Industrial Agitators Market Report

Published Date: 22 January 2026 | Report Code: industrial-agitators

Industrial Agitators Market Size, Share, Industry Trends and Forecast to 2033

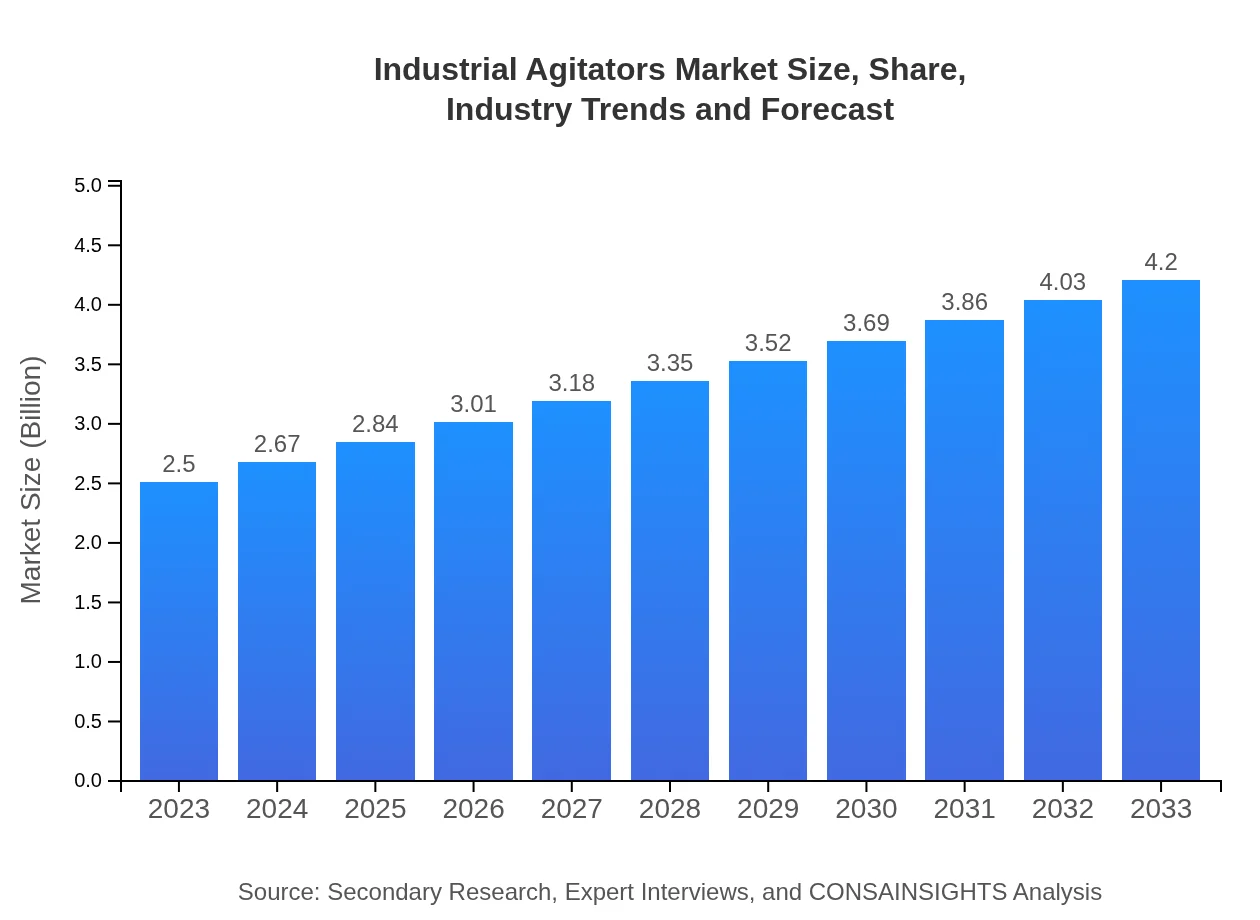

This report provides an in-depth analysis of the Industrial Agitators market, covering key insights, growth trends, and a decade-long forecast from 2023 to 2033. Readers will gain a comprehensive understanding of market size, segmentation, regional dynamics, and technology innovations affecting the industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $4.20 Billion |

| Top Companies | Mixing Equipment Co., Agitator Technologies, ChemMix Inc., Fluid Dynamics |

| Last Modified Date | 22 January 2026 |

Industrial Agitators Market Overview

Customize Industrial Agitators Market Report market research report

- ✔ Get in-depth analysis of Industrial Agitators market size, growth, and forecasts.

