High Pressure Processing Equipment Market Report

Published Date: 22 January 2026 | Report Code: high-pressure-processing-equipment

High Pressure Processing Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the High Pressure Processing Equipment market from 2023 to 2033, offering insights into market size, growth trends, competitive landscape, and regional developments to facilitate informed strategic decisions.

| Metric | Value |

|---|---|

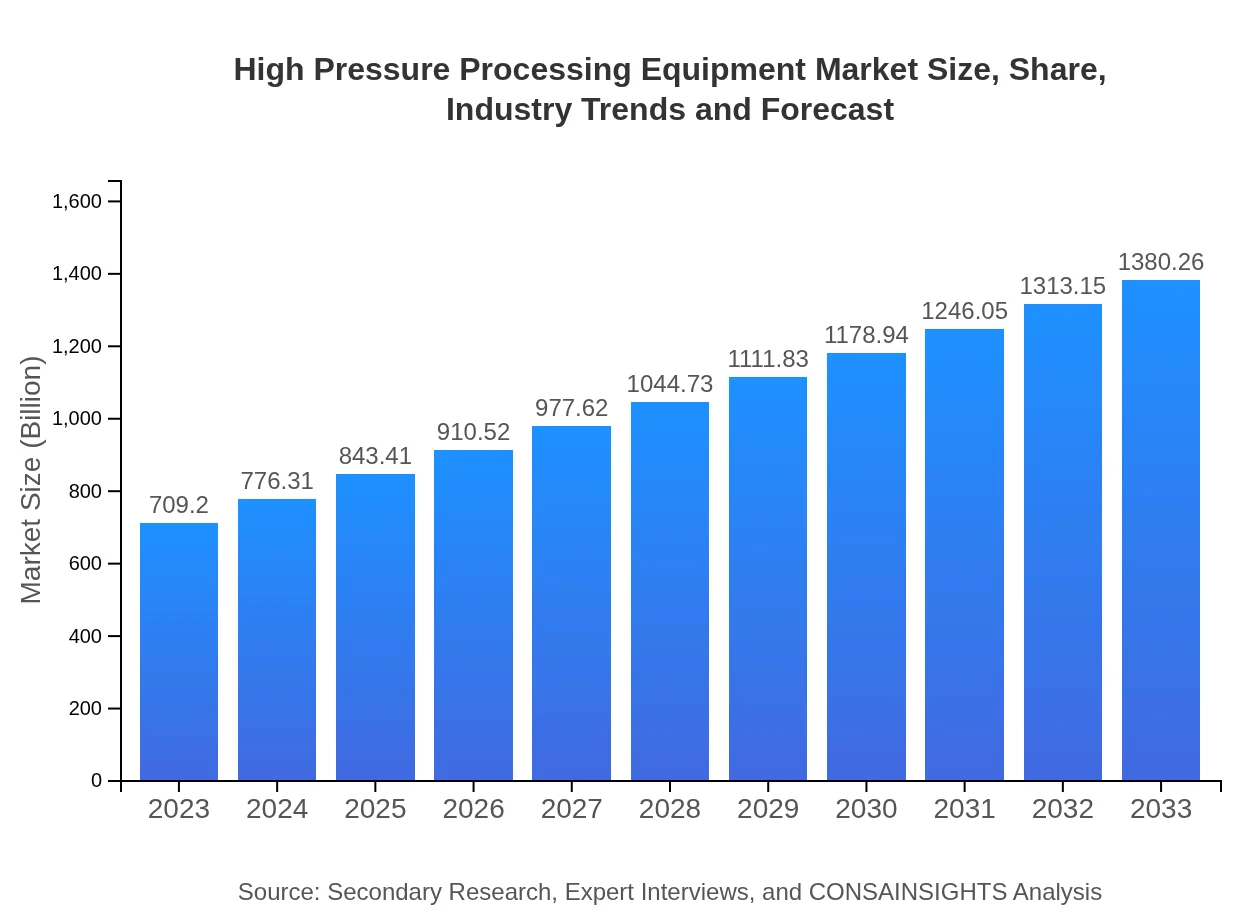

| Study Period | 2023 - 2033 |

| 2023 Market Size | $709.20 Million |

| CAGR (2023-2033) | 6.7% |

| 2033 Market Size | $1380.26 Million |

| Top Companies | Hiperbaric, Avure Technologies, Kobe Steel, Ltd., Eagle Product Inspection |

| Last Modified Date | 22 January 2026 |

High Pressure Processing Equipment Market Overview

Customize High Pressure Processing Equipment Market Report market research report

- ✔ Get in-depth analysis of High Pressure Processing Equipment market size, growth, and forecasts.

