Heavy Duty Connector Market Report

Published Date: 22 January 2026 | Report Code: heavy-duty-connector

Heavy Duty Connector Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the Heavy Duty Connector market, offering comprehensive insights, market size estimates, and growth forecasts for the period from 2023 to 2033. It analyzes trends, segmentation, and regional dynamics, providing a holistic view of the industry's trajectory.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

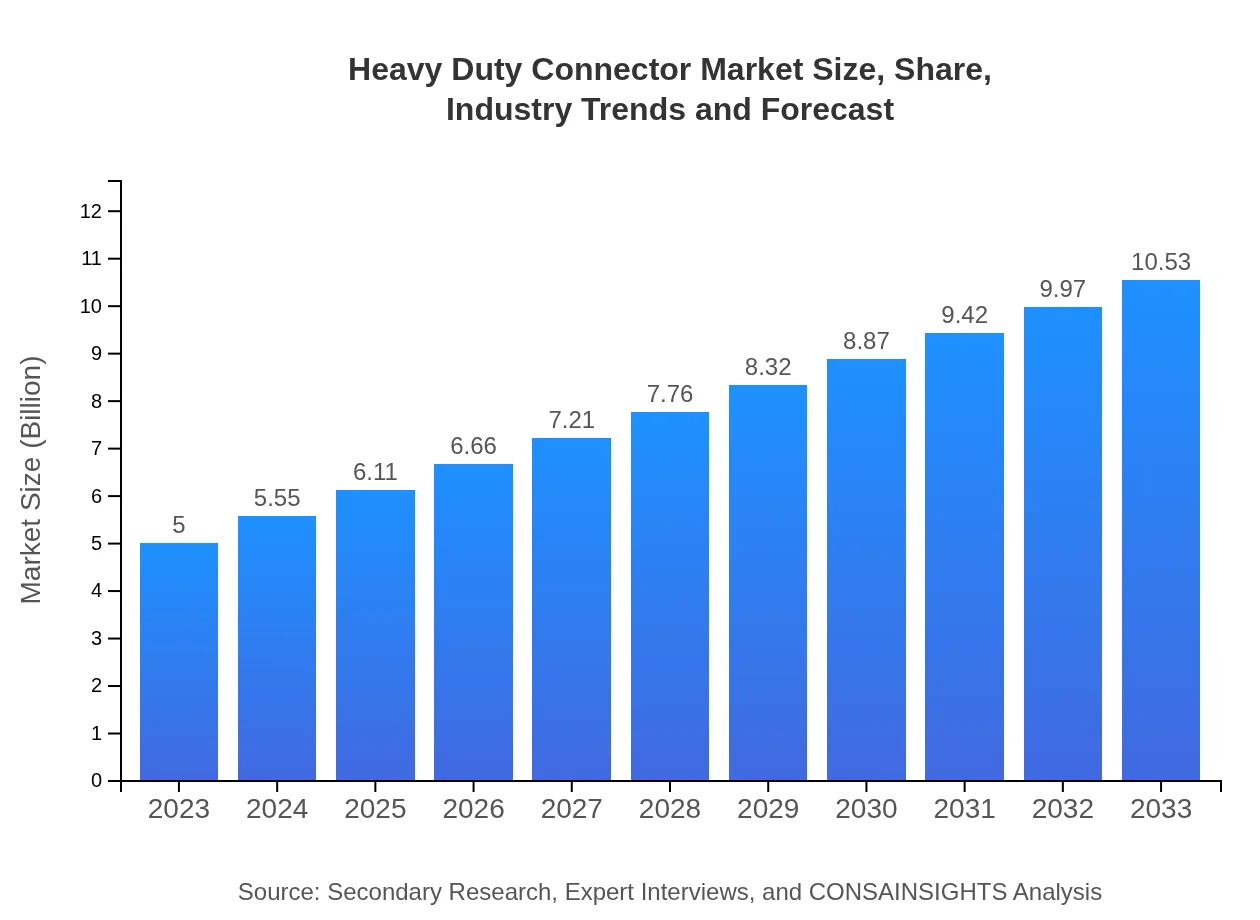

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | TE Connectivity, Molex LLC, Amphenol Corporation, Harting Technology Group |

| Last Modified Date | 22 January 2026 |

Heavy Duty Connector Market Overview

Customize Heavy Duty Connector Market Report market research report

- ✔ Get in-depth analysis of Heavy Duty Connector market size, growth, and forecasts.

