Hydraulic Dosing Pump Market Report

Published Date: 22 January 2026 | Report Code: hydraulic-dosing-pump

Hydraulic Dosing Pump Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Hydraulic Dosing Pump market, covering crucial insights and forecasts over the period from 2023 to 2033. It examines current market trends, regional dynamics, industry segments, and key market players.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

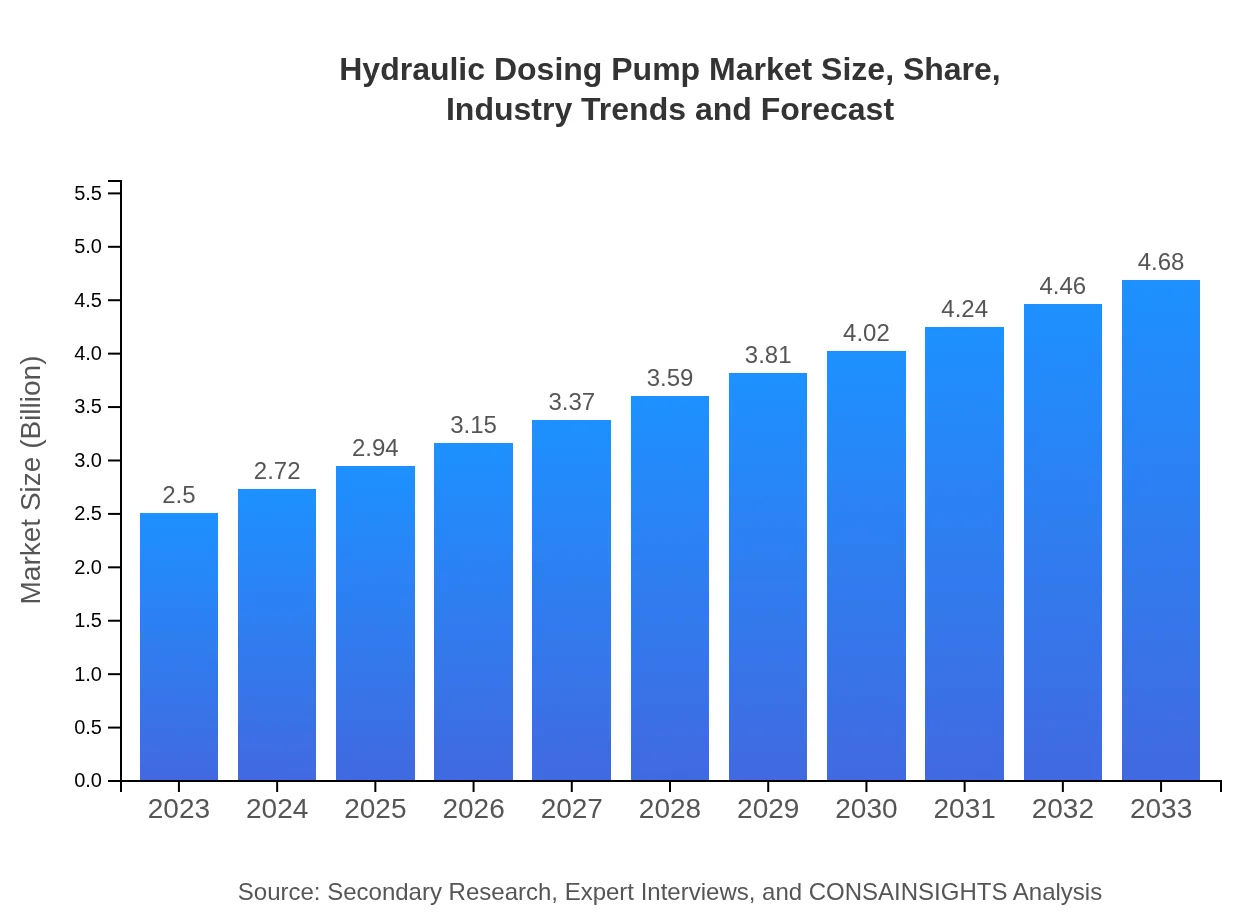

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $4.68 Billion |

| Top Companies | Grundfos, Flowserve, Dover Corporation, ITT Inc. |

| Last Modified Date | 22 January 2026 |

Hydraulic Dosing Pump Market Overview

Customize Hydraulic Dosing Pump Market Report market research report

- ✔ Get in-depth analysis of Hydraulic Dosing Pump market size, growth, and forecasts.