- ✔ Understand Industrial Agitators's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Agitators

What is the Market Size & CAGR of Industrial Agitators market in 2023?

Industrial Agitators Industry Analysis

Industrial Agitators Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Agitators Market Analysis Report by Region

Europe Industrial Agitators Market Report:

Europe's market for industrial agitators is anticipated to grow from $0.79 billion in 2023 to $1.33 billion by 2033, fueled by strict regulations and an increasing demand for automation in industrial processes.Asia Pacific Industrial Agitators Market Report:

The Asia Pacific region is expected to grow from $0.40 billion in 2023 to $0.67 billion by 2033, driven by industrial growth and increasing investments in manufacturing facilities. Countries like China and India are key contributors, focusing on improving production capabilities.North America Industrial Agitators Market Report:

North America will see growth from $0.94 billion in 2023 to $1.58 billion in 2033, backed by advancements in the pharmaceutical sector and heightened regulatory standards in industries.South America Industrial Agitators Market Report:

In South America, the market will expand from $0.23 billion in 2023 to $0.39 billion by 2033, primarily due to the burgeoning food and beverage industry alongside a rising focus on sustainable practices.Middle East & Africa Industrial Agitators Market Report:

The Middle East and Africa market is projected to increase from $0.13 billion in 2023 to $0.22 billion by 2033, driven by the oil & gas and water treatment industries looking for efficient solutions.Tell us your focus area and get a customized research report.

