Hydraulic Cylinder Market Report

Published Date: 22 January 2026 | Report Code: hydraulic-cylinder

Hydraulic Cylinder Market Size, Share, Industry Trends and Forecast to 2033

This report provides an extensive analysis of the Hydraulic Cylinder market, covering key insights, industry trends, and projections from 2023 to 2033. It includes an overview of market dynamics, segmentation, and regional analysis, offering valuable data for stakeholders and investors.

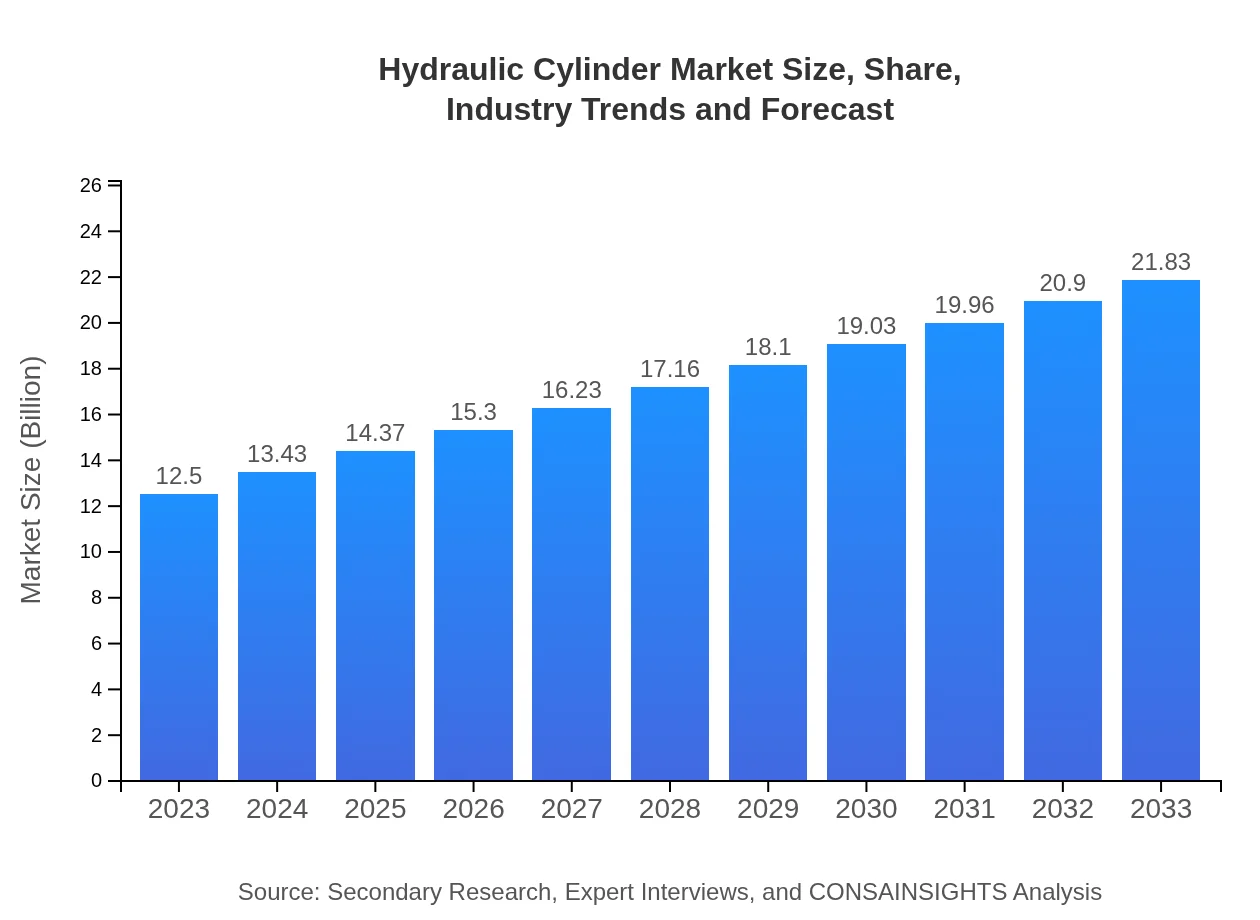

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.50 Billion |

| CAGR (2023-2033) | 5.6% |

| 2033 Market Size | $21.83 Billion |

| Top Companies | Parker Hannifin, Bosch Rexroth, Eaton Corporation, Hydac International, Caterpillar Inc. |

| Last Modified Date | 22 January 2026 |

Hydraulic Cylinder Market Overview

Customize Hydraulic Cylinder Market Report market research report

- ✔ Get in-depth analysis of Hydraulic Cylinder market size, growth, and forecasts.

