Homogenizers Market Report

Published Date: 31 January 2026 | Report Code: homogenizers

Homogenizers Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Homogenizers market, covering insights on market size, growth trends, applications, and key players from 2023 to 2033. It delves into industry dynamics, regional performance, technological advancements, and forecasts to assist stakeholders in making informed decisions.

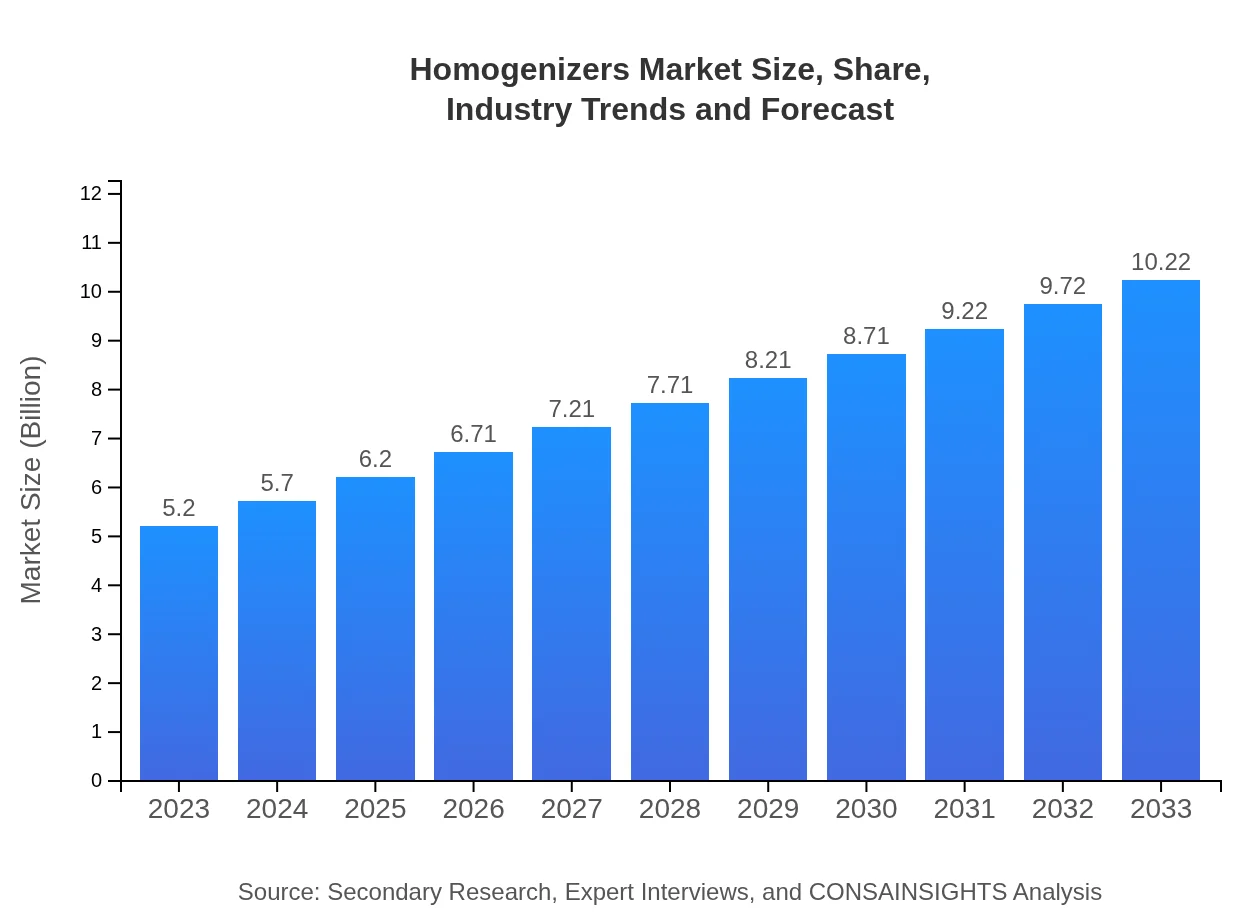

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.20 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $10.22 Billion |

| Top Companies | GEA Group, SPX FLOW, Alfa Laval, Bühler Group |

| Last Modified Date | 31 January 2026 |

Homogenizers Market Overview

Customize Homogenizers Market Report market research report

- ✔ Get in-depth analysis of Homogenizers market size, growth, and forecasts.