- ✔ Understand Hydraulic Dosing Pump's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Hydraulic Dosing Pump

What is the Market Size & CAGR of Hydraulic Dosing Pump market in 2023?

Hydraulic Dosing Pump Industry Analysis

Hydraulic Dosing Pump Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Hydraulic Dosing Pump Market Analysis Report by Region

Europe Hydraulic Dosing Pump Market Report:

The European market is set to grow from 0.63 billion USD in 2023 to 1.18 billion USD by 2033, with a strong focus on sustainability and compliance with stringent environmental regulations. The presence of key manufacturers and innovative product offerings further supports this growth.Asia Pacific Hydraulic Dosing Pump Market Report:

In the Asia Pacific region, the hydraulic dosing pump market is expected to grow from 0.48 billion USD in 2023 to 0.90 billion USD by 2033. This growth can be attributed to industrial expansion and increased investments in water facilities and infrastructure. Countries like China and India are major contributors to this growth, driven by their rapidly developing manufacturing and water treatment sectors.North America Hydraulic Dosing Pump Market Report:

North America is forecasted to see an increase from 0.81 billion USD in 2023 to 1.52 billion USD in 2033, driven by advancements in technology and increased regulatory requirements for water treatment processes. The US remains a key market due to its extensive industrial base and focus on sustainable practices.South America Hydraulic Dosing Pump Market Report:

The South American hydraulic dosing pump market is projected to increase from 0.25 billion USD in 2023 to 0.46 billion USD in 2033. The growth in this region is primarily driven by the booming oil and gas sector, as well as initiatives aimed at improving public utilities and clean water access.Middle East & Africa Hydraulic Dosing Pump Market Report:

In the Middle East and Africa, the market is expected to grow from 0.33 billion USD in 2023 to 0.62 billion USD in 2033, driven by increased investments in water management technologies and industrial processes, particularly in oil-rich nations.Tell us your focus area and get a customized research report.