- ✔ Understand Hydraulic Cylinder's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Hydraulic Cylinder

What is the Market Size & CAGR of Hydraulic Cylinder market in 2023?

Hydraulic Cylinder Industry Analysis

Hydraulic Cylinder Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Hydraulic Cylinder Market Analysis Report by Region

Europe Hydraulic Cylinder Market Report:

By 2033, Europe's market is expected to grow from 4.33 billion USD in 2023 to 7.57 billion USD, supported by stringent regulations driving the need for more efficient hydraulic systems and a significant emphasis on sustainable practices.Asia Pacific Hydraulic Cylinder Market Report:

In 2023, the Asia-Pacific region's hydraulic cylinder market is valued at approximately 2.14 billion USD, expected to grow to 3.74 billion USD by 2033. This growth is driven by rapid industrialization, infrastructure development, and the expansion of manufacturing capabilities in countries like China and India.North America Hydraulic Cylinder Market Report:

North America’s hydraulic cylinder market is set to increase from 4.37 billion USD in 2023 to 7.63 billion USD by 2033, propelled by advancements in technology and a strong focus on automation in industries such as construction and automotive.South America Hydraulic Cylinder Market Report:

The South American market is projected to reach 0.61 billion USD by 2033, growing from 0.35 billion USD in 2023. Factors such as increased agricultural activities and investments in mining infrastructure contribute to this growth trajectory.Middle East & Africa Hydraulic Cylinder Market Report:

The Middle East and Africa market is projected to expand from 1.30 billion USD in 2023 to 2.28 billion USD by 2033. This growth is linked to ongoing infrastructural developments and government initiatives aimed at enhancing manufacturing capabilities.Tell us your focus area and get a customized research report.

