Hydraulic Pump Market Report

Published Date: 22 January 2026 | Report Code: hydraulic-pump

Hydraulic Pump Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Hydraulic Pump market, covering insights from 2023 to 2033. It includes trends, market size, key players, and forecasts to aid stakeholders in making informed decisions.

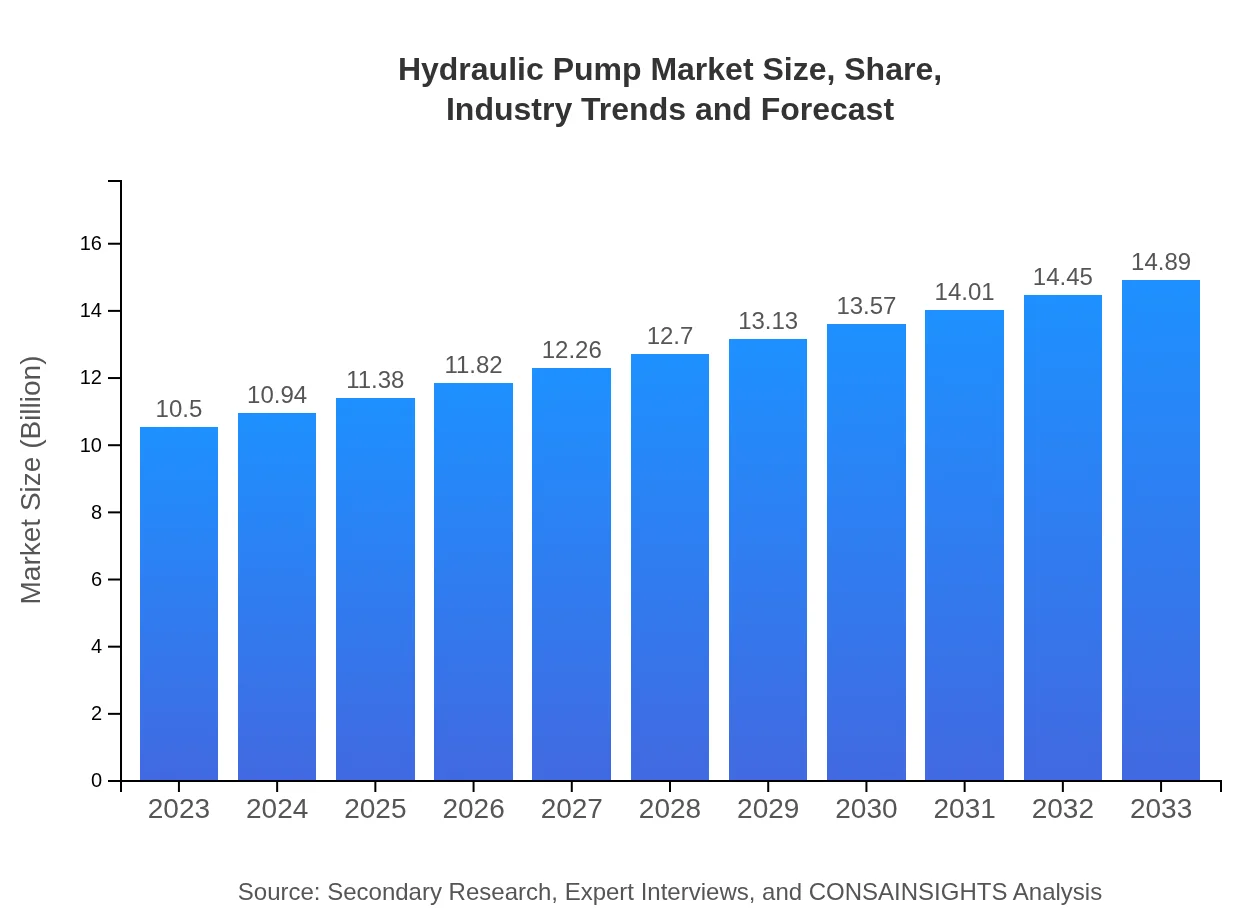

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.50 Billion |

| CAGR (2023-2033) | 3.5% |

| 2033 Market Size | $14.89 Billion |

| Top Companies | Bosch Rexroth AG, Eaton Corporation, Parker Hannifin Corporation |

| Last Modified Date | 22 January 2026 |

Hydraulic Pump Market Overview

Customize Hydraulic Pump Market Report market research report

- ✔ Get in-depth analysis of Hydraulic Pump market size, growth, and forecasts.

