Industrial Boilers Market Report

Published Date: 22 January 2026 | Report Code: industrial-boilers

Industrial Boilers Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Industrial Boilers market from 2023 to 2033, detailing market dynamics, size, segmentation, regional trends, and forecasts to equip stakeholders with essential insights for decision-making.

| Metric | Value |

|---|---|

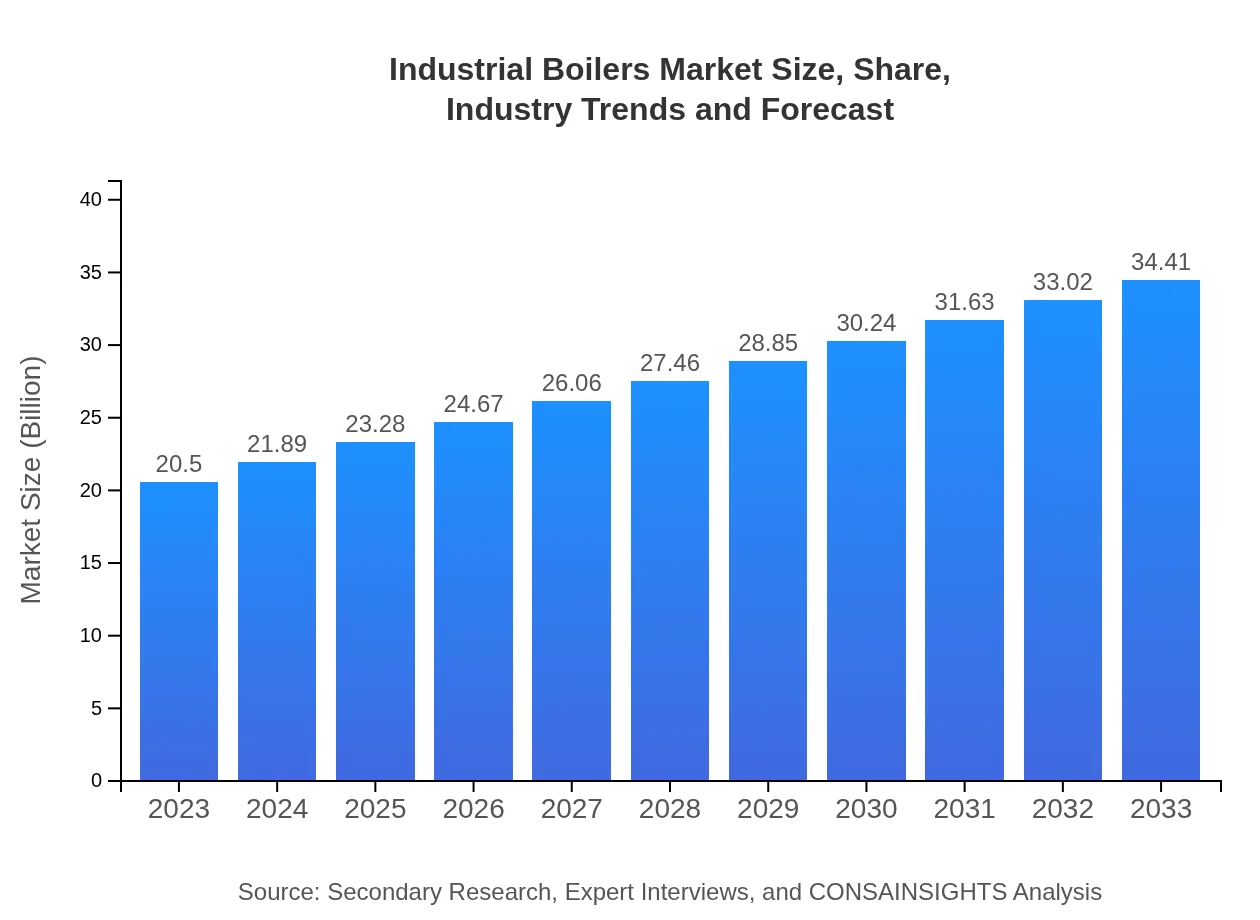

| Study Period | 2023 - 2033 |

| 2023 Market Size | $20.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $34.41 Billion |

| Top Companies | Babcock & Wilcox Enterprises, Inc., Foster Wheeler AG, Siemens AG, Mitsubishi Hitachi Power Systems, Ltd. |

| Last Modified Date | 22 January 2026 |

Industrial Boilers Market Overview

Customize Industrial Boilers Market Report market research report

- ✔ Get in-depth analysis of Industrial Boilers market size, growth, and forecasts.