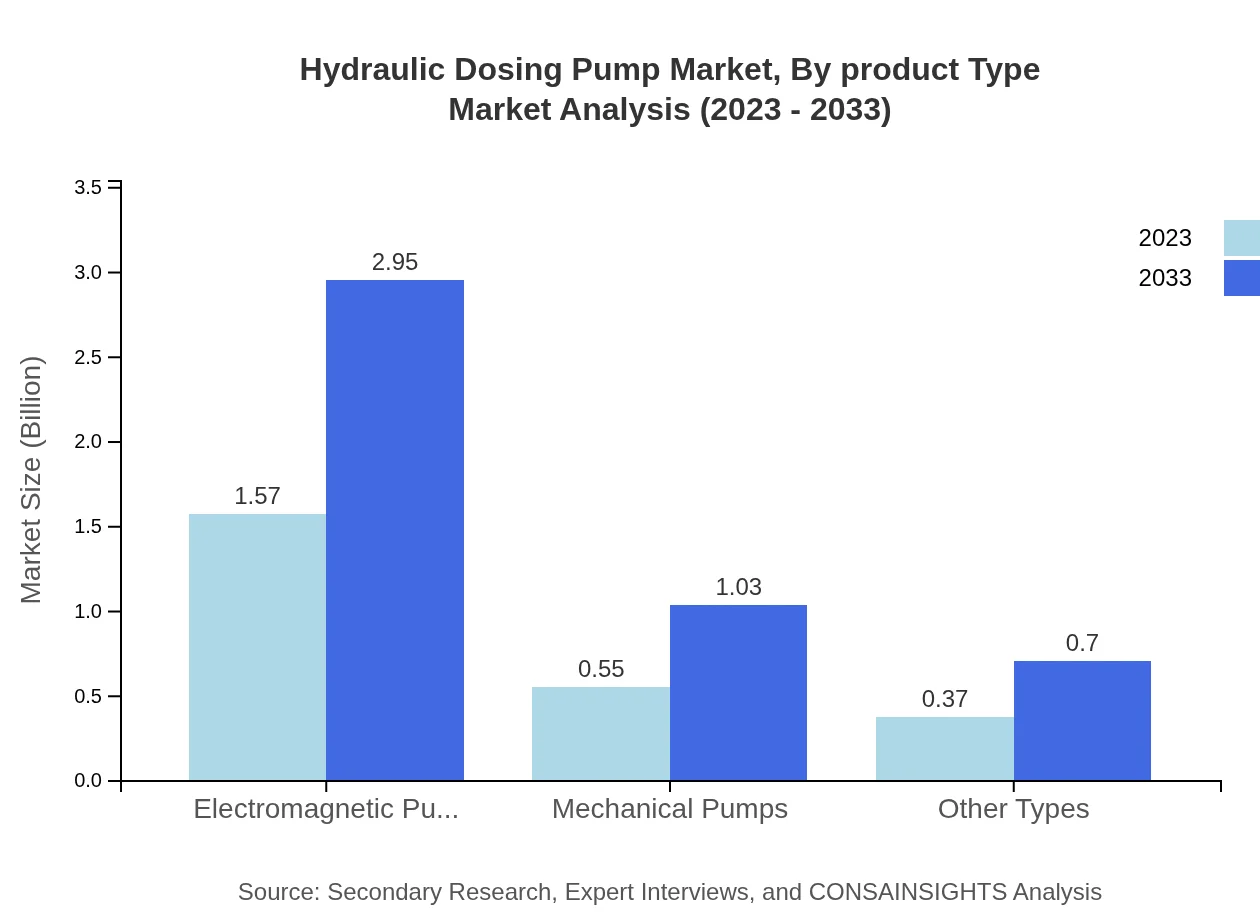

Hydraulic Dosing Pump Market Analysis By Product Type

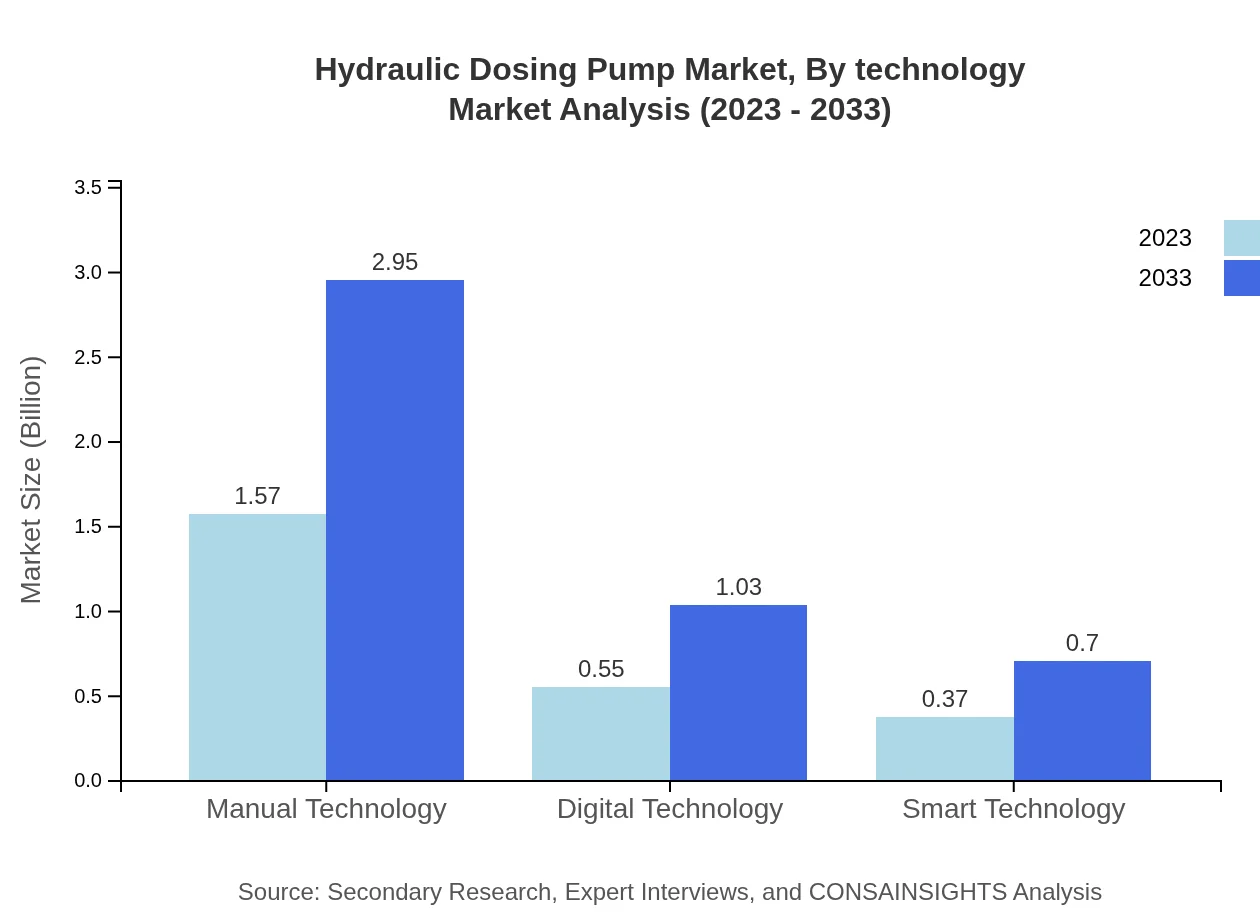

The market analysis by product type reveals that manual technology pumps accounted for a significant market share, with a size of 1.57 billion USD in 2023, projected to grow to 2.95 billion USD by 2033, representing a 62.96% market share. On the other hand, digital technology pumps held 0.55 billion USD in 2023, expected to reach 1.03 billion USD by 2033, showcasing a steady growth trend driven by increasing automation in industries.

