High Heat Foam Market Report

Published Date: 22 January 2026 | Report Code: high-heat-foam

High Heat Foam Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the High Heat Foam market from 2023 to 2033, detailing market size, trends, growth factors, and regional insights. It aims to offer valuable insights for stakeholders looking to understand market dynamics and future opportunities.

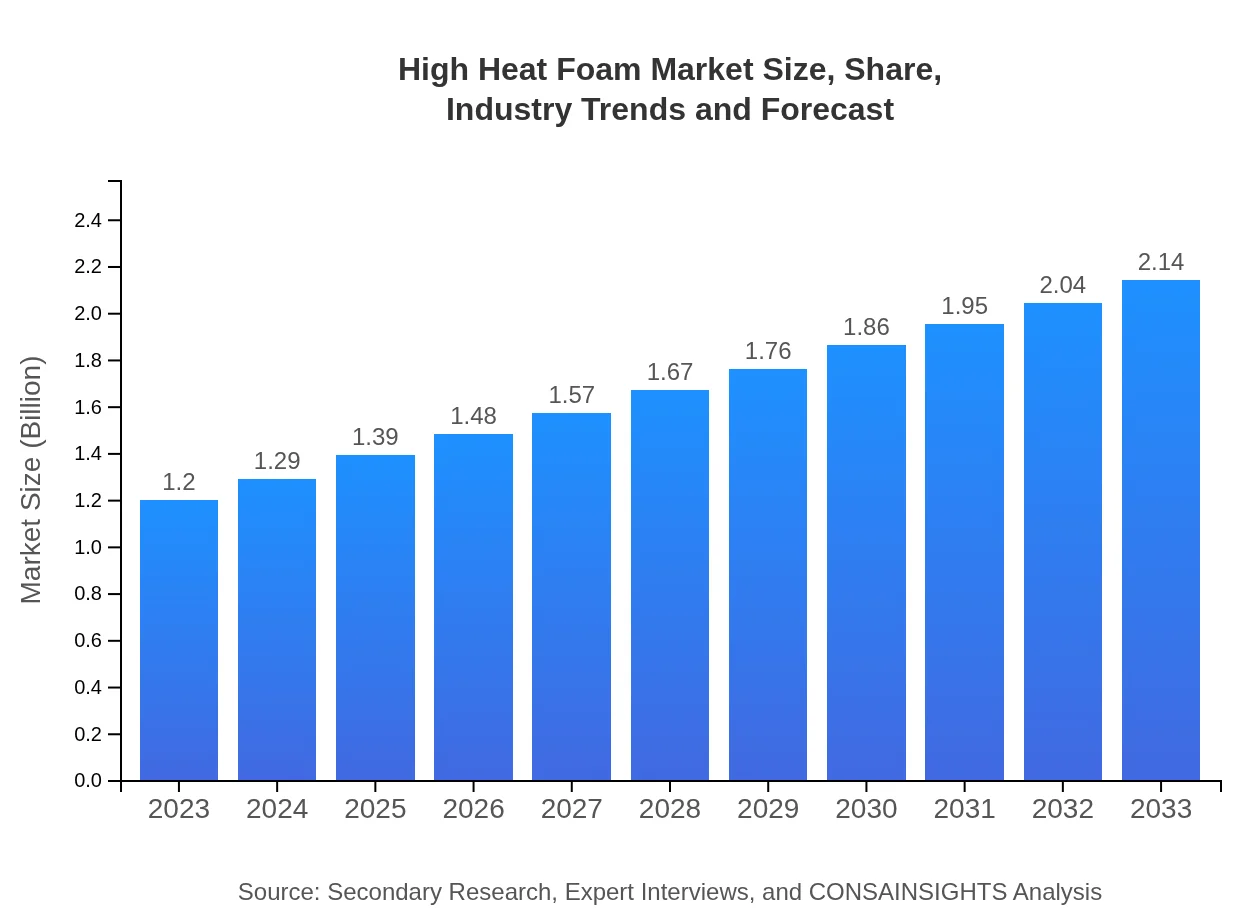

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.20 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $2.14 Billion |

| Top Companies | BASF SE, Huntsman Corporation, Dow Chemical Company, Saint-Gobain, Covestro AG |

| Last Modified Date | 22 January 2026 |

High Heat Foam Market Overview

Customize High Heat Foam Market Report market research report

- ✔ Get in-depth analysis of High Heat Foam market size, growth, and forecasts.