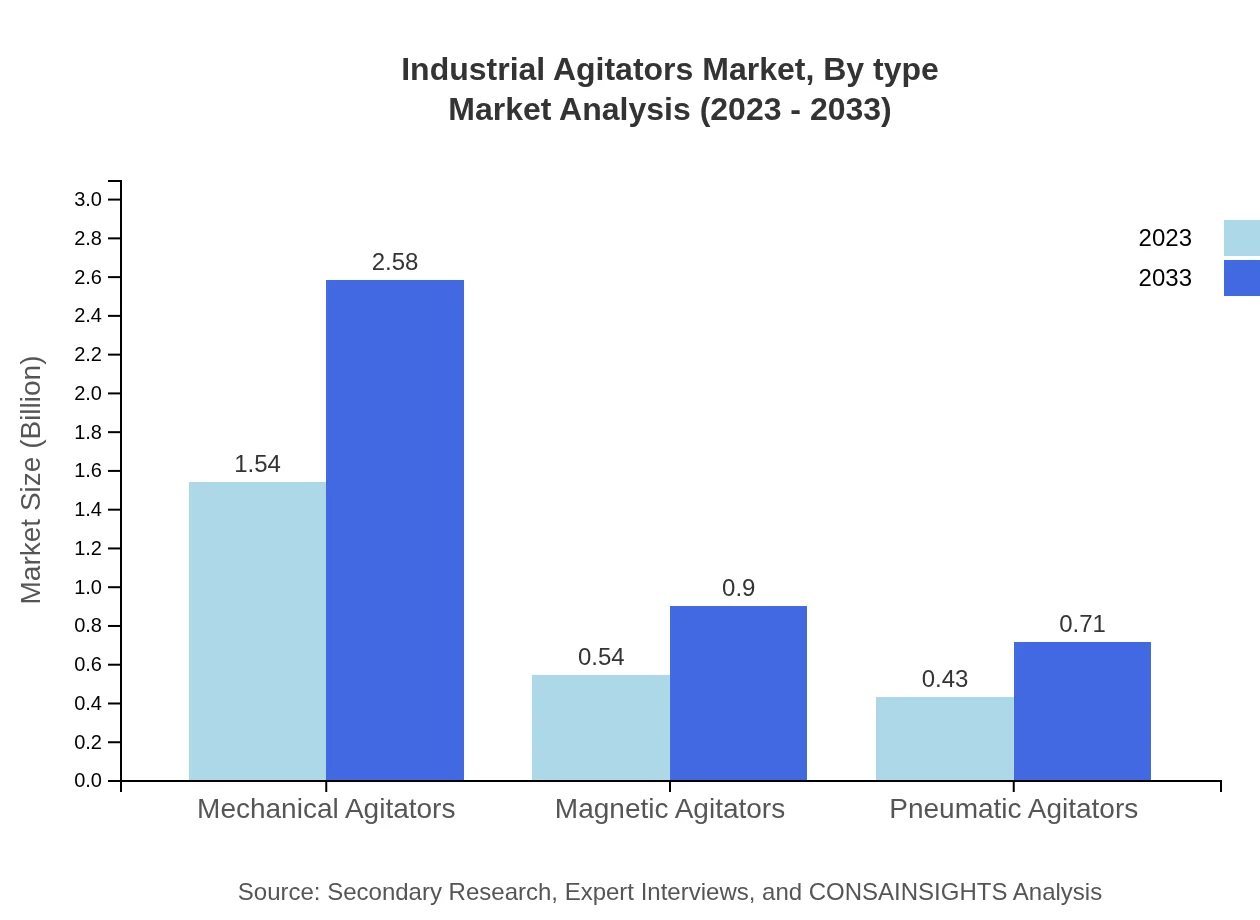

Industrial Agitators Market Analysis By Type

Mechanical agitators are the largest segment in the market, with a size of $1.54 billion in 2023 and projected to grow to $2.58 billion by 2033. Magnetic agitators follow with growth from $0.54 billion to $0.90 billion, while pneumatic agitators will see a rise from $0.43 billion to $0.71 billion.