- ✔ Understand Hydraulic Pump's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Hydraulic Pump

What is the Market Size & CAGR of Hydraulic Pump market in 2023?

Hydraulic Pump Industry Analysis

Hydraulic Pump Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Hydraulic Pump Market Analysis Report by Region

Europe Hydraulic Pump Market Report:

The European market is anticipated to grow from $2.88 billion in 2023 to $4.09 billion in 2033. European industries are increasingly adopting hydraulic systems for energy efficiency, prompted by stringent regulations and environmental concerns.Asia Pacific Hydraulic Pump Market Report:

The Asia Pacific region is forecasted to experience substantial growth, with the market size projected to rise from $2.07 billion in 2023 to $2.94 billion in 2033. Growing industrialization and infrastructure development, particularly in China and India, contribute significantly to this demand.North America Hydraulic Pump Market Report:

North America holds a significant share of the hydraulic pump market, reaching $3.89 billion in 2023 and projecting to grow to $5.52 billion by 2033. The increase in manufacturing and the trend towards automation are critical drivers.South America Hydraulic Pump Market Report:

In South America, the hydraulic pump market is expanding at a steady pace, moving from $0.56 billion in 2023 to $0.80 billion in 2033. The region's agricultural sector plays a pivotal role in sustaining growth, particularly in Brazil and Argentina.Middle East & Africa Hydraulic Pump Market Report:

The Middle East and Africa markets are estimated to grow from $1.09 billion in 2023 to $1.55 billion in 2033, driven by infrastructural investments and the expansion of oil and gas industries.Tell us your focus area and get a customized research report.

