Inductive Proximity Sensor Market Report

Published Date: 31 January 2026 | Report Code: inductive-proximity-sensor

Inductive Proximity Sensor Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Inductive Proximity Sensor market, including current trends, market dynamics, and forecasts from 2023 to 2033. It covers market size, segmentation, regional insights, technology analysis, and key players in the industry.

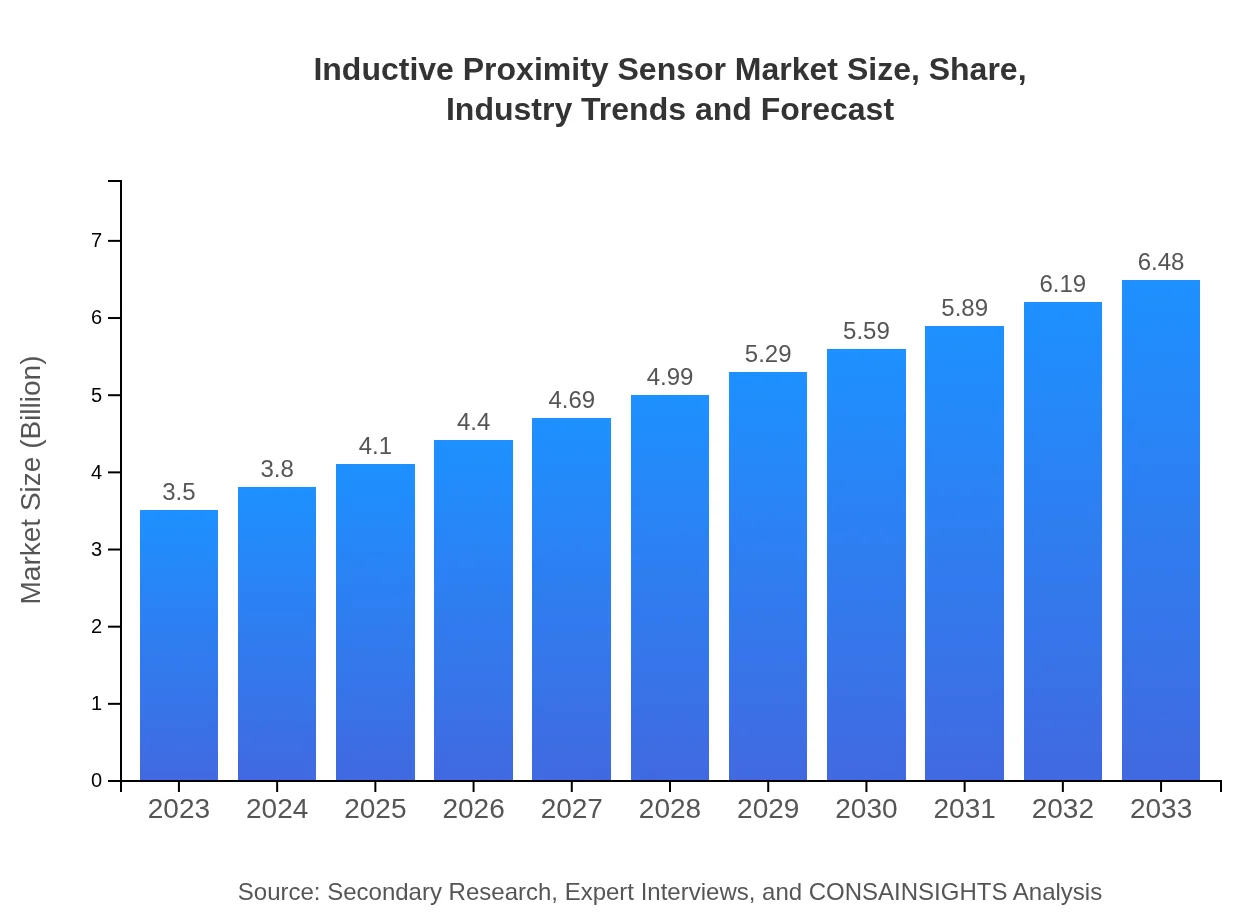

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $6.48 Billion |

| Top Companies | Siemens AG, Rockwell Automation, Inc., Pepperl+Fuchs GmbH, Omron Corporation |

| Last Modified Date | 31 January 2026 |

Inductive Proximity Sensor Market Overview

Customize Inductive Proximity Sensor Market Report market research report

- ✔ Get in-depth analysis of Inductive Proximity Sensor market size, growth, and forecasts.

