Industrial Brakes Market Report

Published Date: 22 January 2026 | Report Code: industrial-brakes

Industrial Brakes Market Size, Share, Industry Trends and Forecast to 2033

This report provides comprehensive insights into the Industrial Brakes market from 2023 to 2033, including market trends, size forecasts, industry analysis, and segmentation. It aims to equip stakeholders with critical data for informed decision-making in this evolving sector.

| Metric | Value |

|---|---|

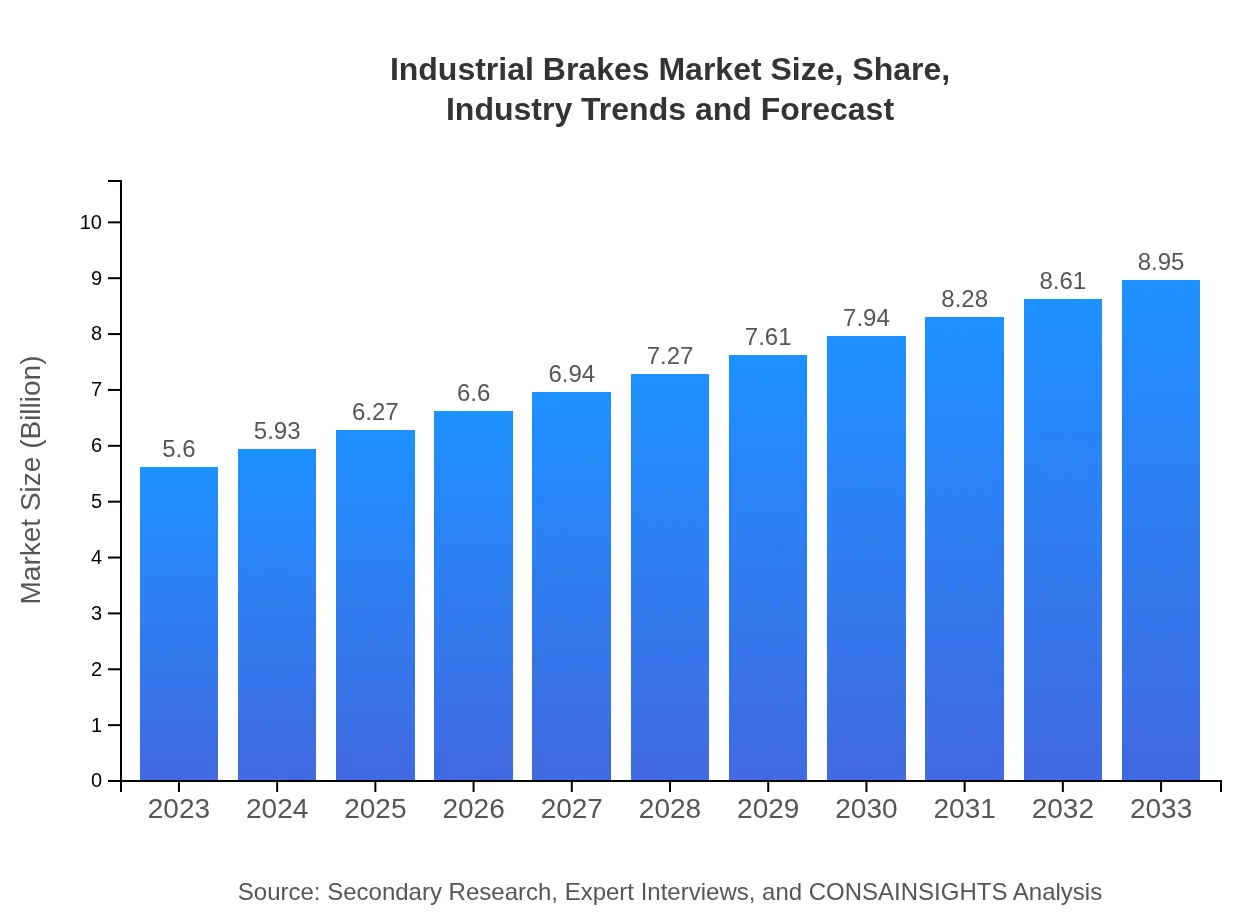

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 4.7% |

| 2033 Market Size | $8.95 Billion |

| Top Companies | Svendborg Brakes, Honeywell International Inc., Brembo S.p.A, Carlisle Companies Inc. |

| Last Modified Date | 22 January 2026 |

Industrial Brakes Market Overview

Customize Industrial Brakes Market Report market research report

- ✔ Get in-depth analysis of Industrial Brakes market size, growth, and forecasts.

