Hydraulic Power Unit Market Report

Published Date: 22 January 2026 | Report Code: hydraulic-power-unit

Hydraulic Power Unit Market Size, Share, Industry Trends and Forecast to 2033

This report covers the Hydraulic Power Unit market, providing comprehensive insights, market trends, and forecasts from 2023 to 2033. It analyzes market size, growth patterns, and key segments, delivering valuable data for stakeholders and decision-makers.

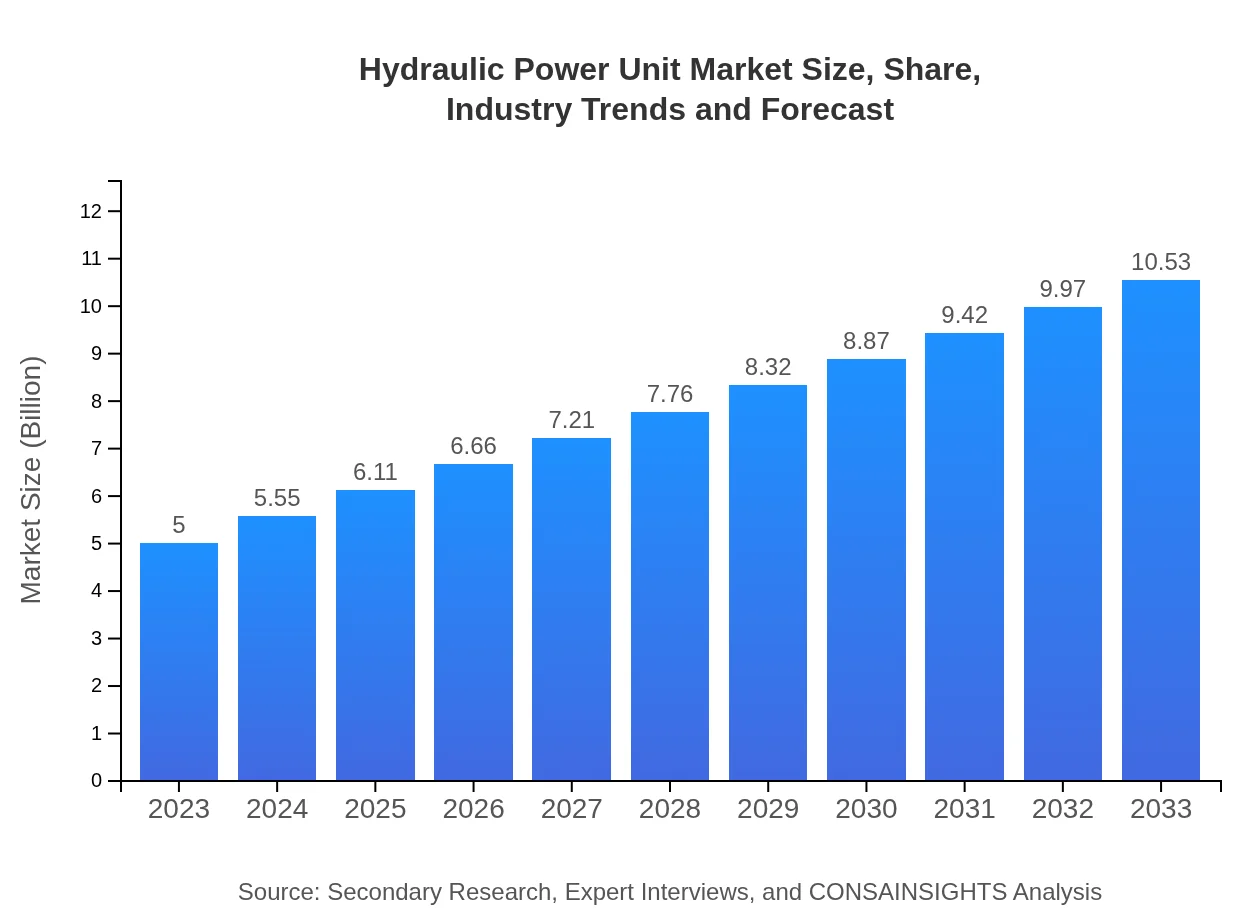

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Parker Hannifin Corporation, Bosch Rexroth AG, Eaton Corporation, Hydac International, Parker Hannifin Corporation |

| Last Modified Date | 22 January 2026 |

Hydraulic Power Unit Market Overview

Customize Hydraulic Power Unit Market Report market research report

- ✔ Get in-depth analysis of Hydraulic Power Unit market size, growth, and forecasts.