- ✔ Understand Inductive Proximity Sensor's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Inductive Proximity Sensor

What is the Market Size & CAGR of Inductive Proximity Sensor market in 2023?

Inductive Proximity Sensor Industry Analysis

Inductive Proximity Sensor Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Inductive Proximity Sensor Market Analysis Report by Region

Europe Inductive Proximity Sensor Market Report:

Europe represents a robust market for inductive proximity sensors, projected to grow from $0.88 billion in 2023 to $1.63 billion by 2033. The region focuses heavily on automation and efficiency in production processes, enhancing the demand for these sensors.Asia Pacific Inductive Proximity Sensor Market Report:

The Asia Pacific region held a significant market share in 2023, valued at approximately $0.75 billion, expected to grow to $1.40 billion by 2033. Key factors driving this growth include advancements in manufacturing technology and increased automation across various industries.North America Inductive Proximity Sensor Market Report:

In North America, the market was valued at around $1.29 billion in 2023 and is anticipated to grow significantly to $2.40 billion by 2033. The region's growth is fueled by extensive adoption of smart manufacturing practices and technological innovations.South America Inductive Proximity Sensor Market Report:

The South American market for Inductive Proximity Sensors is relatively smaller, with a value of $0.19 billion in 2023, projected to reach $0.36 billion by 2033. The growth is primarily driven by gradual industrial development and the rising adoption of automation technologies.Middle East & Africa Inductive Proximity Sensor Market Report:

The Middle East and Africa region is expected to experience steady growth in the Inductive Proximity Sensor market, from approximately $0.38 billion in 2023 to $0.71 billion by 2033. Infrastructure investments and gradual industrialization contribute to this trend.Tell us your focus area and get a customized research report.

