Indium Phosphide Wafer Market Report

Published Date: 31 January 2026 | Report Code: indium-phosphide-wafer

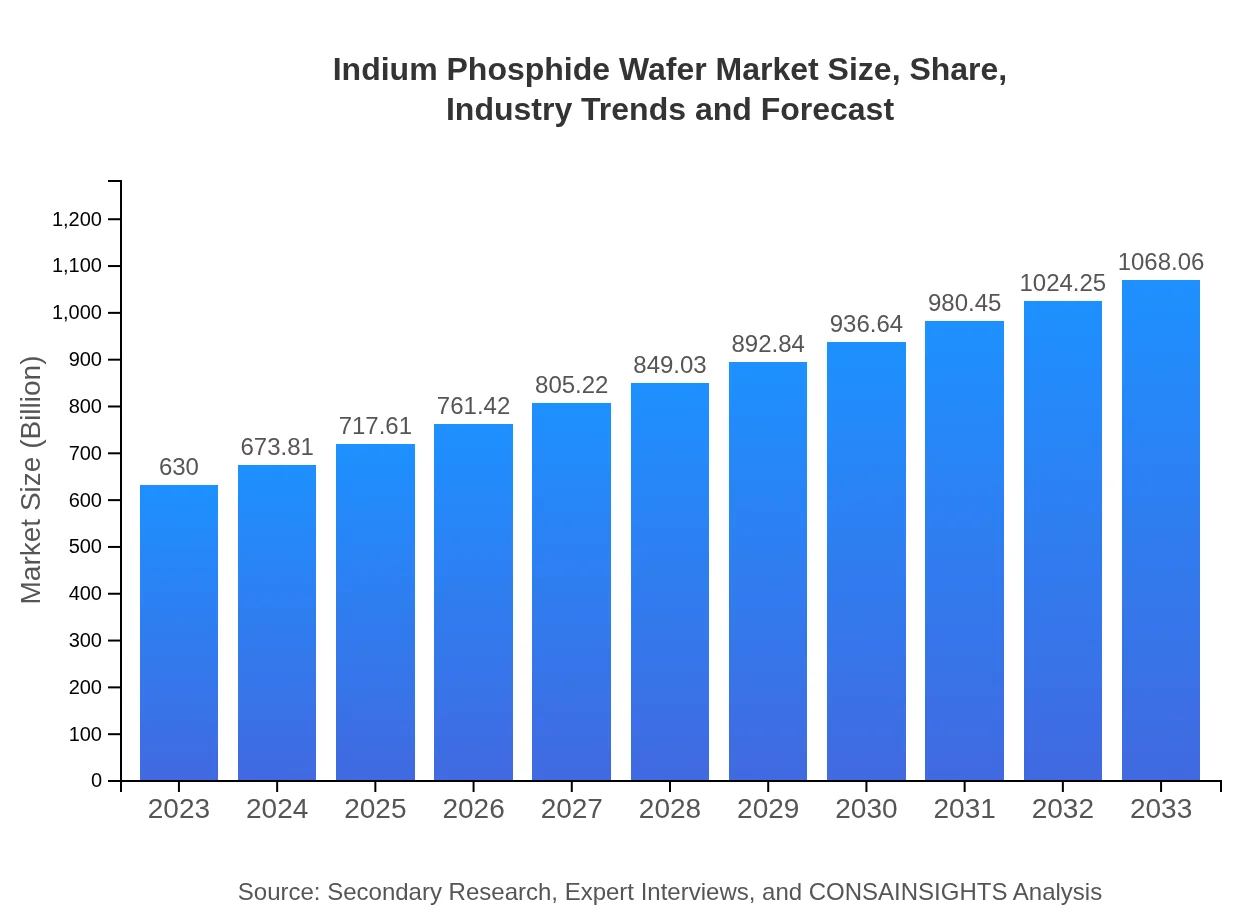

Indium Phosphide Wafer Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Indium Phosphide Wafer market, including market trends, size, growth forecasts from 2023 to 2033, and insights into key regions and segments.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $630.00 Million |

| CAGR (2023-2033) | 5.3% |

| 2033 Market Size | $1068.06 Million |

| Top Companies | IQE plc, Wafer Technology Ltd, Aixtron SE |

| Last Modified Date | 31 January 2026 |

Indium Phosphide Wafer Market Overview

Customize Indium Phosphide Wafer Market Report market research report

- ✔ Get in-depth analysis of Indium Phosphide Wafer market size, growth, and forecasts.