- ✔ Understand High Heat Foam's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in High Heat Foam

What is the Market Size & CAGR of High Heat Foam market in 2023?

High Heat Foam Industry Analysis

High Heat Foam Market Segmentation and Scope

Tell us your focus area and get a customized research report.

High Heat Foam Market Analysis Report by Region

Europe High Heat Foam Market Report:

The European market is projected to increase from $0.36 billion in 2023 to $0.63 billion by 2033. Strong regulatory frameworks aimed at reducing carbon footprints and increasing insulation efficiency significantly contribute to market expansion.Asia Pacific High Heat Foam Market Report:

In the Asia Pacific region, the High Heat Foam market is expected to grow from $0.23 billion in 2023 to $0.41 billion by 2033. This growth is fueled by increasing industrial activities, urbanization, and demands for energy-efficient building solutions. Countries like China and India lead the consumption due to rapid infrastructural developments.North America High Heat Foam Market Report:

North America shows a promising trajectory, starting from $0.41 billion in 2023 to an expected $0.72 billion by 2033. High demand from the automotive and aerospace industries, coupled with the push towards sustainability, drives this growth, supported by robust R&D initiatives.South America High Heat Foam Market Report:

The South American market is anticipated to expand from $0.09 billion in 2023 to $0.16 billion in 2033. The growth is attributed to rising investments in construction projects and industrial sectors, alongside increased awareness of energy efficiency and eco-friendly materials.Middle East & Africa High Heat Foam Market Report:

Growth in the Middle East and Africa is anticipated to increase from $0.12 billion in 2023 to $0.21 billion by 2033, driven by infrastructure developments and the oil and gas sector demanding advanced thermal insulation solutions.Tell us your focus area and get a customized research report.