- ✔ Understand Industrial Boilers's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Boilers

What is the Market Size & CAGR of Industrial Boilers market in 2023?

Industrial Boilers Industry Analysis

Industrial Boilers Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Boilers Market Analysis Report by Region

Europe Industrial Boilers Market Report:

The European market for Industrial Boilers is valued at $5.68 billion in 2023 and projected to rise to $9.54 billion by 2033. The focus on carbon neutrality and renewable energy adoption has led to significant innovation and investment in clean boiler technologies.Asia Pacific Industrial Boilers Market Report:

The Asia Pacific region is expected to witness significant growth, driven by rapid industrialization and urbanization. In 2023, the market size stands at $3.89 billion, projected to reach $6.53 billion by 2033. Countries like China and India are key growth drivers due to escalating demand for energy and robust manufacturing sectors.North America Industrial Boilers Market Report:

North America leads the market with an estimated value of $7.85 billion in 2023, expected to grow to $13.18 billion by 2033. The demand is driven by stringent environmental regulations and advancements in technology that facilitate the adoption of more efficient and cleaner boilers.South America Industrial Boilers Market Report:

The South American market, valued at $0.95 billion in 2023, is projected to grow to $1.60 billion by 2033. The region's growth is driven by increasing investments in infrastructure and the food and beverage industry, along with a growing emphasis on renewable energy sources.Middle East & Africa Industrial Boilers Market Report:

In the Middle East and Africa, the market stands at $2.12 billion in 2023 and is expected to reach $3.55 billion by 2033. The growth is primarily driven by the rising industrial sectors and the need for efficient and sustainable energy solutions.Tell us your focus area and get a customized research report.

