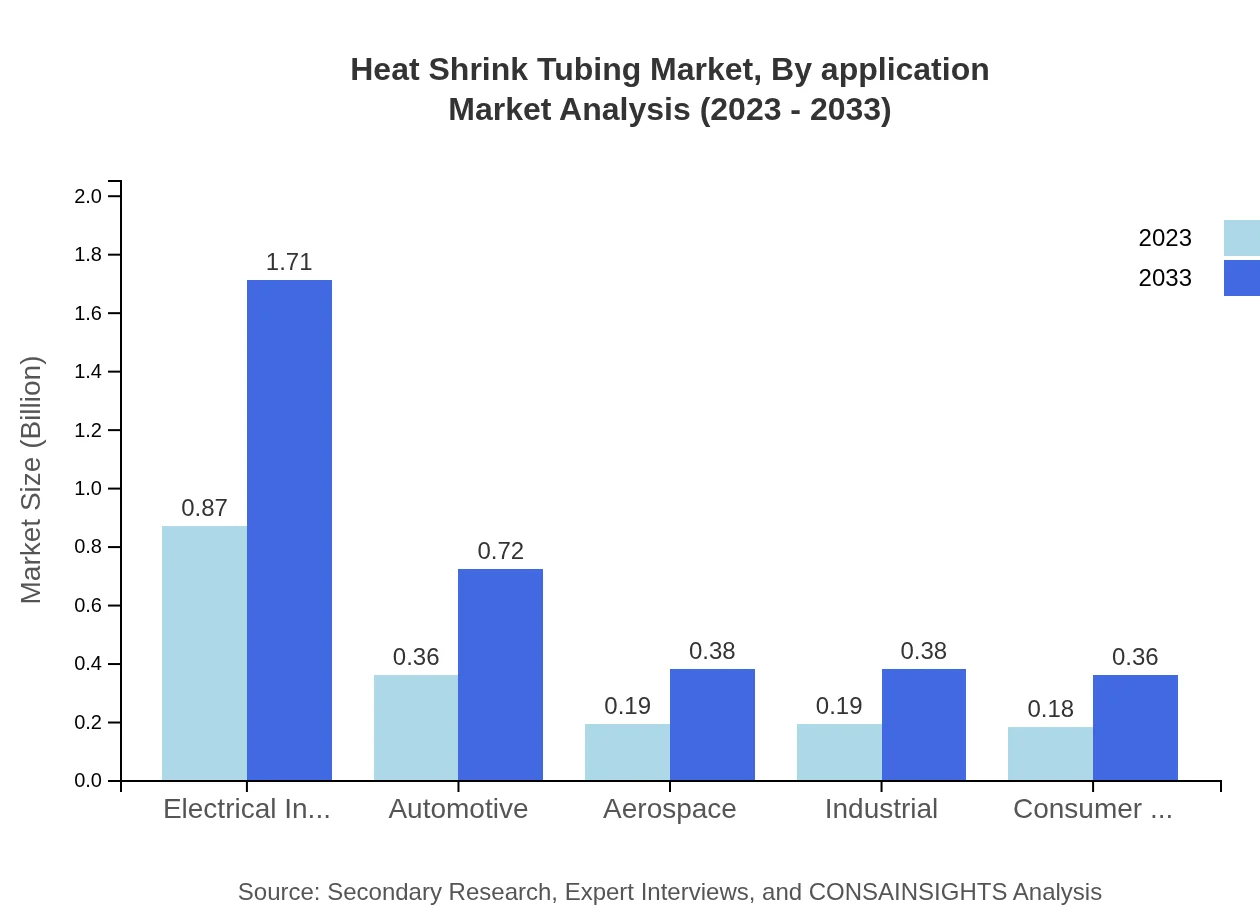

Heat Shrink Tubing Market Analysis By Application

The electrical insulation application holds a major market share of 48.27%, with projections to expand from $0.87 billion in 2023 to $1.71 billion by 2033. Other applications, such as telecommunications, automotive, and medical diagnostics, contribute as well, showcasing the versatility of heat shrink tubing across sectors.