- ✔ Understand Hydraulic Power Unit's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Hydraulic Power Unit

What is the Market Size & CAGR of Hydraulic Power Unit market in 2023?

Hydraulic Power Unit Industry Analysis

Hydraulic Power Unit Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Hydraulic Power Unit Market Analysis Report by Region

Europe Hydraulic Power Unit Market Report:

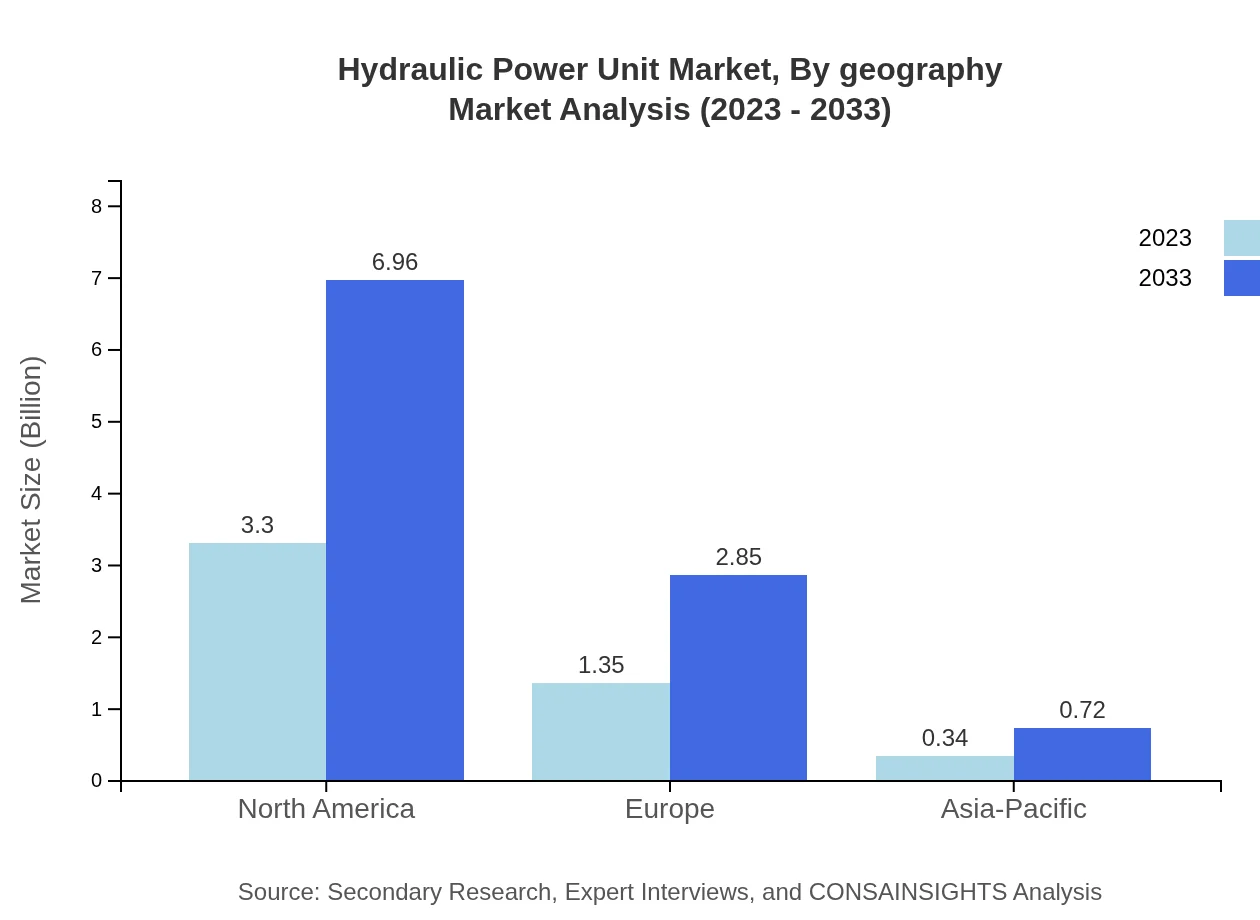

Europe's market is expected to increase from $1.49 billion in 2023 to $3.15 billion in 2033. The focus on sustainability and energy-efficient hydraulic solutions positions Europe as a leader in hydraulic technology advancements and innovation.Asia Pacific Hydraulic Power Unit Market Report:

In Asia Pacific, the Hydraulic Power Unit market is growing significantly, projected to reach $1.96 billion by 2033 from $0.93 billion in 2023. The region's rapid industrialization, infrastructure developments, and increasing adoption of technologically advanced hydraulic solutions are key drivers of this growth.North America Hydraulic Power Unit Market Report:

North America holds a substantial share of the Hydraulic Power Unit market, forecasted to grow from $1.94 billion in 2023 to $4.08 billion in 2033. This growth is due to the expansive manufacturing sector, infrastructure development, and a shift towards automation and sustainable energy solutions.South America Hydraulic Power Unit Market Report:

The South American Hydraulic Power Unit market, though relatively smaller, is expected to grow from $0.01 billion in 2023 to $0.03 billion by 2033. Growth will be supported by increased infrastructure projects and investment in mining and energy sectors.Middle East & Africa Hydraulic Power Unit Market Report:

The Middle East and Africa region is projected to witness growth from $0.63 billion in 2023 to $1.32 billion by 2033. Factors such as increased oil and gas exploration and infrastructure investment are expected to drive demand for hydraulic power units.Tell us your focus area and get a customized research report.

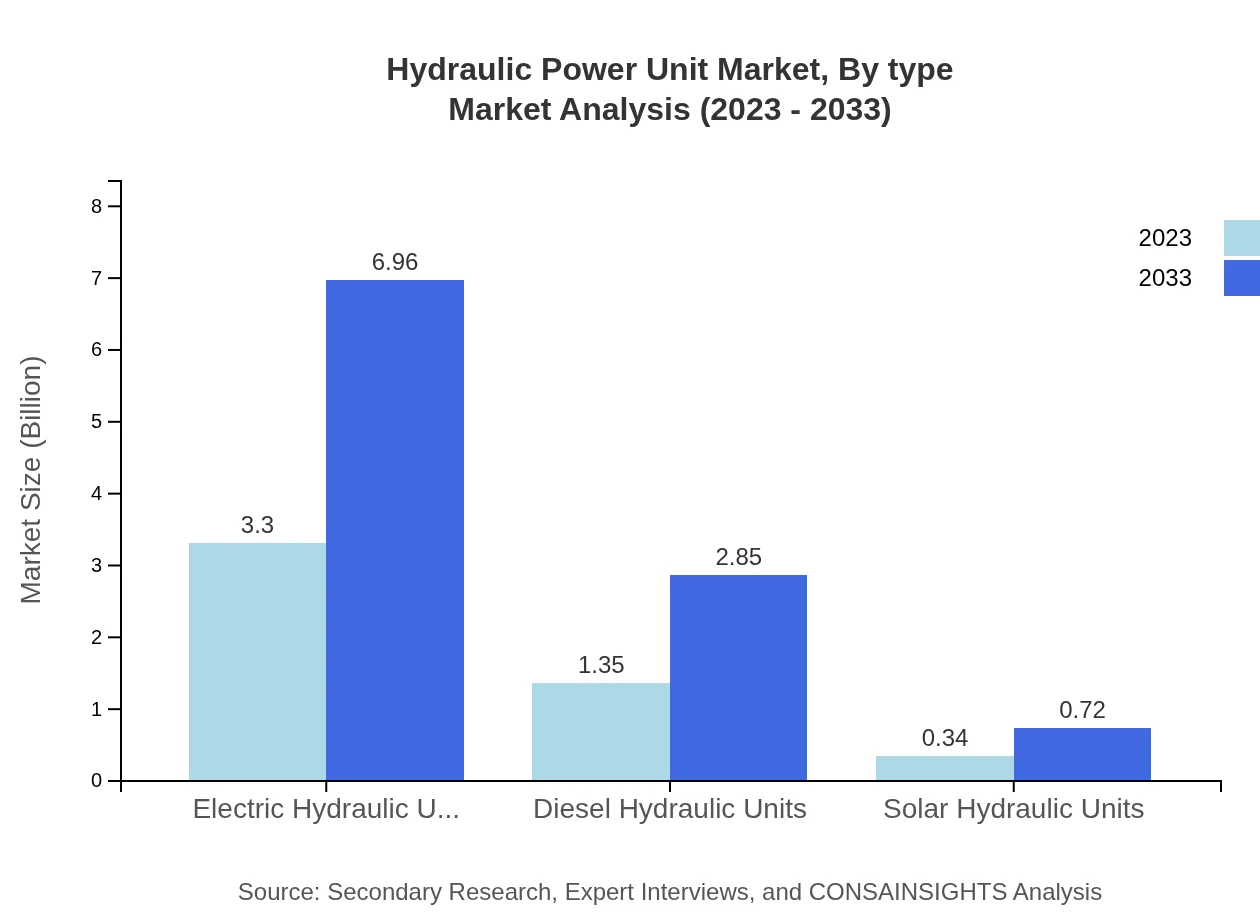

Hydraulic Power Unit Market Analysis By Type

The market is dominated by electric hydraulic units, with a market size reaching $6.96 billion in 2033 from $3.30 billion in 2023. Diesel hydraulic units are also significant, growing to $2.85 billion in 2033 from $1.35 billion in 2023. Solar hydraulic units, while smaller in share, are set to grow to $0.72 billion by 2033, indicating a shift towards sustainable solutions.