- ✔ Understand High Pressure Processing Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in High Pressure Processing Equipment

What is the Market Size & CAGR of High Pressure Processing Equipment market in 2023?

High Pressure Processing Equipment Industry Analysis

High Pressure Processing Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

High Pressure Processing Equipment Market Analysis Report by Region

Europe High Pressure Processing Equipment Market Report:

Europe's market is also significant, valued at $179.43 million in 2023 and projected to reach $349.20 million by 2033, driven by high consumer demand for safe and naturally preserved food products, supported by regulatory standards.Asia Pacific High Pressure Processing Equipment Market Report:

In the Asia Pacific region, the market is expected to witness significant growth, driven by rising urbanization and the demand for processed foods. In 2023, the market size is approximately $146.88 million and is projected to reach $285.85 million by 2033, fueled by growing health awareness and improving food safety standards.North America High Pressure Processing Equipment Market Report:

North America holds the largest share of the market, valued at $274.89 million in 2023. With a projected increase to $534.99 million by 2033, the region's growth is supported by stringent food safety regulations and innovative food processing technologies.South America High Pressure Processing Equipment Market Report:

The South American market is relatively smaller, with a value of $13.62 million in 2023, projected to grow to $26.50 million by 2033. The growth is primarily due to the increasing domestic consumption of processed food products in countries like Brazil and Argentina.Middle East & Africa High Pressure Processing Equipment Market Report:

The Middle East and Africa region exhibits growth potential, with the market valued at $94.39 million in 2023, expected to grow to $183.71 million by 2033. The upsurge is fueled by a growing food processing industry and increasing investments in food safety technologies.Tell us your focus area and get a customized research report.

