Hopper Loaders Market Report

Published Date: 22 January 2026 | Report Code: hopper-loaders

Hopper Loaders Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Hopper Loaders market, focusing on market size, growth trends, technological advancements, and key players from 2023 to 2033. Insights throughout the report will inform stakeholders of current conditions and future outlooks for optimal decision-making.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.7% |

| 2033 Market Size | $2.92 Billion |

| Top Companies | Schwing Stetter, Coperion, Meyer Industrial |

| Last Modified Date | 22 January 2026 |

Hopper Loaders Market Overview

Customize Hopper Loaders Market Report market research report

- ✔ Get in-depth analysis of Hopper Loaders market size, growth, and forecasts.

- ✔ Understand Hopper Loaders's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Hopper Loaders

What is the Market Size & CAGR of Hopper Loaders market in 2023?

Hopper Loaders Industry Analysis

Hopper Loaders Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Hopper Loaders Market Analysis Report by Region

Europe Hopper Loaders Market Report:

Currently valued at $0.47 billion, the European Hopper Loaders market is forecasted to grow to $0.91 billion by 2033. The stringent regulations on manufacturing and materials handling, along with a strong focus on sustainability, create favorable conditions for market growth.Asia Pacific Hopper Loaders Market Report:

In Asia Pacific, the Hopper Loaders market is valued at $0.28 billion in 2023 and is expected to reach $0.55 billion by 2033. The region's rapid industrialization, especially in manufacturing and food production, is driving demand, supported by investments in automation technologies.North America Hopper Loaders Market Report:

Hopper Loaders in North America market is valued at $0.54 billion in 2023 and is expected to grow to $1.05 billion by 2033. The focus on green technologies and automation in the manufacturing sector is propelling market expansion.South America Hopper Loaders Market Report:

The market in South America is valued at $0.11 billion in 2023 and is projected to grow to $0.21 billion by 2033. As industries modernize and seek efficiency, the adoption of Hopper Loaders is anticipated to increase, particularly in agriculture and food processing.Middle East & Africa Hopper Loaders Market Report:

The Middle East and Africa market is valued at $0.10 billion in 2023, growing to $0.20 billion by 2033. The rising demand for efficient material handling processes and infrastructural developments in various sectors are key factors in this growth.Tell us your focus area and get a customized research report.

