Industrial Control Transformer Market Report

Published Date: 22 January 2026 | Report Code: industrial-control-transformer

Industrial Control Transformer Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Industrial Control Transformer market, covering market size, segmentation, regional insights, and trends. Forecasting from 2023 to 2033, it presents key data and insights for stakeholders to strategize effectively.

| Metric | Value |

|---|---|

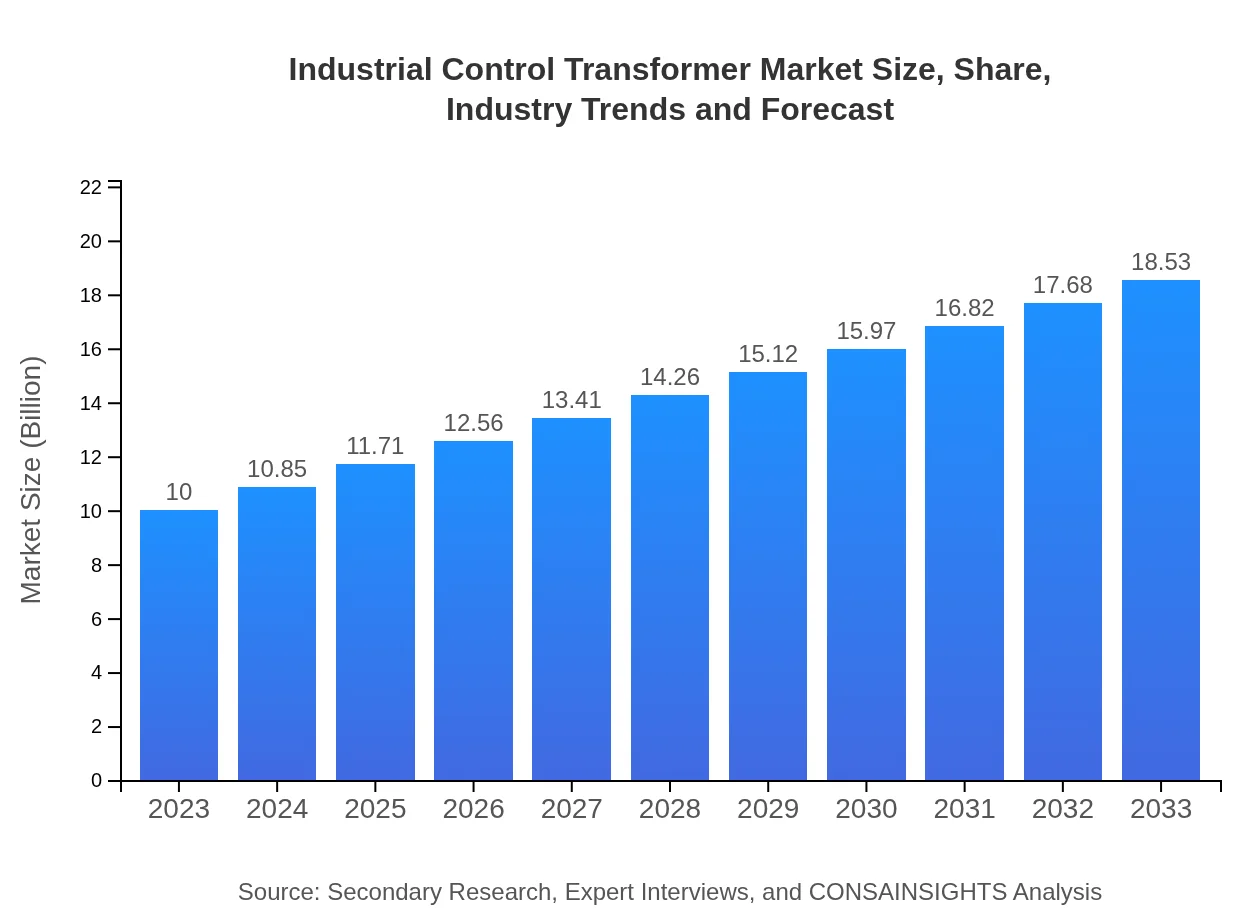

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.00 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $18.53 Billion |

| Top Companies | Schneider Electric, Siemens AG, Eaton Corporation, ABB Ltd. |

| Last Modified Date | 22 January 2026 |

Industrial Control Transformer Market Overview

Customize Industrial Control Transformer Market Report market research report

- ✔ Get in-depth analysis of Industrial Control Transformer market size, growth, and forecasts.