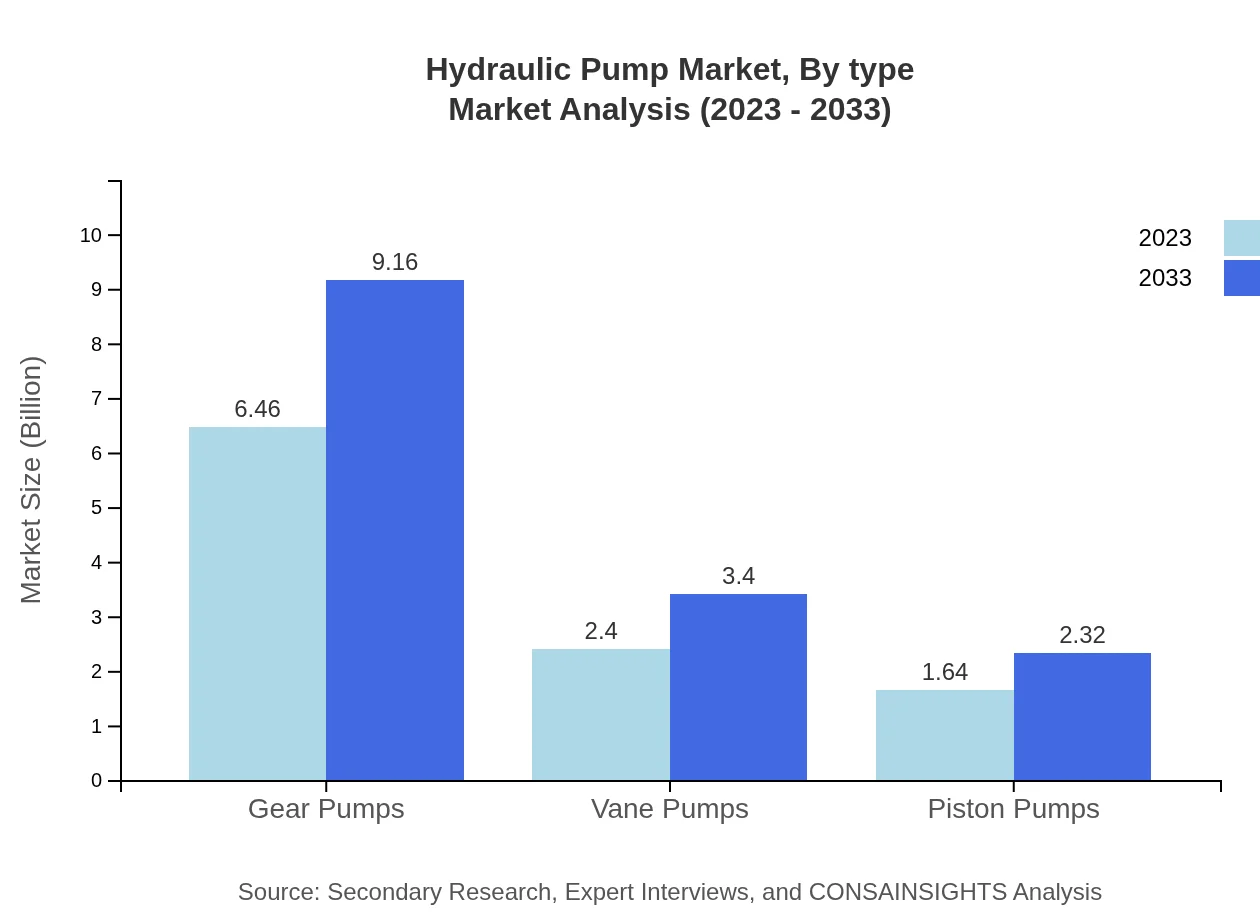

Hydraulic Pump Market Analysis By Type

The Hydraulic Pump Market is primarily segmented into Gear Pumps, Vane Pumps, and Piston Pumps. Gear Pumps dominate the market with a size of $6.46 billion in 2023, expected to grow to $9.16 billion by 2033, holding a share of 61.54%. Vane Pumps follow with a market size of $2.40 billion in 2023, expanding to $3.40 billion by 2033, showcasing a 22.86% market share. Piston Pumps, with a size of $1.64 billion in 2023, will grow to $2.32 billion by 2033, maintaining a 15.6% share.