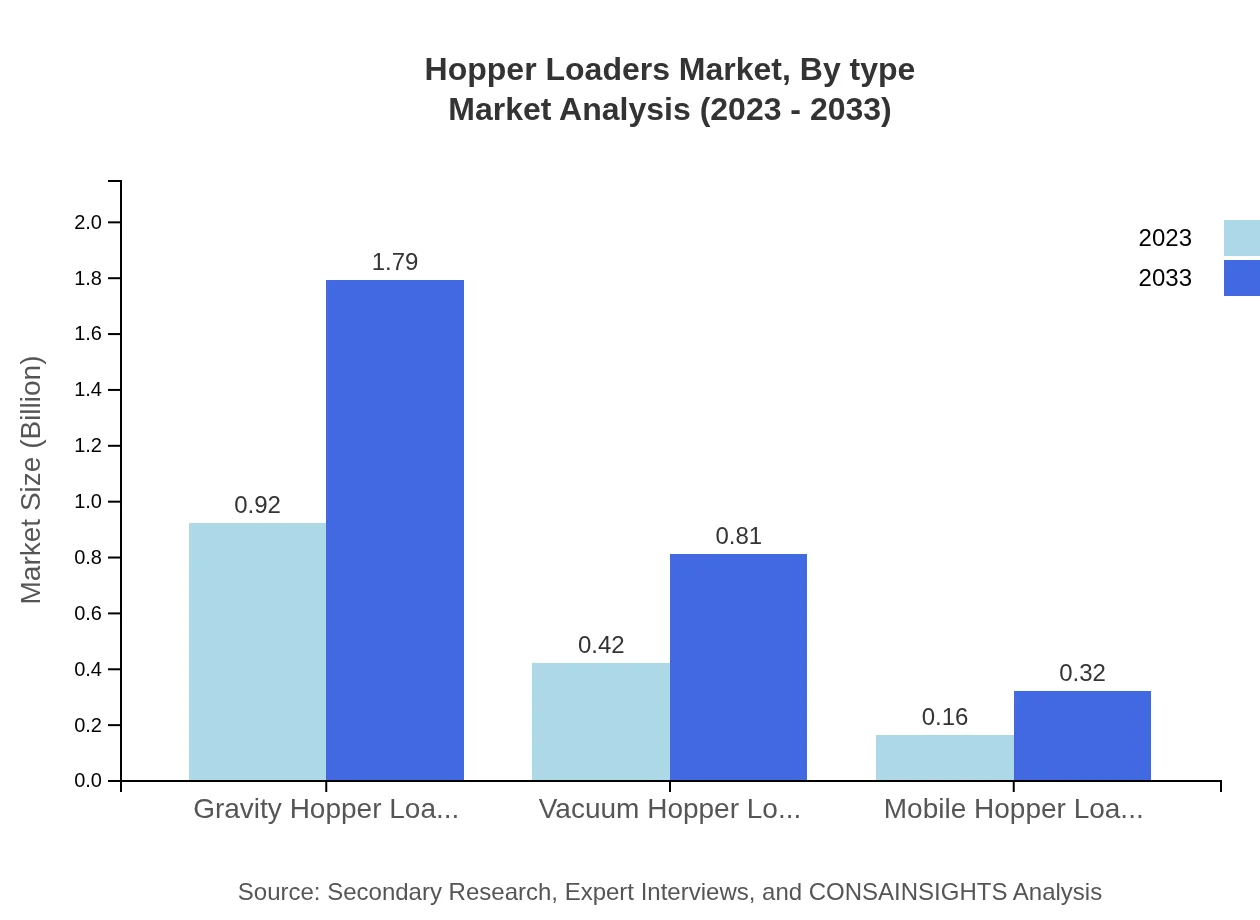

Hopper Loaders Market Analysis By Type

The Hopper Loaders market is divided primarily into Gravity Hopper Loaders, Vacuum Hopper Loaders, and Mobile Hopper Loaders. In 2023, Gravity Hopper Loaders hold a significant market share with a size of $0.92 billion, projected to grow to $1.79 billion by 2033. Vacuum Hopper Loaders follow with a market size of $0.42 billion in 2023, expected to reach $0.81 billion by 2033. Mobile Hopper Loaders, while smaller, highlight the industry's innovation with a current market size of $0.16 billion, predicted to reach $0.32 billion by 2033.