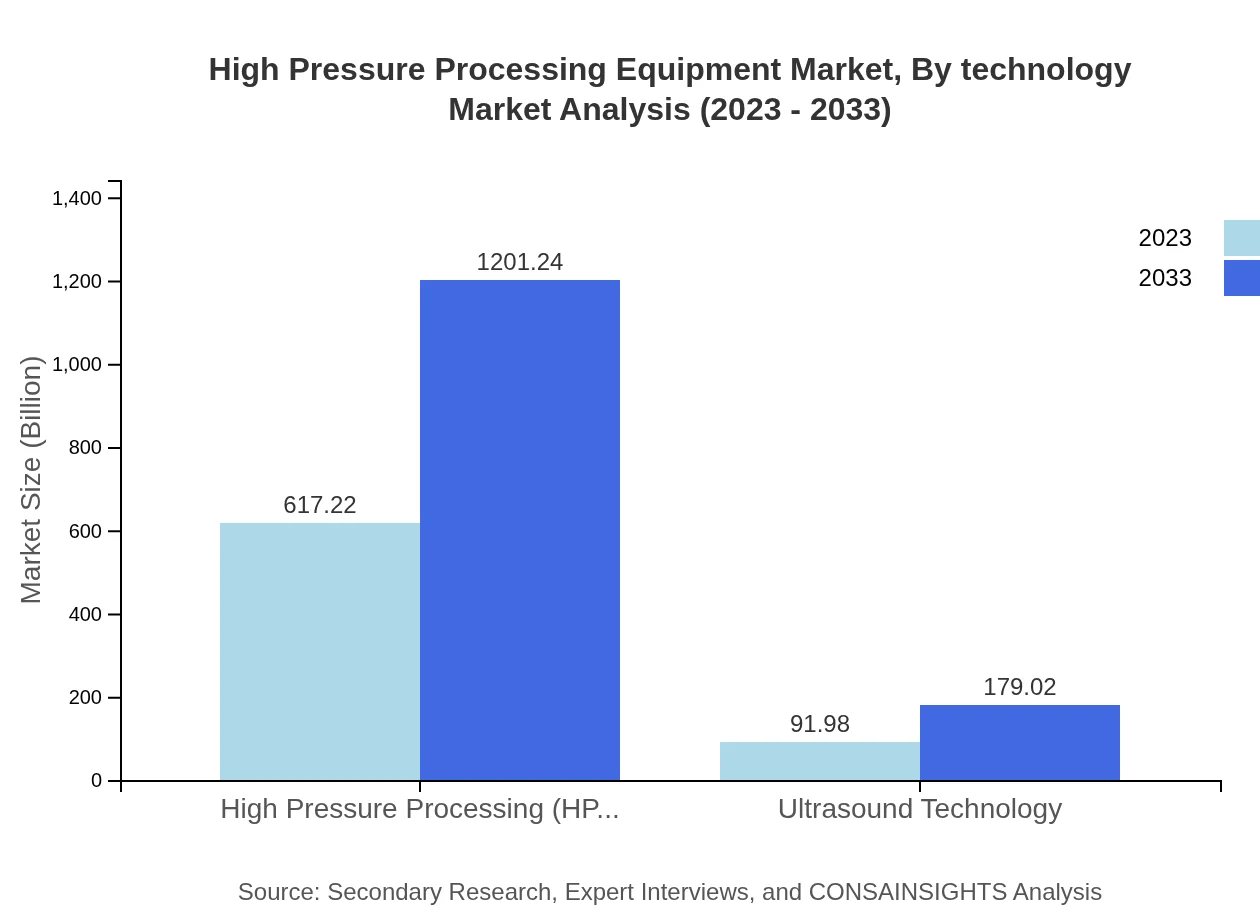

High Pressure Processing Equipment Market Analysis By Technology

The High Pressure Processing Equipment market, segmented by technology, includes Manual Systems and Automated Systems. The market for automated systems is growing rapidly, projected to increase from $476.80 million in 2023 to $927.95 million in 2033, as manufacturers opt for efficiency and consistency in production.