- ✔ Understand Industrial Control Transformer's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Control Transformer

What is the Market Size & CAGR of Industrial Control Transformer market in 2023?

Industrial Control Transformer Industry Analysis

Industrial Control Transformer Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Control Transformer Market Analysis Report by Region

Europe Industrial Control Transformer Market Report:

Europe is expected to expand significantly, with a projected market size of $5.81 billion by 2033. The growing emphasis on renewable energy sources and stringent energy efficiency regulations are pivotal for this market's progression.Asia Pacific Industrial Control Transformer Market Report:

The Asia Pacific region, with a projected market size of $3.45 billion by 2033, is experiencing significant growth due to rapid industrialization and urbanization, particularly in countries like China and India. The ongoing investments in electrical infrastructure and manufacturing are key drivers of this growth.North America Industrial Control Transformer Market Report:

North America is forecasted to reach approximately $6.58 billion in market size by 2033. The region's demand is driven by modernized power distribution networks and the adoption of advanced transformer technology.South America Industrial Control Transformer Market Report:

In South America, the Industrial Control Transformer market is expected to grow from $0.31 billion in 2023 to $0.57 billion by 2033. The region's growth is supported by increasing energy demands and investments in industrial developments.Middle East & Africa Industrial Control Transformer Market Report:

The Middle East and Africa region is forecasted to achieve a market size of $2.11 billion by 2033, bolstered by infrastructural developments and the expansion of industrial sectors, particularly in the Gulf Cooperation Council (GCC) countries.Tell us your focus area and get a customized research report.