- ✔ Understand Heavy Duty Connector's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Heavy Duty Connector

What is the Market Size & CAGR of Heavy Duty Connector market in 2023?

Heavy Duty Connector Industry Analysis

Heavy Duty Connector Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Heavy Duty Connector Market Analysis Report by Region

Europe Heavy Duty Connector Market Report:

Europe is another critical market for heavy duty connectors, expected to increase from $1.48 billion in 2023 to $3.11 billion by 2033. The region's commitment to technological advancements in industry 4.0 and a robust automotive sector contribute significantly to the demand for high-performance connectors.Asia Pacific Heavy Duty Connector Market Report:

The Asia Pacific region is projected to experience significant growth, with the market estimated to reach $2.20 billion by 2033, up from $1.05 billion in 2023. The rapid industrialization and growing manufacturing capabilities in countries like China and India are driving demand for heavy duty connectors, along with initiatives to expand infrastructure in the telecommunications and automotive sectors.North America Heavy Duty Connector Market Report:

North America holds a substantial share of the market, valued at $1.70 billion in 2023 and projected to grow to $3.57 billion by 2033. The demand for heavy duty connectors is being fueled by advancements in electric vehicle technology and automation in manufacturing processes. Moreover, increasing focus on renewable energy sources enhances market potential in the region.South America Heavy Duty Connector Market Report:

In South America, the heavy duty connector market is expected to grow from $0.17 billion in 2023 to $0.36 billion in 2033. The region is seeing increased investments in infrastructure and energy sectors, driving demand for robust connectors that can withstand environmental challenges and operational stress.Middle East & Africa Heavy Duty Connector Market Report:

The Middle East and Africa region's market is forecasted to grow from $0.61 billion in 2023 to $1.28 billion by 2033. The expansion of oil and gas industries, coupled with infrastructural development projects, drives the demand for reliable and durable connector solutions, supporting overall market growth.Tell us your focus area and get a customized research report.