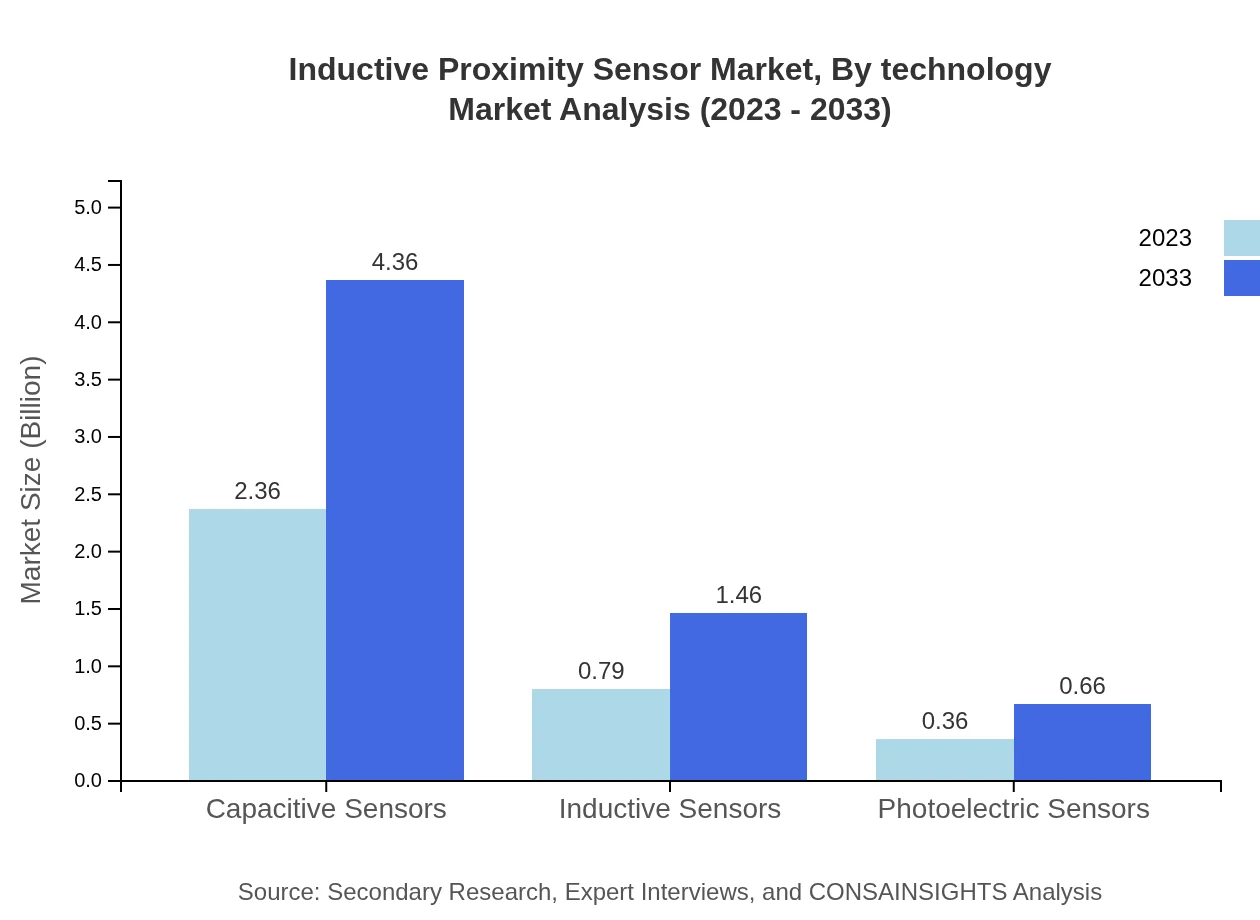

Inductive Proximity Sensor Market Analysis By Technology

Inductive Sensors dominate the market, accounting for approximately 67.3% share in 2023, valued at $2.36 billion, projected to grow to $4.36 billion by 2033. Capacitive Sensors follow, holding a share of 22.51%, with a market size of $0.79 billion in 2023, expected to rise to $1.46 billion by 2033, while Photoelectric Sensors, though smaller, play a vital role in specific applications.