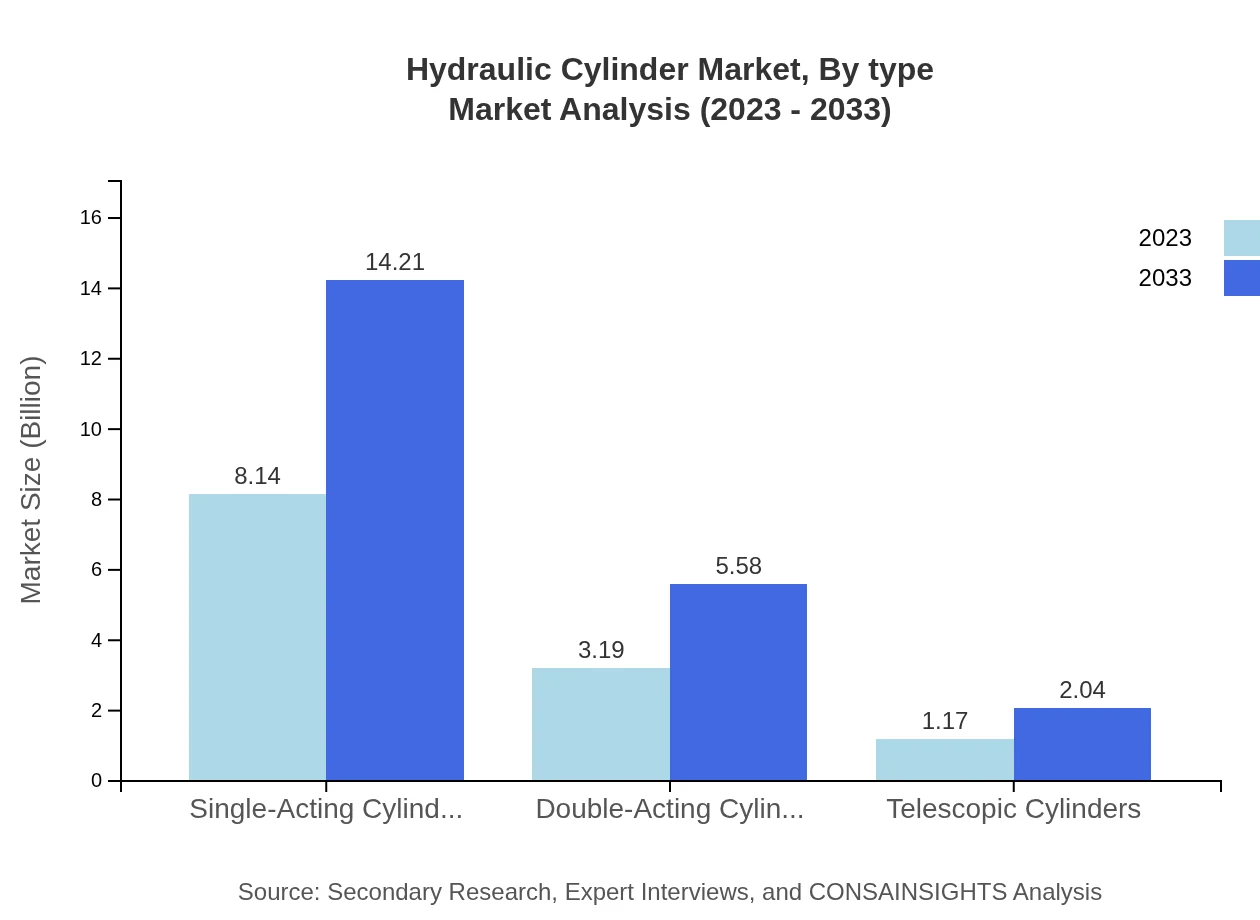

Hydraulic Cylinder Market Analysis By Type

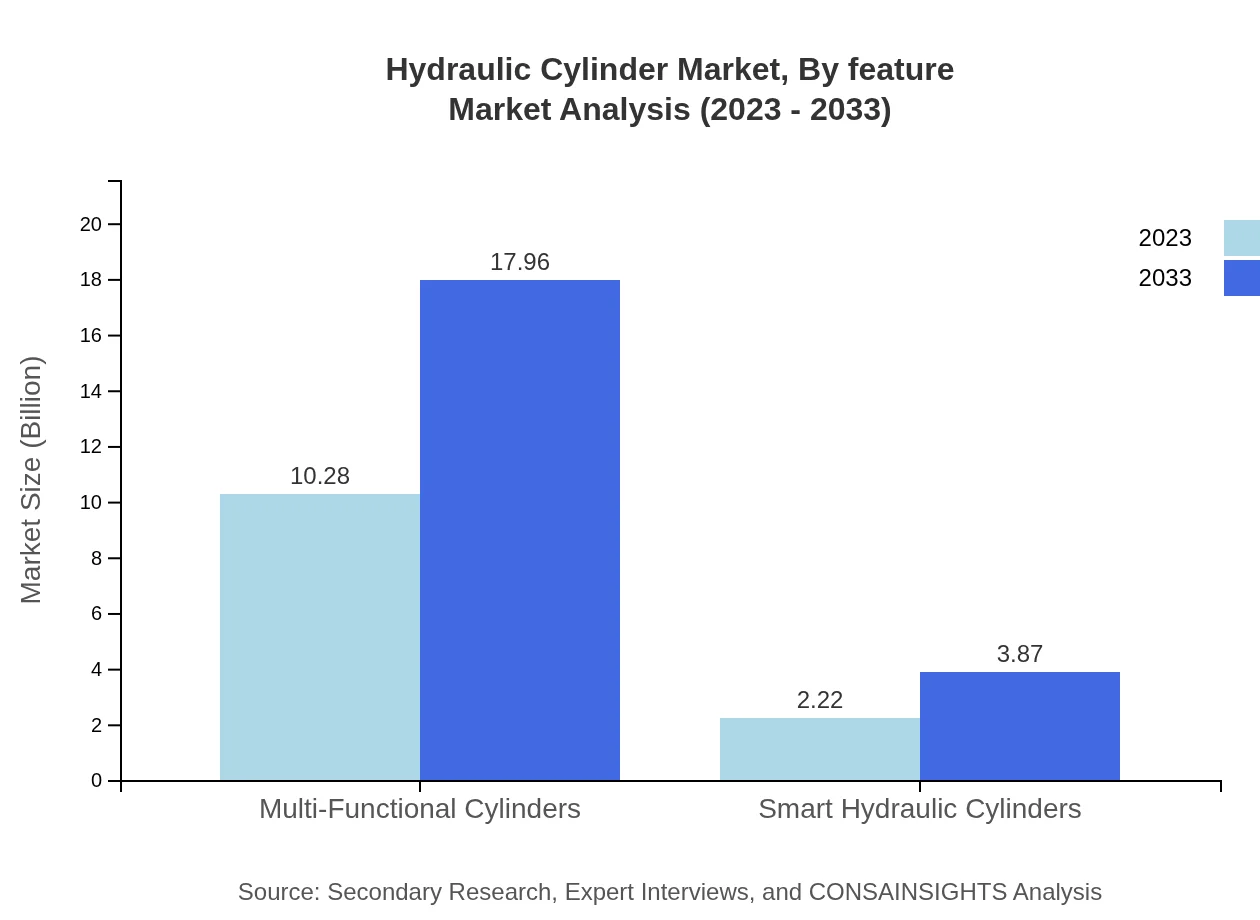

Single-acting cylinders dominate the market with an estimated size of 8.14 billion USD in 2023 and projected to reach 14.21 billion USD by 2033, accounting for 65.1% market share consistently. Double-acting cylinders follow, with a market size of 3.19 billion USD in 2023, growing to 5.58 billion USD by 2033, holding 25.55% share. Telescopic cylinders and smart hydraulic cylinders also contribute positively, while multi-functional cylinders emerge as innovative solutions catering to complex hydraulic demands.