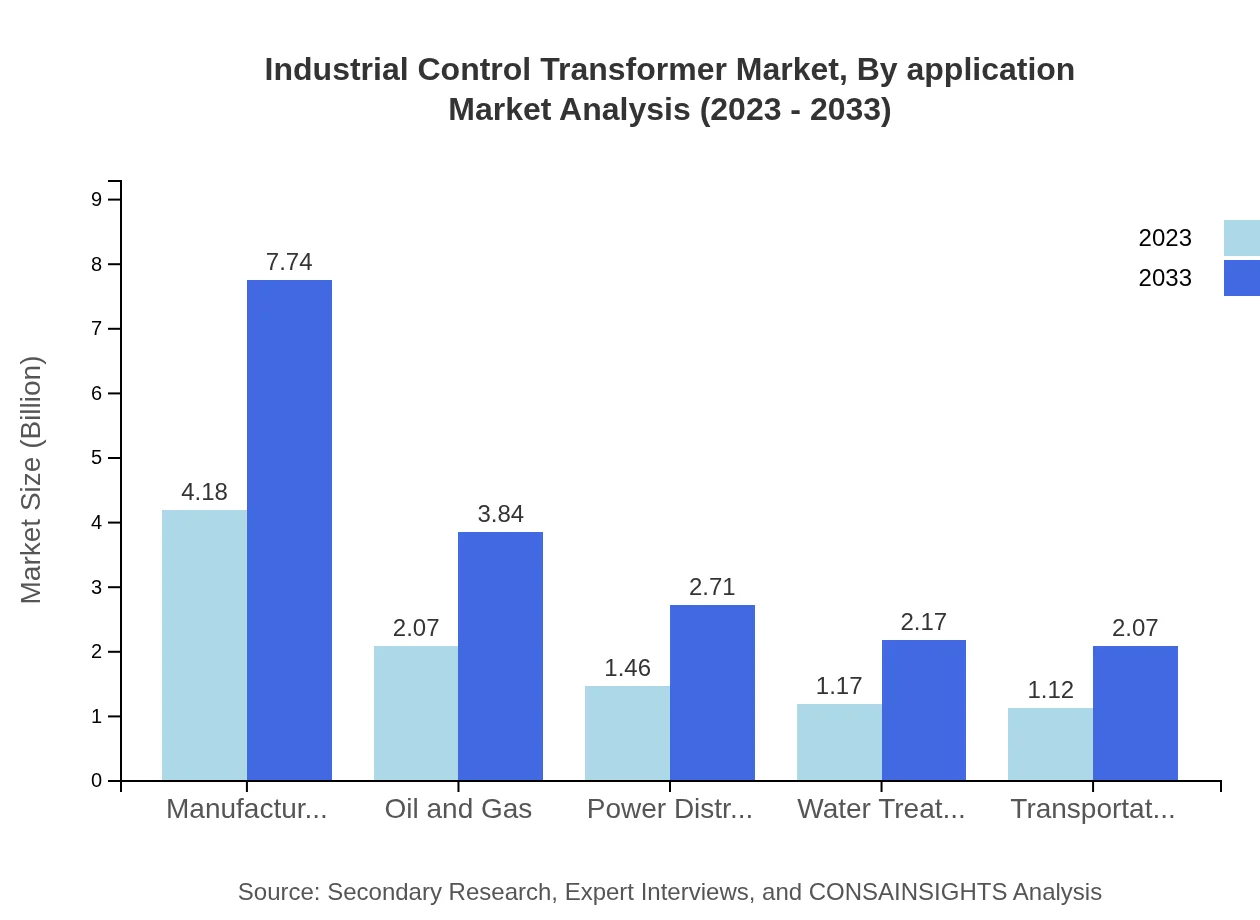

Industrial Control Transformer Market Analysis By Application

The application segmentation of the Industrial Control Transformer market is diverse, with Manufacturing representing the largest share at approximately 56.3%, followed by Commercial and Oil & Gas sectors. Each application demands specific transformer solutions tailored to operational complexities.

