Industrial Analytics Market Report

Published Date: 31 January 2026 | Report Code: industrial-analytics

Industrial Analytics Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Industrial Analytics market from 2023 to 2033, detailing market dynamics, growth factors, regional insights, and competitive landscape to guide stakeholders in strategic decision-making.

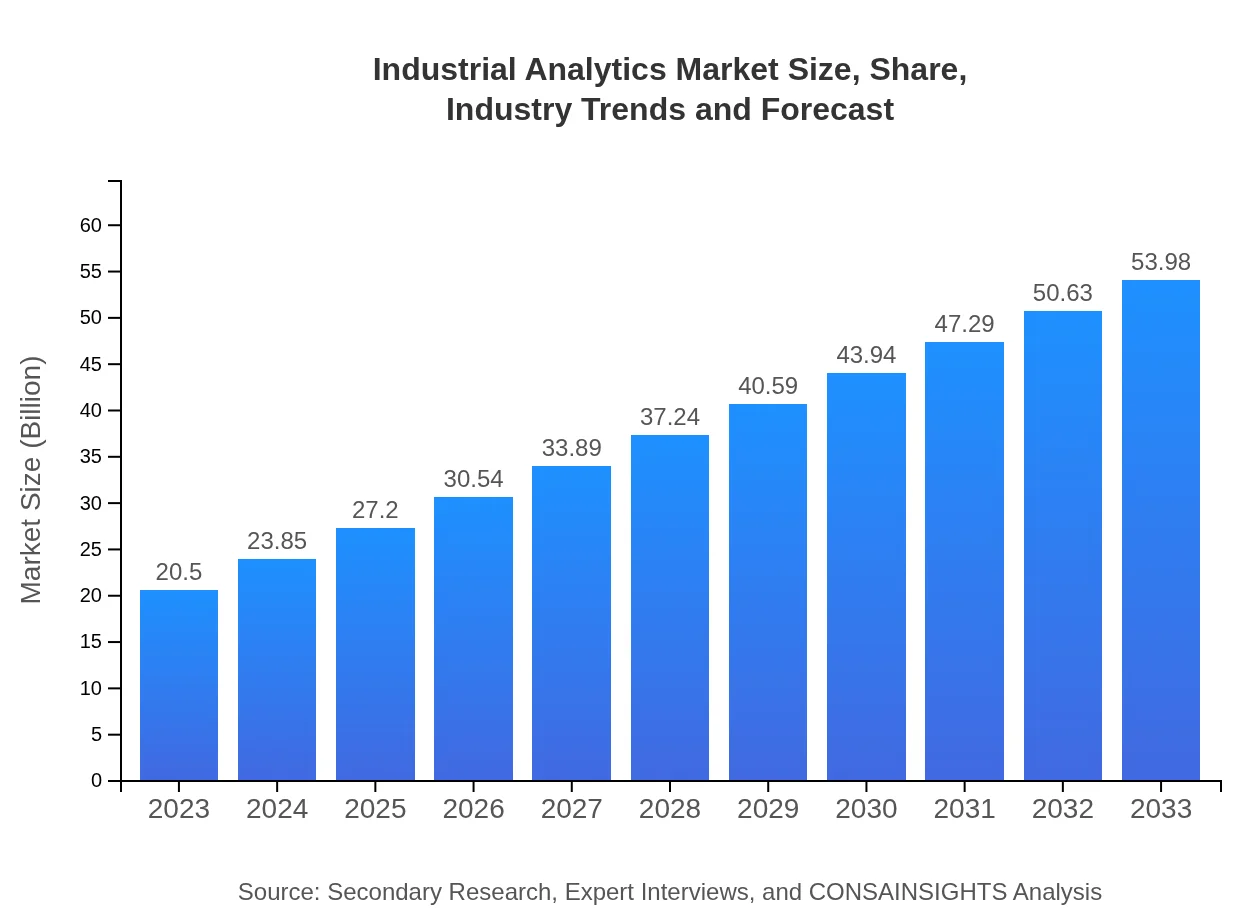

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $20.50 Billion |

| CAGR (2023-2033) | 9.8% |

| 2033 Market Size | $53.98 Billion |

| Top Companies | IBM Corporation, Siemens AG, Honeywell International Inc., SAP SE |

| Last Modified Date | 31 January 2026 |

Industrial Analytics Market Overview

Customize Industrial Analytics Market Report market research report

- ✔ Get in-depth analysis of Industrial Analytics market size, growth, and forecasts.