- ✔ Understand Indium Phosphide Wafer's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Indium Phosphide Wafer

What is the Market Size & CAGR of Indium Phosphide Wafer market in 2023?

Indium Phosphide Wafer Industry Analysis

Indium Phosphide Wafer Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Indium Phosphide Wafer Market Analysis Report by Region

Europe Indium Phosphide Wafer Market Report:

The European market is experiencing steady growth, anticipated to grow from $185.79 million in 2023 to $314.97 million by 2033. This growth is spurred by advancements in photonics technology and increasing research ventures, especially in the field of quantum computing.Asia Pacific Indium Phosphide Wafer Market Report:

The Asia Pacific region is projected to show significant growth, with the market expected to rise from $115.79 million in 2023 to $196.31 million in 2033. The region benefits from a booming electronics sector and increasing demand for high-speed telecommunications, supported by investments in R&D.North America Indium Phosphide Wafer Market Report:

North America remains a dominant player in the Indium Phosphide wafer market, with a projected increase from $239.09 million in 2023 to $405.33 million in 2033. The presence of leading semiconductor companies and growing defense applications contribute significantly to this growth.South America Indium Phosphide Wafer Market Report:

In South America, the market for Indium Phosphide wafers is set to grow from $60.16 million in 2023 to $102.00 million in 2033, driven by investments in telecommunications infrastructure and expansion in research capabilities.Middle East & Africa Indium Phosphide Wafer Market Report:

The Middle East and Africa market is small yet growing, projected to move from $29.17 million in 2023 to $49.45 million in 2033, as increasing focus on technology infrastructure drives demand for high-performance components.Tell us your focus area and get a customized research report.