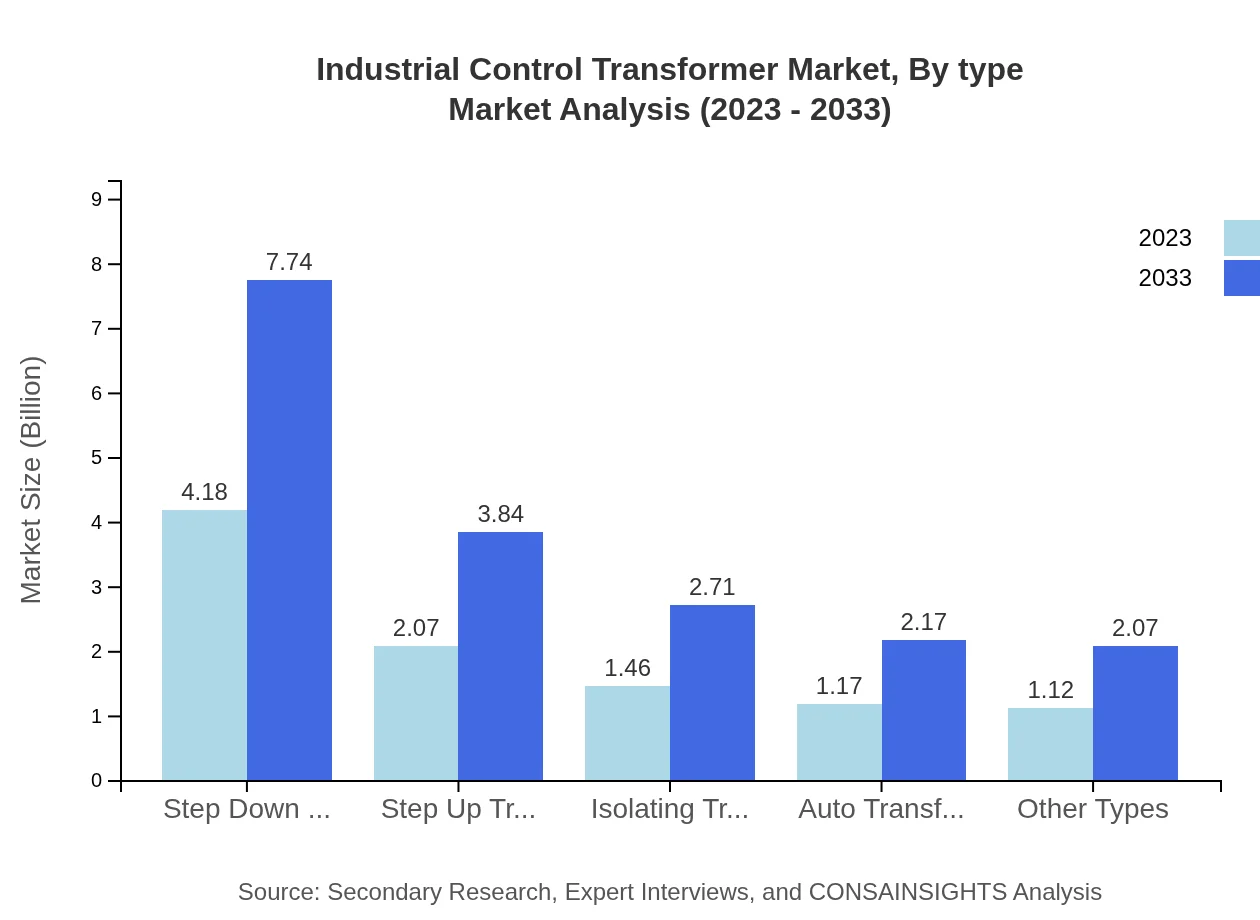

Industrial Control Transformer Market Analysis By Type

In terms of type, Step Down Transformers are predominant, expected to grow from $4.18 billion in 2023 to $7.74 billion by 2033. Other notable types include Step Up Transformers, Isolating Transformers, and Auto Transformers, which serve unique roles in various applications.