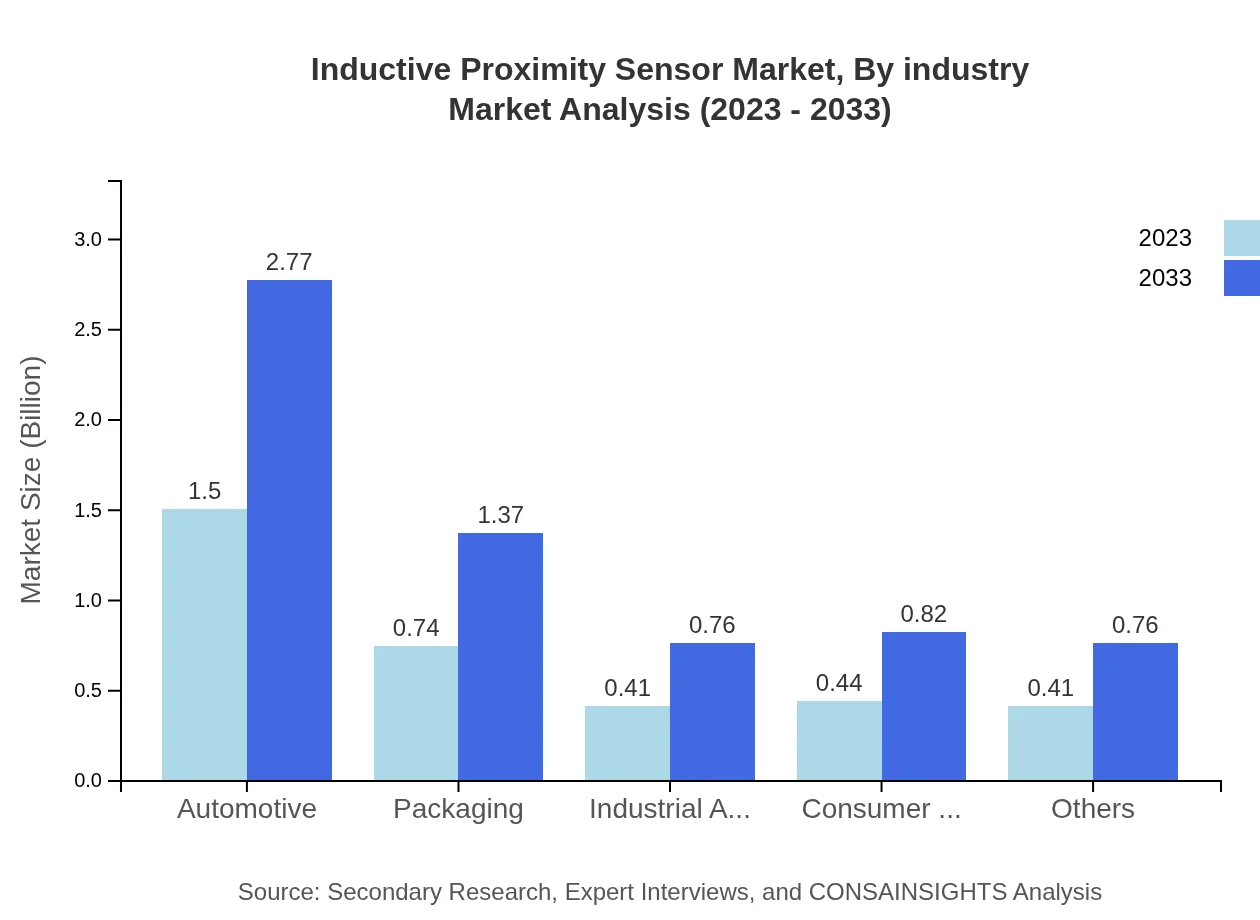

Inductive Proximity Sensor Market Analysis By Industry

The automotive sector is the largest consumer, with a market size of $1.50 billion in 2023, growing to $2.77 billion by 2033, holding a share of 42.76%. Industrial automation seamlessly integrates inductive sensors, valued at $0.41 billion in 2023, projected at $0.76 billion by 2033. Other notable sectors include packaging and consumer electronics, which emphasize necessitated automation.

