High Speed Steel Cutting Tools Market Report

Published Date: 22 January 2026 | Report Code: high-speed-steel-cutting-tools

High Speed Steel Cutting Tools Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the High Speed Steel Cutting Tools market from 2023 to 2033. It covers market dynamics, size projections, industry trends, segmentation insights, and regional analyses to assist stakeholders in making informed decisions.

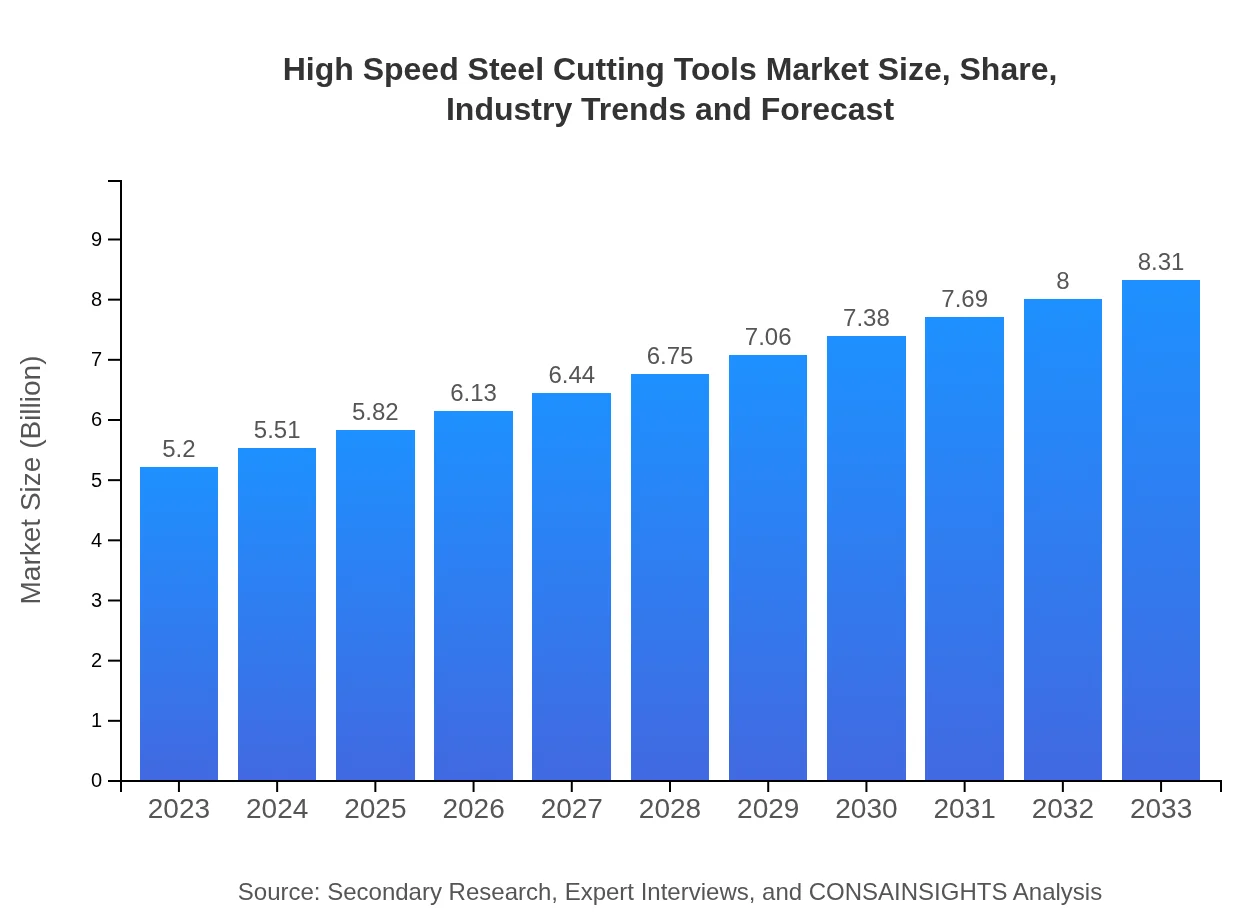

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.20 Billion |

| CAGR (2023-2033) | 4.7% |

| 2033 Market Size | $8.31 Billion |

| Top Companies | Sandvik Coromant, Kennametal Inc., Carbide Tools Co., Ltd., Machinists Inc. |

| Last Modified Date | 22 January 2026 |

High Speed Steel Cutting Tools Market Overview

Customize High Speed Steel Cutting Tools Market Report market research report

- ✔ Get in-depth analysis of High Speed Steel Cutting Tools market size, growth, and forecasts.