- ✔ Understand Industrial Analytics's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Analytics

What is the Market Size & CAGR of Industrial Analytics market in 2023?

Industrial Analytics Industry Analysis

Industrial Analytics Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Analytics Market Analysis Report by Region

Europe Industrial Analytics Market Report:

In Europe, the market is set to grow from $6.00 billion in 2023 to $15.79 billion by 2033. The focus on Industry 4.0 and the increasing regulatory requirements for operational efficiency are driving demand for industrial analytics solutions.Asia Pacific Industrial Analytics Market Report:

In the Asia Pacific region, the Industrial Analytics market is expected to grow from $3.67 billion in 2023 to $9.65 billion by 2033. The surge is mainly driven by the rapid industrialization, advancements in manufacturing technologies, and the increasing integration of IoT across industries.North America Industrial Analytics Market Report:

North America holds a significant share of the market, projected to increase from $7.95 billion in 2023 to $20.92 billion by 2033. The region's advanced infrastructure, significant investments in analytics technologies, and the presence of major industry players are key contributors to this growth.South America Industrial Analytics Market Report:

The South American market, though smaller, is poised for growth from $0.20 billion in 2023 to $0.53 billion by 2033. The rise in demand for refining operational processes and the adoption of smart technologies in manufacturing are key growth factors.Middle East & Africa Industrial Analytics Market Report:

The Middle East and Africa market is forecast to expand from $2.69 billion in 2023 to $7.08 billion by 2033. Growing investments in digital transformation and the adoption of data-driven decision-making in various sectors will fuel this growth.Tell us your focus area and get a customized research report.