- ✔ Understand Homogenizers's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Homogenizers

What is the Market Size & CAGR of Homogenizers market in 2023?

Homogenizers Industry Analysis

Homogenizers Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Homogenizers Market Analysis Report by Region

Europe Homogenizers Market Report:

The European homogenizers market is anticipated to expand from $1.73 billion in 2023 to $3.40 billion by 2033. Key factors include the rising inclination towards organic food products and the growth of the pharmaceutical industry, along with the implementation of strict EU regulations concerning food safety.Asia Pacific Homogenizers Market Report:

The Asia Pacific region is projected to experience significant growth, with the market size reaching $1.83 billion by 2033, from $0.93 billion in 2023. This growth is driven by the rapid industrialization in countries like China and India, coupled with increasing investments in food processing and pharmaceutical sectors.North America Homogenizers Market Report:

North America is set to maintain a strong presence in the homogenizers market, growing from $1.77 billion in 2023 to $3.49 billion in 2033. The region is characterized by the high adoption of advanced technologies in food and beverage production and stringent food safety regulations.South America Homogenizers Market Report:

In South America, the market is expected to grow from $0.12 billion in 2023 to $0.24 billion by 2033. The growth is attributed to the expanding agricultural sector and rising demand for processed food, necessitating advanced homogenizing solutions.Middle East & Africa Homogenizers Market Report:

The Middle East and Africa region will see the market grow from $0.64 billion in 2023 to $1.26 billion by 2033. The increasing demand for modern food processing techniques and the growth of the healthcare sector will drive this expansion.Tell us your focus area and get a customized research report.