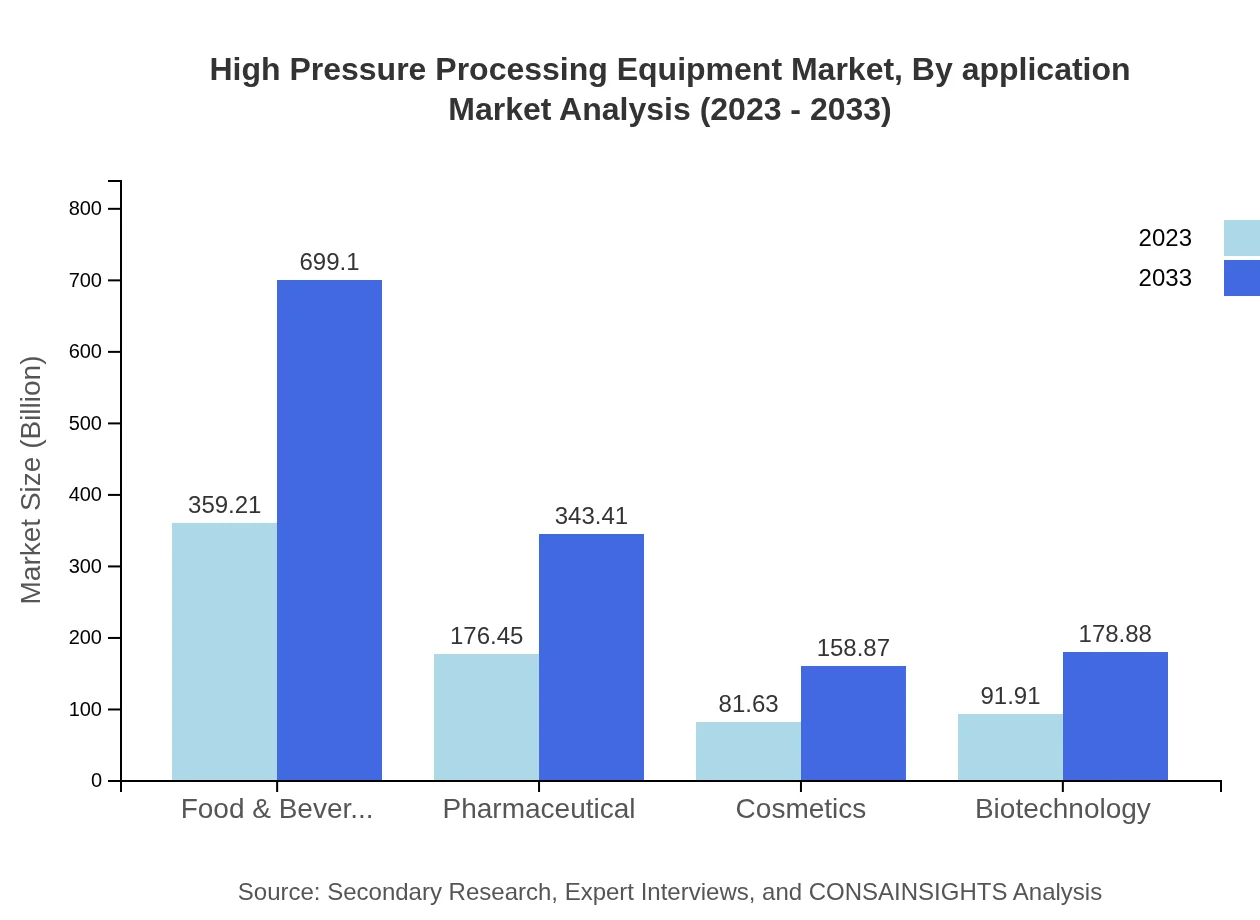

High Pressure Processing Equipment Market Analysis By Application

In terms of application, the food and beverage sector dominates the market, accounting for a share of 67.23%. The market's value is set to grow from $476.80 million in 2023 to $927.95 million by 2033 as HPP continues to gain traction in producing safe and high-quality food products.