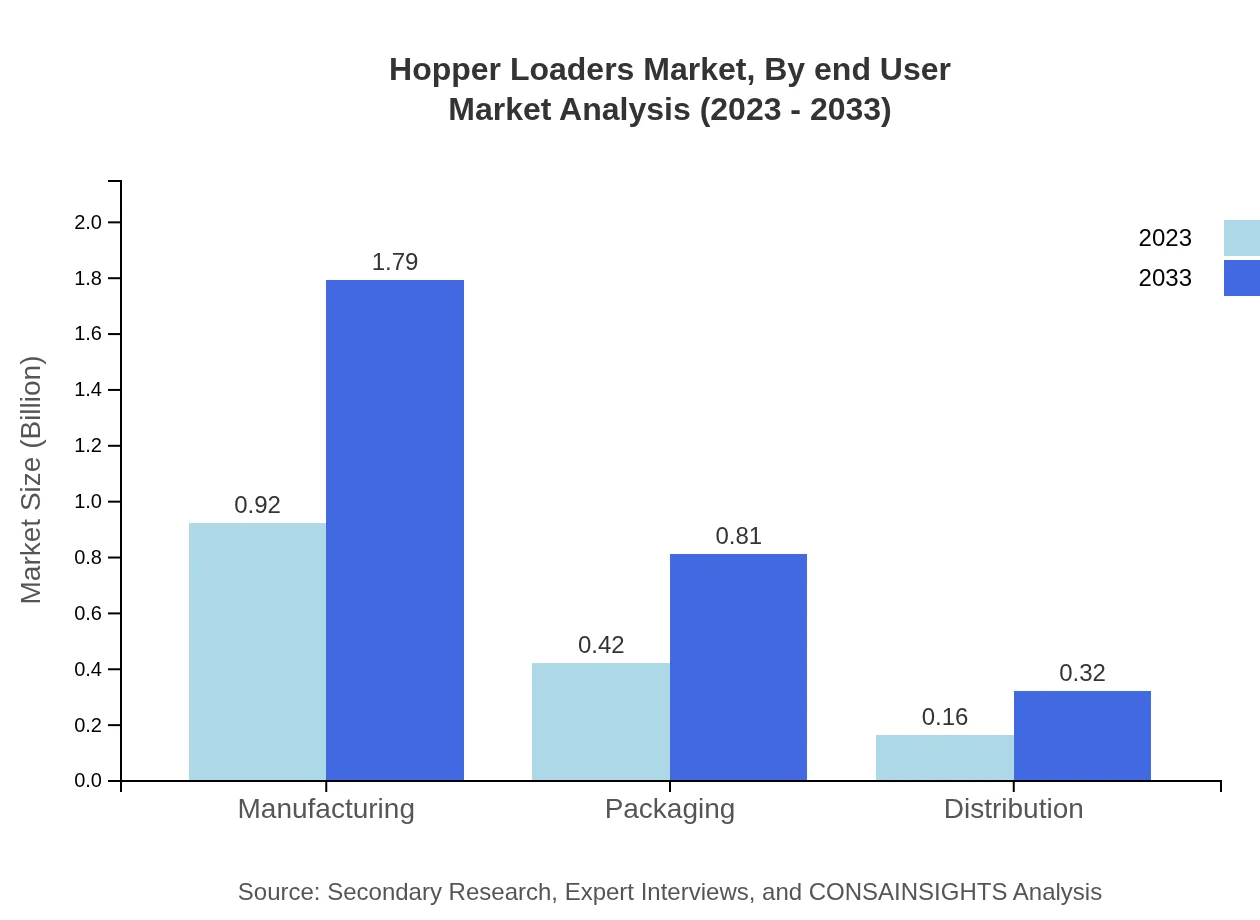

Hopper Loaders Market Analysis By Application

The applications of Hopper Loaders can be categorized into Manufacturing, Packaging, and Distribution. The Manufacturing sector accounts for $0.92 billion in 2023, predicting a growth to $1.79 billion by 2033. Packaging also holds significant traction at $0.42 billion, with projections of reaching $0.81 billion given the increasing demand across consumer goods. Distribution applications are on the rise too, currently at $0.16 billion, expected to attain $0.32 billion within the forecast period.