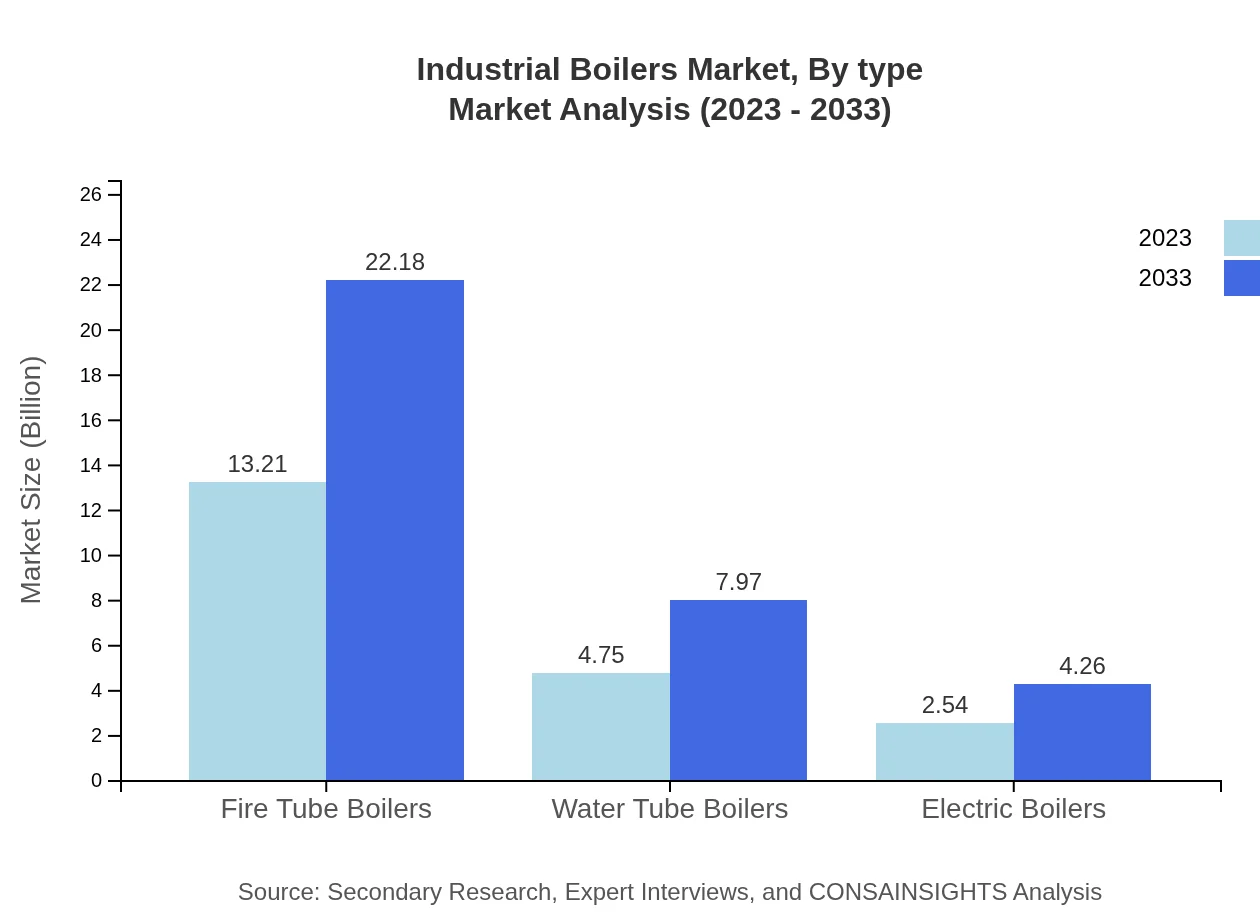

Industrial Boilers Market Analysis By Type

The market is dominated by Fire Tube Boilers, with a projected size of $13.21 billion in 2023 growing to $22.18 billion by 2033, capturing 64.45% of the market share. Water Tube Boilers follow with a current market of $4.75 billion, expected to grow to $7.97 billion. Electric Boilers, while smaller in scale at $2.54 billion, show growing potential due to increased electrification.