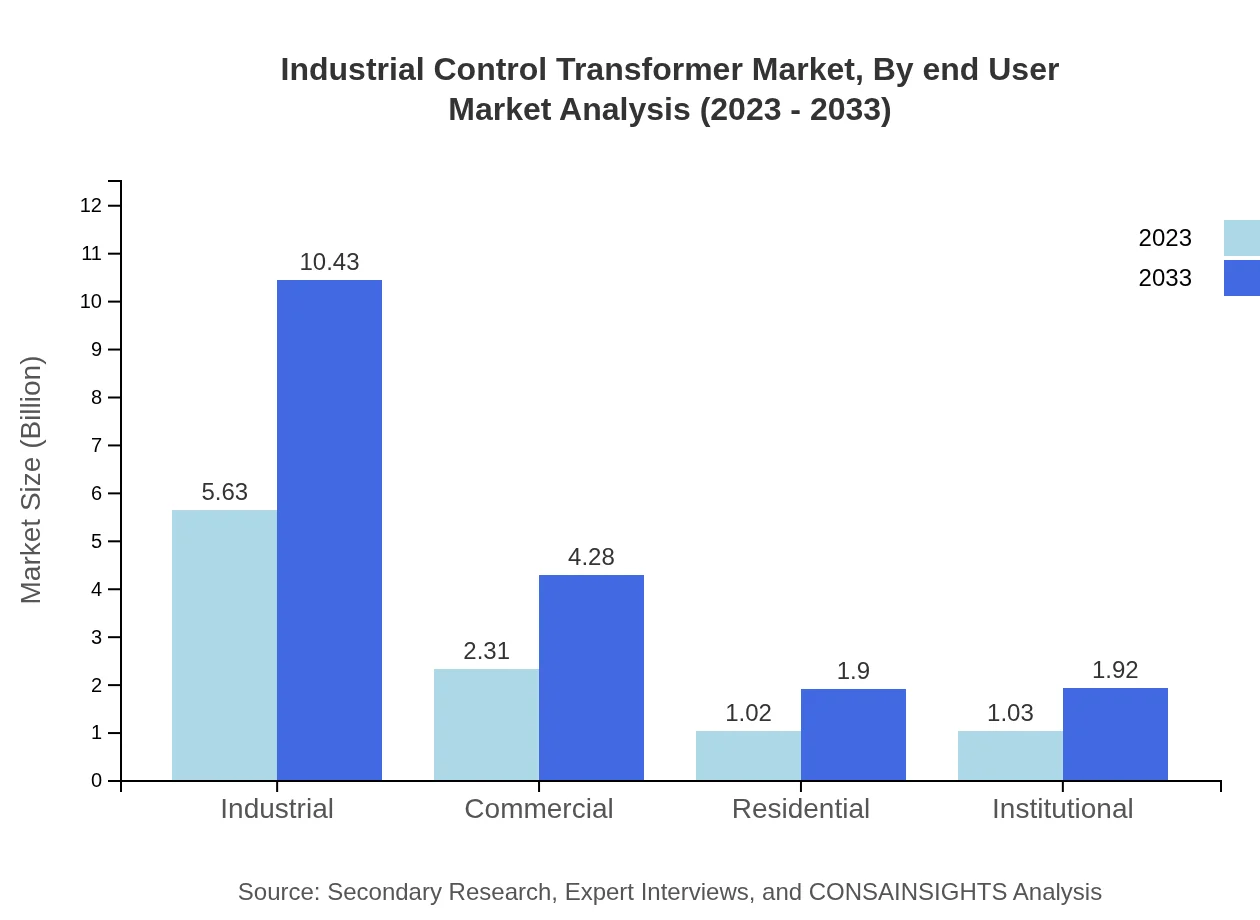

Industrial Control Transformer Market Analysis By End User

End-user analysis indicates Manufacturing and Commercial sectors as the most significant contributors to market growth. Residential and Institutional segments, while smaller, are poised for steady growth, reflecting increased consumer demand for transformers.