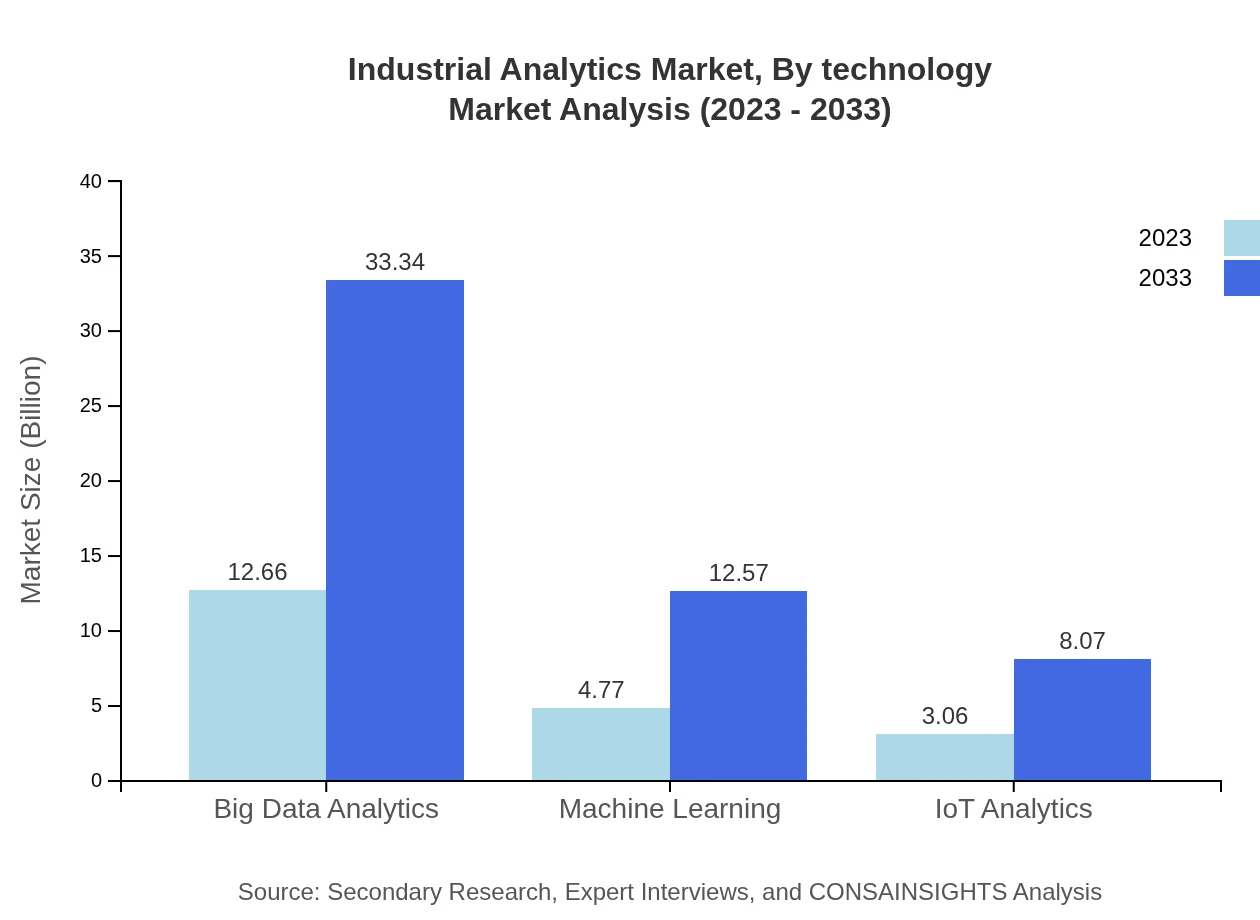

Industrial Analytics Market Analysis By Technology

The technology segment in the Industrial Analytics market includes Big Data Analytics, Machine Learning, and IoT Analytics. Big Data Analytics dominates the market, valued at $12.66 billion in 2023, and projected to reach $33.34 billion in 2033, attributed to its ability to process vast volumes of data efficiently. Machine Learning and IoT Analytics also significantly contribute, with respective market sizes of $4.77 billion and $3.06 billion in 2023.