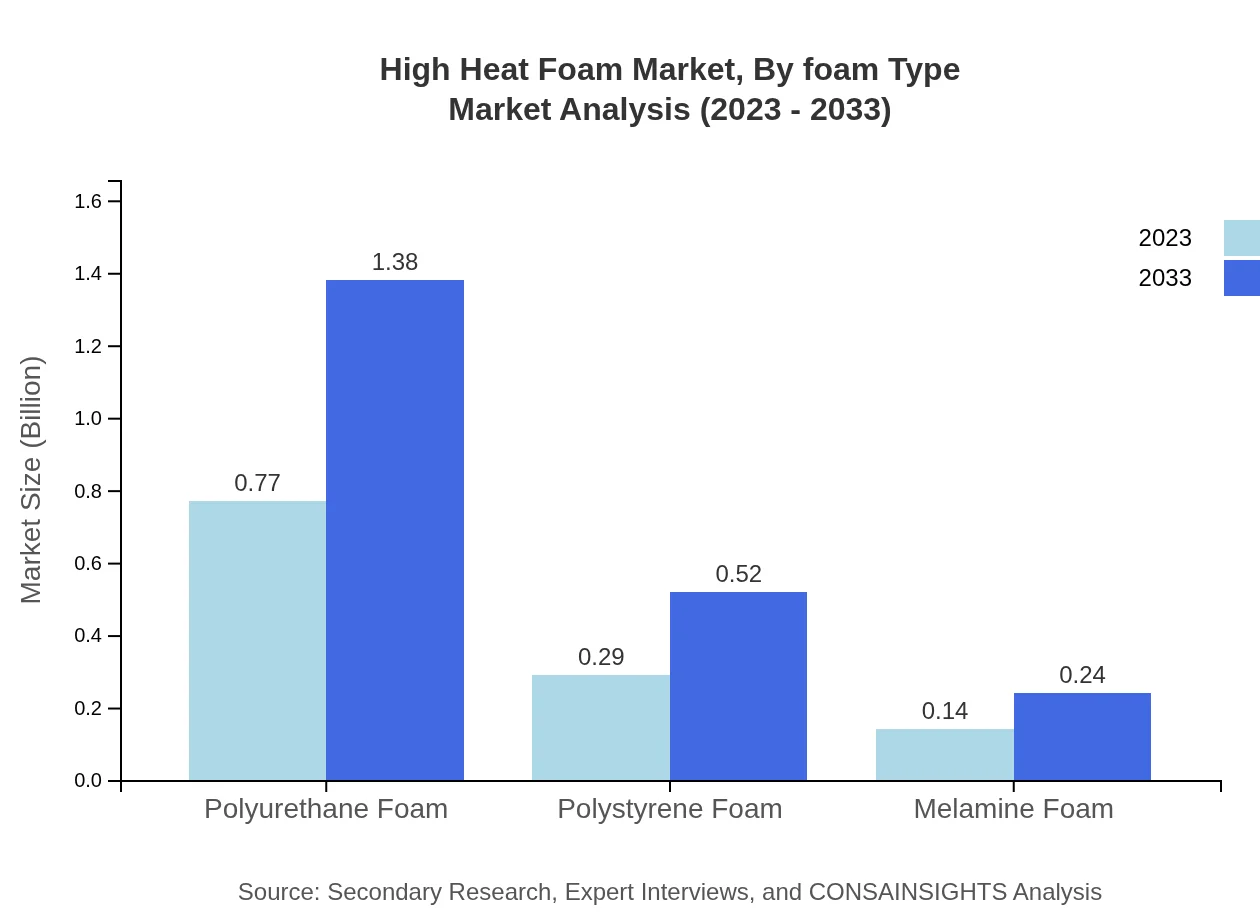

High Heat Foam Market Analysis By Foam Type

The High Heat Foam market is dominated by polyurethane foam, expected to expand from $0.77 billion in 2023 to $1.38 billion in 2033, representing 64.34% market share. Polystyrene foam also enjoys significant traction, expected to rise from $0.29 billion to $0.52 billion, maintaining a 24.29% share. Melamine foam sees a rise from $0.14 billion to $0.24 billion, holding an 11.37% share, influenced largely by its application in acoustic and insulation materials.