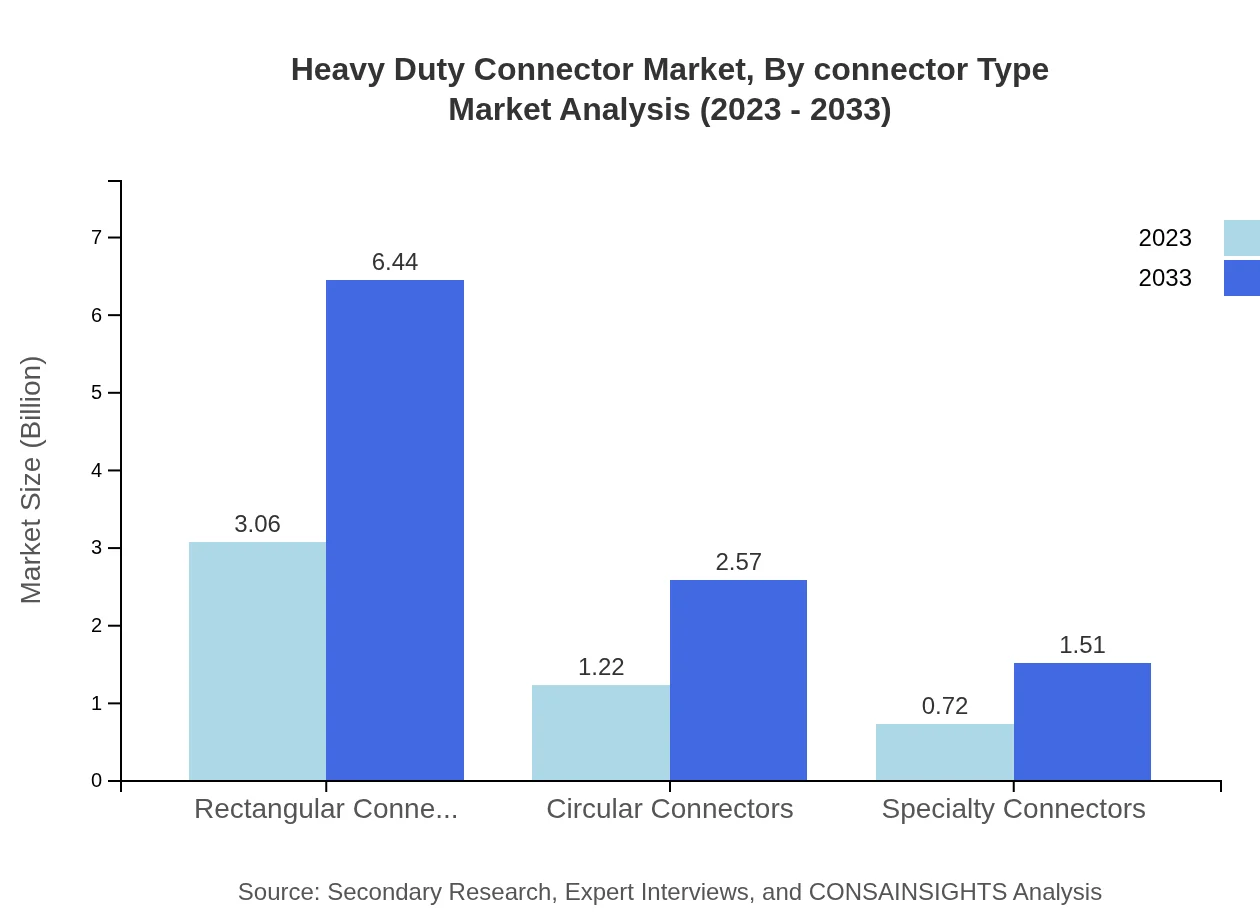

Heavy Duty Connector Market Analysis By Connector Type

The Heavy Duty Connector market can be segmented into various connector types, including rectangular connectors, circular connectors, MIL-SPEC connectors, and specialty connectors. Rectangular connectors dominate the market due to their versatility and reliability, particularly in industrial applications. Circular connectors also hold significant market share, favored for their compact design and high-performance capabilities in automotive and aerospace applications. MIL-SPEC connectors are essential for defense and military applications, ensuring durability and protection under extreme conditions.