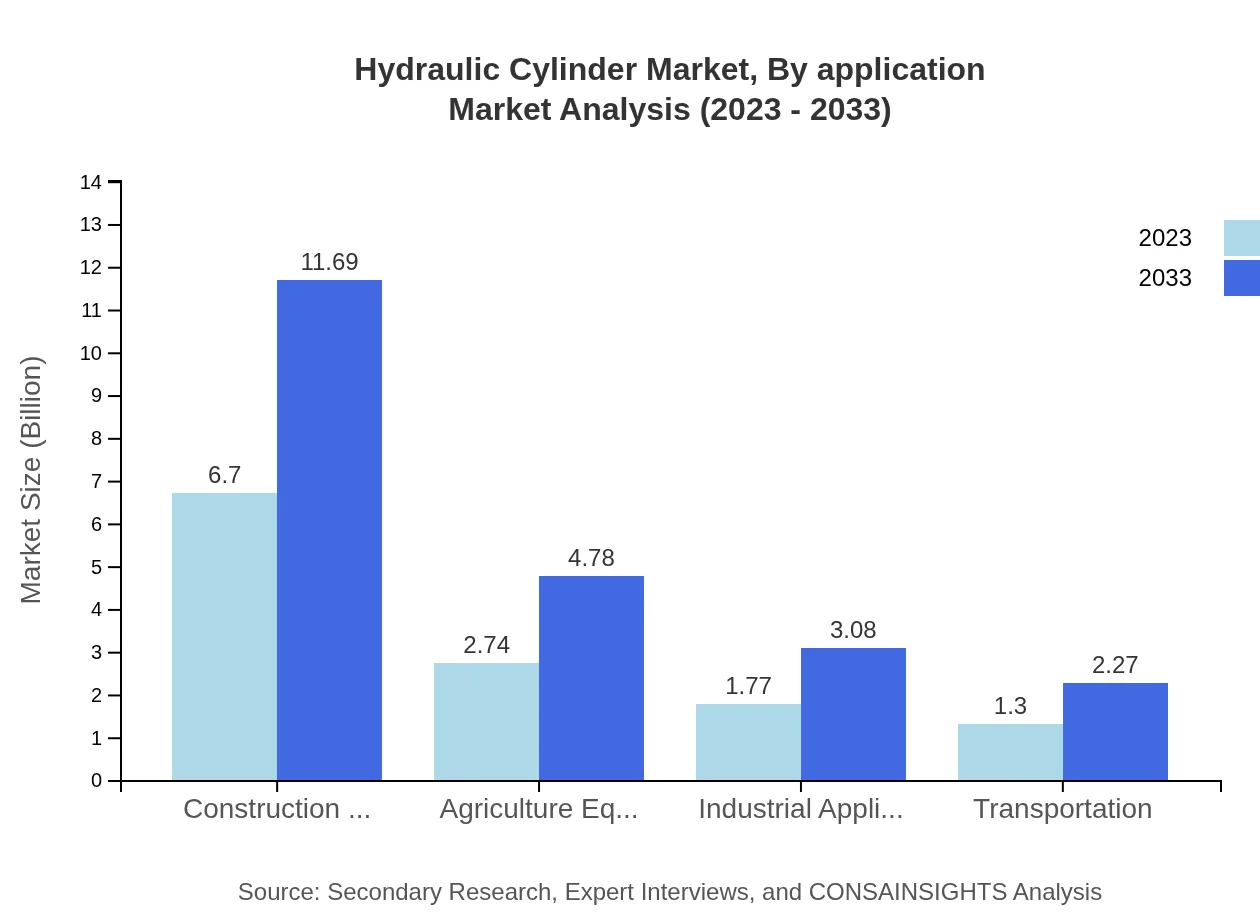

Hydraulic Cylinder Market Analysis By Application

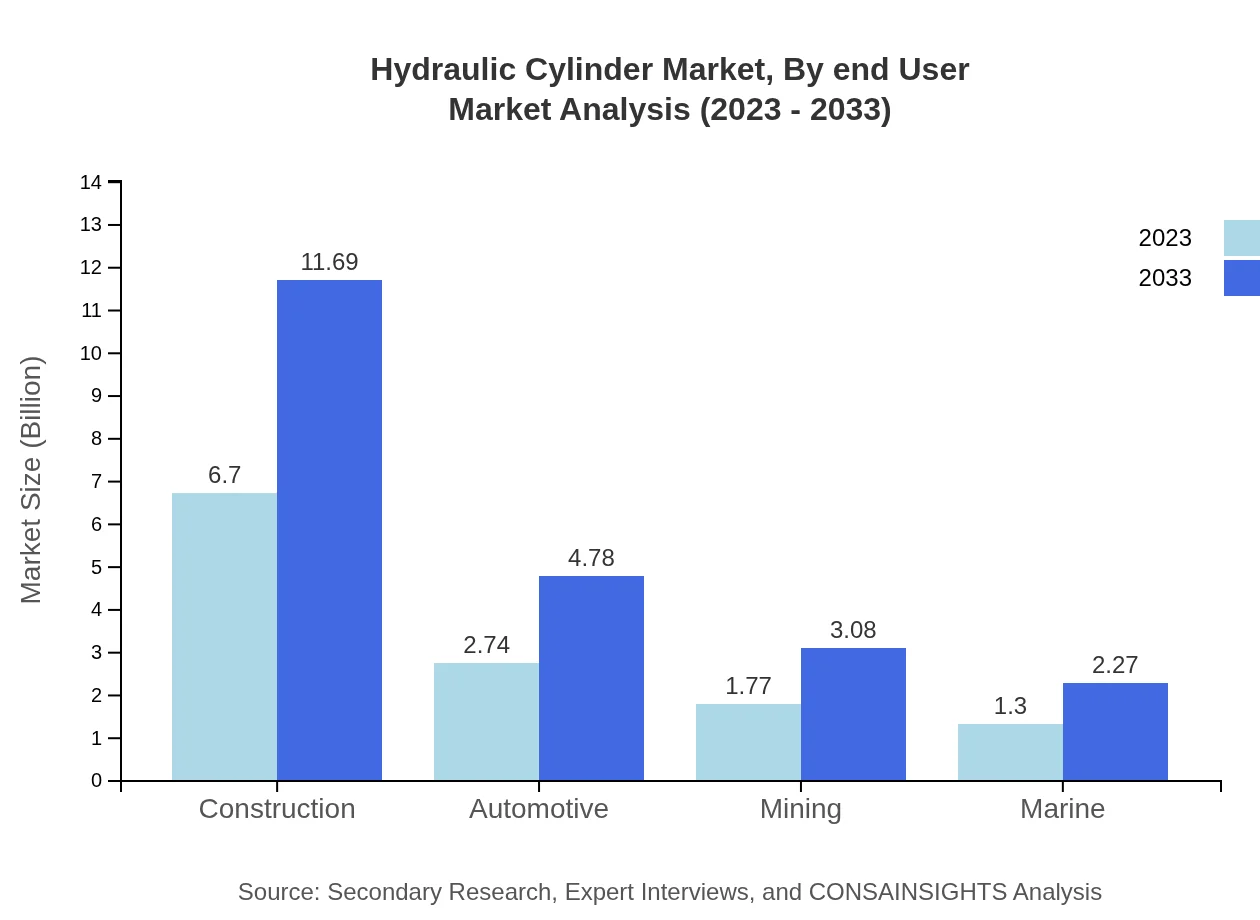

The construction sector represents the largest application area, valued at 6.70 billion USD in 2023, set to rise to 11.69 billion USD by 2033, with a market share of 53.57%. This is followed by automotive applications, projected to grow from 2.74 billion USD to 4.78 billion USD. Mining, marine, and industrial applications are also significant contributors, showcasing the diverse utility of hydraulic cylinders.