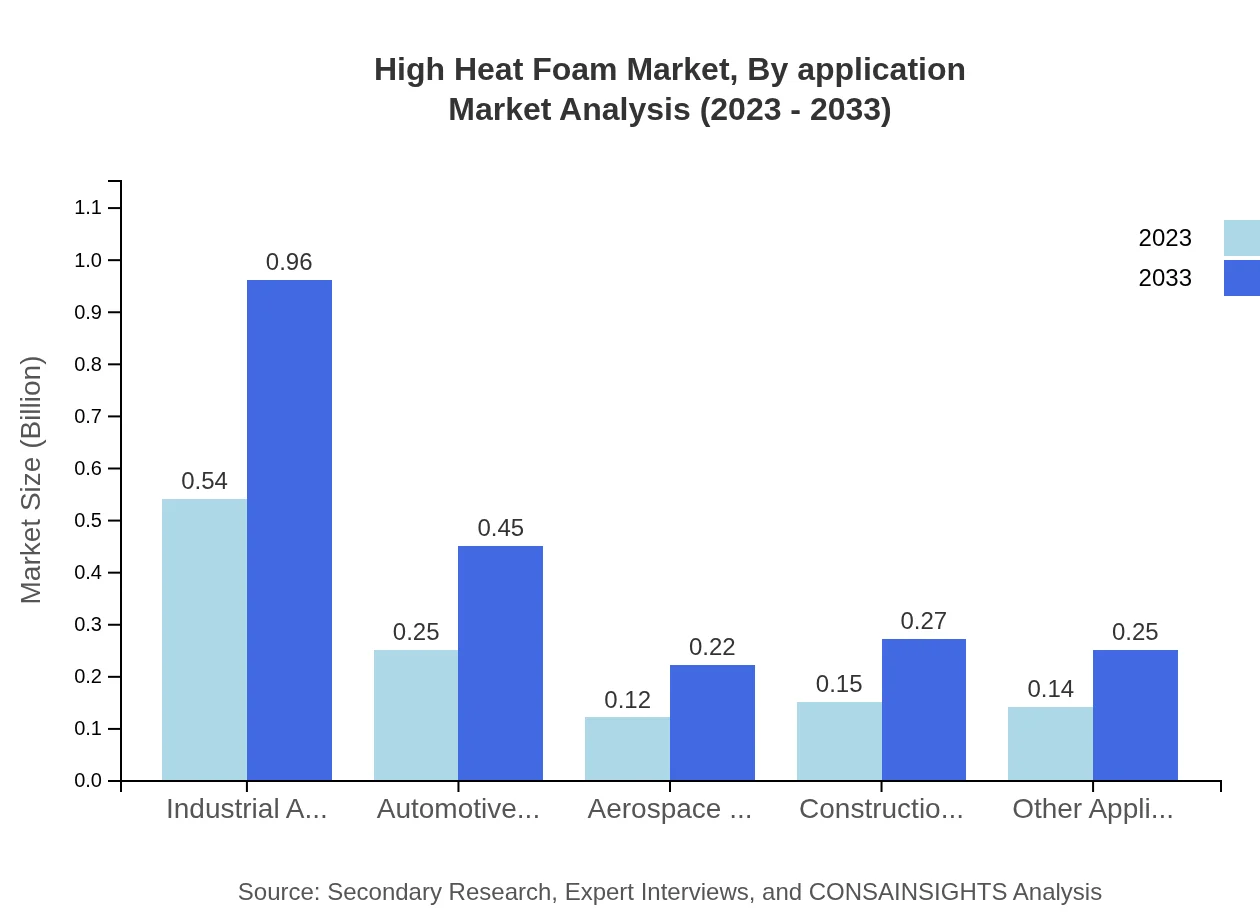

High Heat Foam Market Analysis By Application

In terms of applications, industrial applications dominate the market, with an increase from $0.54 billion in 2023 to $0.96 billion in 2033, representing a 44.82% share. Automotive applications follow closely, growing from $0.25 billion to $0.45 billion with a share of 20.97%. Significant contributions also arise from aerospace (10.21% share), construction (12.48% share), and other applications (11.52% share) showing promising growth patterns.