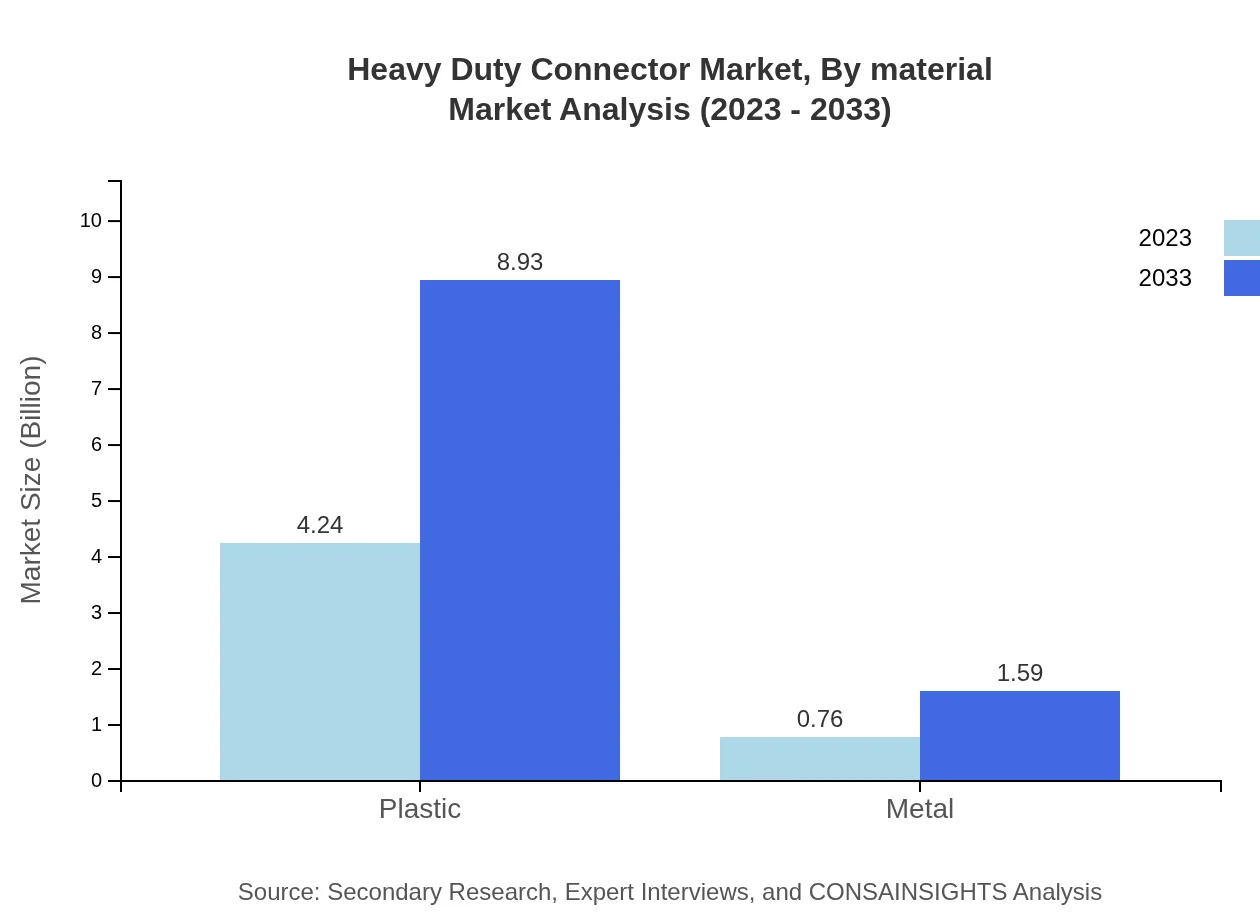

Heavy Duty Connector Market Analysis By Material

The market is segmented by material type into plastic and metal connectors. Plastic connectors are predominantly used due to their lightweight and cost-effective nature, accounting for a substantial share of the market. In contrast, metal connectors are valued for their strength and high conductivity, finding applications in industries that demand robustness, such as aerospace and defense.