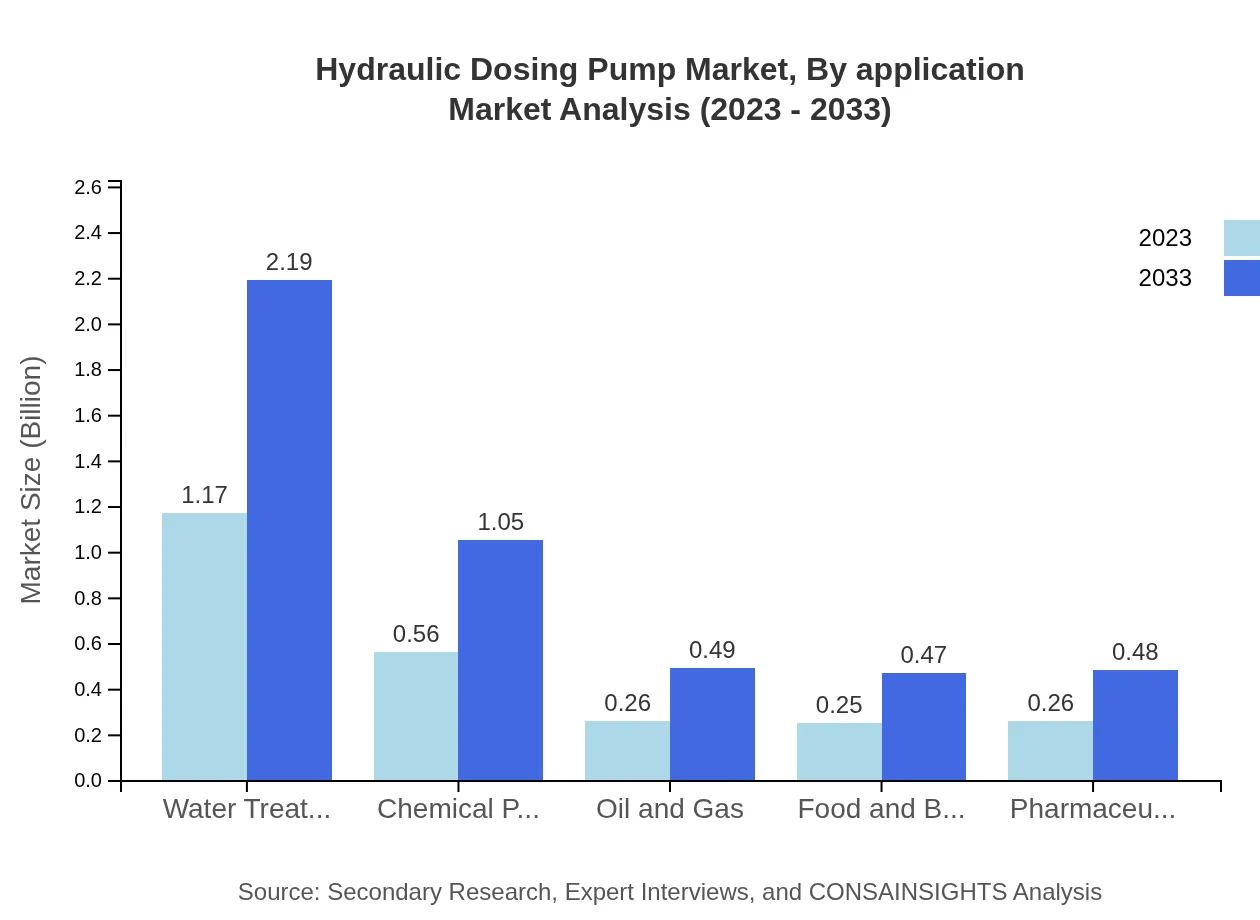

Hydraulic Dosing Pump Market Analysis By Application

By application, the water treatment segment represents the largest share of the hydraulic dosing pump market, with a size of 1.17 billion USD in 2023, anticipated to grow to 2.19 billion USD by 2033, making up 46.79% of the market. Other significant segments include chemical processing (0.56 billion USD in 2023, growing to 1.05 billion USD), reflecting the demand for precise dosing in various chemical applications.

Hydraulic Dosing Pump Market Analysis By Technology

The market analysis by technology indicates that electromagnetic pumps lead with a size of 1.57 billion USD in 2023, projected to reach 2.95 billion USD by 2033. This dominance is due to their efficiency and reliability in demanding applications. Mechanical pumps are also significant in terms of share, with a gradual increase from 0.55 billion USD in 2023 to 1.03 billion USD by 2033.