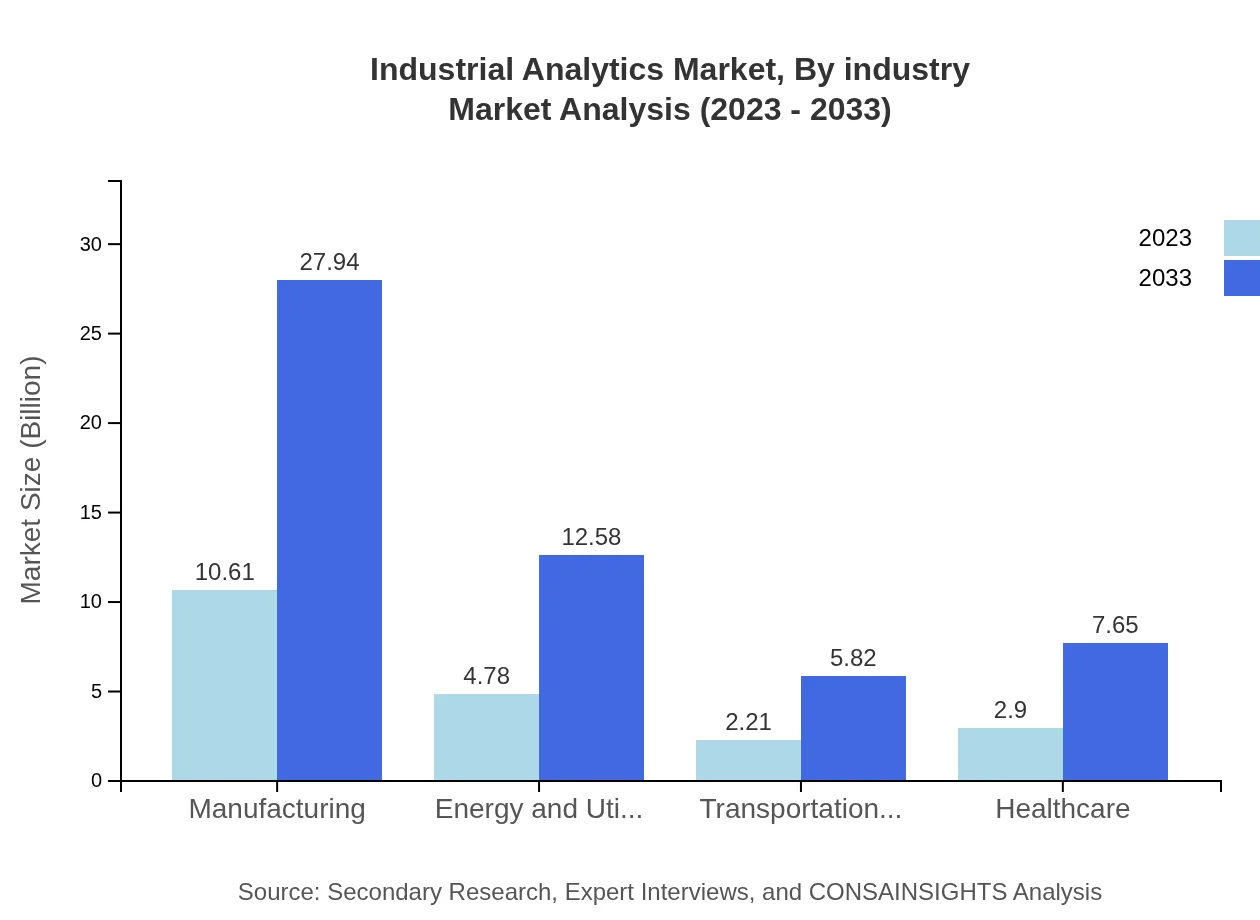

Industrial Analytics Market Analysis By Industry

The Industrial Analytics market segmentation by industry includes Manufacturing, Energy and Utilities, Transportation and Logistics, and Healthcare. The manufacturing sector leads with a market size of $10.61 billion in 2023, expected to grow to $27.94 billion by 2033, driven by automation and efficiency demands. Energy and Utilities and Transportation are also pivotal, valued at $4.78 billion and $2.21 billion respectively in 2023.