Homogenizers Market Analysis By Product Type

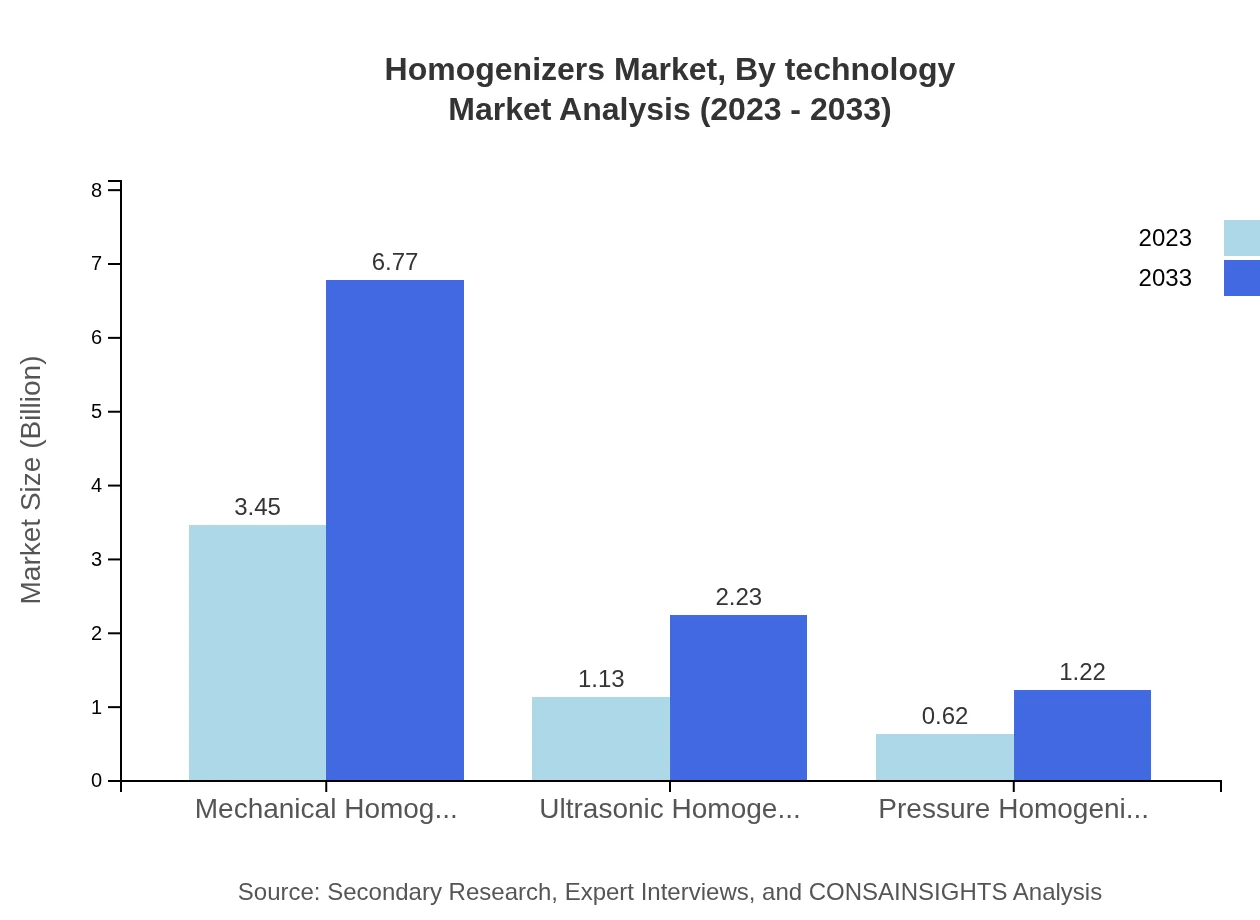

In 2023, the mechanical homogenizers segment holds the largest market share, valued at approximately $3.45 billion, and is projected to reach about $6.77 billion by 2033, approximately 66.26% of the market. Ultrasonic homogenizers and pressure homogenizers are also significant, valued at $1.13 billion and $0.62 billion respectively in 2023, indicating a growing preference for these technologies due to their efficiency in various applications.