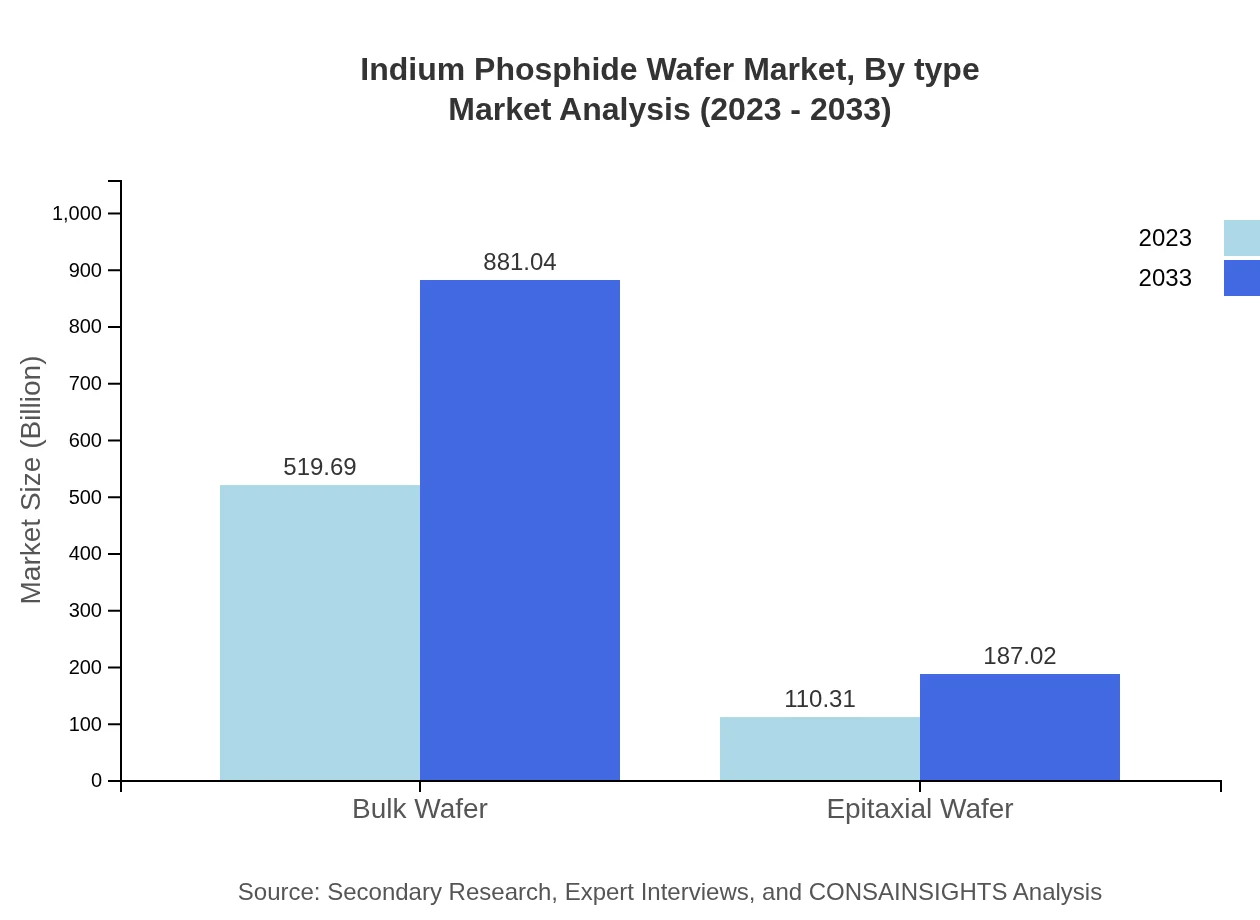

Indium Phosphide Wafer Market Analysis By Type

The Indium Phosphide wafer market is divided into Bulk Wafer and Epitaxial Wafer segments. Bulk Wafers hold the majority share, with a market size expected to increase from $519.69 million in 2023 to $881.04 million in 2033. Epitaxial Wafers follow, growing from $110.31 million to $187.02 million over the same period, capturing the needs of advanced applications in research and telecommunication.