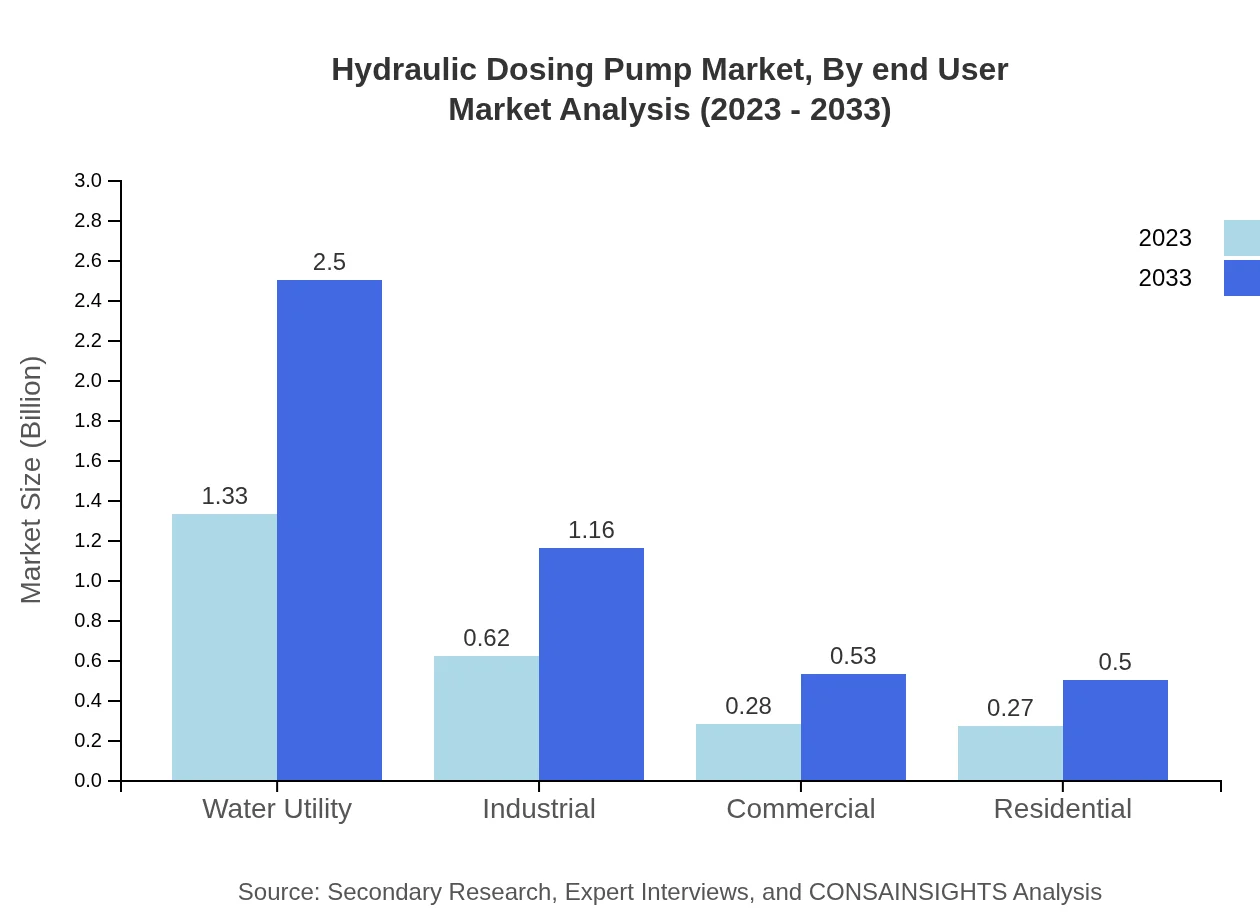

Hydraulic Dosing Pump Market Analysis By End User

In the context of end-user industries, the industrial segment is expected to show substantial growth, increasing from 0.62 billion USD in 2023 to 1.16 billion USD by 2033. The market’s resilience is greatly influenced by the demand for hydraulic dosing pumps in sectors such as pharmaceuticals and food and beverage manufacturing, where precision is paramount.

Hydraulic Dosing Pump Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Hydraulic Dosing Pump Industry

Grundfos:

A leading global manufacturer known for its advanced pump solutions, Grundfos offers a wide range of hydraulic dosing pumps with a focus on energy efficiency and innovative control technologies.Flowserve:

Flowserve is recognized for its comprehensive portfolio of pumps and valves, providing reliable hydraulic dosing solutions to various industries including oil and gas and water treatment.Dover Corporation:

Dover manufactures high-quality hydraulic dosing pumps noted for their technological advancements and robust design, serving diverse applications across global markets.ITT Inc.:

ITT is a major player in the pump industry, delivering a range of hydraulic dosing pumps engineered for durability and efficiency, especially in harsh environments.We're grateful to work with incredible clients.

FAQs

What is the market size of hydraulic Dosing Pump?

The global hydraulic dosing pump market is valued at approximately 2.5 billion in 2023 and is projected to grow at a CAGR of 6.3%, reaching new heights over the next decade by 2033.

What are the key market players or companies in the hydraulic Dosing Pump industry?

Key players in the hydraulic dosing pump industry include renowned manufacturers and suppliers that specialize in fluid management and dosing technologies, contributing significantly to market dynamics and innovations.

What are the primary factors driving the growth in the hydraulic Dosing Pump industry?

Growth in the hydraulic dosing pump industry is primarily driven by rising demand in various sectors like water utilities and industrial applications, alongside advancements in technology and increased environmental regulations requiring precise chemical dosing.

Which region is the fastest Growing in the hydraulic Dosing Pump?

Asia Pacific is anticipated to be the fastest-growing region, experiencing significant market growth from 0.48 billion in 2023 to an expected 0.90 billion by 2033, alongside Europe and North America also showing robust growth.

Does ConsaInsights provide customized market report data for the hydraulic Dosing Pump industry?

Yes, ConsaInsights offers tailored market report data for the hydraulic dosing pump industry, enabling clients to gain insights specific to their strategic needs and market interests.

What deliverables can I expect from this hydraulic Dosing Pump market research project?

Deliverables from the hydraulic dosing pump market research project may include comprehensive market analysis, segmentation data, competitive landscape overview, trends, and forecasts, all tailored to client requirements.

What are the market trends of hydraulic Dosing Pump?

Current trends in the hydraulic dosing pump market include adopting smart and digital technologies, enhancing energy efficiency, and integrating automation solutions to optimize performance across various applications.