- ✔ Understand Industrial Brakes's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Brakes

What is the Market Size & CAGR of Industrial Brakes market in 2023 and 2033?

Industrial Brakes Industry Analysis

Industrial Brakes Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Brakes Market Analysis Report by Region

Europe Industrial Brakes Market Report:

The European Industrial Brakes market size is projected to rise from $1.66 billion in 2023 to $2.65 billion by 2033. This growth is driven by stringent government initiatives on safety and an increasing focus on automation across various industries. The UK, Germany, and France are key markets in this region.Asia Pacific Industrial Brakes Market Report:

The Asia Pacific region is projected to witness substantial growth, with the market expected to increase from $1.07 billion in 2023 to $1.72 billion by 2033. Rapid industrialization, along with increased infrastructure investments, particularly in countries like China and India, is driving demand for industrial brakes. Furthermore, rising safety concerns and regulatory measures are spurring market growth.North America Industrial Brakes Market Report:

North America is poised for robust growth, with the market expected to expand from $1.97 billion in 2023 to $3.15 billion by 2033. Key factors driving this growth include technological advancements and increased focus on workplace safety regulations. The presence of established manufacturers and their ongoing investments in R&D further enhance market potential.South America Industrial Brakes Market Report:

In South America, the market size is anticipated to grow from $0.25 billion in 2023 to $0.39 billion by 2033. The growth can be attributed to increasing mining activities and a gradual recovery in the construction sector post-pandemic. However, economic instability in some regions may pose challenges to growth.Middle East & Africa Industrial Brakes Market Report:

The Middle East and Africa market is expected to grow from $0.65 billion in 2023 to $1.04 billion by 2033. Growth is driven by ongoing infrastructural developments and a rise in mineral extraction in several countries. Despite some political and economic uncertainties, the demand for industrial brakes is on the rise.Tell us your focus area and get a customized research report.