- ✔ Understand High Speed Steel Cutting Tools's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in High Speed Steel Cutting Tools

What is the Market Size & CAGR of High Speed Steel Cutting Tools market in 2023?

High Speed Steel Cutting Tools Industry Analysis

High Speed Steel Cutting Tools Market Segmentation and Scope

Tell us your focus area and get a customized research report.

High Speed Steel Cutting Tools Market Analysis Report by Region

Europe High Speed Steel Cutting Tools Market Report:

Europe is expected to increase from $1.67 billion in 2023 to $2.68 billion in 2033, supported by strong automotive and aerospace sectors focusing on precision-engineered tools and materials.Asia Pacific High Speed Steel Cutting Tools Market Report:

The Asia Pacific region, valued at $0.94 billion in 2023, is expected to grow to $1.50 billion by 2033, driven by increased manufacturing in countries like China and India, enhancing the market competitiveness of High Speed Steel Cutting Tools.North America High Speed Steel Cutting Tools Market Report:

The North American market, valued at $1.90 billion in 2023, is projected to reach $3.03 billion by 2033. The growth is attributed to technological advancements and the increasing production rates in the automotive and aerospace sectors.South America High Speed Steel Cutting Tools Market Report:

In South America, the market for High Speed Steel Cutting Tools is expected to expand from $0.16 billion in 2023 to $0.26 billion in 2033 due to growing industrial activities and a rising focus on modernized manufacturing technologies.Middle East & Africa High Speed Steel Cutting Tools Market Report:

The Middle East and Africa's market is set to grow from $0.53 billion in 2023 to $0.85 billion by 2033, spurred by infrastructural developments and the push towards manufacturing resilience in the region.Tell us your focus area and get a customized research report.