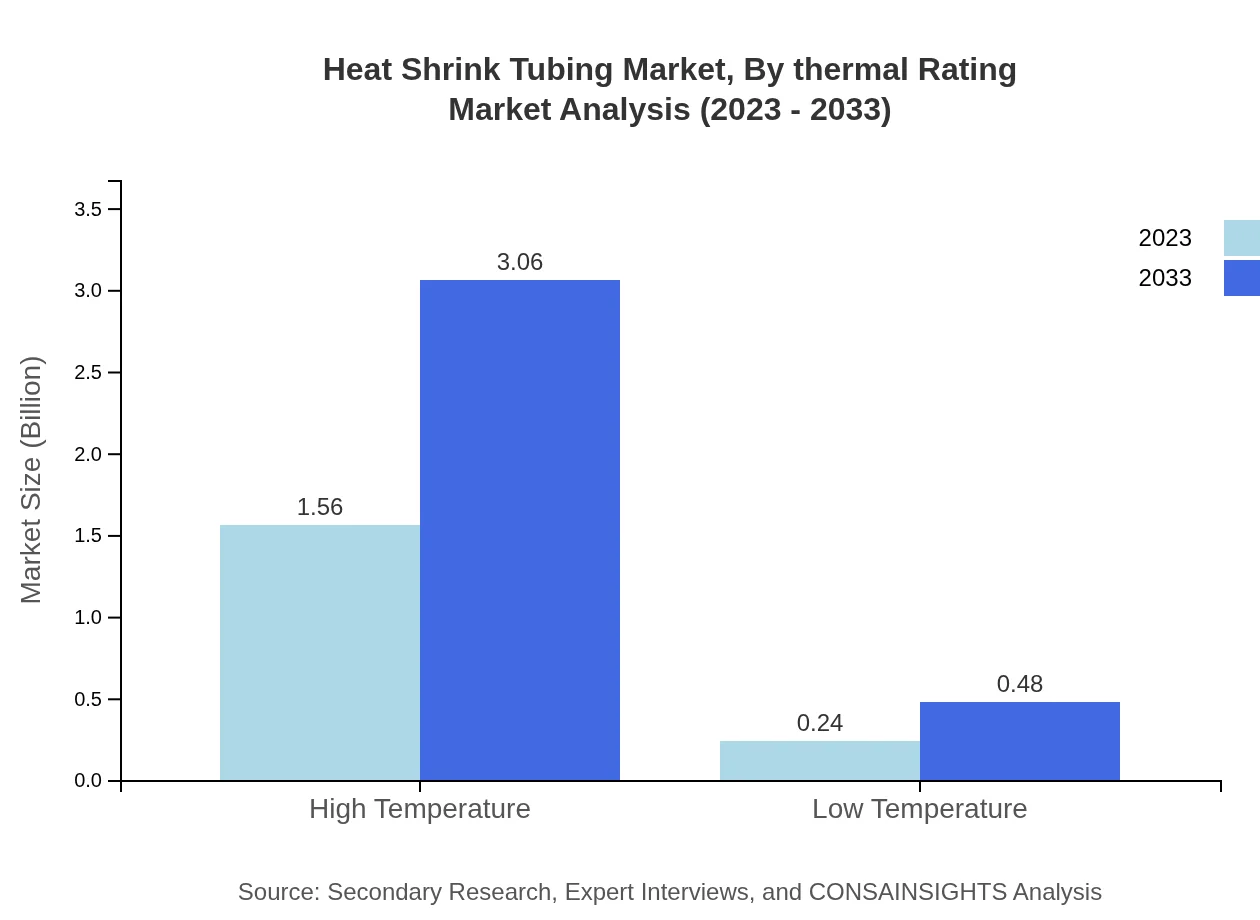

Heat Shrink Tubing Market Analysis By Thermal Rating

High-temperature heat shrink tubing continues to lead the segment, holding an 86.41% market share in 2023 and expected to rise significantly. Low-temperature varieties account for the remaining segment, displaying a steady growth trajectory as applications expand in various sectors.