Homogenizers Market Analysis By Application

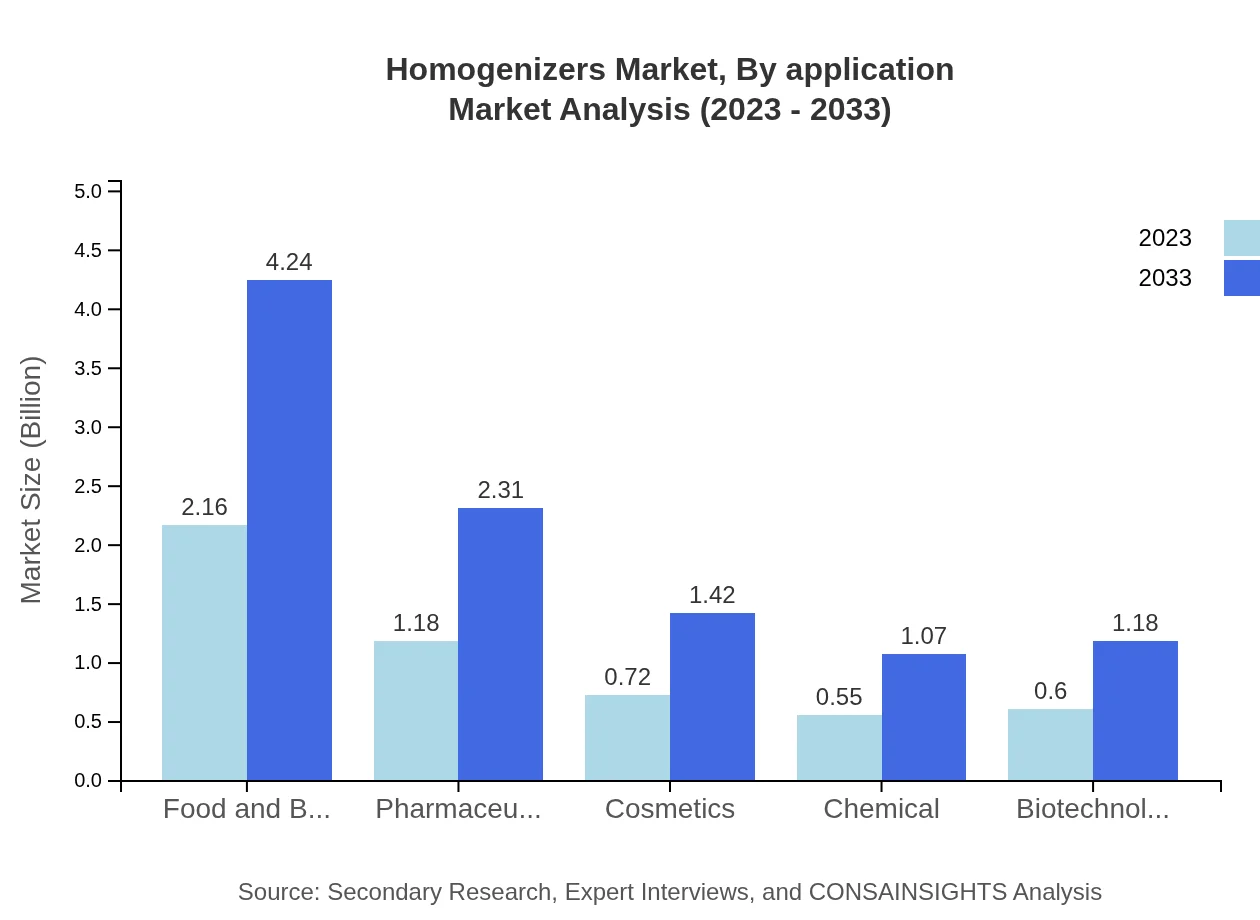

The food and beverage application dominates the homogenizers market, accounting for $2.16 billion in 2023, expected to grow to $4.24 billion by 2033, maintaining a market share of approximately 41.45%. The pharmaceutical sector follows, with considerable growth from $1.18 billion in 2023 to $2.31 billion by 2033, showcasing the importance of homogenization in drug formulations.