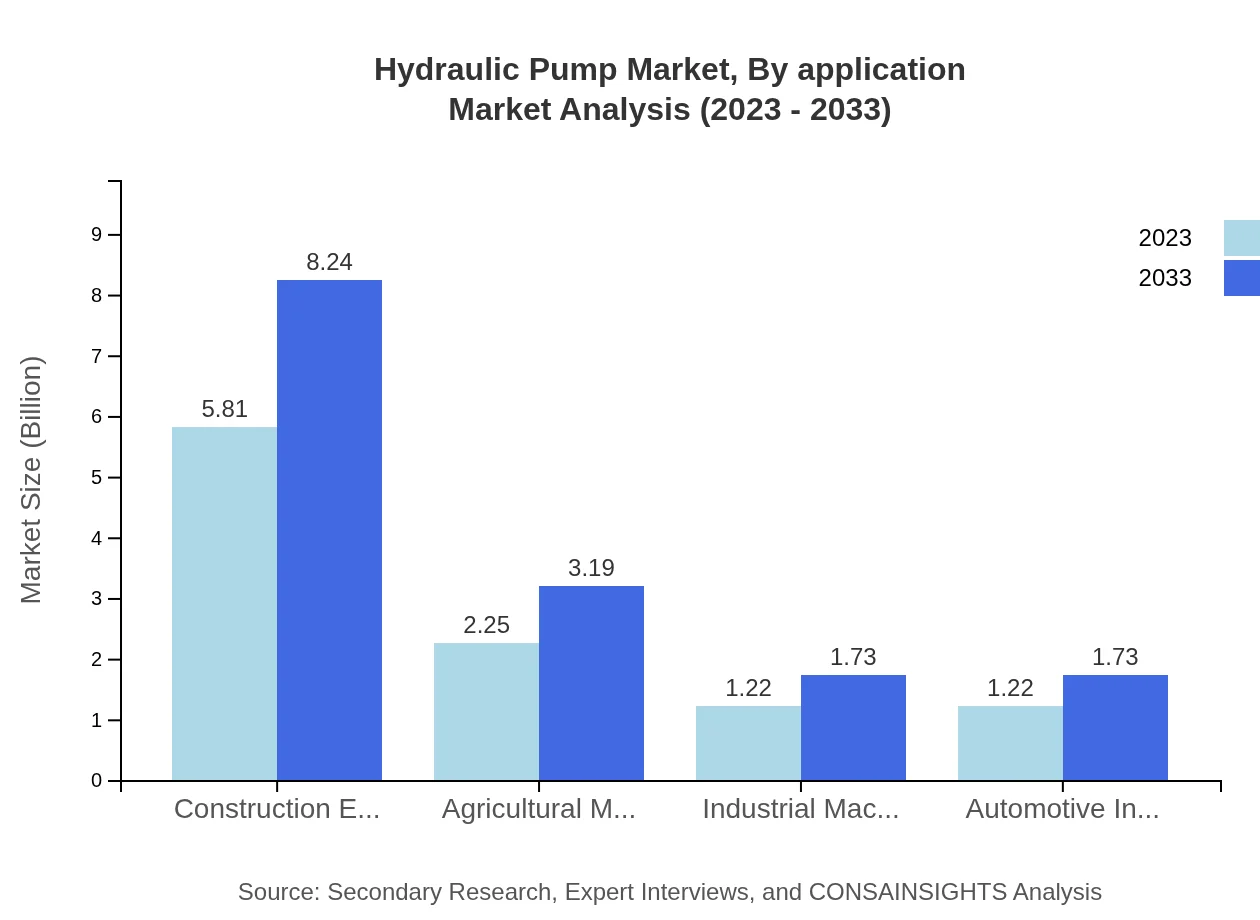

Hydraulic Pump Market Analysis By Application

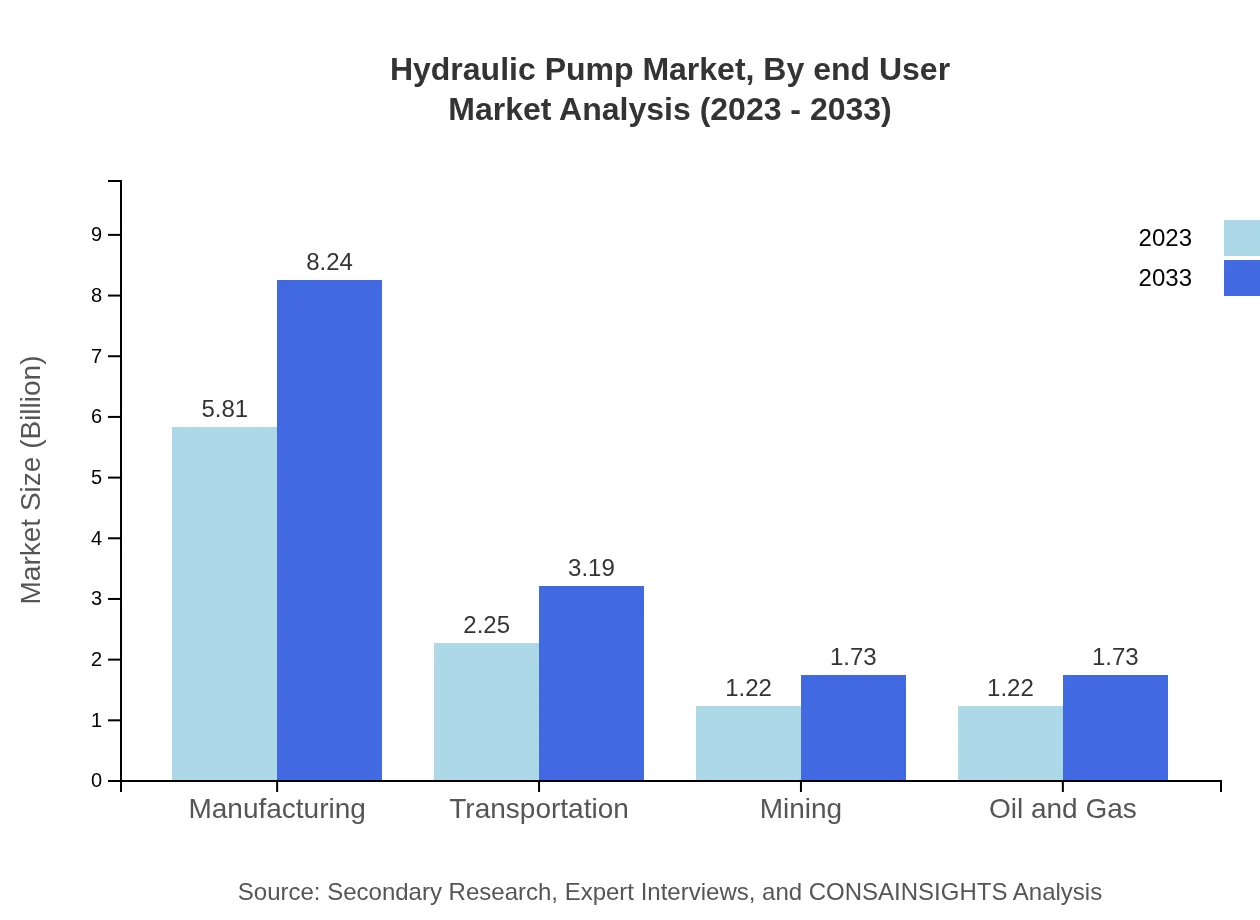

The market is classified into manufacturing, transportation, mining, and oil & gas applications, with manufacturing leads at $5.81 billion in 2023 and $8.24 billion in 2033 (55.36% market share). Transportation and mining applications have significant contributions too, valued at $2.25 billion and $1.22 billion in 2023, respectively.