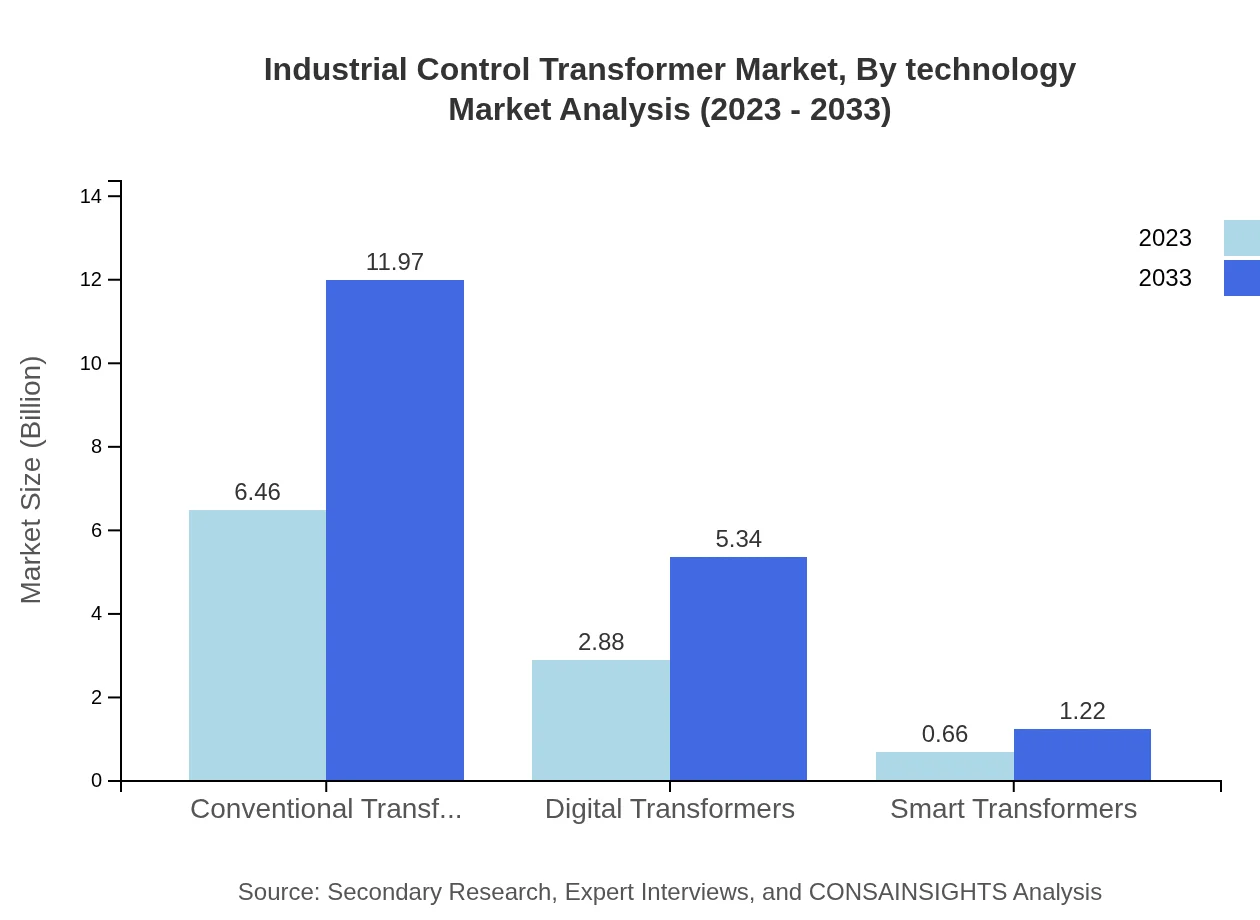

Industrial Control Transformer Market Analysis By Technology

Technological innovations in transformers are shifting the focus towards smart and digital transformers, which enhance operational efficiencies and enable real-time monitoring. Conventional transformer technologies continue to dominate but are increasingly complemented by advanced digital solutions.