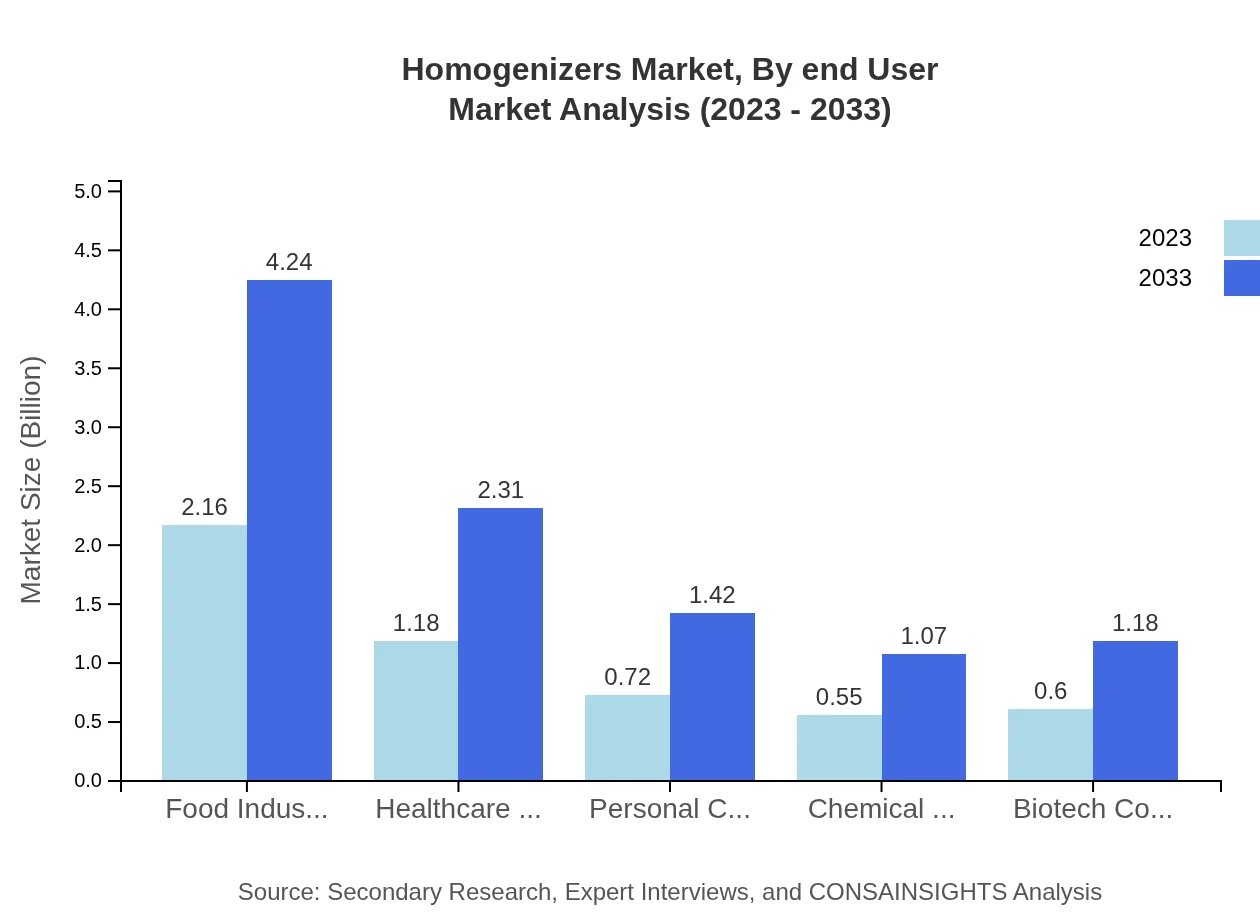

Homogenizers Market Analysis By End User

Key end-users of homogenizers include the food and beverage, pharmaceutical, and cosmetics industries. The food and beverage sector demands advanced homogenization processes to enhance product safety and quality, expected to grow at a steady pace. Pharmaceuticals also leverage homogenizers for precise mixing and formulation processes, indicating promising growth trends.