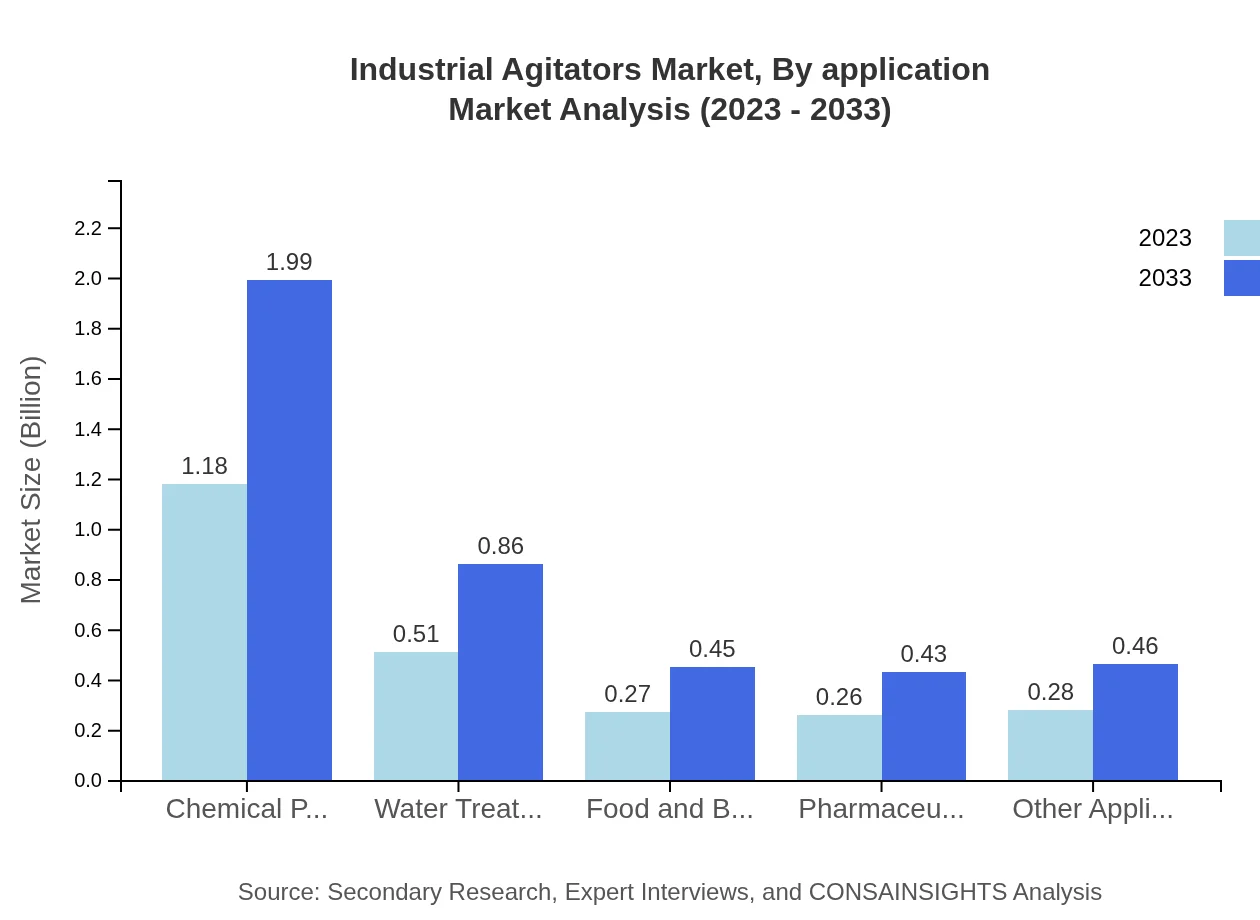

Industrial Agitators Market Analysis By Application

The chemical processing segment is expected to maintain a leading share, starting at $1.18 billion in 2023 and reaching $1.99 billion by 2033. The water treatment segment will also see growth from $0.51 billion to $0.86 billion, reflecting the global needs for clean water solutions.