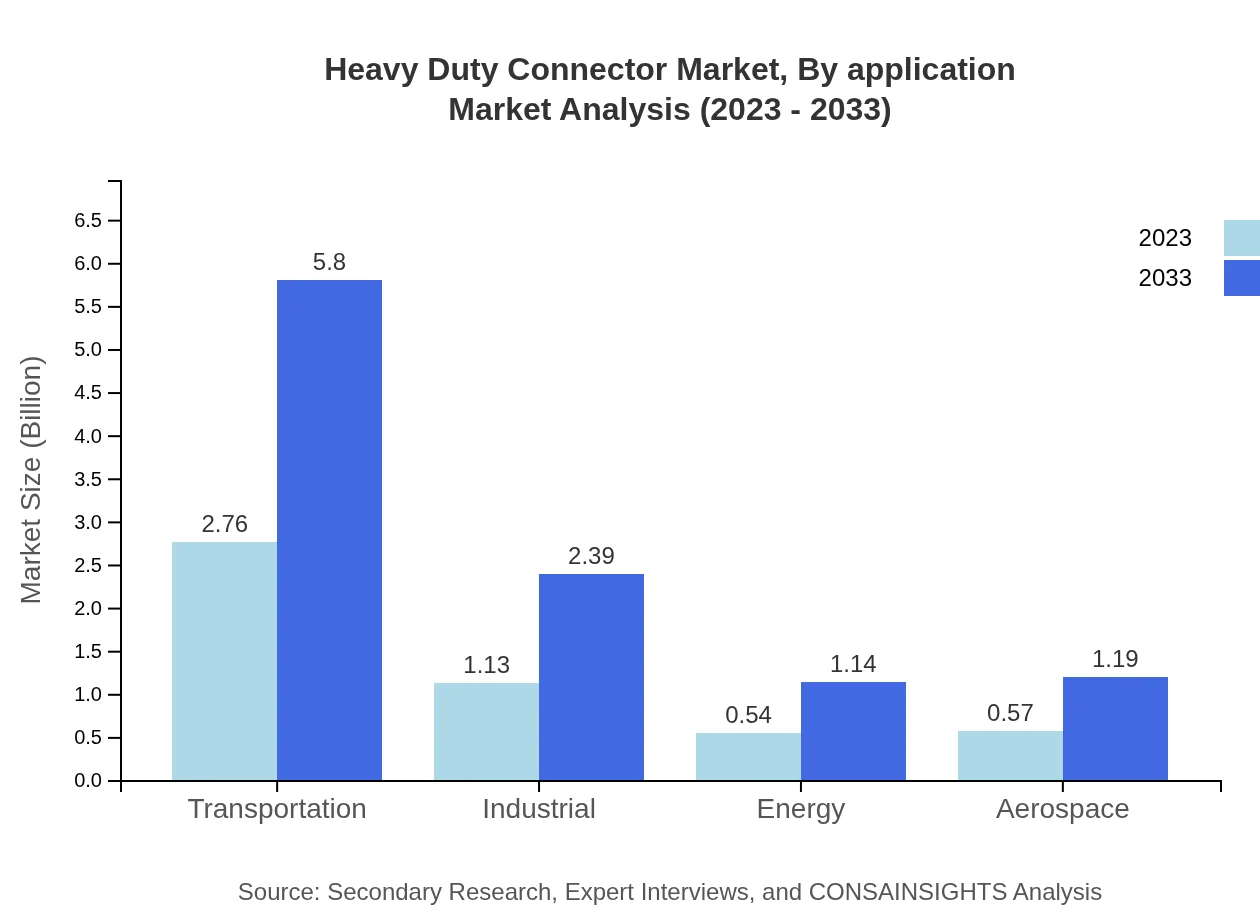

Heavy Duty Connector Market Analysis By Application

Key applications of Heavy Duty Connectors include automotive, telecommunications, defense, and industrial sectors. The automotive sector is the largest end-user, demanding connectors that can withstand vibrations and temperature extremes. Telecommunications follow closely, driven by a robust need for reliable connectivity solutions in infrastructure development.