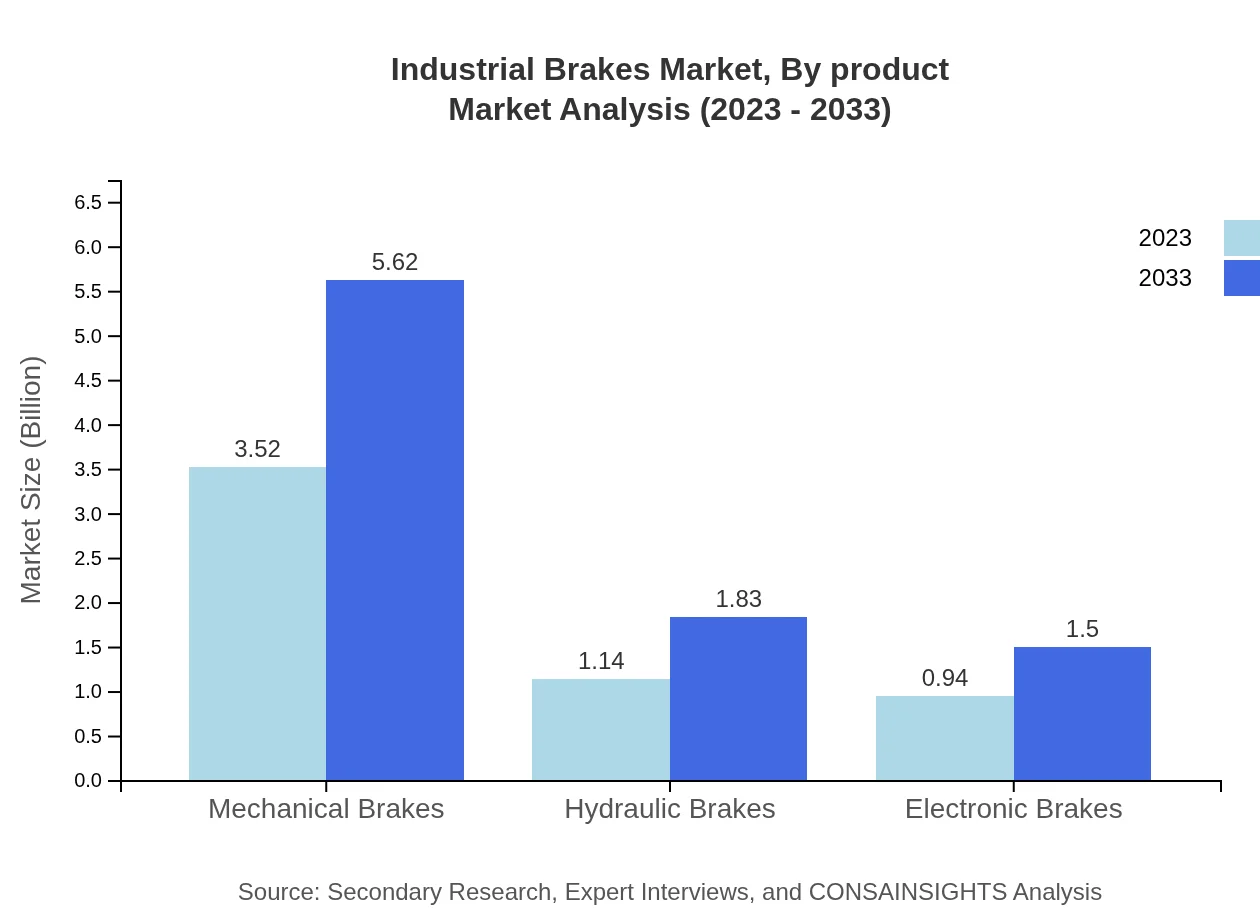

Industrial Brakes Market Analysis By Product

Mechanical Brakes lead the market, valued at $3.52 billion in 2023 and projected to reach $5.62 billion by 2033, holding a 62.82% market share. Hydraulic Brakes follow with a current market size of $1.14 billion, expected to grow to $1.83 billion, maintaining a 20.44% share. Electronic Brakes, while smaller at $0.94 billion in 2023, will grow to $1.50 billion, holding a 16.74% share.