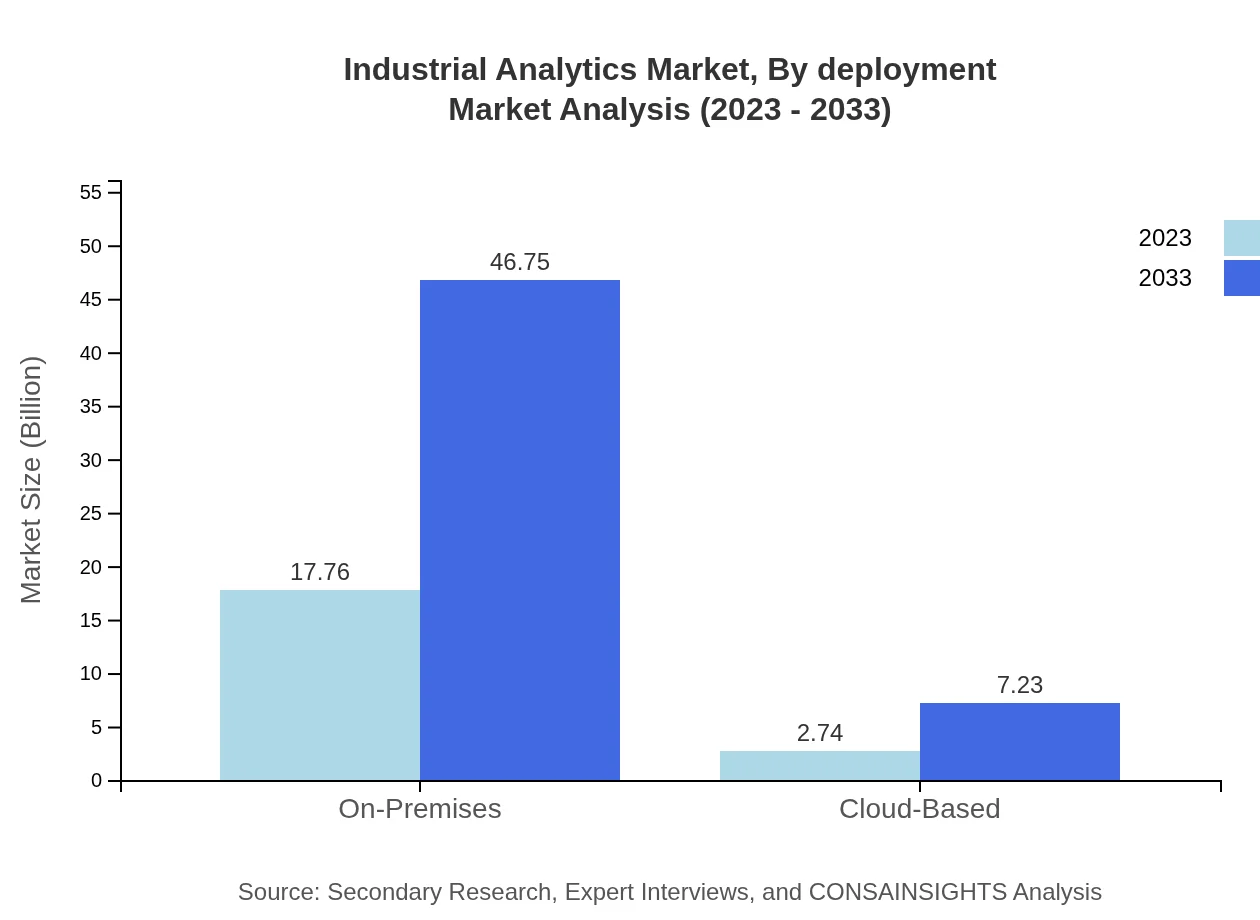

Industrial Analytics Market Analysis By Deployment

Deployment types include On-Premises and Cloud-Based solutions. On-Premises solutions dominate, accounting for $17.76 billion in 2023, while Cloud-Based solutions are emerging with a significant growth trajectory. By 2033, both deployment types are expected to leverage the growing trend of businesses seeking scalable and efficient analytics solutions.