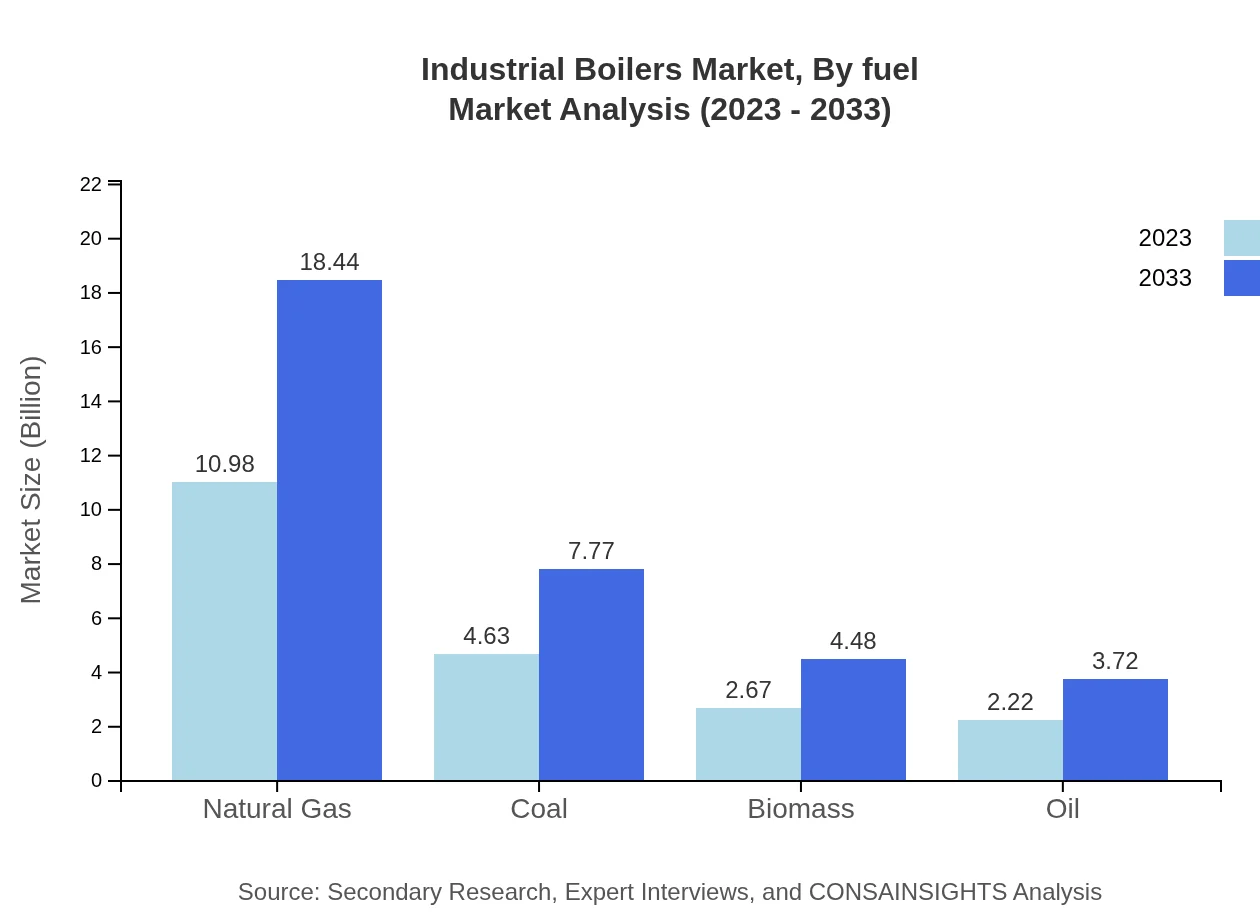

Industrial Boilers Market Analysis By Fuel

Natural Gas fuels the lion's share at $10.98 billion in 2023, projected to reach $18.44 billion by 2033, accounting for 53.58% of market share. Coal follows with $4.63 billion growing to $7.77 billion. Biomass is also increasing in prominence with a market size of $2.67 billion expected to grow to $4.48 billion.