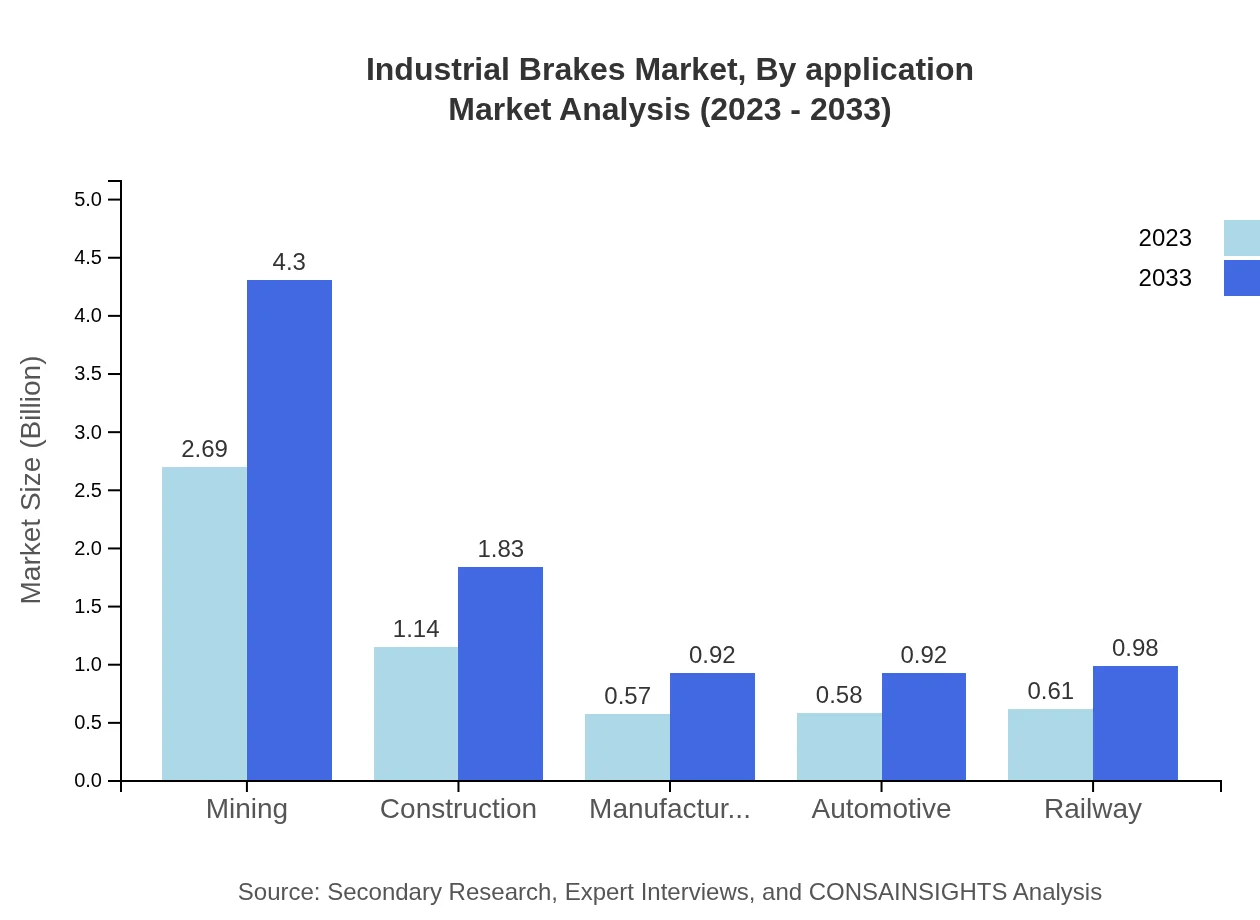

Industrial Brakes Market Analysis By Application

The Mining sector dominates applications, reaching $2.69 billion in 2023 with expectations to grow to $4.30 billion by 2033, accounting for a 48.11% share. The Construction sector shows significant potential, climbing from $1.14 billion to $1.83 billion, maintaining a 20.43% share. Manufacturing and Automotive applications are also important, projected to grow steadily.