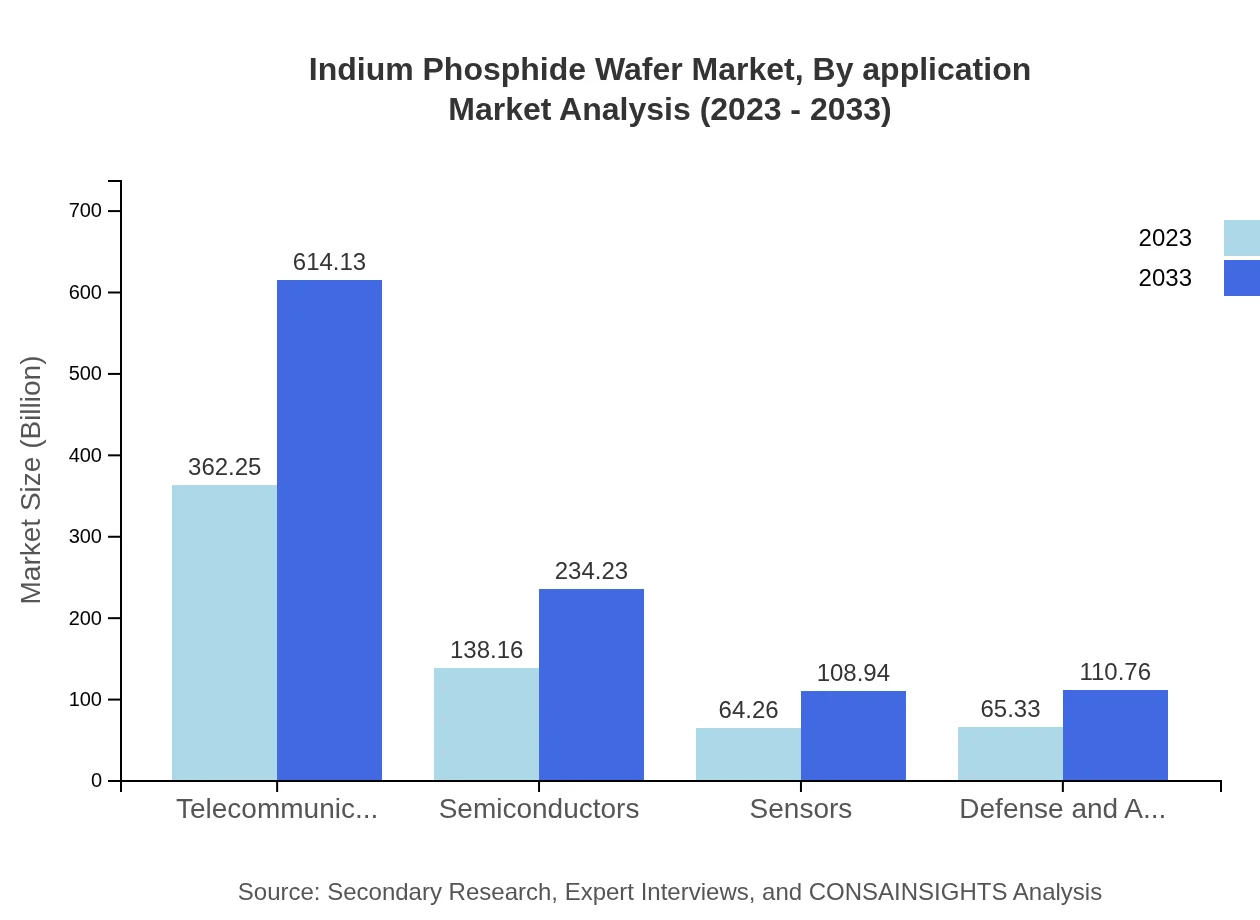

Indium Phosphide Wafer Market Analysis By Application

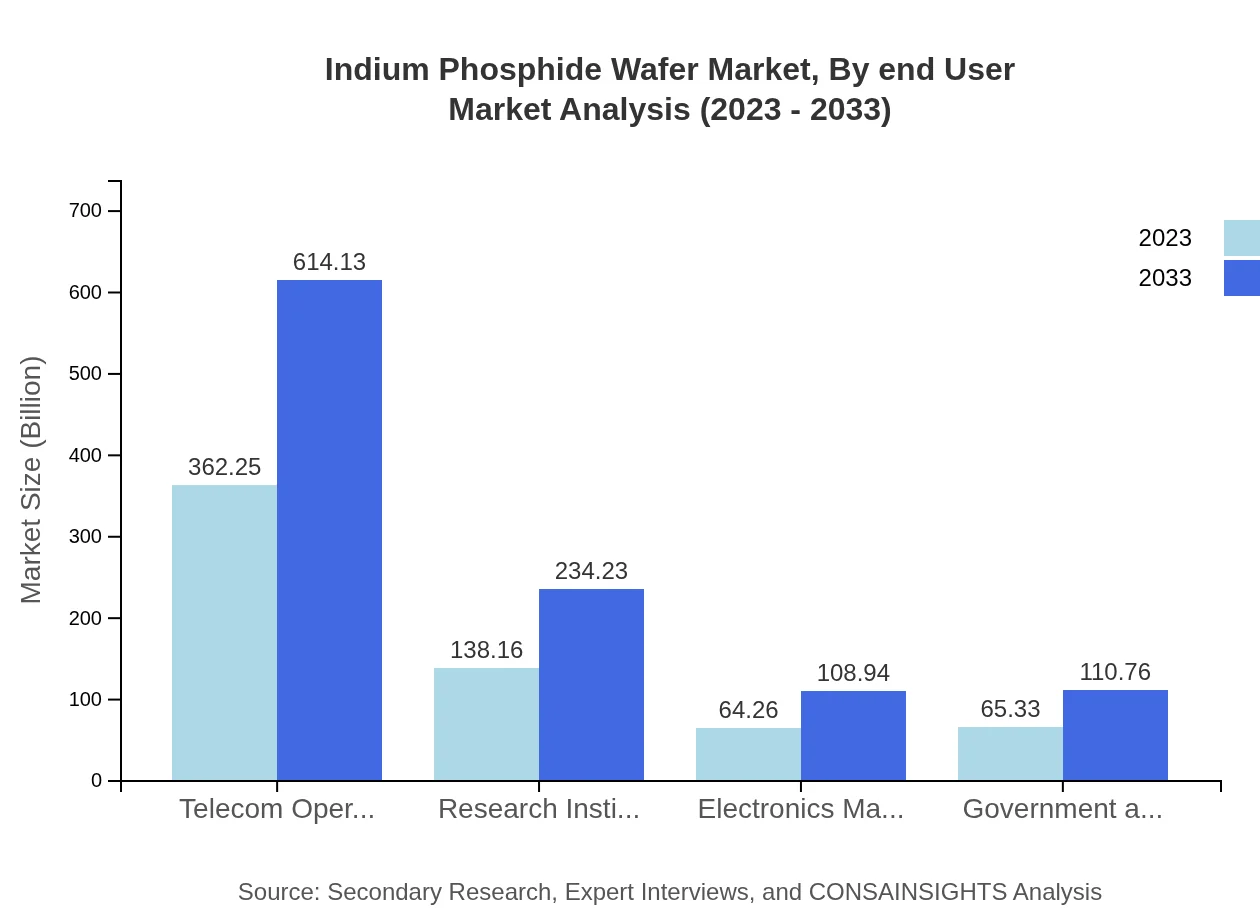

In terms of applications, telecommunications dominates the market, valued at $362.25 million in 2023 and projected to reach $614.13 million in 2033. Research institutes, electronics manufacturers, and government/defense sectors also represent significant segments, reflecting the widespread utility of InP wafers across various high-tech applications.