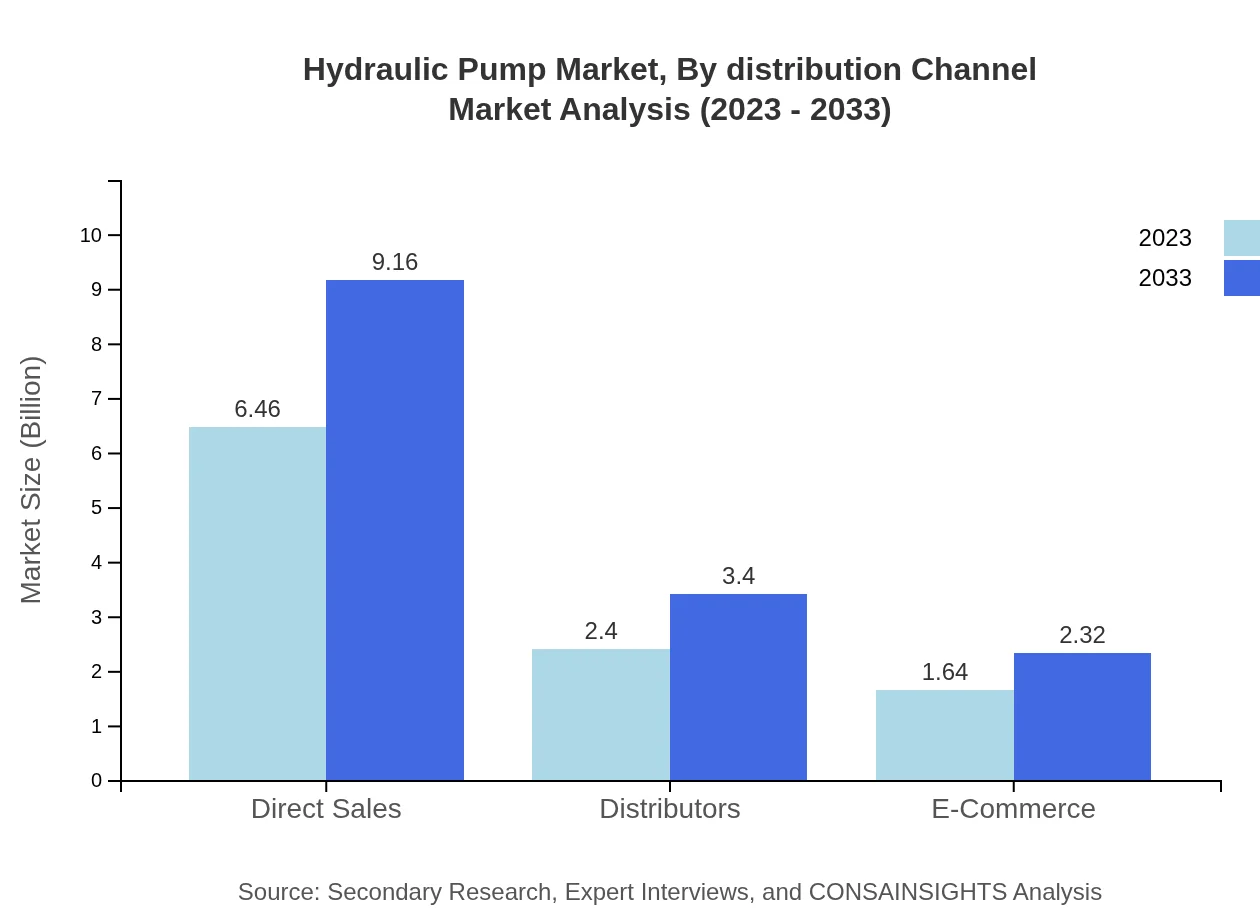

Hydraulic Pump Market Analysis By Distribution Channel

The Hydraulic Pump Market distribution channels include direct sales, distributors, and e-commerce. Direct sales account for a significant size of $6.46 billion in 2023 and will rise to $9.16 billion by 2033, representing 61.54%. Distributors and e-commerce show growing trends, supporting overall market accessibility.