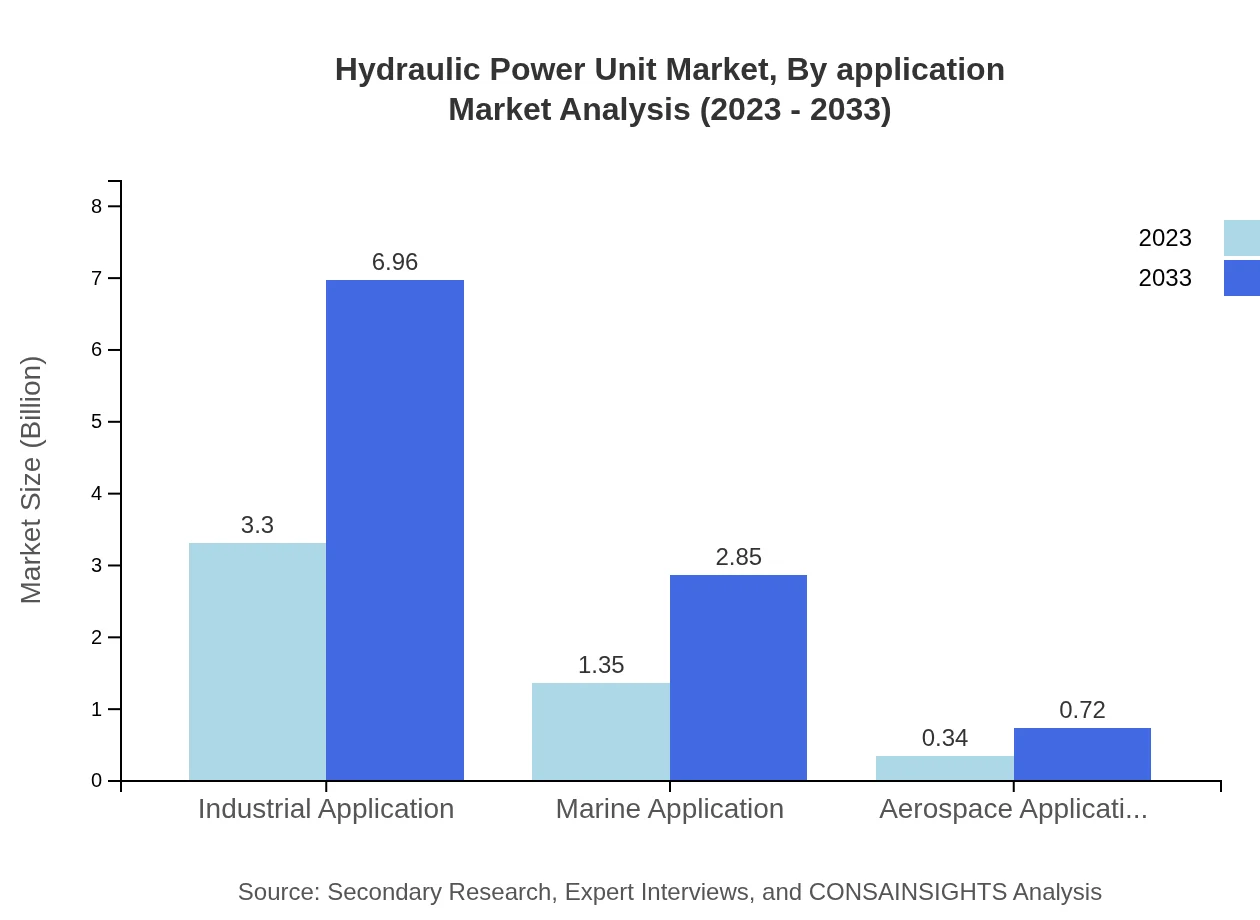

Hydraulic Power Unit Market Analysis By Application

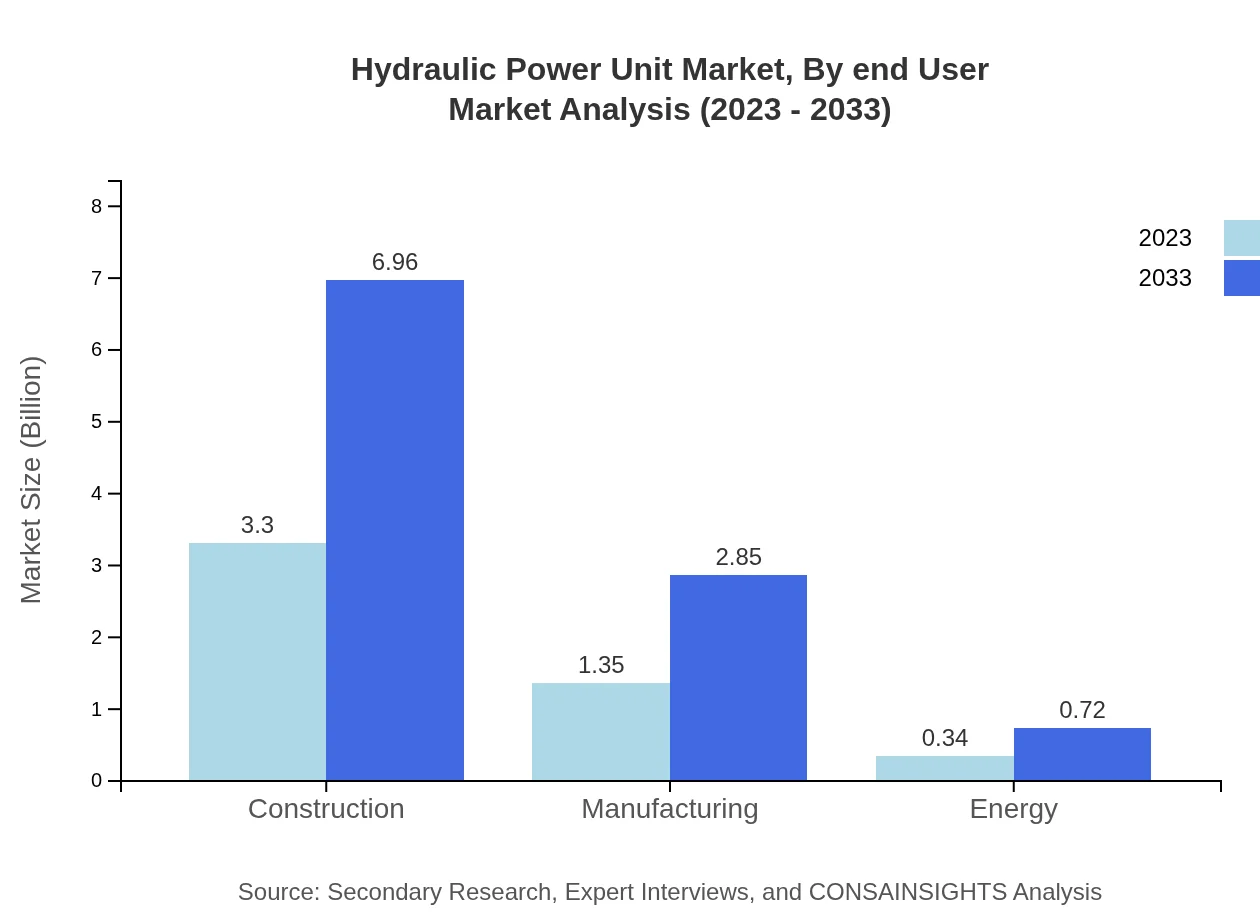

Applications in construction dominate the market, maintaining a robust share of 66.1% and expected to grow from $3.30 billion in 2023 to $6.96 billion in 2033. The manufacturing sector follows, with a consistent 27.1% share and market growth anticipated to reach $2.85 billion by 2033. The energy sector, though smaller, is projected to reach $0.72 billion by 2033, reflecting rising demand in renewable sectors.