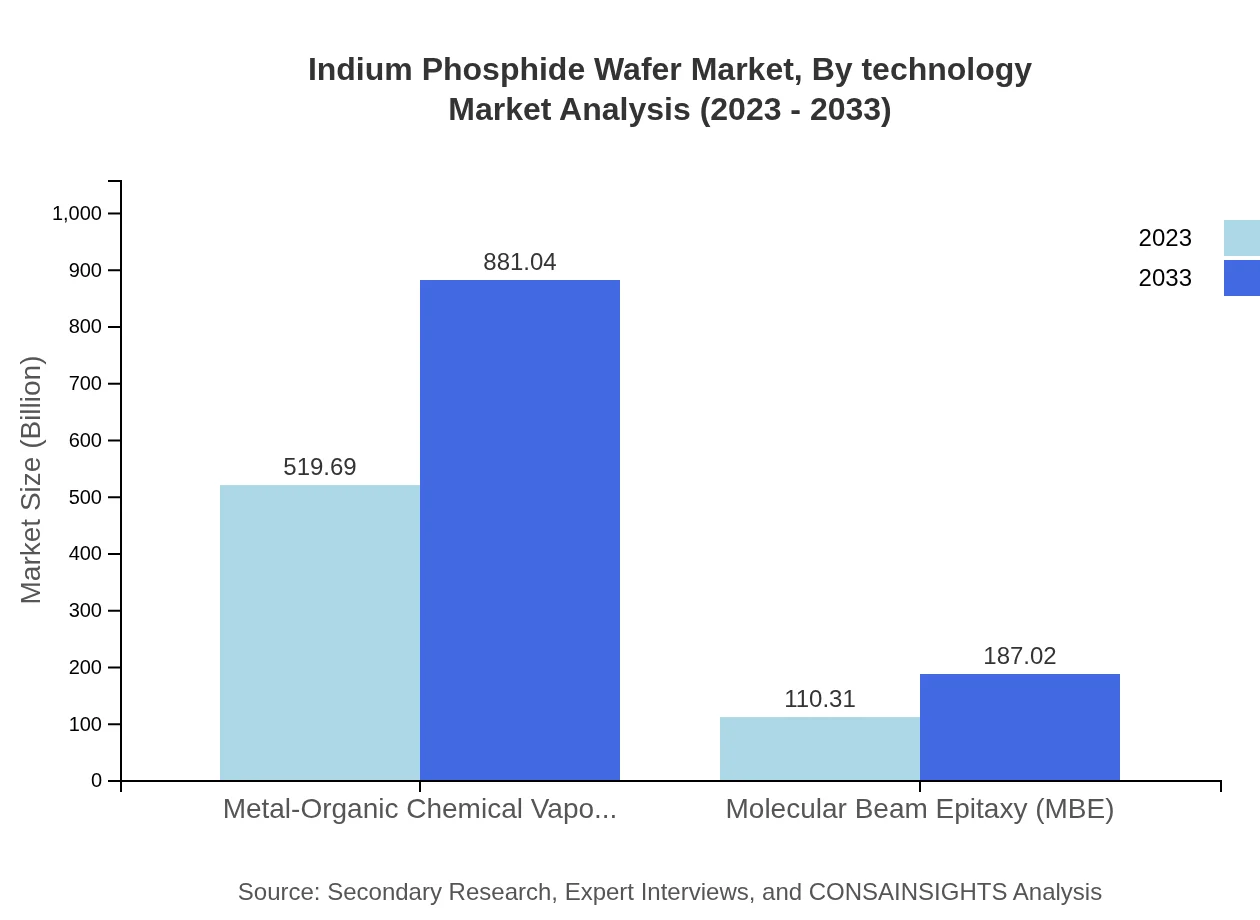

Indium Phosphide Wafer Market Analysis By Technology

The manufacturing techniques employed in the Indium Phosphide wafer sector include MOCVD and MBE, with MOCVD leading the charge. This segment accounts for approximately $519.69 million and is expected to grow to $881.04 million by 2033. MBE technology is also on the rise, enhancing the production of quality wafers for advanced tech applications.

Indium Phosphide Wafer Market Analysis By End User

The key end-users of Indium Phosphide wafers span telecommunications operators, research organizations, and defense sectors. The telecommunications segment contributes significantly with a market share of 57.5%, underlining the indispensable utility of InP wafers in this domain.

Indium Phosphide Wafer Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Indium Phosphide Wafer Industry

IQE plc:

A global leading supplier of advanced compound semiconductor wafers, IQE is renowned for their high-quality InP wafers used across multiple applications in the photonics and telecommunications sectors.Wafer Technology Ltd:

Specializing in the manufacture of InP epitaxial wafers, Wafer Technology Ltd is a crucial player in the market, contributing significantly to the growth and technological advancements in high-speed electronics.Aixtron SE:

A manufacturer known for its innovative MOCVD technology used for producing compound semiconductors including InP wafers, Aixtron SE plays a pivotal role in enhancing production capabilities within the market.We're grateful to work with incredible clients.

FAQs

What is the market size of indium Phosphide Wafer?

The indium-phosphide wafer market is currently valued at approximately $630 million in 2023, with an expected CAGR of 5.3% from 2023 to 2033. By 2033, the market is projected to continue growing significantly.

What are the key market players or companies in the indium Phosphide Wafer industry?

Key players in the indium-phosphide wafer industry include major semiconductor manufacturers, research institutions, and telecom operators. Their expertise contributes to advancements in technology and drives the market forward.

What are the primary factors driving the growth in the indium Phosphide Wafer industry?

Growth in the indium-phosphide wafer market is driven by increasing demand in telecommunications, advancements in semiconductor technology, and the rise of optical devices, which utilize indium phosphide for their efficiency.

Which region is the fastest Growing in the indium Phosphide Wafer?

The North American region is the fastest-growing in the indium-phosphide wafer market, with market size projections rising from approximately $239.09 million in 2023 to $405.33 million by 2033, highlighting significant growth potential.

Does ConsaInsights provide customized market report data for the indium Phosphide Wafer industry?

Yes, ConsaInsights offers customized market report data for the indium-phosphide wafer industry, allowing clients to obtain tailored insights and analyses that cater to their specific research and business needs.

What deliverables can I expect from this indium Phosphide Wafer market research project?

Deliverables from the indium-phosphide wafer market research project include detailed market analysis reports, growth projections by region and segment, competitive landscape assessments, and insights into market trends and opportunities.

What are the market trends of indium Phosphide Wafer?

Current trends in the indium-phosphide wafer market include a shift towards high-efficiency optical systems, advancements in wafer manufacturing technologies, and a growing focus on sustainable practices within semiconductor production.