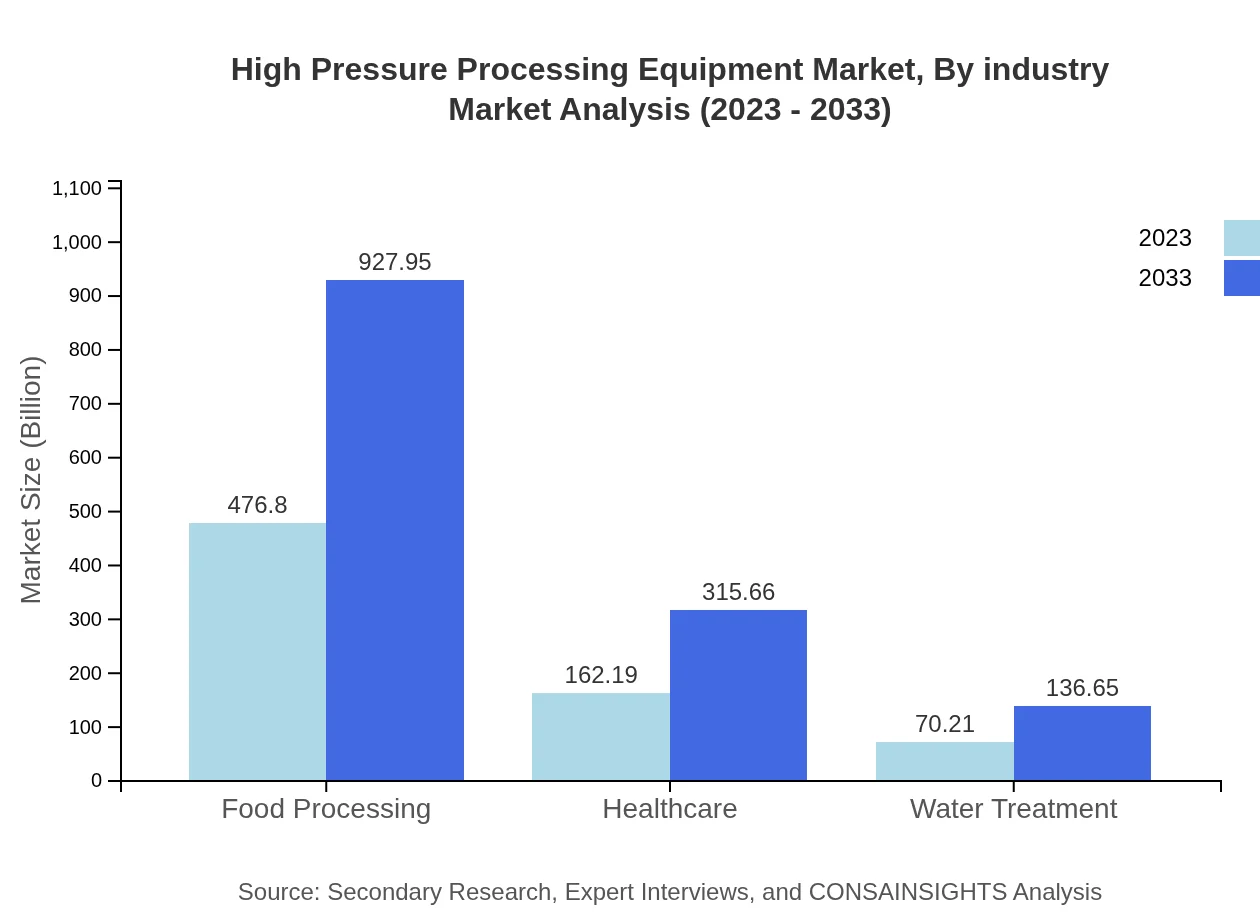

High Pressure Processing Equipment Market Analysis By Industry

The healthcare industry is also a key segment, currently valued at $162.19 million in 2023 and predicted to rise to $315.66 million by 2033, indicating a strong demand for HPP in pharmaceutical applications due to its effectiveness in maintaining product quality.