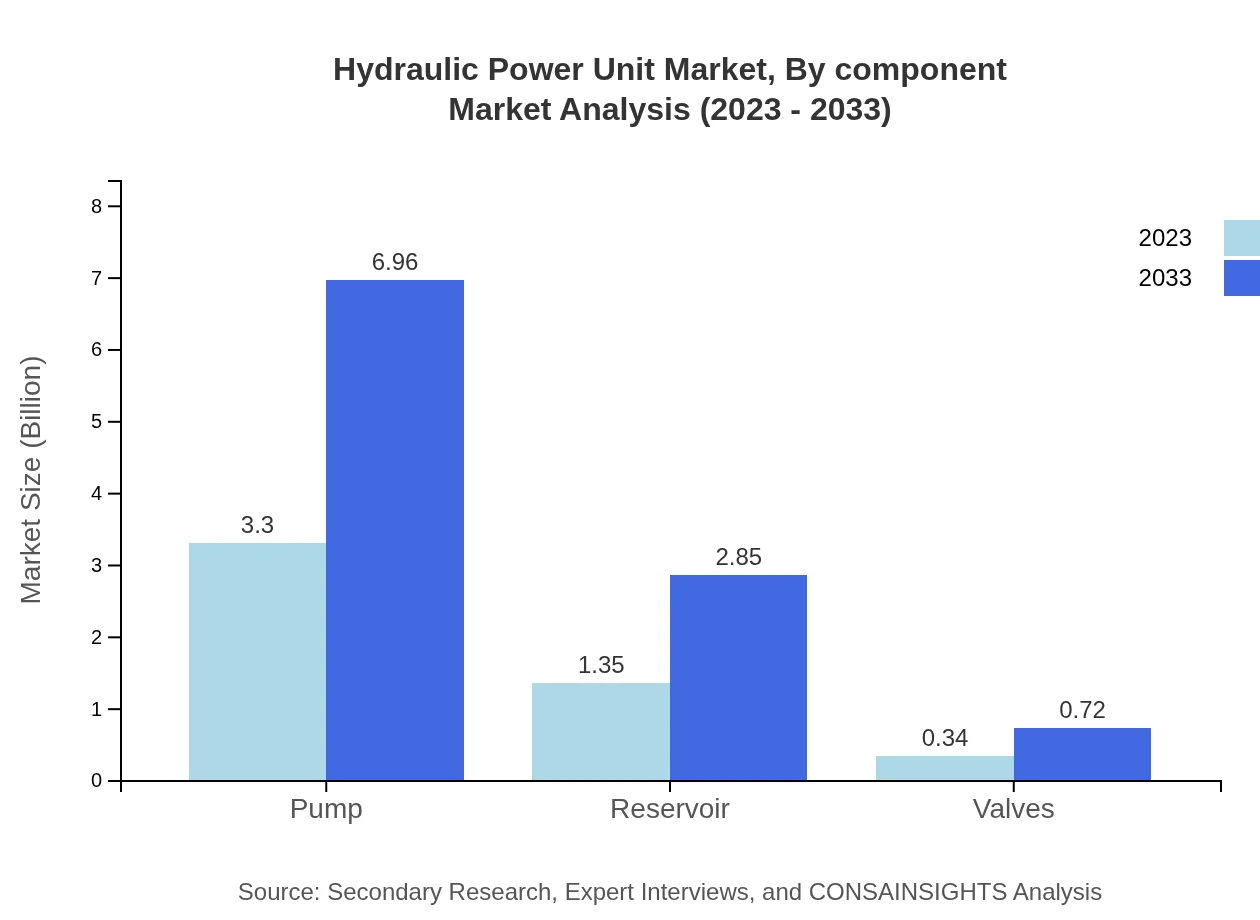

Hydraulic Power Unit Market Analysis By Component

The hydraulic power unit market can be assessed by its components, including pumps, reservoirs, and valves. Pumps are set to dominate the market size at $6.96 billion by 2033 with a consistent share of 66.1%. Reservoirs and valves are also integral, with respective anticipated market sizes reaching $2.85 billion and $0.72 billion by 2033.

Hydraulic Power Unit Market Analysis By End User

The primary end-users include industrial applications and marine applications. Industrial applications lead the market share with 66.1% and projected growth from $3.30 billion in 2023 to $6.96 billion by 2033. Marine applications, while smaller, are expected to grow to $2.85 billion indicating a growing focus on marine energy efficiency and automation.

Hydraulic Power Unit Market Analysis By Geography

Geographically, North America leads in total revenue, driven by advanced industrial operations and a significant manufacturing base. Europe follows closely, showcasing a commitment to energy-efficient solutions and technological innovation. Asia Pacific is rapidly expanding due to increasing urbanization and industrial projects, while the Middle East continues to leverage oil and gas opportunities.

Hydraulic Power Unit Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Hydraulic Power Unit Industry

Parker Hannifin Corporation:

Parker Hannifin is a global leader in motion and control technologies, providing a diverse range of hydraulic products and systems that enhance performance and efficiency for various industries.Bosch Rexroth AG:

Bosch Rexroth specializes in drive and control technologies, offering cutting-edge hydraulic solutions including customized hydraulic power units for industrial applications.Eaton Corporation:

Eaton provides hydraulic systems and solutions geared towards energy-efficient performance, serving diverse sectors including aerospace, automotive, and industrial markets.Hydac International:

Hydac is recognized for its innovative hydraulic products and systems, catering to a variety of applications while emphasizing sustainability and efficiency.Parker Hannifin Corporation:

Parker Hannifin Corporation is a financial and technology leader in motion control and fluid power offering state-of-the-art services for hydraulic solutions, focusing on diverse industries.We're grateful to work with incredible clients.

FAQs

What is the market size of Hydraulic Power Unit?

The hydraulic power unit market is projected to grow from approximately $5 billion in 2023, with a compound annual growth rate (CAGR) of 7.5%, reaching around $11 billion by 2033.

What are the key market players or companies in the Hydraulic Power Unit industry?

Key players in the hydraulic power unit market include major manufacturers and suppliers such as Parker Hannifin, Bosch Rexroth, Eaton Corporation, and Hydac. These companies are known for their innovation and extensive product portfolios in the hydraulic systems sector.

What are the primary factors driving the growth in the Hydraulic Power Unit industry?

The growth of the hydraulic power unit industry is driven by factors such as increasing demand in construction and manufacturing sectors, technological advancements, and a focus on renewable energy sources, with electric and solar units gaining popularity.

Which region is the fastest Growing in the Hydraulic Power Unit market?

North America is currently the fastest-growing region in the hydraulic power unit market, projected to grow from $1.94 billion in 2023 to $4.08 billion by 2033, indicating a robust expansion of infrastructure and industrial applications.

Does ConsaInsights provide customized market report data for the Hydraulic Power Unit industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs within the hydraulic power unit industry, providing detailed insights and analyses based on clients' requirements.

What deliverables can I expect from this Hydraulic Power Unit market research project?

Expect to receive comprehensive market analysis, including market size, trends, growth forecasts, segmented data by region and application, along with actionable insights for strategic decision-making.

What are the market trends of Hydraulic Power Unit?

Current market trends in hydraulic power units include the increasing adoption of electric and solar units, growing automation in industrial applications, and a push towards more energy-efficient solutions in diverse sectors.