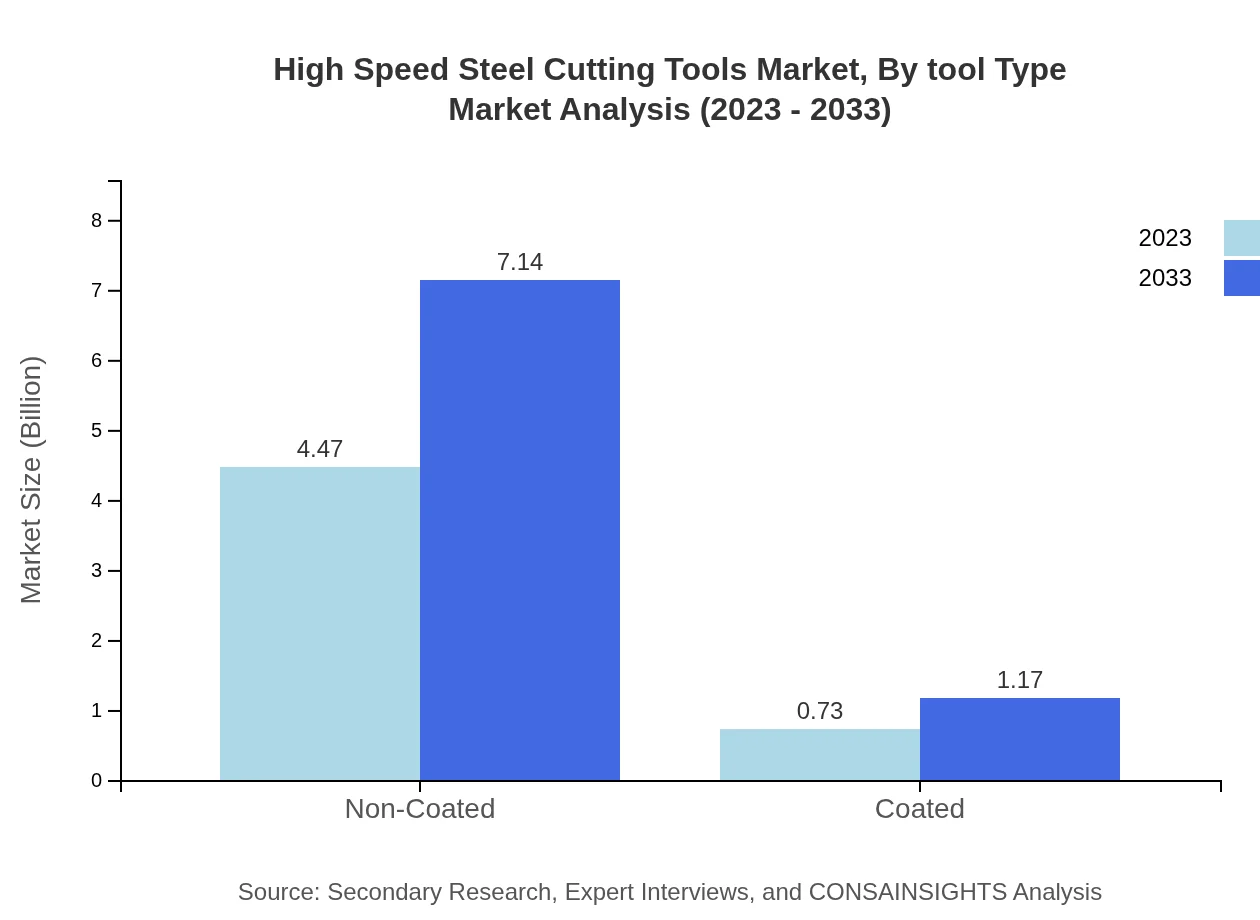

High Speed Steel Cutting Tools Market Analysis By Product Type

The High-Speed Steel Cutting Tools market by product type shows that Non-Coated tools dominate with a size of $4.47 billion in 2023 and projected to grow to $7.14 billion by 2033, capturing an 85.91% market share, whereas Coated tools, though smaller, are also set to grow from $0.73 billion to $1.17 billion, with a market share of 14.09%.