High Pressure Processing Equipment Market Analysis By End User

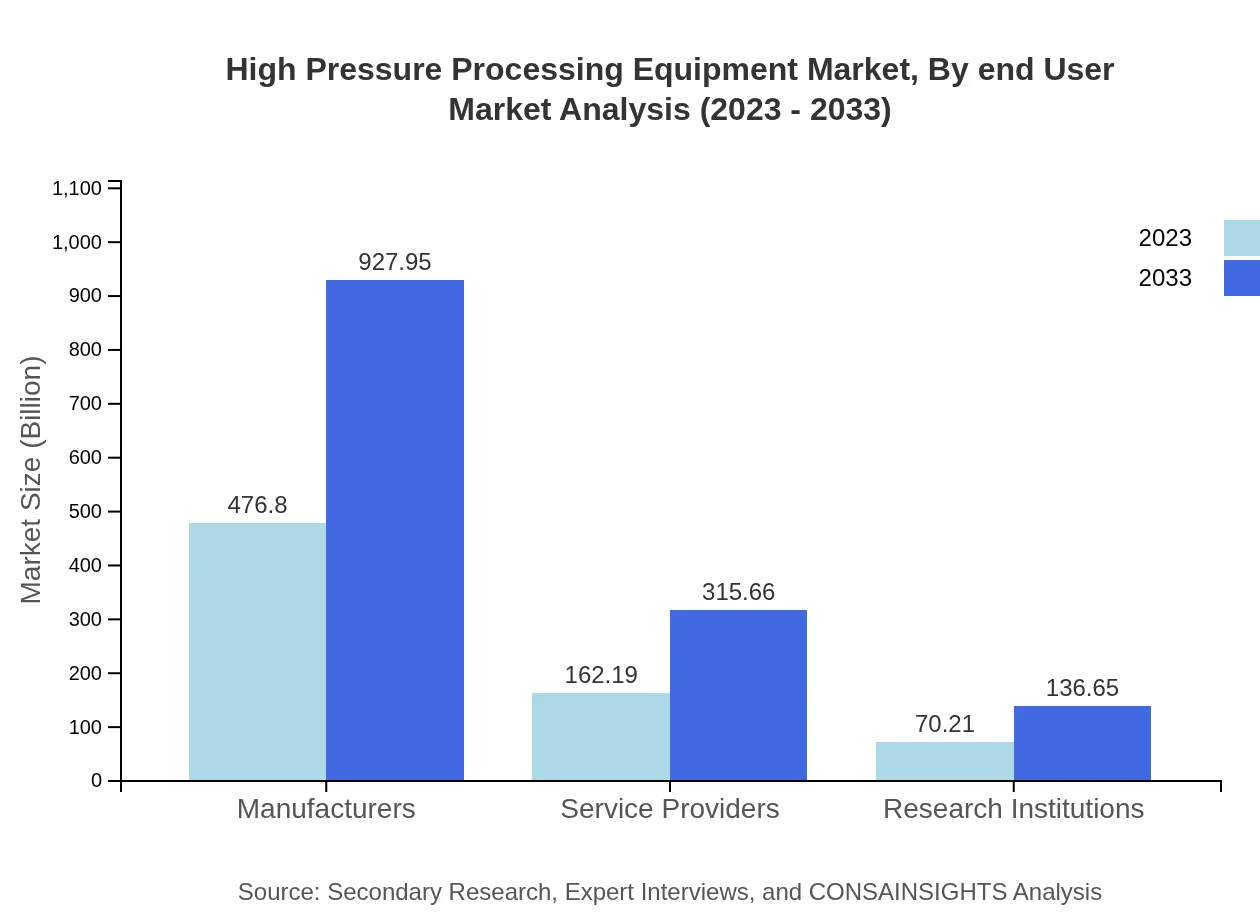

The end-user segment shows that manufacturers lead the market with a current size of $476.80 million, expected to grow to $927.95 million by 2033. Meanwhile, service providers and research institutions are also significant contributors, promoting diverse applications of high pressure processing technology across industries.

High Pressure Processing Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in High Pressure Processing Equipment Industry

Hiperbaric:

A leading manufacturer in the HPP market, Hiperbaric specializes in high-pressure technology equipment for the food industry, providing innovative solutions to enhance food safety and quality.Avure Technologies:

Avure Technologies is known for its pioneering role in developing high-pressure equipment and systems, serving the food, beverage, and life sciences sectors with advanced packaging solutions.Kobe Steel, Ltd.:

Kobe Steel manufactures HPP equipment and focuses on developing various high-pressure technologies, contributing significantly to efficiency improvements across multiple applications.Eagle Product Inspection:

Eagle Product Inspection offers advanced detection solutions, including HPP technology, ensuring product safety and compliance within food processing industries.We're grateful to work with incredible clients.

FAQs

What is the market size of High Pressure Processing Equipment?

The global market size for High Pressure Processing Equipment is projected to reach approximately $709.2 million by 2033, growing at a CAGR of 6.7% from 2023. This growth reflects increasing adoption across various sectors benefiting from high-pressure technology.

What are the key market players or companies in this High Pressure Processing Equipment industry?

Key players in the High Pressure Processing Equipment industry include leading manufacturers such as Avure Technologies, Hiperbaric, and Ultra High Pressure Technologies. These companies significantly contribute to technological advancements and market dynamics.

What are the primary factors driving the growth in the High Pressure Processing Equipment industry?

Growth in the High Pressure Processing Equipment industry is primarily driven by rising demand for food safety, quality preservation, and shelf-life extension. Additionally, innovations and technological advancements are propelling the market forward.

Which region is the fastest Growing in the High Pressure Processing Equipment?

The fastest-growing region for High Pressure Processing Equipment is North America, projected to grow from $274.89 million in 2023 to $534.99 million by 2033. Other key regions include Europe and Asia Pacific, exhibiting significant growth.

Does ConsaInsights provide customized market report data for the High Pressure Processing Equipment industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the High Pressure Processing Equipment industry. Clients can obtain detailed insights addressing unique market segments, regional trends, and competitive landscapes.

What deliverables can I expect from this High Pressure Processing Equipment market research project?

Deliverables from the High Pressure Processing Equipment market research project include detailed market reports, insights on key players, growth trends, competitive analysis, regional market sizes, and segment-specific forecasts and recommendations.

What are the market trends of High Pressure Processing Equipment?

Current market trends in the High Pressure Processing Equipment industry include a significant shift towards eco-friendly processing solutions, increasing investment in R&D, and a rise in applications across food processing, healthcare, and biotechnology sectors.