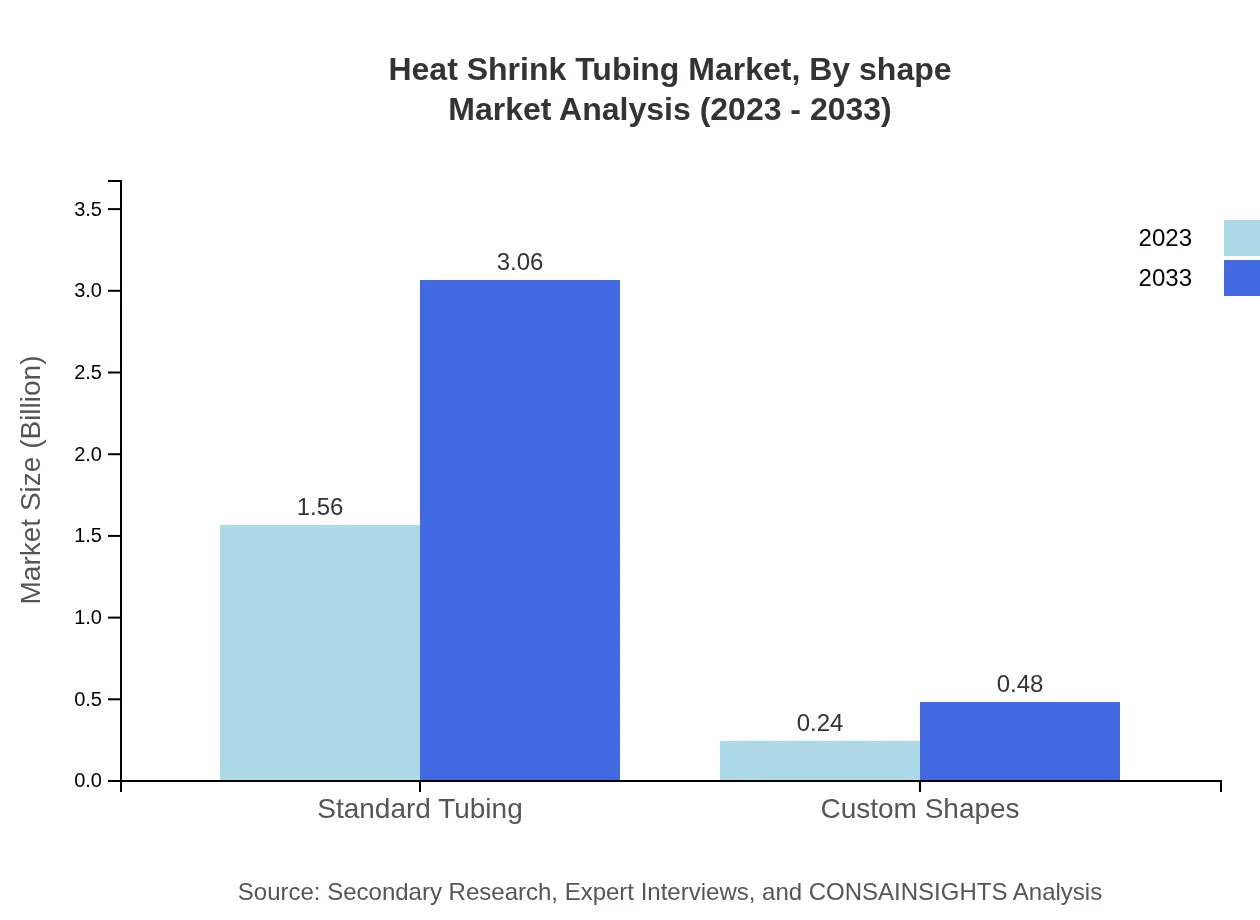

Heat Shrink Tubing Market Analysis By Shape

Standard tubing shapes account for the largest share of the market, with projected values increasing from $1.56 billion in 2023 to $3.06 billion by 2033. Custom-shaped products are also finding their foothold, as industries demand more specialized designs.