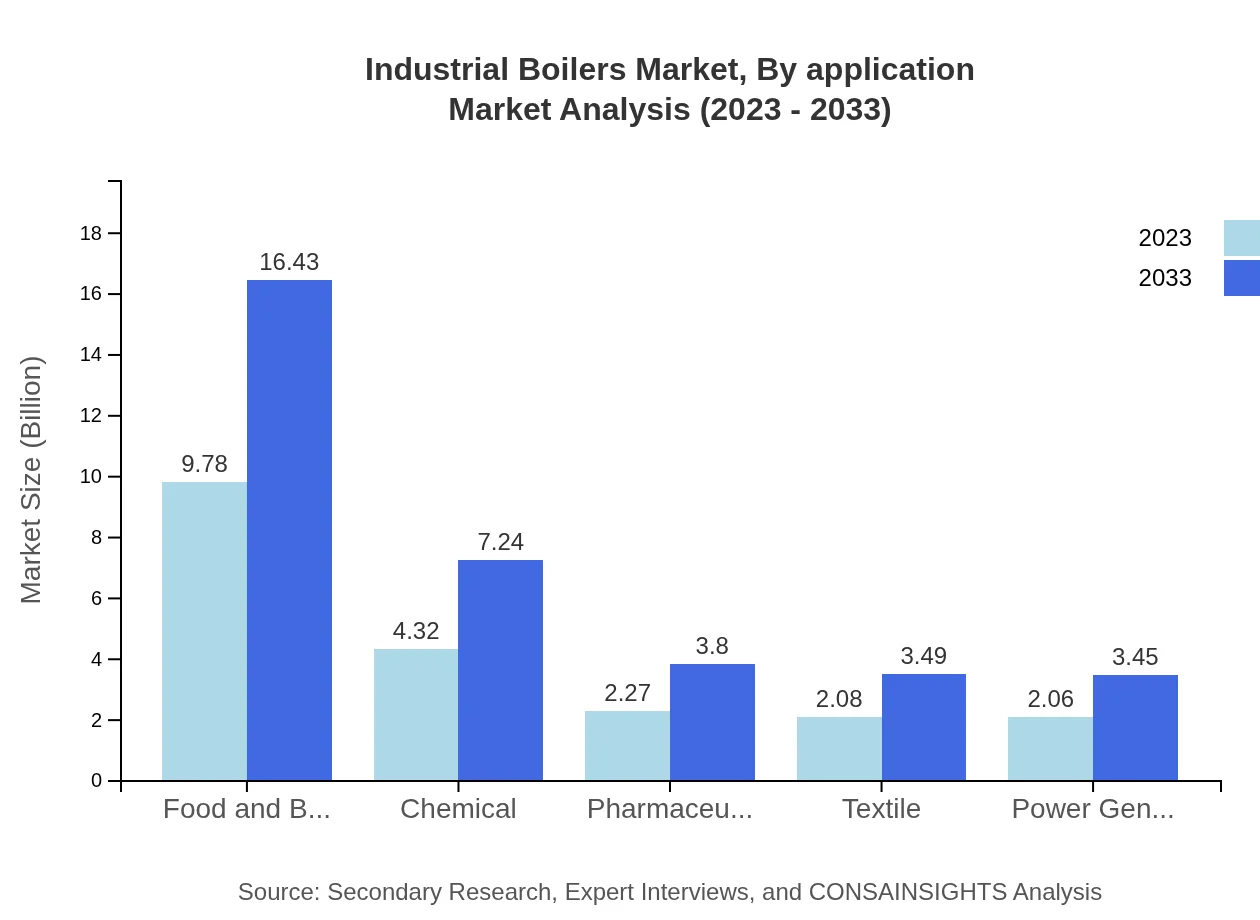

Industrial Boilers Market Analysis By Application

The Food and Beverage sector leads application types, with significant growth from $9.78 billion in 2023 to $16.43 billion by 2033. The Chemical sector holds $4.32 billion and is projected to grow to $7.24 billion. Pharmaceuticals and Textiles also play significant roles, valuing at $2.27 billion and $2.08 billion respectively.