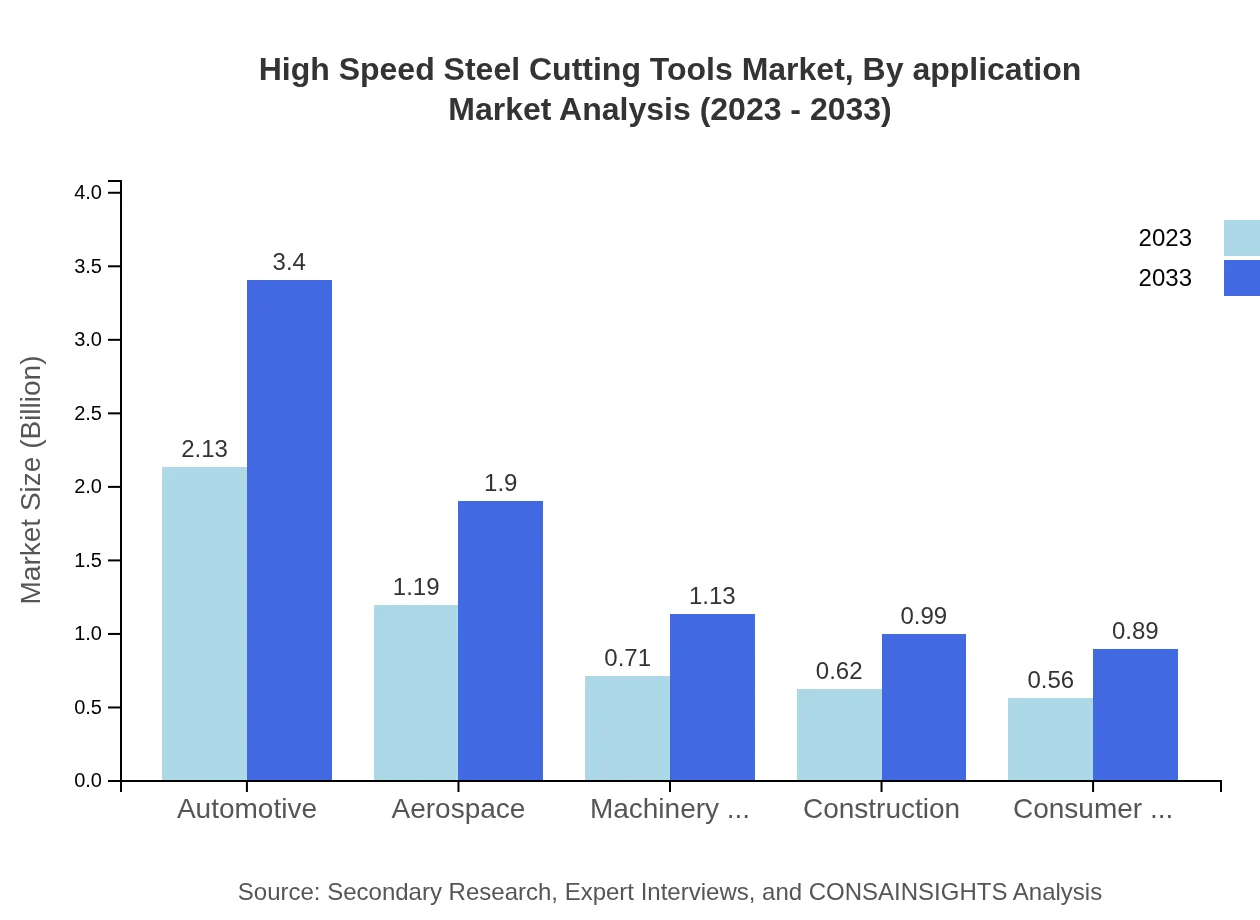

High Speed Steel Cutting Tools Market Analysis By Application

The market segmentation by application reveals significant demand in the Automotive sector with a size of $2.13 billion in 2023 and expected to reach $3.40 billion by 2033, maintaining a 40.92% share. Aerospace follows with notable growth projected from $1.19 billion to $1.90 billion.