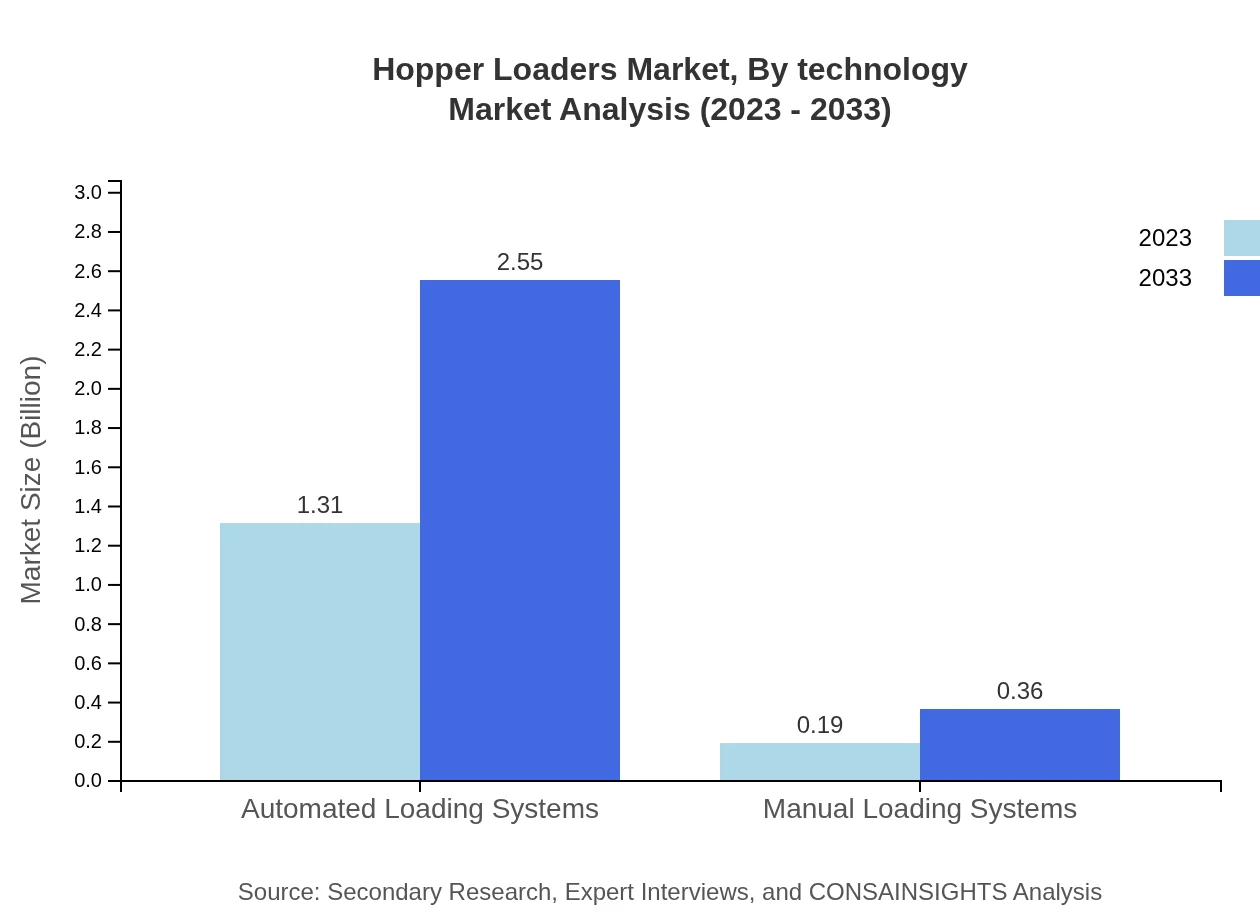

Hopper Loaders Market Analysis By Technology

Technology segments of the Hopper Loaders market include Automated Loading Systems and Manual Loading Systems. Automated Loading Systems dominate with a size of $1.31 billion in 2023, expected to climb to $2.55 billion by 2033 as industries continue to prioritize automation. Manual Loading Systems currently account for $0.19 billion in 2023, with expectations of the market reaching $0.36 billion in the ensuing years as companies optimize their operational capabilities.