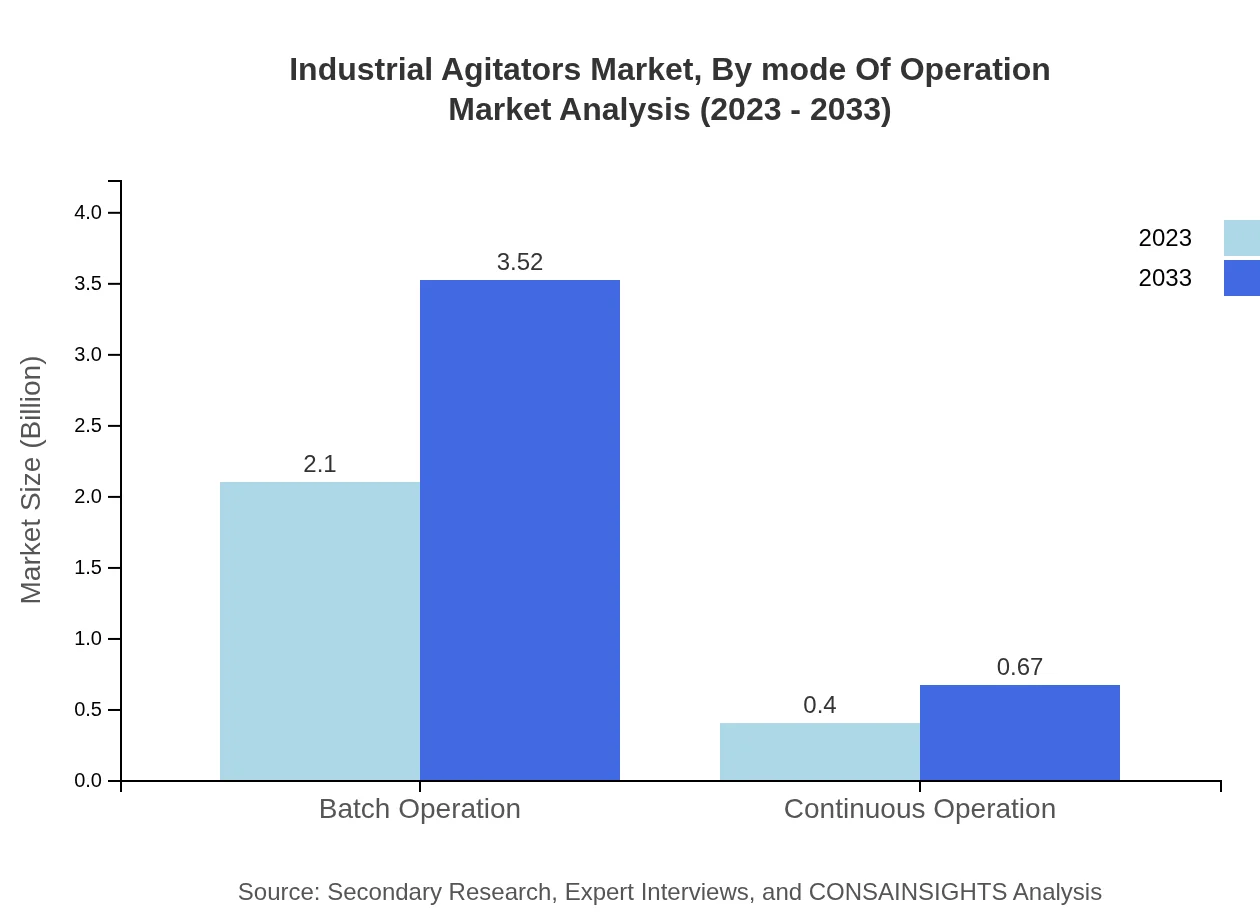

Industrial Agitators Market Analysis By Mode Of Operation

Batch operation systems dominate, accounting for 83.94% of the market share in 2023. This segment is projected to increase from $2.10 billion to $3.52 billion by 2033, emphasizing the importance of efficient processes in manufacturing.