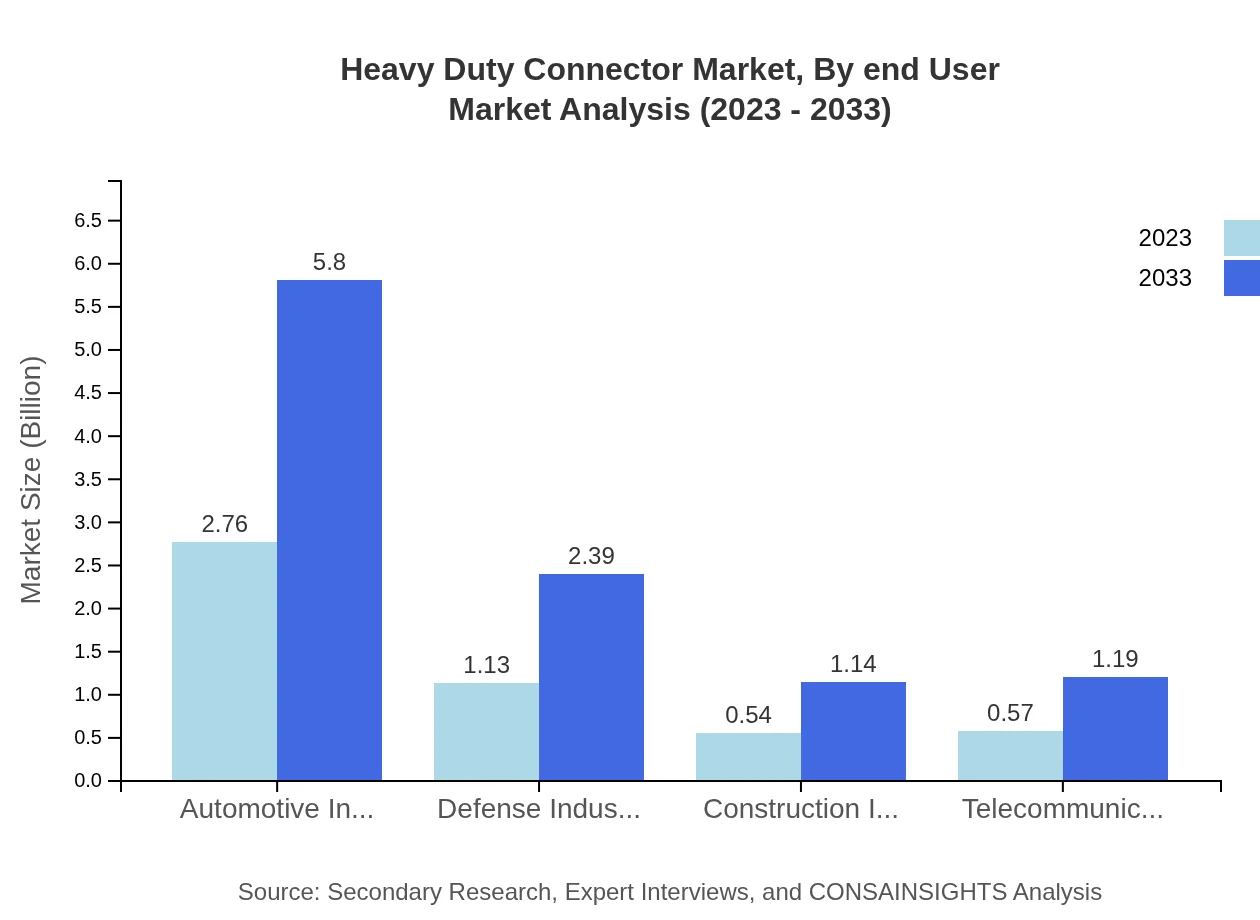

Heavy Duty Connector Market Analysis By End User

End-users of heavy-duty connectors span across various sectors, including automotive, industrial, and military. The automotive industry, representing a major segment, emphasizes the need for high-performance connectors that provide efficient electrical connections while maintaining safety standards. The industrial sector also demonstrates a growing demand for reliable connector solutions to enhance operational efficiency.