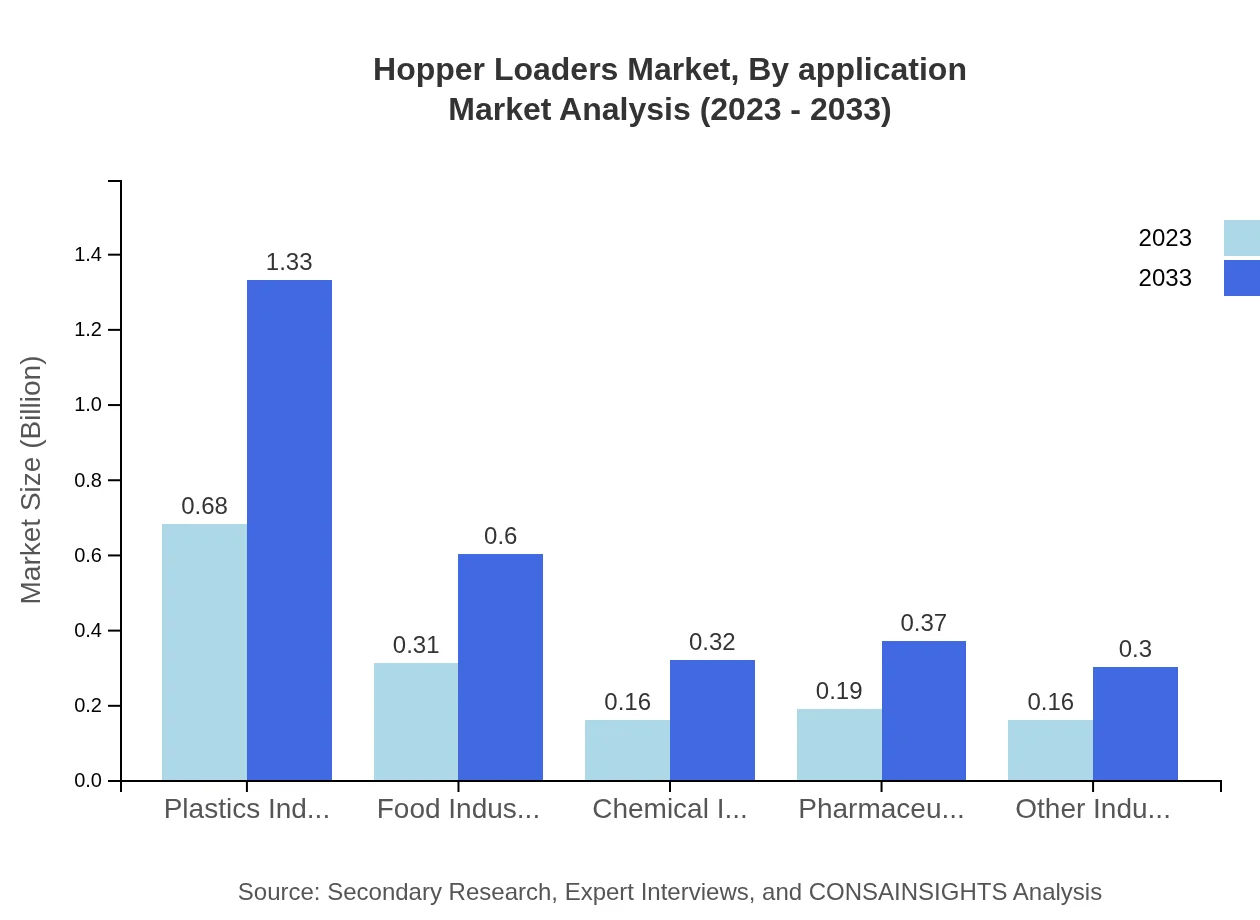

Hopper Loaders Market Analysis By End User

End-user segments in the Hopper Loaders market include Plastics, Food, Chemical, Pharmaceutical industries, and Other Industries. The Plastics Industry commands a substantial share, valued at $0.68 billion in 2023, forecasted to reach $1.33 billion by 2033. The Food Industry holds $0.31 billion, predicting a rise to $0.60 billion owing to increasing consumer demands. The Chemical and Pharmaceutical Industries reflect smaller but steady growth trajectories, currently valued at $0.16 billion and $0.19 billion respectively, expected to reach $0.32 billion and $0.37 billion by 2033.

Hopper Loaders Market Analysis By Region

Global Hopper Loaders Market, By Geographic Region Market Analysis (2023 - 2033)

Geographic analysis highlights North America and Europe as significant markets in 2023, with respective values of $0.54 billion and $0.47 billion. Meanwhile, growth potential in the Asia Pacific region is evident from a growing market size from $0.28 billion to $0.55 billion by 2033. South America and Middle East & Africa present emerging opportunities as industries evolve, with forecasts of $0.11 billion to $0.21 billion and $0.10 billion to $0.20 billion respectively.

Hopper Loaders Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Hopper Loaders Industry

Schwing Stetter:

A prominent manufacturer in the material handling sector, Schwing Stetter specializes in innovative products that enhance performance and efficiency in construction and industrial applications.Coperion:

Coperion leads with advanced solutions in bulk material handling and processing systems, particularly noted for their high-quality hopper loaders that integrate seamless automation.Meyer Industrial:

Meyer Industrial provides customized material handling solutions, offering a wide range of hopper loaders and systems designed for efficient and flexible operation.We're grateful to work with incredible clients.

FAQs

What is the market size of hopper Loaders?

The global hopper-loaders market is valued at approximately $1.5 billion in 2023, with a compound annual growth rate (CAGR) of 6.7%. This growth is expected to reflect significant advancements and increased demand across various industries in the following years.

What are the key market players or companies in this hopper Loaders industry?

Key players in the hopper-loaders market include major manufacturers that specialize in automated and manual loading systems. Leading companies drive innovation and market expansion, enabling significant contributions to both regional and global growth.

What are the primary factors driving the growth in the hopper Loaders industry?

The growth of the hopper-loaders industry is driven by increasing demand for efficiency in manufacturing processes, technological advancements in loading systems, and the expansion of the plastics and food industries, which heavily utilize hopper-loaders.

Which region is the fastest Growing in the hopper Loaders?

North America is the fastest-growing region in the hopper-loaders market, projected to increase from $0.54 billion in 2023 to $1.05 billion by 2033. This growth correlates with rising industrial automation across manufacturing sectors.

Does ConsaInsights provide customized market report data for the hopper Loaders industry?

Yes, ConsaInsights offers customized market report data tailored to your specific needs in the hopper-loaders industry, allowing clients to gain targeted insights and analyses that support strategic decision-making.

What deliverables can I expect from this hopper Loaders market research project?

From this market research project, you can expect comprehensive reports including market analysis, segment insights, regional performance data, and competitive landscape evaluations that facilitate informed business strategies in the hopper-loaders market.

What are the market trends of hopper Loaders?

Significant trends include the increasing integration of automation in loading systems, a shift toward sustainable materials, and a burgeoning demand for enhanced efficiency in manufacturing, significantly reshaping the hopper-loaders market landscape.