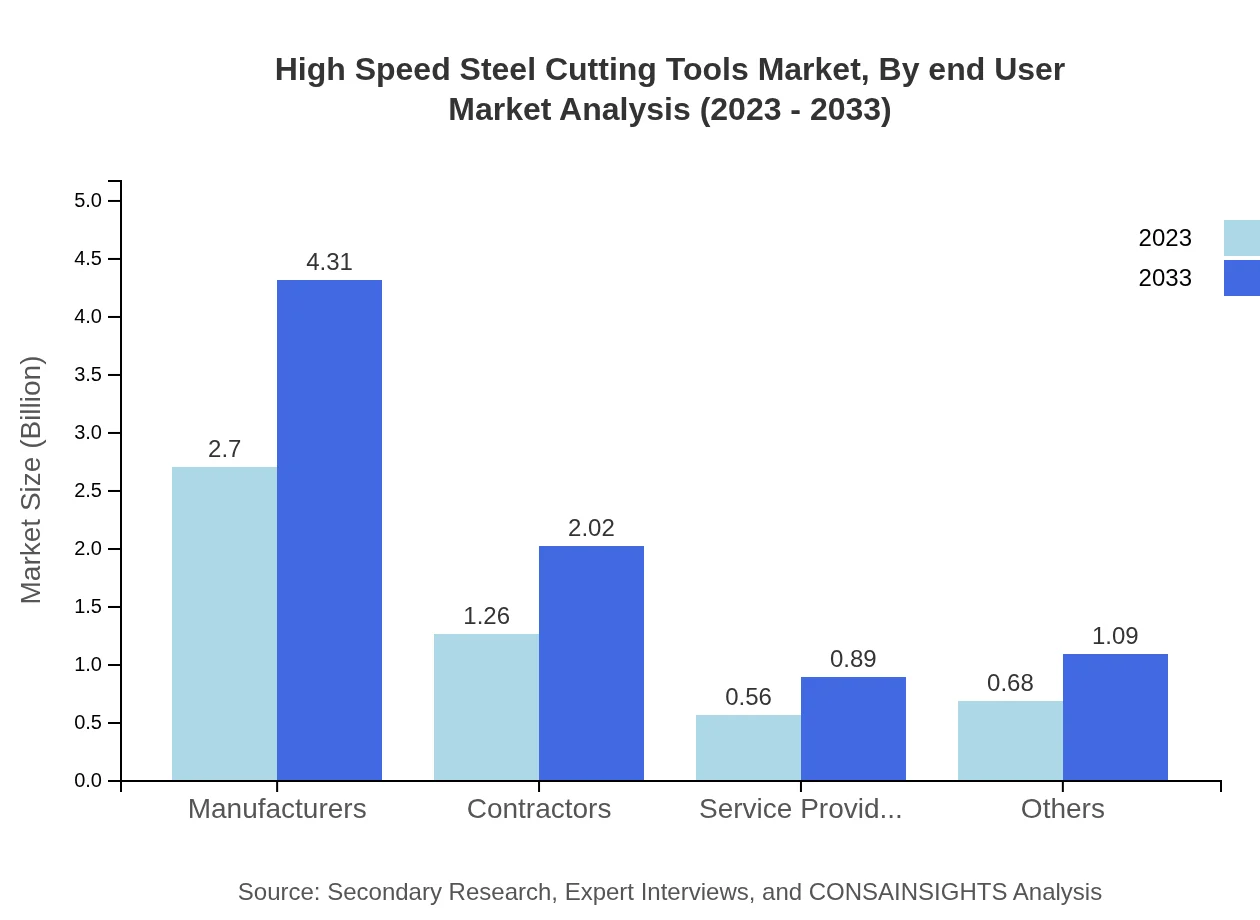

High Speed Steel Cutting Tools Market Analysis By End User

Key end-user industries include Automotive, Aerospace, and Machinery Manufacturing, where Automotive leads with $2.13 billion in 2023, while the Machinery Manufacturing sector shows consistent growth, projected from $0.71 billion to $1.13 billion.