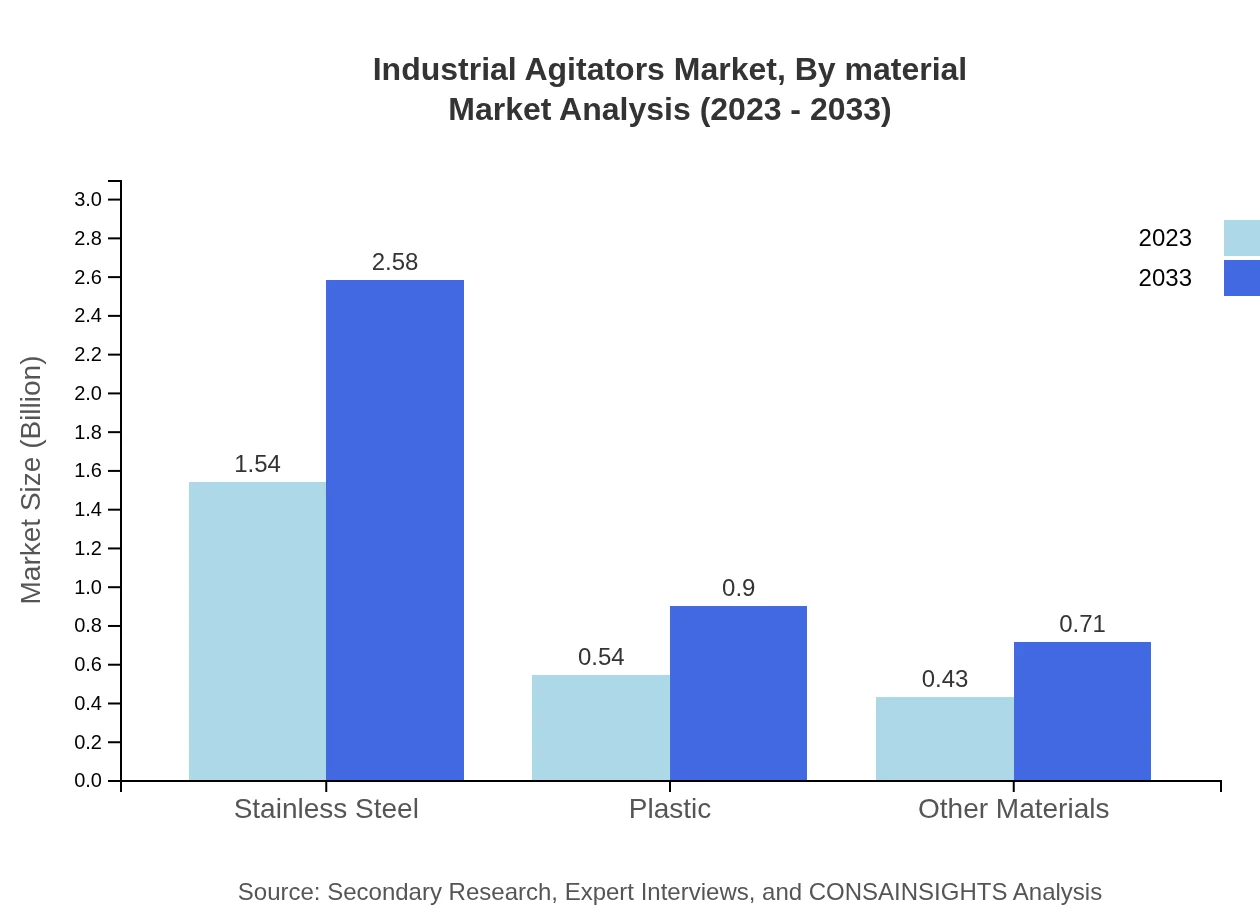

Industrial Agitators Market Analysis By Material

Stainless steel remains the preferred material, with a market size of $1.54 billion in 2023 projected to grow to $2.58 billion by 2033. Plastic materials will see growth due to their cost-effectiveness, from $0.54 billion to $0.90 billion in the same period.