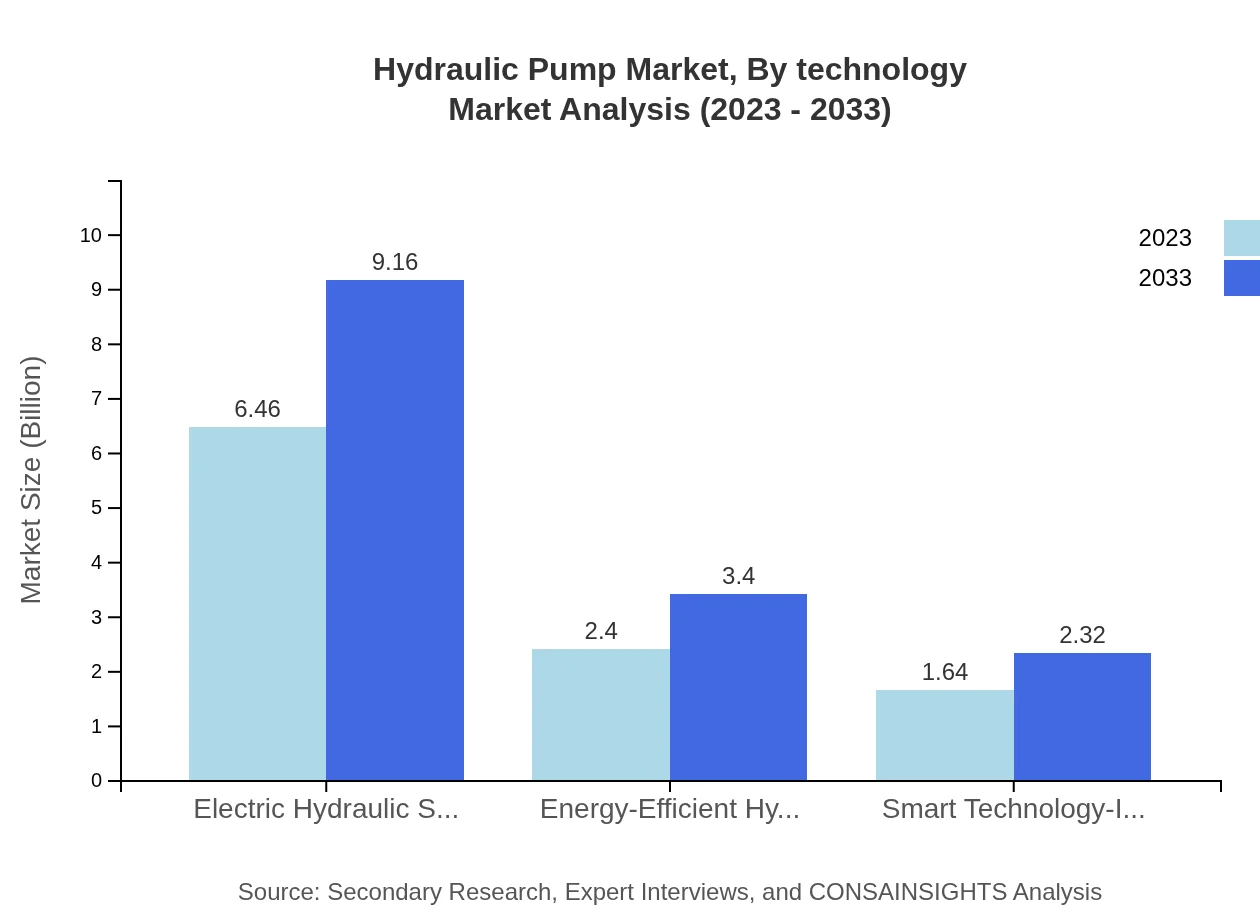

Hydraulic Pump Market Analysis By Technology

Technological advancements, specifically energy-efficient hydraulic pumps and smart technology-integrated pumps, play fundamental roles in market growth. Energy-efficient pumps valued at $2.40 billion in 2023 will reach $3.40 billion by 2033, while smart technology integrated pumps grow from $1.64 billion to $2.32 billion, reflecting innovations in operational efficiency.

Hydraulic Pump Market Analysis By End User

End-user segmentation consists mainly of construction, agricultural machinery, industrial machinery, and automotive industries. The construction industry is a major contributor with a $5.81 billion market size in 2023, set to increase to $8.24 billion by 2033, followed by agricultural machinery at $2.25 billion in 2023, matching that growth trajectory.

Hydraulic Pump Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Hydraulic Pump Industry

Bosch Rexroth AG:

A leading global supplier of drive and control technologies offering a diverse range of hydraulic pumps and systems, Bosch Rexroth is known for its innovative solutions in industrial applications.Eaton Corporation:

Eaton specializes in power management and hydraulic systems, providing products that improve performance and efficiency in a variety of sectors, including aerospace, automotive, and manufacturing.Parker Hannifin Corporation:

Parker is a significant player in hydraulics, providing a comprehensive selection of hydraulic pumps, technology, and solutions to enhance machine productivity across multiple industries.We're grateful to work with incredible clients.

FAQs

What is the market size of hydraulic Pump?

As of 2023, the hydraulic pump market is valued at approximately $10.5 billion, with an expected CAGR of 3.5% projected until 2033. This growth reflects increasing demand across various sectors, including construction, manufacturing, and agriculture.

What are the key market players or companies in the hydraulic Pump industry?

Key players in the hydraulic pump industry include Parker Hannifin, Bosch Rexroth, Eaton, and Danfoss. These companies significantly influence market trends through innovation and sustainability practices, catering to diverse applications across multiple sectors.

What are the primary factors driving the growth in the hydraulic Pump industry?

Primary growth drivers include rising infrastructure investments, advancements in manufacturing technology, and a focus on energy-efficient solutions. Additionally, the demand for automation and smart machinery further boosts the hydraulic pump market's expansion.

Which region is the fastest Growing in the hydraulic Pump market?

The North American region is currently the fastest-growing market for hydraulic pumps, projected to grow from $3.89 billion in 2023 to $5.52 billion in 2033. This growth is driven by increased manufacturing activities and innovation in hydraulic technologies.

Does ConsaInsights provide customized market report data for the hydraulic Pump industry?

Yes, ConsaInsights offers customized reports tailored to specific client needs within the hydraulic-pump industry. Clients can access detailed analyses of market trends, competitive landscapes, and forecasts tailored to their business requirements.

What deliverables can I expect from this hydraulic Pump market research project?

Deliverables typically include detailed market analysis reports, segment data insights, regional growth forecasts, and competitive landscape reviews. Clients receive actionable recommendations to guide strategic decisions in the hydraulic pump sector.

What are the market trends of hydraulic Pump?

Current trends in the hydraulic pump market highlight a shift towards energy-efficient pumps, integration of smart technologies, and increasing automation in manufacturing processes. These trends reflect evolving customer demands for sustainable solutions and improved operational efficiency.