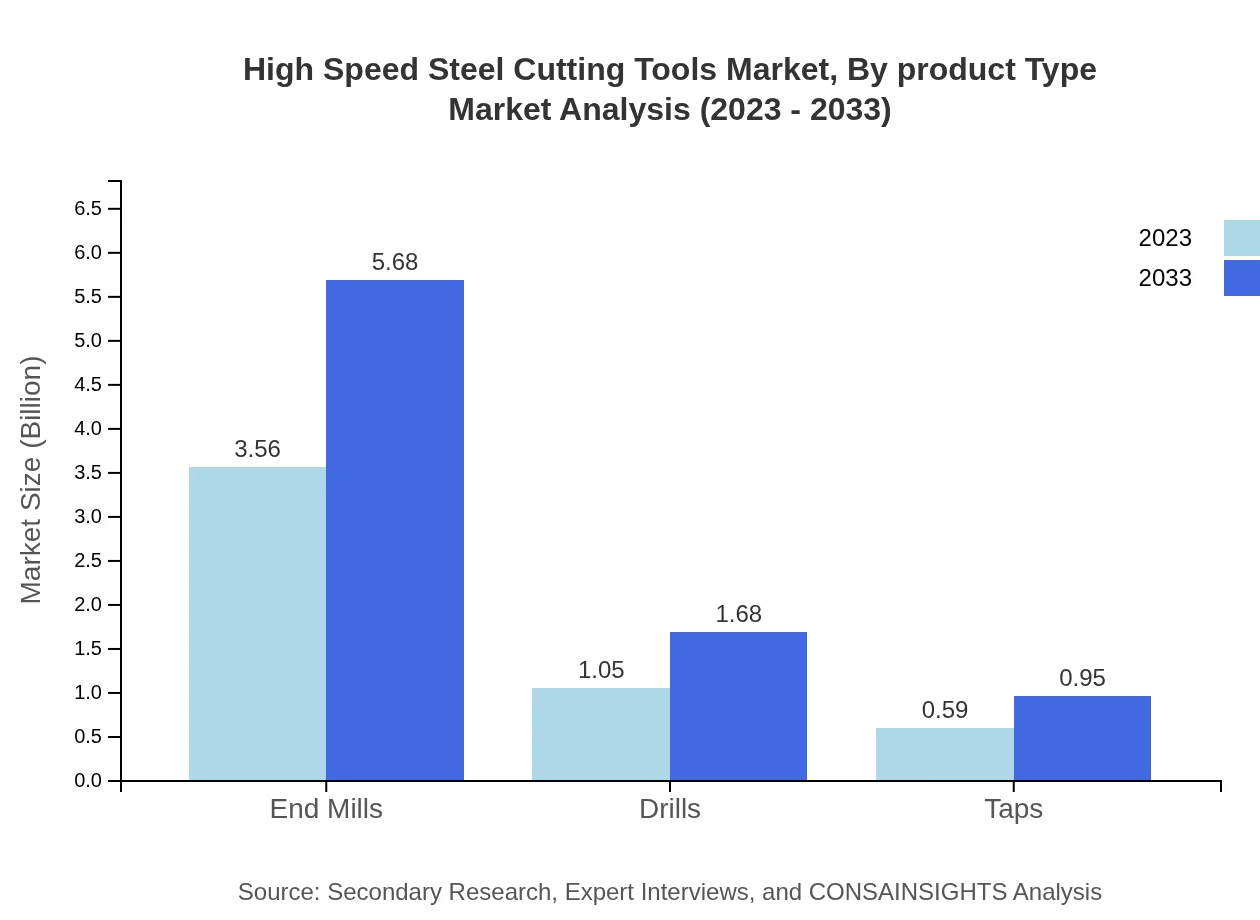

High Speed Steel Cutting Tools Market Analysis By Tool Type

Tool types like End Mills hold the largest market share at 68.38% with a size of $3.56 billion predicted to grow to $5.68 billion by 2033, pointing to a higher demand for versatile machining solutions.