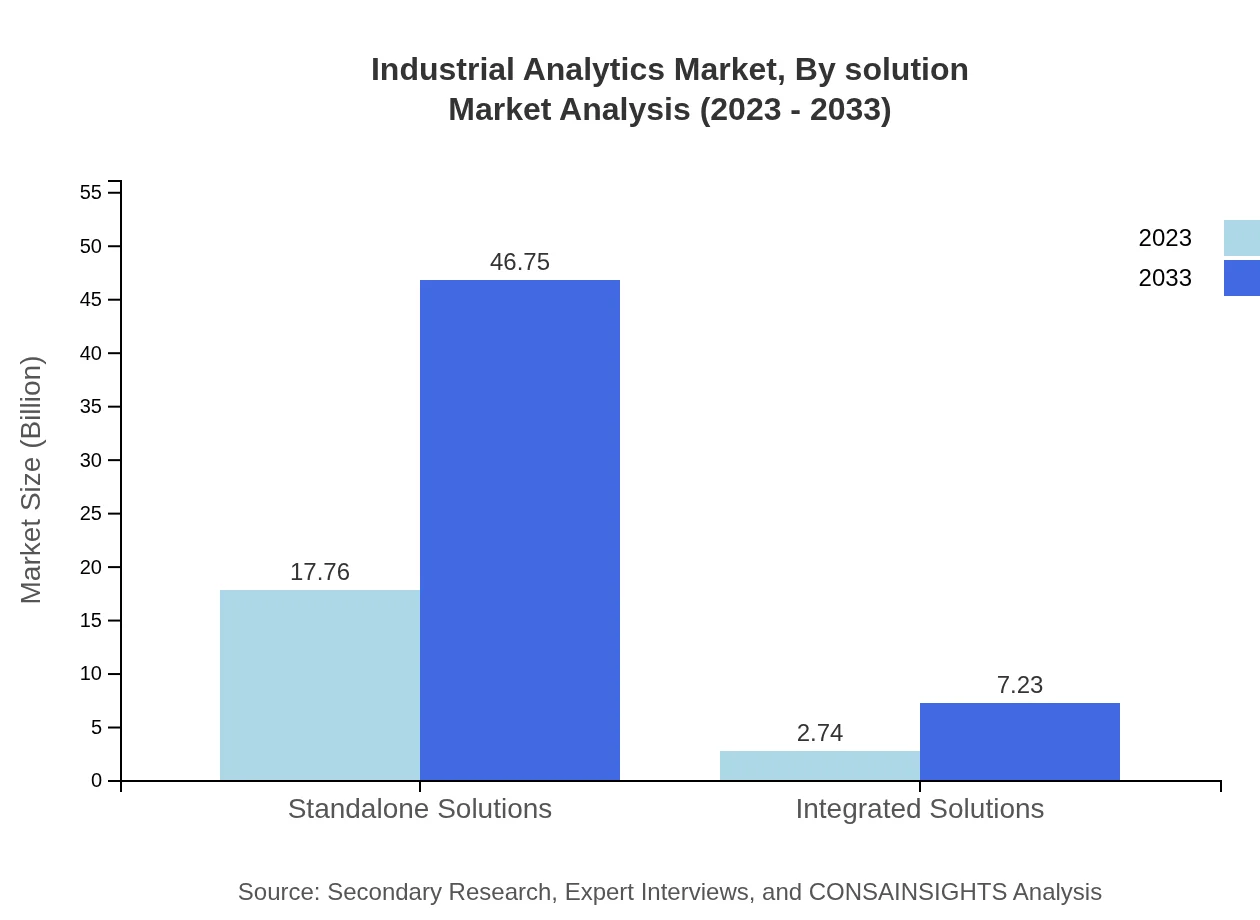

Industrial Analytics Market Analysis By Solution

The market segments into Standalone and Integrated Solutions. Standalone Solutions hold a substantial market share at $17.76 billion in 2023 and will rise significantly. Integrated Solutions, while smaller, are increasingly being adopted for their comprehensive capabilities.