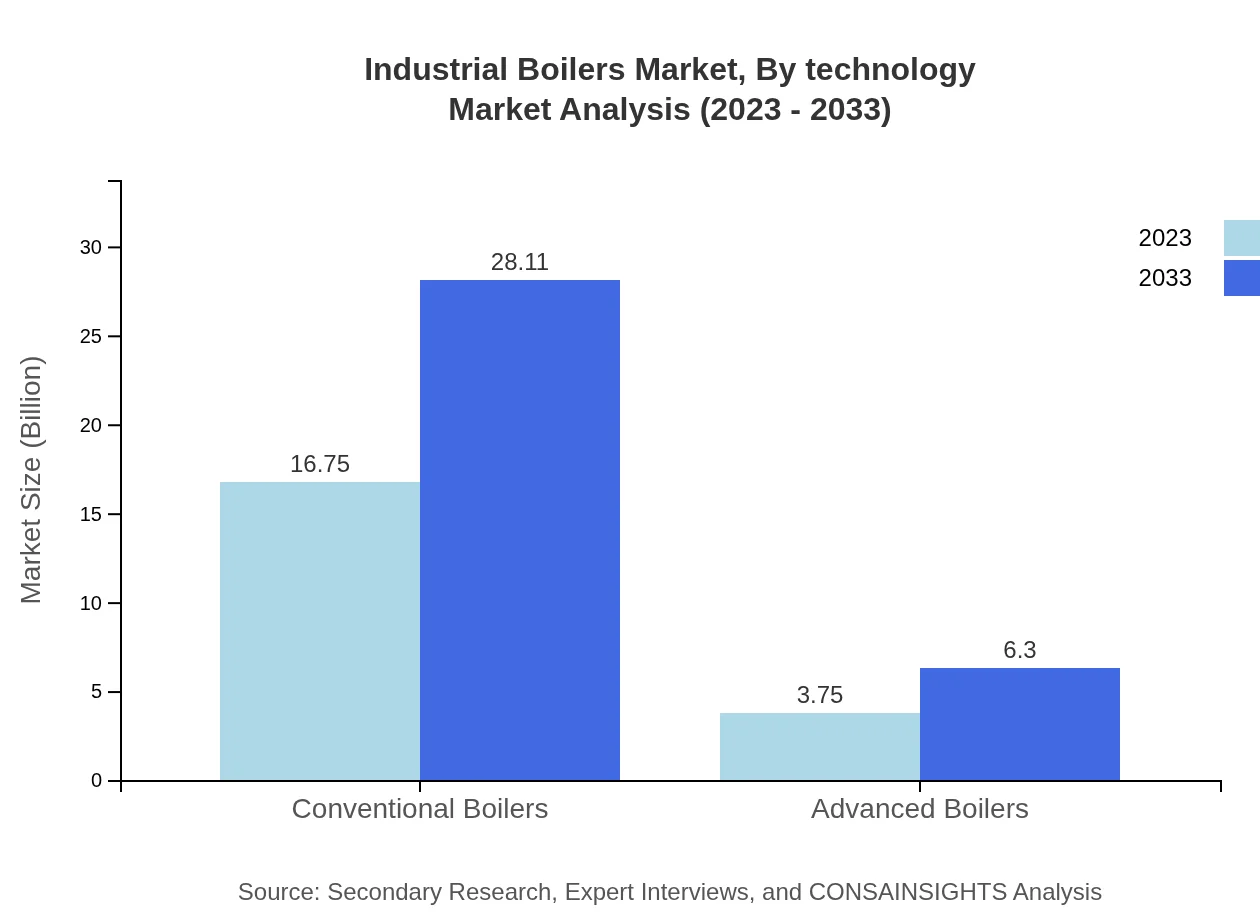

Industrial Boilers Market Analysis By Technology

Fire Tube and Water Tube Technologies are the most implemented, but advancements in Electric Boiler technology are gaining traction. The demand for intelligent boiler systems featuring IoT integration highlights the trend toward automation and efficiency.