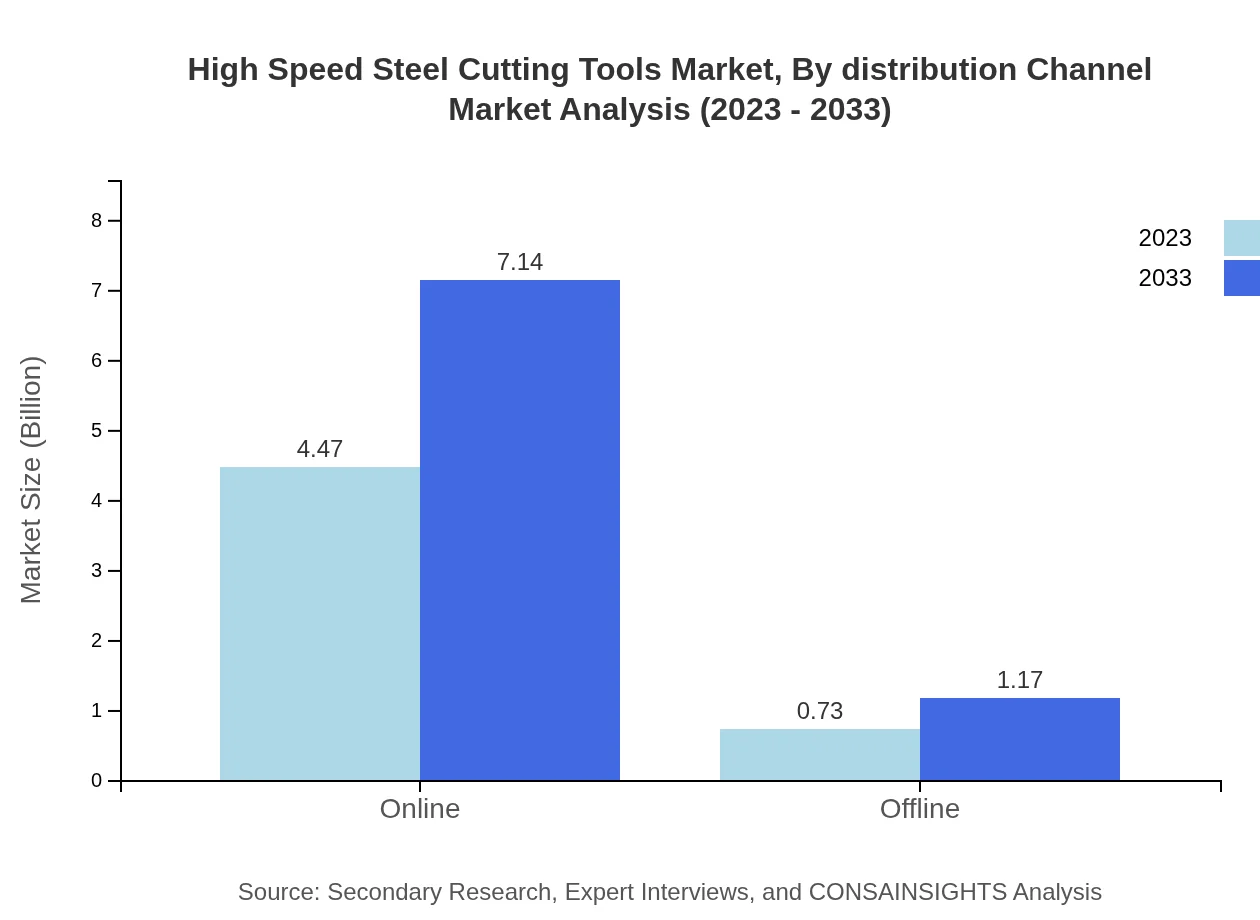

High Speed Steel Cutting Tools Market Analysis By Distribution Channel

Online distribution channels significantly dominate with $4.47 billion in value, expected to grow to $7.14 billion by 2033, emphasizing the shift towards digital procurement and wider market reach.

High Speed Steel Cutting Tools Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in High Speed Steel Cutting Tools Industry

Sandvik Coromant:

A leading manufacturer of cutting tools, known for its innovative solutions and high-quality products in the cutting tools sector.Kennametal Inc.:

Specializes in advanced materials and engineered components, providing precision cutting tools to various manufacturing sectors.Carbide Tools Co., Ltd.:

A prominent player in the HSS cutting tools market, committed to quality and technology innovation in tool design.Machinists Inc.:

Offers a comprehensive range of precision cutting tools and services, focusing on customer satisfaction and technical expertise.We're grateful to work with incredible clients.

FAQs

What is the market size of high Speed Steel Cutting Tools?

The global market size for high-speed steel cutting tools is projected to reach approximately $5.2 billion by 2033, growing at a CAGR of 4.7% from 2023. This indicates a steady demand for high-speed steel tools across various industries.

What are the key market players or companies in this high Speed Steel Cutting Tools industry?

Key players in the high-speed steel cutting tools industry include prominent manufacturers who contribute to the increasing market share, which is expected to reach 51.89% for manufacturers by 2033. Their innovation drives competitiveness.

What are the primary factors driving the growth in the high Speed Steel Cutting Tools industry?

Growth in the high-speed steel cutting tools market is driven by advancements in manufacturing technologies, increased demand from industries such as automotive and aerospace, and the need for efficient cutting solutions, fostering a robust market landscape.

Which region is the fastest Growing in the high Speed Steel Cutting Tools?

The fastest-growing region in the high-speed steel cutting tools market is expected to be North America, with market size growing from $1.90 billion in 2023 to $3.03 billion by 2033, demonstrating a significant expansion.

Does ConsaInsights provide customized market report data for the high Speed Steel Cutting Tools industry?

Yes, ConsaInsights offers customized market report data tailored for the high-speed steel cutting tools industry. This allows businesses to gain insights specific to their needs, enhancing their strategic decision-making.

What deliverables can I expect from this high Speed Steel Cutting Tools market research project?

From this market research project, you can expect comprehensive deliverables including market size analysis, segmented data insights, competitive landscape, and growth forecasts, enabling informed strategic planning for stakeholders.

What are the market trends of high Speed Steel Cutting Tools?

Current market trends indicate a shift toward the adoption of coated and non-coated tools, with non-coated tools holding an 85.91% share. Also, increased digital sales channels are reshaping how cutting tools reach consumers.