Homogenizers Market Analysis By Technology

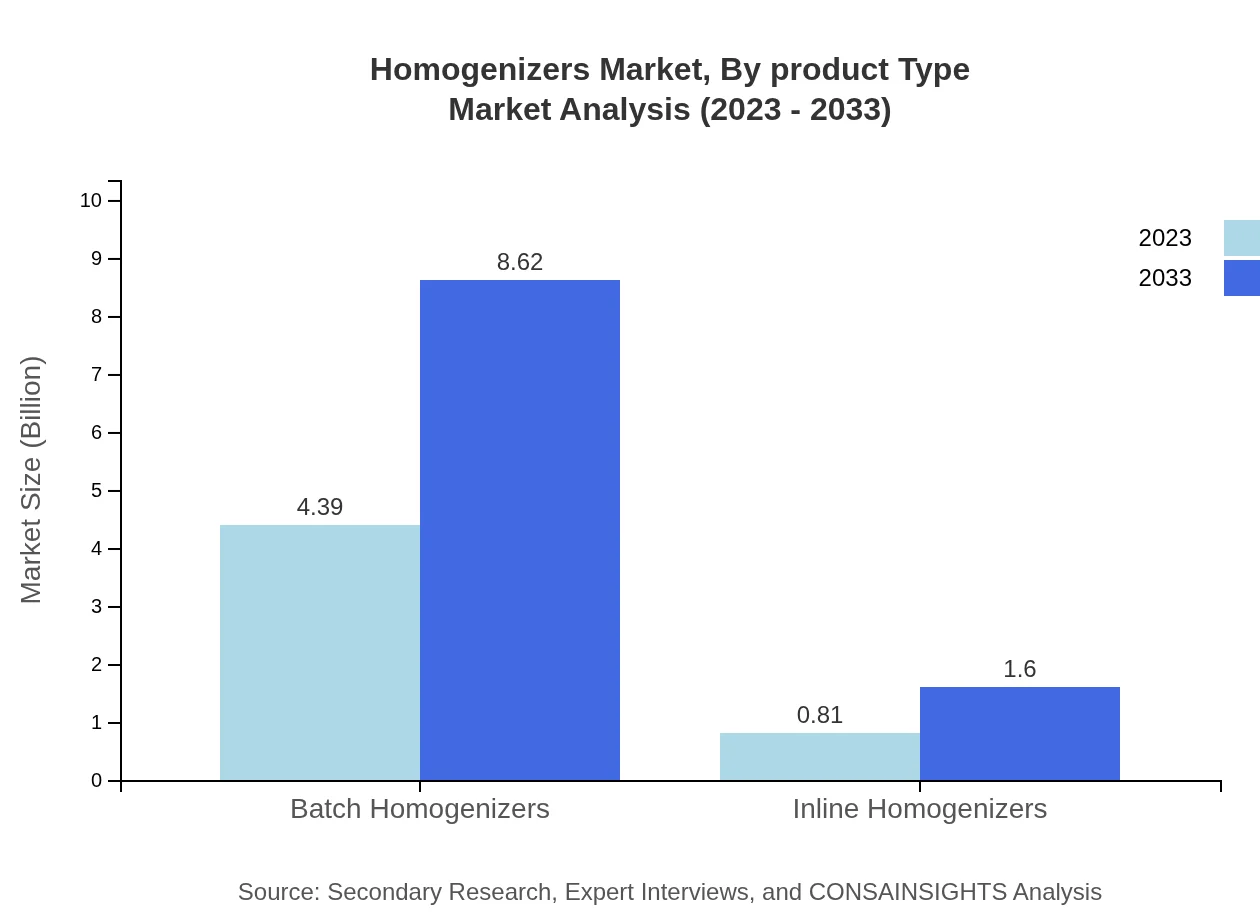

Technologically, batch homogenizers dominate the market with a size of $4.39 billion in 2023, projected to grow to $8.62 billion by 2033, reflecting an 84.34% share. Inline homogenizers are also crucial for continuous production processes, expected to expand from $0.81 billion to $1.60 billion by 2033, exhibiting a 15.66% market share.

Homogenizers Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Homogenizers Industry

GEA Group:

A leading global supplier of process technology for the food, pharmaceutical, and chemical industries, known for its innovative homogenization solutions.SPX FLOW:

Recognized for its comprehensive portfolio of processing equipment, SPX FLOW provides advanced homogenizers that meet diverse industry requirements.Alfa Laval:

Specializes in heat transfer, separation, and fluid handling; Alfa Laval offers various homogenizers that ensure superior quality and efficiency.Bühler Group:

Internationally renowned for its food processing and advanced materials solutions, Bühler produces high-performance homogenizers mainly for the food industry.We're grateful to work with incredible clients.

FAQs

What is the market size of Homogenizers?

The global homogenizers market is projected to reach $5.2 billion by 2033, growing at a CAGR of 6.8% from 2023. This growth is driven by increasing demand in food, healthcare, and cosmetics industries.

What are the key market players or companies in this Homogenizers industry?

Key players in the homogenizers market include GEA Group, SPX FLOW, and Hockmeyer Equipment Corporation. These companies lead the industry with innovative technologies and products, providing efficient solutions for various sectors.

What are the primary factors driving the growth in the Homogenizers industry?

The growth of the homogenizers industry is driven by factors such as increasing demand for processed food, advancements in pharmaceutical applications, and the need for quality control in various manufacturing processes.

Which region is the fastest Growing in the Homogenizers market?

The Asia Pacific region is projected to be the fastest-growing market for homogenizers, expanding from $0.93 billion in 2023 to $1.83 billion by 2033, driven by rising industrial activities and technological advancements.

Does ConsaInsights provide customized market report data for the Homogenizers industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the homogenizers industry, ensuring clients receive relevant insights and analyses for their business strategies.

What deliverables can I expect from this Homogenizers market research project?

Deliverables from the homogenizers market research project typically include detailed market analysis, segmentation data, growth forecasts, and strategic insights for key players and emerging trends in the industry.

What are the market trends of Homogenizers?

Current trends in the homogenizers market include increased automation in manufacturing processes, rising demand for high-quality products in food and pharmaceuticals, and the shift towards more energy-efficient homogenization technologies.