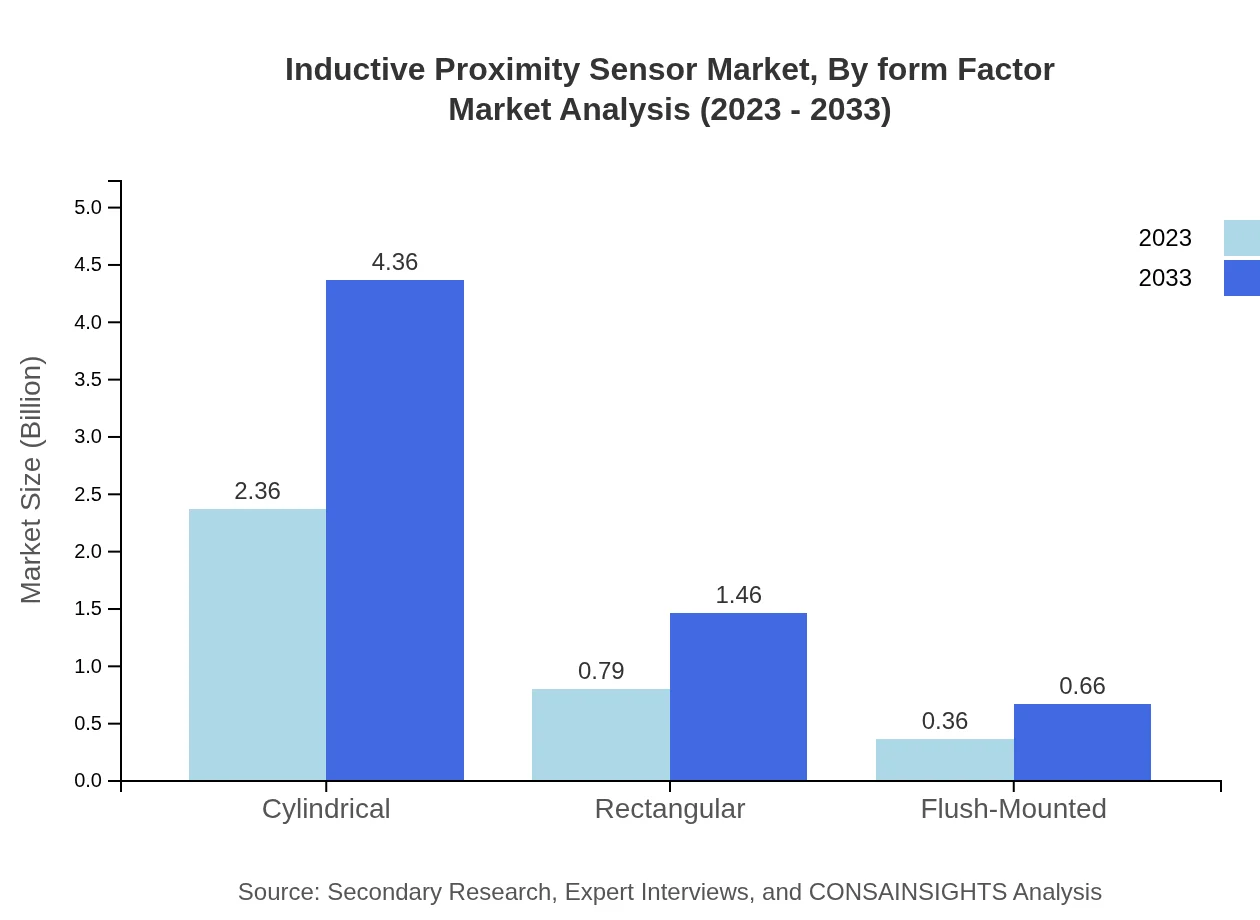

Inductive Proximity Sensor Market Analysis By Form Factor

Cylindrical sensors dominate the market with a size of $2.36 billion in 2023, expected to reach $4.36 billion by 2033. Rectangular sensors contribute significantly, valued at $0.79 billion in 2023 and anticipated to grow to $1.46 billion in the same period. Flush-mount sensors, while smaller, still hold importance in specific applications, indicating diversification in adoption by form factors.