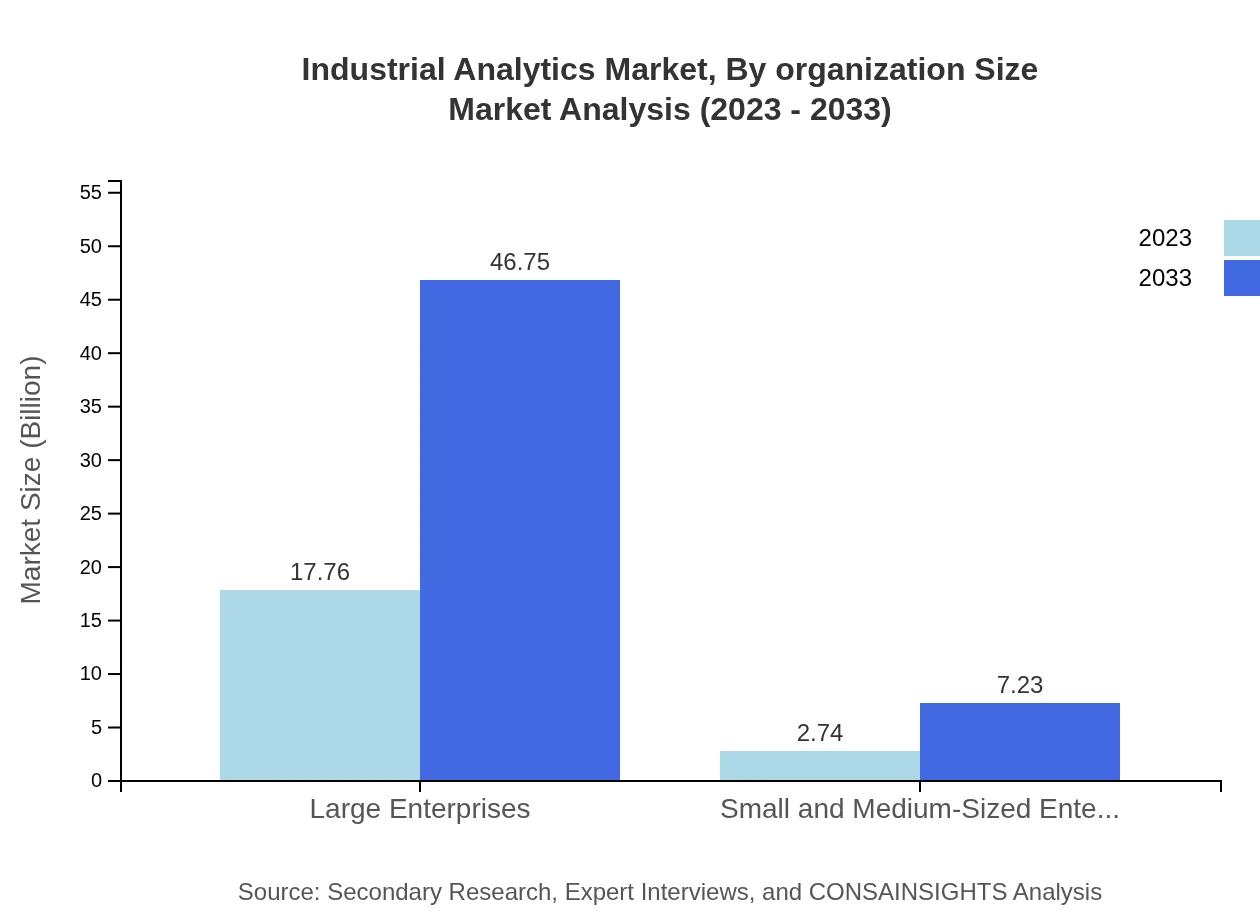

Industrial Analytics Market Analysis By Organization Size

The analysis by organization size reveals that Large Enterprises represent a majority at $17.76 billion in 2023, accounting for 86.61% of the market share. Small and Medium-Sized Enterprises, while smaller, are gradually increasing their adoption of analytics solutions, projected to grow from $2.74 billion in 2023 to $7.23 billion by 2033.

Industrial Analytics Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Analytics Industry

IBM Corporation:

A leader in the analytics space, IBM offers an extensive portfolio of solutions that integrate AI and data analytics to enhance operational efficiency and provide actionable insights.Siemens AG:

Siemens plays a crucial role in the Industrial Analytics market by providing a wide range of solutions focused on the automation and digitalization of industries.Honeywell International Inc.:

Honeywell leverages its expertise in technology and analytics to provide innovative solutions that streamline industrial operations and enhance safety standards.SAP SE:

SAP provides intelligent analytics solutions that empower organizations to harness their data for better decision-making and operational improvements.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial Analytics?

The industrial analytics market is valued at approximately $20.5 billion in 2023 and is anticipated to grow at a CAGR of 9.8%, reaching significant milestones by 2033.

What are the key market players or companies in this industrial Analytics industry?

The industrial analytics industry includes prominent players like Siemens, IBM, SAP, and Microsoft, which lead in providing advanced analytics solutions and technologies to various sectors.

What are the primary factors driving the growth in the industrial analytics industry?

Key factors include increasing operational efficiency, the rise of IoT and automation, demand for real-time data analytics, and the growing focus on predictive maintenance across industries.

Which region is the fastest Growing in industrial analytics?

The fastest-growing region in industrial analytics is North America, projected to expand from $7.95 billion in 2023 to $20.92 billion by 2033, representing a robust growth trajectory.

Does ConsaInsights provide customized market report data for the industrial analytics industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs and insights in the industrial analytics industry, ensuring clients receive relevant and actionable information.

What deliverables can I expect from this industrial analytics market research project?

Expect comprehensive market reports including detailed analysis, executive summaries, regional insights, competitive landscapes, and forecasts segmented by industry and geography.

What are the market trends of industrial analytics?

Current trends include increased adoption of AI and machine learning, emphasis on cloud-based solutions, scaling of big data analytics, and integration with IoT for smarter industrial applications.