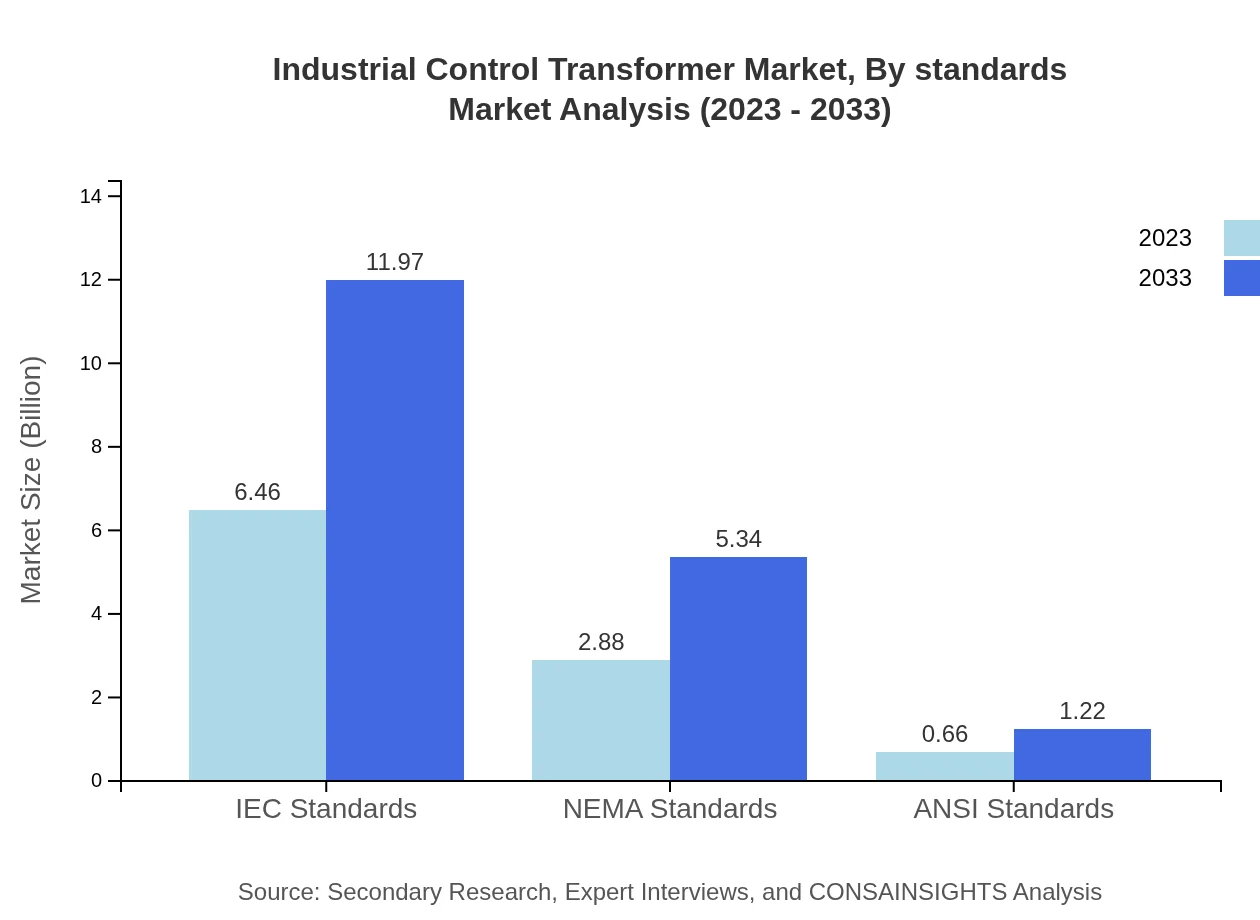

Industrial Control Transformer Market Analysis By Standards

The market is segmented based on standards such as IEC, NEMA, and ANSI, with IEC Standards capturing a significant market share. Compliance with these standards is critical for ensuring safety and efficiency in transformer operations.

Industrial Control Transformer Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Control Transformer Industry

Schneider Electric:

A global leader in energy management and automation, Schneider Electric produces a range of industrial control transformers known for their reliability and efficiency.Siemens AG:

Siemens AG is a major player in engineering and electronics, offering innovative industrial transformer solutions that focus on sustainability and performance.Eaton Corporation:

Eaton is renowned for its comprehensive range of electrical products, including transformers, focusing on energy-efficient designs.ABB Ltd.:

ABB is a leader in industrial technology and electrical equipment, providing advanced transformer solutions that enhance productivity and reduce environmental impact.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial control transformer?

The industrial control transformer market is projected to reach $10 billion by 2033, growing at a CAGR of 6.2% from its current market size in 2023.

What are the key market players or companies in the industrial control transformer industry?

Key players in the industrial control transformer market include Siemens, ABB, Schneider Electric, General Electric, and Eaton. These companies drive innovation and competition in this growing sector.

What are the primary factors driving the growth in the industrial control transformer industry?

Growth in industrial automation, rising demand for energy-efficient solutions, and infrastructure development are significant drivers for the industrial control transformer market. Innovations in transformer technology also contribute to its expansion.

Which region is the fastest Growing in the industrial control transformer?

North America is the fastest-growing region in the industrial control transformer market, projected to grow from $3.55 billion in 2023 to $6.58 billion in 2033, reflecting increased demand in industrial sectors.

Does ConsaInsights provide customized market report data for the industrial control transformer industry?

Yes, ConsaInsights offers customized market report data tailored to specific requirements in the industrial control transformer sector, ensuring relevant and actionable insights.

What deliverables can I expect from this industrial control transformer market research project?

You can expect comprehensive market analysis reports, segmentation data, growth forecasts, competitive landscape insights, and trends analysis as deliverables from this industrial control transformer market research.

What are the market trends of industrial control transformer?

Current trends include increased adoption of digital and smart transformers, a shift towards energy-efficient solutions, and the integration of IoT in transformer management systems, enhancing performance and reliability.