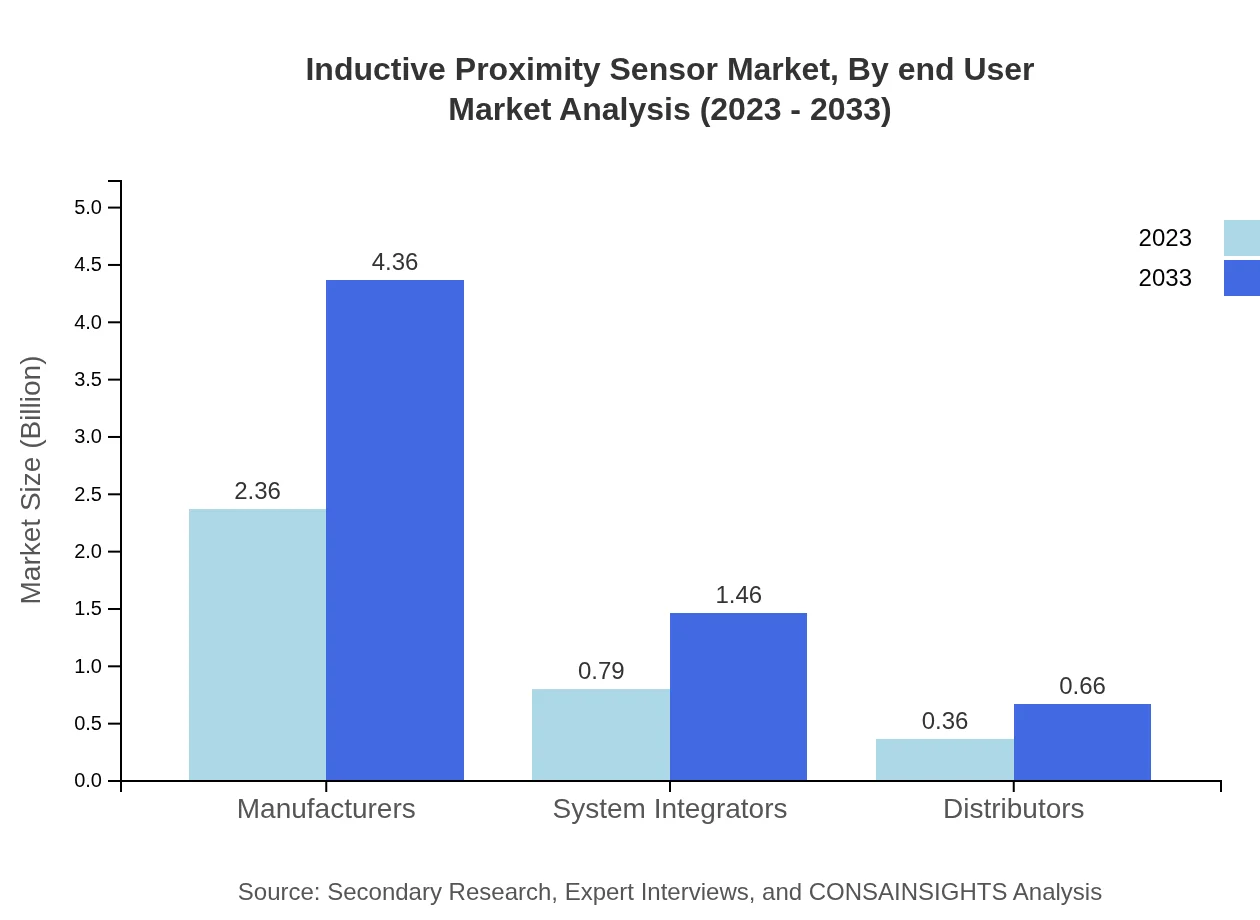

Inductive Proximity Sensor Market Analysis By End User

Manual system integrators hold around 22.51% of the market share, valued at $0.79 billion in 2023 and projected to reach $1.46 billion by 2033. Distributors account for 10.19%, with an expected increase from $0.36 billion to $0.66 billion during the forecast period, demonstrating collaboration across various channels to meet growing demands.

Inductive Proximity Sensor Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Inductive Proximity Sensor Industry

Siemens AG:

A multinational company, Siemens is involved in industrial automation and its solutions. Their innovative sensor technologies significantly contribute to the inductive proximity sensor market.Rockwell Automation, Inc.:

Known for its advanced automation solutions, Rockwell Automation manufactures a wide range of sensors for industrial applications, focusing on efficiency and connectivity.Pepperl+Fuchs GmbH:

A global leader in industrial automation, Pepperl+Fuchs specializes in sensor technology, particularly inductive and photoelectric proximity sensors.Omron Corporation:

An established name in factory automation, Omron develops innovative sensing technologies, enhancing productivity across various industries.We're grateful to work with incredible clients.

FAQs

What is the market size of inductive Proximity Sensor?

The global inductive proximity sensor market is valued at approximately $3.5 billion in 2023, with a projected CAGR of 6.2%, indicating robust growth in various industrial applications over the next decade.

What are the key market players or companies in this inductive Proximity Sensor industry?

Key players in the inductive proximity sensor market include manufacturers such as Siemens, Omron, and Honeywell, alongside system integrators and distributors who play a critical role in this evolving industry landscape.

What are the primary factors driving the growth in the inductive Proximity Sensor industry?

Growth in the inductive proximity sensor industry is driven by increasing automation across various sectors, advancements in manufacturing technologies, and the demand for improved process efficiency and safety within industrial applications.

Which region is the fastest Growing in the inductive Proximity Sensor?

The Asia Pacific region is the fastest-growing market for inductive proximity sensors, expected to grow from $0.75 billion in 2023 to $1.40 billion by 2033, fueled by industrial expansion and technological adoption.

Does ConsaInsights provide customized market report data for the inductive Proximity Sensor industry?

Yes, ConsaInsights offers customized market report data tailored to specific requirements in the inductive proximity sensor industry, accommodating particular interests in regions, applications, or market segments.

What deliverables can I expect from this inductive Proximity Sensor market research project?

The deliverables include a comprehensive market analysis report, segmented forecasts, competitive landscape assessments, and insights on industry trends, along with customized data visualizations and strategic recommendations.

What are the market trends of inductive Proximity Sensor?

Current trends in the inductive proximity sensor market include the shift towards smart manufacturing, increasing integration of IoT technologies, miniaturization of devices, and a growing preference for wireless sensor solutions.