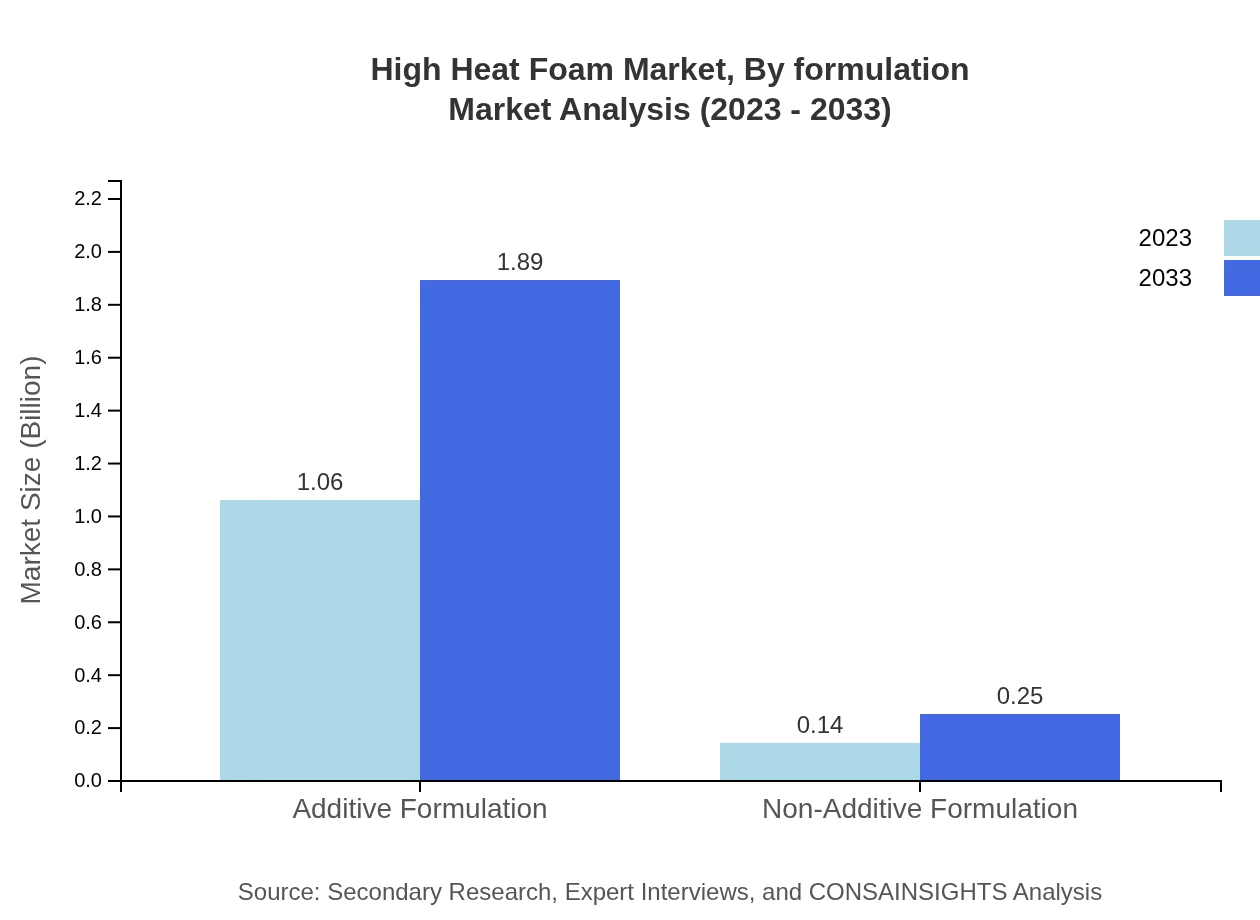

High Heat Foam Market Analysis By Formulation

The High Heat Foam market is primarily segmented by formulation type, with the additive formulation segment leading the market at $1.06 billion in 2023, projected to grow to $1.89 billion in 2033. This segment represents an 88.52% market share, driven by technological enhancements. Non-additive formulations hold a smaller share but are expected to grow from $0.14 billion to $0.25 billion, making up 11.48% of the market.