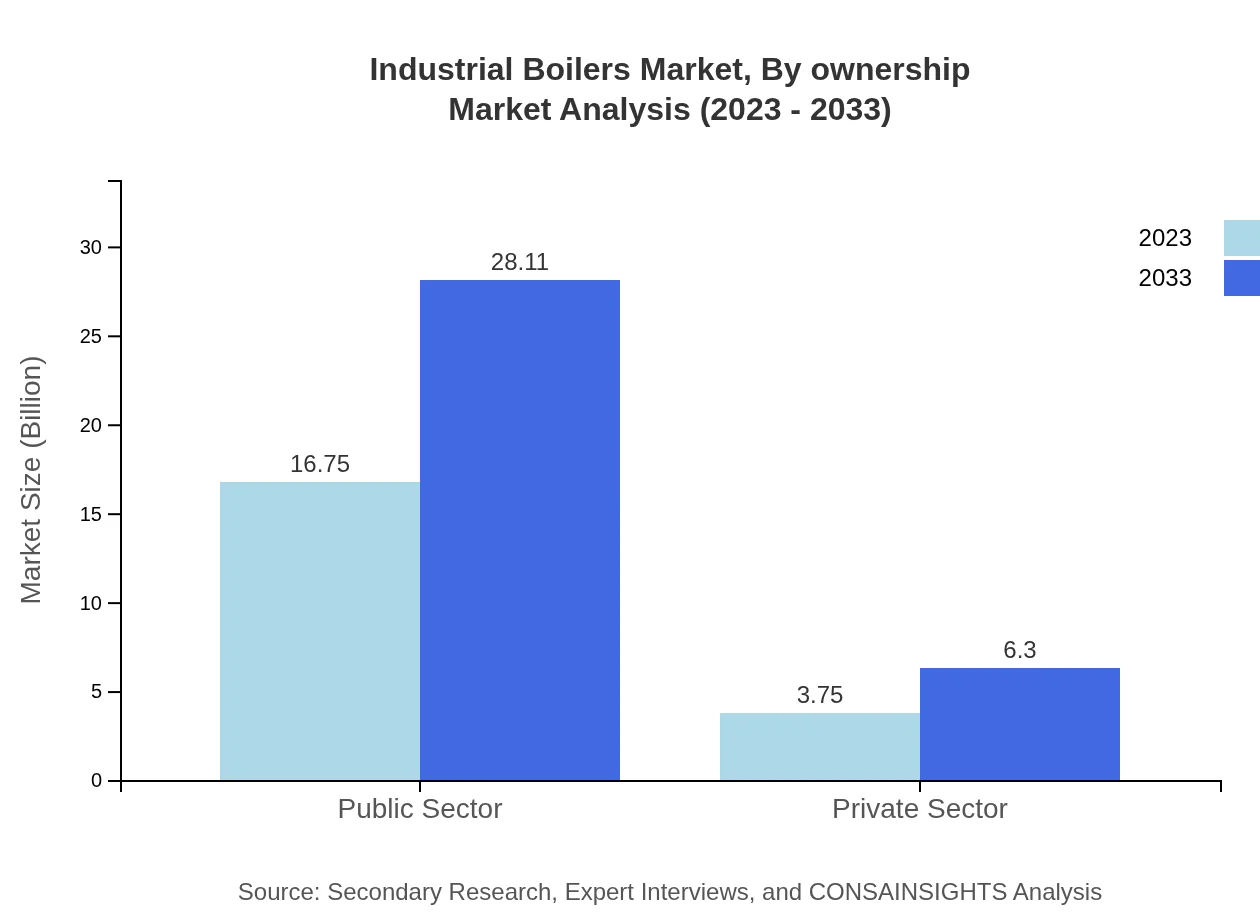

Industrial Boilers Market Analysis By Ownership

The Public sector dominates with a size of $16.75 billion in 2023, while the Private sector sizes at $3.75 billion. The analysis shows sustained growth due to increasing public health and safety standards and private sector investments in modernizing facilities.

Industrial Boilers Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Boilers Industry

Babcock & Wilcox Enterprises, Inc.:

A leader in advanced power generation and industrial boiler systems, known for its innovative technologies and commitment to sustainability.Foster Wheeler AG:

Specializes in engineering and construction solutions for power generation and process industries, with a strong focus on thermal technology.Siemens AG:

A global technology company that provides energy-efficient products and solutions in the Industrial Boiler segment, focusing on automation and smart technologies.Mitsubishi Hitachi Power Systems, Ltd.:

Known for high-efficiency steam and industrial boilers, the company emphasizes integration of renewable energy solutions.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial boilers?

The market size of the industrial boilers industry is projected to reach approximately $20.5 billion by 2033, with a CAGR of 5.2% from 2023 to 2033.

What are the key market players or companies in this industrial boilers industry?

Key players in the industrial boilers market include leading companies that specialize in manufacturing and supplying a variety of boiler types, although specific names are not listed here.

What are the primary factors driving the growth in the industrial boilers industry?

Factors contributing to growth in the industrial boilers market include rising energy demand, advancements in boiler technology, and the increasing focus on energy efficiency across various sectors.

Which region is the fastest Growing in the industrial boilers?

North America is expected to be the fastest-growing region for industrial boilers, projected to grow from $7.85 billion in 2023 to $13.18 billion by 2033, showcasing significant demand in the region.

Does ConsaInsights provide customized market report data for the industrial boilers industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the industrial boilers industry, ensuring comprehensive insights and competitive analysis.

What deliverables can I expect from this industrial boilers market research project?

Deliverables for the industrial boilers market research project may include a detailed market analysis report, segmentation analysis, trends, and competitive landscape assessments.

What are the market trends of industrial boilers?

Current trends in the industrial boilers market include a rise in eco-friendly boiler technologies, increased usage of natural gas over coal, and innovations in energy efficiency.