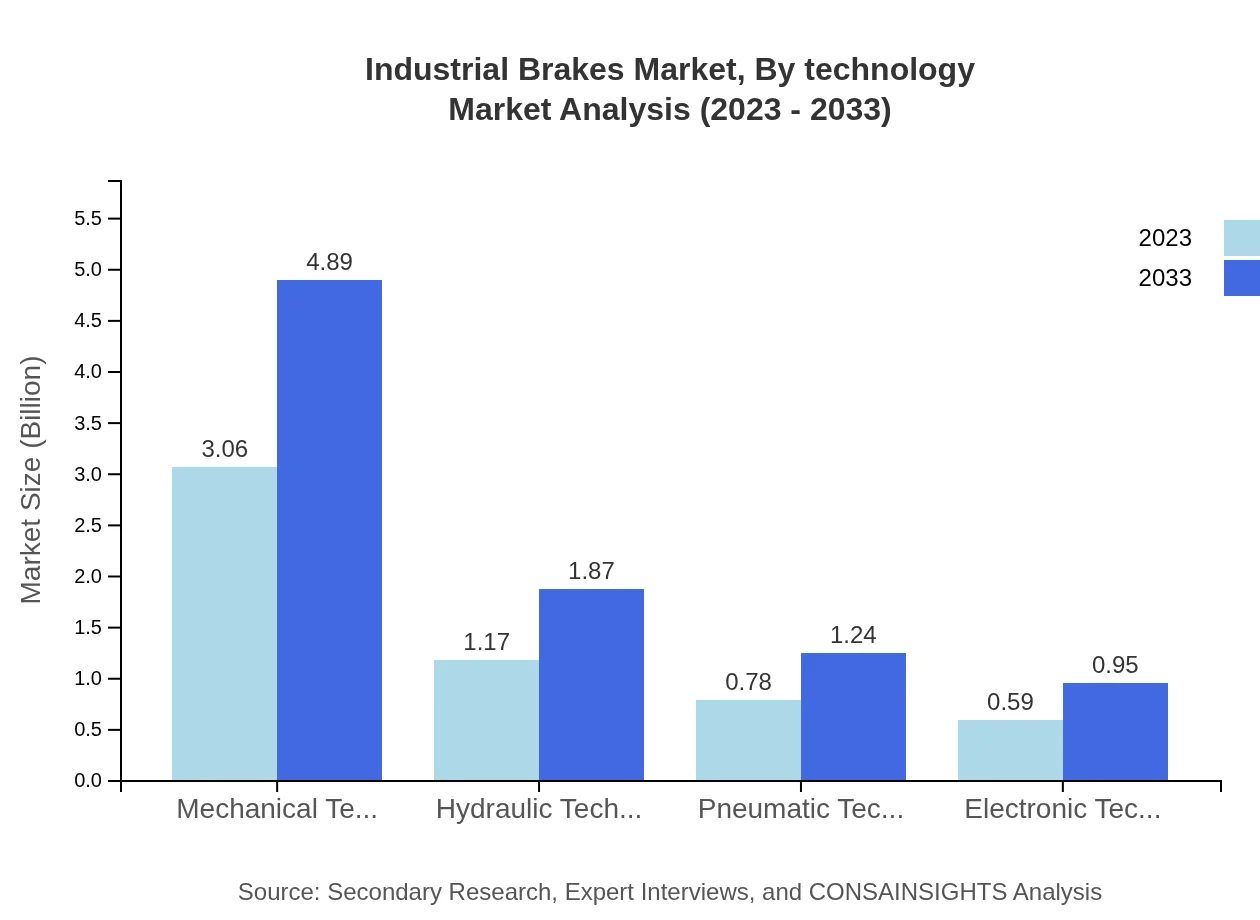

Industrial Brakes Market Analysis By Technology

Mechanical Technology remains predominant, with its market at $3.06 billion in 2023, forecasted to reach $4.89 billion by 2033, representing a 54.66% share. Hydraulic Technology, valued at $1.17 billion, is expected to grow to $1.87 billion, with a 20.88% share, while Pneumatic Technology will climb from $0.78 billion to $1.24 billion, capturing 13.84% of the market.