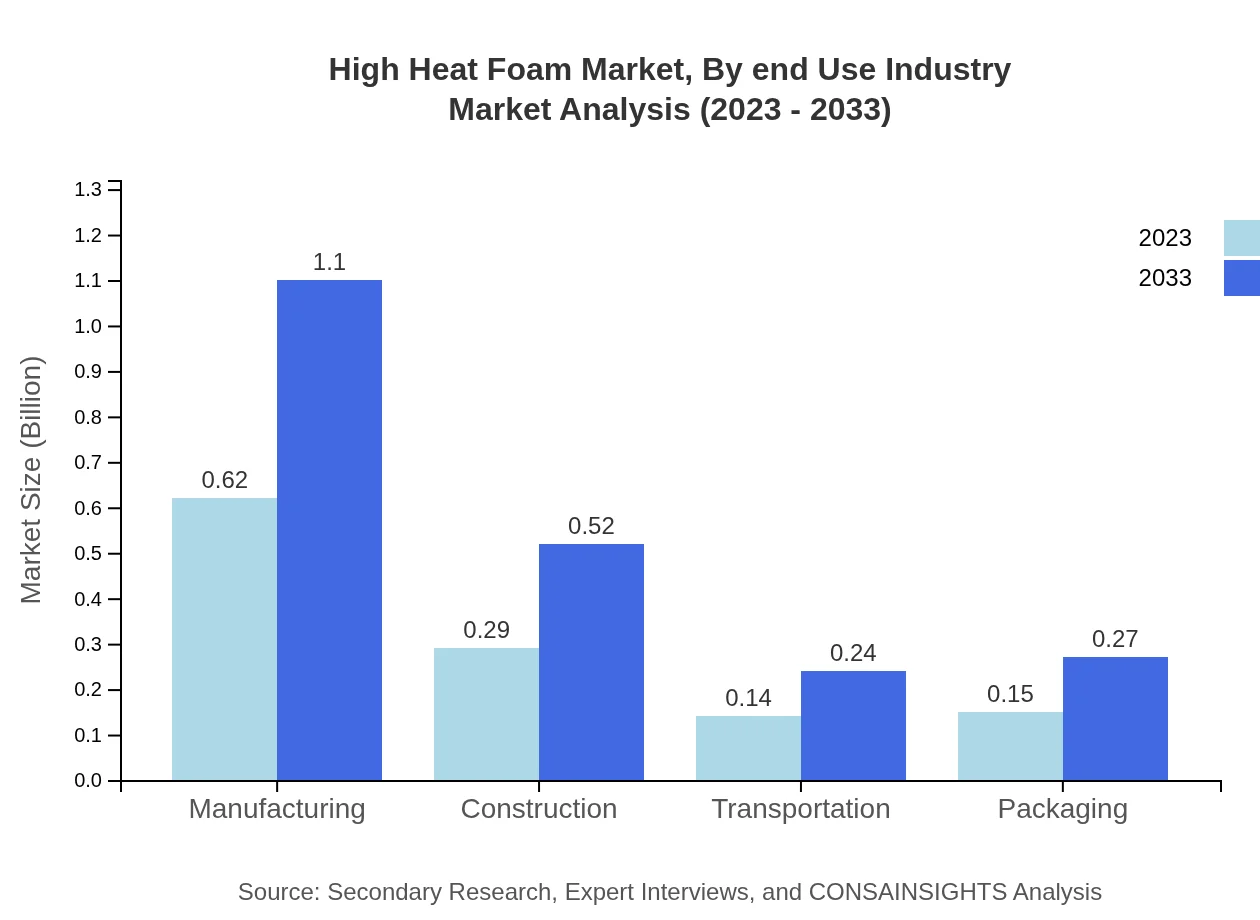

High Heat Foam Market Analysis By End Use Industry

In the end-use industry segment, manufacturing applications dominate with a total market size of $0.62 billion in 2023 growing to $1.10 billion by 2033, comprising a share of 51.62%. Construction and transportation industries demonstrate growth trajectories from $0.29 billion to $0.52 billion and $0.14 billion to $0.24 billion respectively, optimizing thermal management requirements across infrastructures.

High Heat Foam Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in High Heat Foam Industry

BASF SE:

BASF SE is a leading chemical company offering innovative foam solutions known for their thermally effective insulation products across numerous industries.Huntsman Corporation:

Huntsman Corporation specializes in advanced materials and additives, providing tailored foam products that meet high-performance requirements in extreme environments.Dow Chemical Company:

Dow Chemical Company is recognized for its extensive portfolio in polyurethane foams, focusing on sustainability and energy efficiency within high heat applications.Saint-Gobain:

Saint-Gobain produces a variety of insulation solutions including advanced foam materials for construction and industrial applications, emphasizing performance and eco-friendliness.Covestro AG:

Covestro AG is renowned for developing high-performance polycarbonate and polyurethane foams, utilized in automotive and construction sectors, ensuring rigorous quality standards.We're grateful to work with incredible clients.

FAQs

What is the market size of high Heat Foam?

The high-heat-foam market is projected to reach approximately $1.2 billion by 2033, growing at a CAGR of 5.8%. The significant growth reflects increasing demand in industries such as automotive, aerospace, and construction.

What are the key market players or companies in this high Heat Foam industry?

Key players in the high-heat-foam market include companies specializing in polymer manufacturing, such as BASF, Huntsman Corporation, and Dow Chemical. These firms are known for innovative foam solutions catering to industrial and consumer needs.

What are the primary factors driving the growth in the high Heat Foam industry?

Growth in the high-heat-foam industry is driven by rising demand for lightweight, thermal-insulating materials in the automotive and aerospace sectors, increased energy efficiency regulations, and expanding construction activities globally.

Which region is the fastest Growing in the high Heat Foam?

The North American region is the fastest-growing market, projected to increase from $0.41 billion in 2023 to $0.72 billion by 2033. The region's growth is influenced by advancements in automotive and aerospace technologies.

Does ConsaInsights provide customized market report data for the high Heat Foam industry?

Yes, ConsaInsights offers customized market report data tailored to specific industry needs within the high-heat-foam sector. This includes detailed analysis based on geography, application, and market trends.

What deliverables can I expect from this high Heat Foam market research project?

Deliverables from the high-heat-foam market research project include detailed market analysis reports, forecasts by segment and region, insights on competitive landscape, and key market trends affecting future growth.

What are the market trends of high Heat Foam?

Current trends in the high-heat-foam market include the increasing adoption of sustainable and recyclable materials, advancements in foam technology for enhanced performance, and rising focus on energy efficiency in industrial applications.