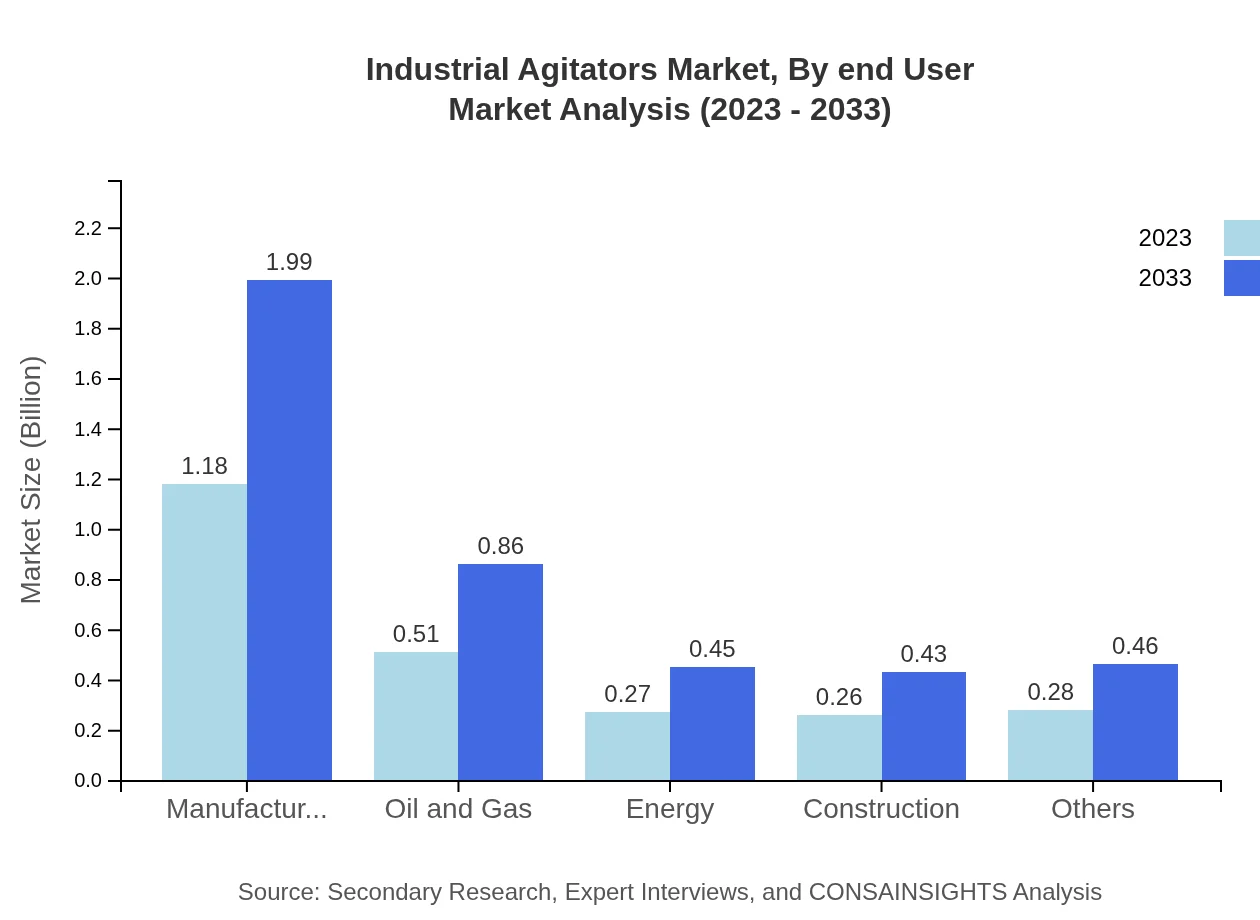

Industrial Agitators Market Analysis By End User

Manufacturing is the largest end-user segment, starting at $1.18 billion in 2023 and predicted to reach $1.99 billion by 2033. The food & beverage and pharmaceuticals sectors are also significant contributors to the market.

Industrial Agitators Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Agitators Industry

Mixing Equipment Co.:

A leading manufacturer specializing in high-performance mixing equipment for various industries, with a strong focus on innovation and customer service.Agitator Technologies:

Known for its advanced agitator solutions, Agitator Technologies has a significant market presence, particularly in the food and beverage sector, emphasizing energy-efficient designs.ChemMix Inc.:

A key player in the chemical processing industry, ChemMix offers a wide range of agitators that integrate smart technology to streamline operations.Fluid Dynamics:

Fluid Dynamics is renowned for its robust agitator systems widely used in water treatment and pharmaceuticals, focusing on sustainable practices.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial Agitators?

The global industrial agitators market is projected to reach $2.5 billion by 2033, growing at a CAGR of 5.2% from 2023, which is expected to see steady demand due to increasing industrial applications across various sectors.

What are the key market players or companies in this industrial Agitators industry?

Key players in the industrial agitators market include major companies such as Xylem Inc., SPX Flow Inc., and KSB AG that dominate the market due to their product innovation and extensive distribution networks, providing a competitive edge.

What are the primary factors driving the growth in the industrial Agitators industry?

Factors driving market growth include the rising demand in chemical manufacturing, the increasing need for efficient mixing solutions in pharmaceuticals, and advancements in agitator technology, which enhance operational efficiency and reduce costs.

Which region is the fastest Growing in the industrial Agitators?

Among regions, North America is the fastest-growing market for industrial agitators, expected to grow from $0.94 billion in 2023 to $1.58 billion by 2033, led by advancements in technology and increasing industrial activities.

Does ConsaInsights provide customized market report data for the industrial Agitators industry?

Yes, ConsaInsights offers customized market report data tailored to specific client needs in the industrial agitators industry, ensuring relevant insights that align with unique operational goals and market demands.

What deliverables can I expect from this industrial Agitators market research project?

Deliverables from the industrial agitators market research project include detailed market analysis reports, segment breakdowns, competitive landscape insights, and actionable recommendations to aid strategic decision-making.

What are the market trends of industrial Agitators?

Current trends in the industrial agitators market include a shift towards energy-efficient designs, increased adoption of automated systems, and an expanding application range within environmental sustainability sectors.