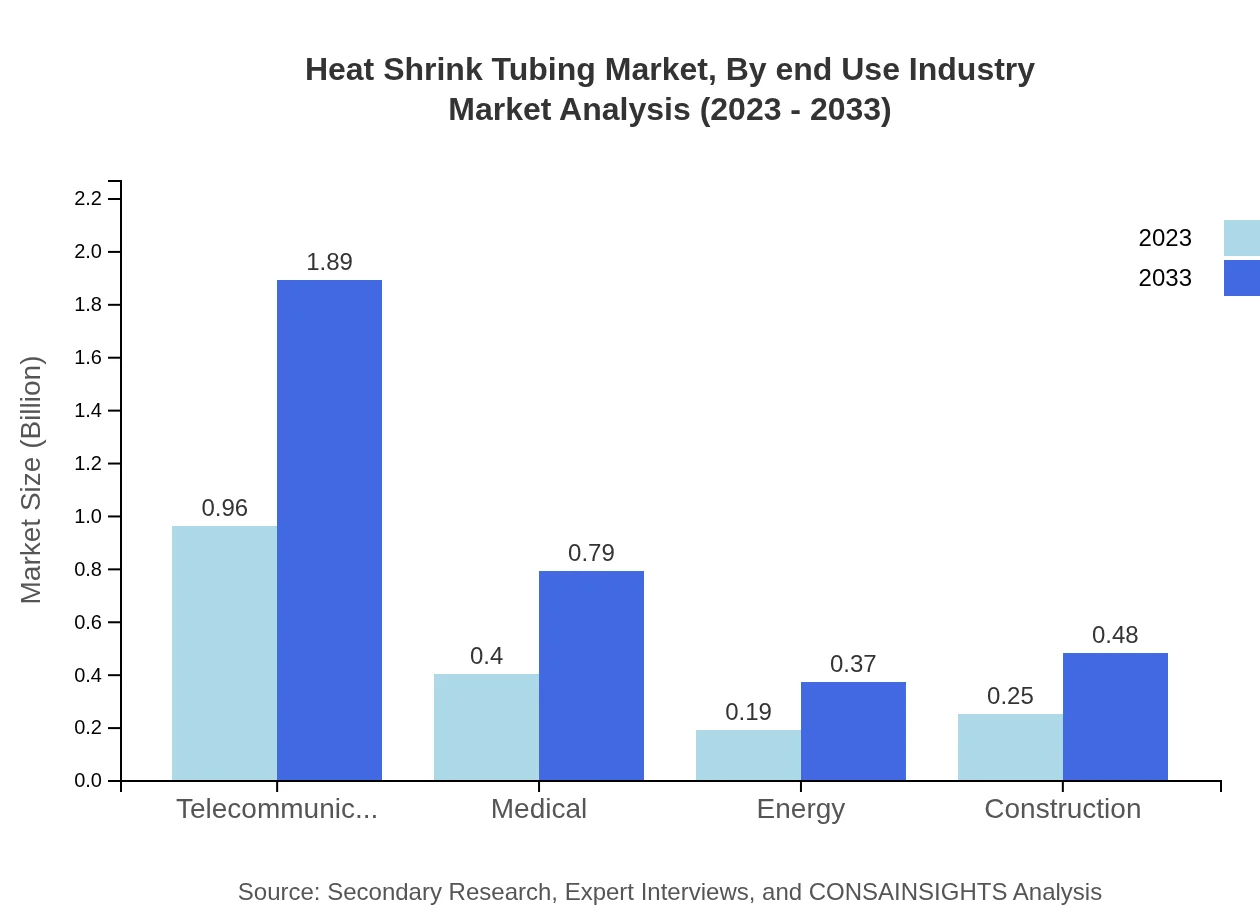

Heat Shrink Tubing Market Analysis By End Use Industry

Key end-use industries for heat shrink tubing include telecommunications, automotive, and medical sectors. Telecommunications dominates with a share of 53.53%, while automotive applications contribute significantly due to rising electrical components in vehicles, enhancing overall safety and efficacy.

Heat Shrink Tubing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Heat Shrink Tubing Industry

3M Company:

A leading player known for its innovative materials and comprehensive product range in heat shrink tubing, 3M serves multiple sectors including automotive and aerospace.TE Connectivity:

Specializes in connectivity and sensor solutions, TE Connectivity enhances the heat shrink tubing industry with high-performance products catered to the automotive and industrial sectors.Amphenol Corporation:

A prominent manufacturer of heat shrink tubing solutions utilized in telecommunications and military applications, focusing on delivering reliable protection and durability.Alpha Wire:

Recognized for its commitment to quality, Alpha Wire provides a range of heat shrink tubing aimed at enhancing wire protection in high-stress environments.We're grateful to work with incredible clients.

FAQs

What is the market size of heat Shrink Tubing?

The global heat-shrink tubing market is valued at approximately $1.8 billion in 2023, and it is projected to grow at a CAGR of 6.8% through 2033, indicating robust demand across various industries.

What are the key market players or companies in the heat Shrink Tubing industry?

Prominent players in the heat-shrink-tubing market include companies specializing in electrical insulation and components, contributing significantly to the innovation and supply in this sector.

What are the primary factors driving the growth in the heat Shrink Tubing industry?

Key growth drivers include the rising demand for electrical insulation, increased industrial automation, and growing trends in consumer electronics and automotive applications, all benefiting from effective sealing and insulation provided by heat-shrink tubing.

Which region is the fastest Growing in the heat Shrink Tubing market?

North America is the fastest-growing region, with market growth from $0.63 billion in 2023 to $1.23 billion in 2033, driven by advancements in automotive and telecommunications sectors, reflecting a strong demand for heat-shrink solutions.

Does ConsaInsights provide customized market report data for the heat Shrink Tubing industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the heat-shrink tubing industry, providing insights that align with business objectives and market dynamics.

What deliverables can I expect from this heat Shrink Tubing market research project?

Deliverables from this project include comprehensive market analysis reports, detailed segment-wise data, regional insights, competitive landscape assessments, and future growth forecasts for the heat-shrink tubing market.

What are the market trends of heat Shrink Tubing?

Current market trends include increasing adoption of polyolefin and fluoropolymer materials, heightened demand in the telecommunications sector, and innovations in product design to cater to specific industrial and consumer needs.