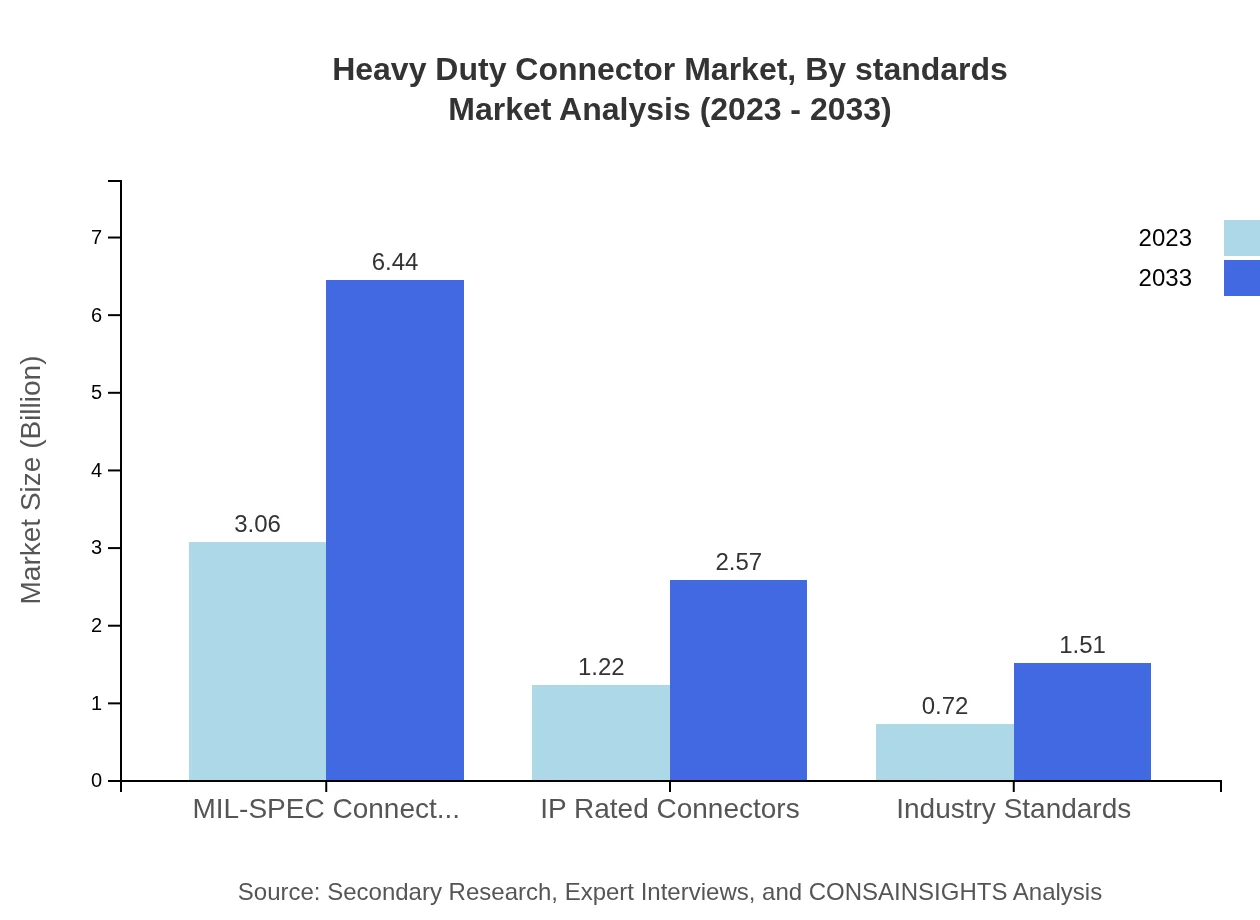

Heavy Duty Connector Market Analysis By Standards

The Heavy Duty Connector market operates under numerous industrial and military standards, including MIL-SPEC and IP ratings. Compliance with these standards is crucial for ensuring product reliability and safety. Products adhering to stringent standards find significant adoption, particularly in defense and aerospace applications where failure is not an option, ensuring a critical growth area for manufacturers.

Heavy Duty Connector Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Heavy Duty Connector Industry

TE Connectivity:

TE Connectivity is a global leader in connectivity solutions, offering a wide range of heavy duty connectors designed for harsh environments. The company's commitment to innovation and advancements in technology ensures high-performance products for various applications.Molex LLC:

Molex LLC specializes in electronic connectors, focusing on heavy duty applications across several industries. Their robust product development and focus on customer solutions have positioned them as a reliable partner in the market.Amphenol Corporation:

Amphenol Corporation is one of the largest manufacturers of connectors, offering a comprehensive portfolio including heavy duty connectors for automotive and industrial markets. Their extensive experience and product reliability drive significant market share.Harting Technology Group:

Harting is known for its high-quality heavy duty connectors used extensively in industrial applications. Their emphasis on sustainability and innovative technologies makes them a preferred choice among many businesses.We're grateful to work with incredible clients.

FAQs

What is the market size of heavy Duty connector?

The heavy-duty connector market is expected to grow from a current size of $5 billion in 2023 to an estimated value by 2033. This growth corresponds to a CAGR of 7.5%, indicating a robust demand over the next decade.

What are the key market players or companies in this heavy Duty connector industry?

The heavy-duty connector market features key players including TE Connectivity, Amphenol, Molex, and Hubbell, renowned for their innovative solutions and competitive strategies. Their combined market presence significantly influences industry dynamics and service delivery.

What are the primary factors driving the growth in the heavy Duty connector industry?

Key factors driving growth in the heavy-duty connector market include increasing automation across industries, the rise of electric vehicles, and stringent safety regulations. Additionally, advancements in connector technology and growing demand for reliable connections are crucial.

Which region is the fastest Growing in the heavy Duty connector?

The Asia Pacific region is the fastest-growing in the heavy-duty connector market, expanding from $1.05 billion in 2023 to $2.20 billion by 2033. This growth is fuelled by industrialization and increasing manufacturing activities in countries like China and India.

Does ConsaInsights provide customized market report data for the heavy Duty connector industry?

Yes, ConsaInsights offers customized market report data tailored to specific client requirements in the heavy-duty connector industry. Clients can obtain in-depth insights and analyses which cater to their unique business objectives.

What deliverables can I expect from this heavy Duty connector market research project?

Expect comprehensive deliverables, including market size analysis, competitive landscape, growth forecasts, segment analysis by industry and region, and insights into key trends. Customized reports can also focus on specific segments or geographic areas.

What are the market trends of heavy Duty connectors?

Market trends for heavy-duty connectors include increasing use in automotive and defense sectors, a shift towards environmentally friendly materials, and a focus on enhanced durability. There is also a growing demand for connectors that meet advanced technological standards.