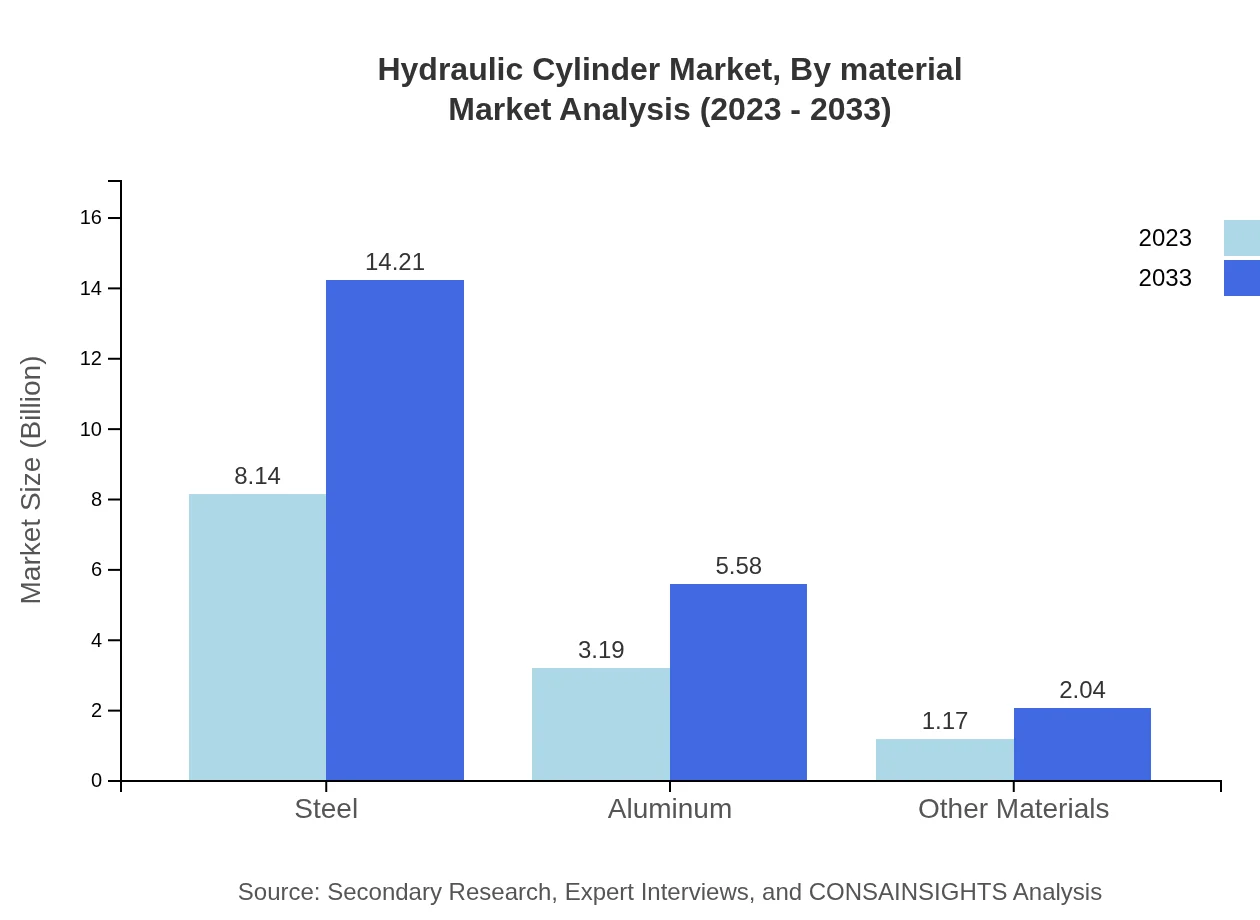

Hydraulic Cylinder Market Analysis By Material

Steel remains the predominant material in hydraulic cylinders, with a market size of 8.14 billion USD in 2023, expected to increase to 14.21 billion USD by 2033. Aluminum holds a substantial share, valued at 3.19 billion USD in 2023, anticipated to grow to 5.58 billion USD, catering to sectors requiring lightweight solutions. Other materials are utilized based on specific application needs.

Hydraulic Cylinder Market Analysis By End User

Key end-user industries include construction, agriculture, and mining, with each segment driving demand based on their operational needs. Construction remains the largest end-user industry, significantly impacting overall usage patterns. The automotive sector also showcases a growing trend, particularly in vehicle assembly and maintenance, reflecting broader market dynamics.

Hydraulic Cylinder Market Analysis By Feature

Smart hydraulic cylinders are emerging as a trend, driven by advancements in IoT and automation, marking a market presence of 2.22 billion USD in 2023, projected to grow to 3.87 billion USD by 2033. Multi-functional cylinders lead with an 82.27% market share, reflecting their ability to meet complex operational needs.

Hydraulic Cylinder Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Hydraulic Cylinder Industry

Parker Hannifin:

A leading player in motion and control technologies, Parker Hannifin offers innovative hydraulic products across multiple sectors, ensuring high efficiency and reliability.Bosch Rexroth:

Renowned for its hydraulic drive and control technology, Bosch Rexroth leads in providing smart solutions that enhance productivity and sustainability in manufacturing.Eaton Corporation:

Eaton offers a broad range of hydraulic solutions designed to improve performance and reduce downtime, playing a vital role in multiple industries, including automotive and aerospace.Hydac International:

Hydac specializes in hydraulic and electronic systems, contributing substantially to hydraulic cylinder innovations with a focus on high-quality standards.Caterpillar Inc.:

Known for its heavy machinery, Caterpillar also produces hydraulic components that ensure optimal performance in challenging environments.We're grateful to work with incredible clients.

FAQs

What is the market size of hydraulic Cylinder?

The hydraulic cylinder market size is projected to grow from $12.5 billion in 2023 to larger values by 2033, reflecting a CAGR of 5.6%. This growth indicates increasing demand across various industries for hydraulic technology.

What are the key market players or companies in the hydraulic Cylinder industry?

Key players in the hydraulic cylinder market include Parker Hannifin, Bosch Rexroth, Eaton, and Caterpillar Inc. These companies dominate through innovation, robust product portfolios, and strategic partnerships, influencing the market dynamics significantly.

What are the primary factors driving the growth in the hydraulic Cylinder industry?

Factors driving growth in the hydraulic cylinder industry include rising demand for construction and mining equipment, advancements in hydraulic technology, and increasing automation in industrial applications. Additionally, growing investments in infrastructure globally further contribute to this growth.

Which region is the fastest Growing in the hydraulic Cylinder market?

The fastest-growing region in the hydraulic cylinder market is Europe, with a market size expected to expand from $4.33 billion in 2023 to $7.57 billion by 2033. This growth is driven by increasing industrial activities and infrastructure development.

Does ConsaInsights provide customized market report data for the hydraulic Cylinder industry?

Yes, ConsaInsights provides customized market report data tailored to specific needs within the hydraulic cylinder industry. Clients can request detailed analyses focusing on segments, regions, and emerging trends specific to their interests.

What deliverables can I expect from this hydraulic Cylinder market research project?

Deliverables from the hydraulic cylinder market research project include comprehensive market analysis reports, detailed segmentation data, competitive landscape assessments, and forecasts. Clients will also receive actionable insights for strategic decision-making.

What are the market trends of hydraulic Cylinder?

Market trends include the rising adoption of multi-functional hydraulic cylinders and smart technologies. There is also a shift towards sustainability, prompting innovations in material usage and designs to enhance efficiency across sectors like construction and agriculture.