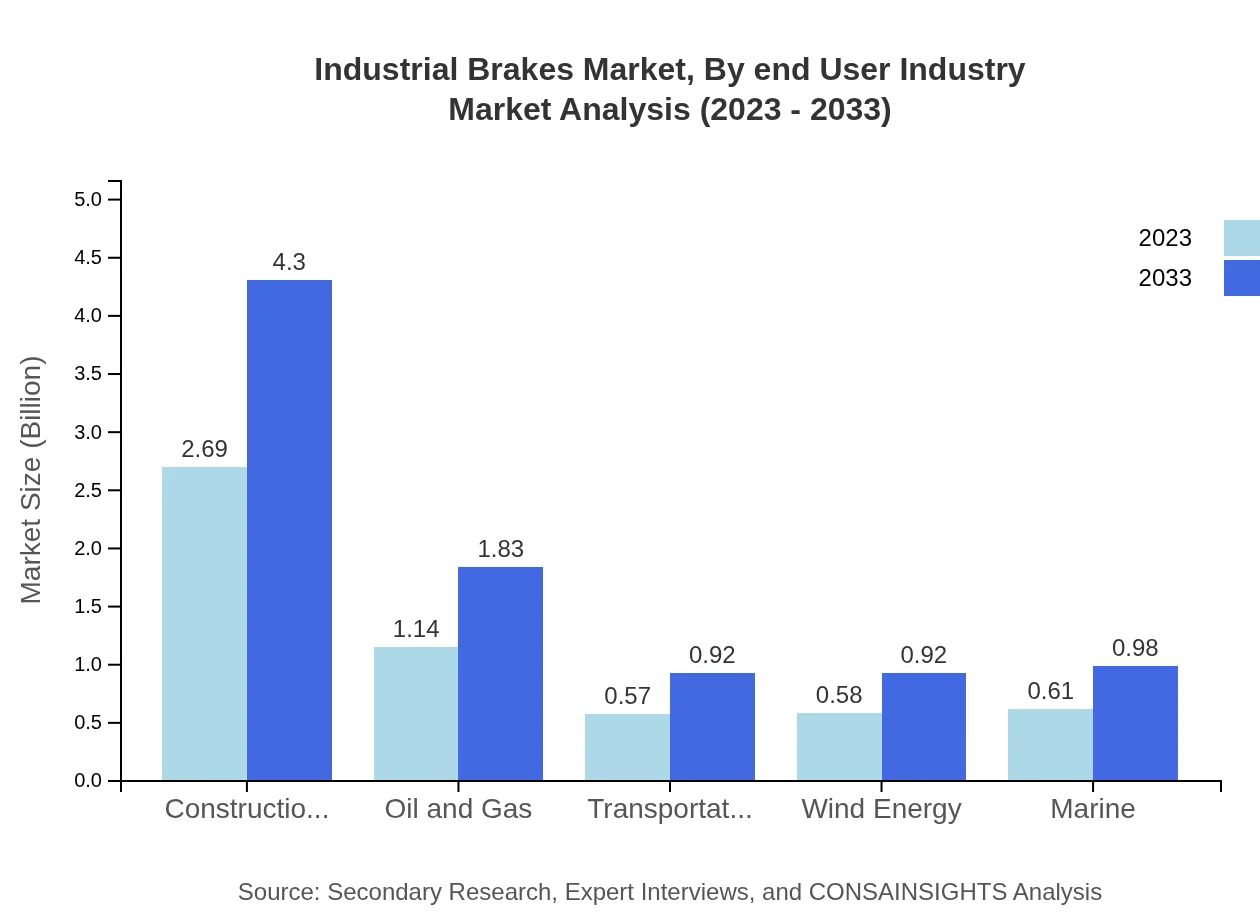

Industrial Brakes Market Analysis By End User Industry

The Oil and Gas sector is notable for its size, anticipated to grow from $1.14 billion to $1.83 billion by 2033, holding a 20.43% share. Other significant sectors include Transportation and Logistics, expected to see a steady rise, along with Wind Energy and Marine sectors, each maintaining around 10-11% market shares.

Industrial Brakes Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Brakes Industry

Svendborg Brakes:

A leading manufacturer of braking systems for heavy industries and wind power, recognized for innovative brake designs and solutions.Honeywell International Inc.:

Global leader in diversified technology and manufacturing, providing a range of high-performance braking solutions for industrial applications.Brembo S.p.A:

Renowned automotive brake manufacturer that has expanded into industrial markets, focusing on high-performance brake components.Carlisle Companies Inc.:

A diversified global company engaged in the manufacturing of brake pads and related products for a wide range of applications.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial brakes?

The industrial brakes market is valued at approximately $5.6 billion in 2023, with a projected growth at a CAGR of 4.7%. This growth indicates increasing demand across various sectors, anticipating significant market expansion through 2033.

What are the key market players or companies in this industrial brakes industry?

Key players in the industrial brakes market include major manufacturers and suppliers that specialize in high-performance braking systems. These companies are instrumental in driving innovation and market growth by offering advanced braking solutions to diverse industrial sectors.

What are the primary factors driving the growth in the industrial brakes industry?

Growth in the industrial brakes market is primarily driven by rising automation in industries, increasing safety regulations, and the demand for advanced braking technologies. Additionally, the expansion of the construction and mining sectors contributes to this upward trend.

Which region is the fastest Growing in the industrial brakes market?

The Asia Pacific region shows significant growth potential within the industrial brakes market, with a market size expectation of $1.72 billion by 2033, up from $1.07 billion in 2023. This growth is fueled by expanding industrial activities and increasing investments.

Does ConsaInsights provide customized market report data for the industrial brakes industry?

Yes, Consainsights offers customized market report data for the industrial brakes industry. This tailored data allows clients to gain specific insights that suit their business needs and strategic objectives.

What deliverables can I expect from this industrial brakes market research project?

From the industrial brakes market research project, you can expect detailed reports including market analysis, competitive landscape, segment-wise performance, regional insights, and forecasts, providing a comprehensive overview for strategic planning.

What are the market trends of industrial brakes?

Current trends in the industrial brakes market include increased adoption of electronic braking systems, integration of IoT technologies for enhanced safety, and a shift towards eco-friendly materials. These trends highlight the industry's focus on innovation and sustainability.