Industrial Dryers Market Report

Published Date: 22 January 2026 | Report Code: industrial-dryers

Industrial Dryers Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Industrial Dryers market, including market size, growth forecasts, trends, segments, regional insights, and key players from 2023 to 2033.

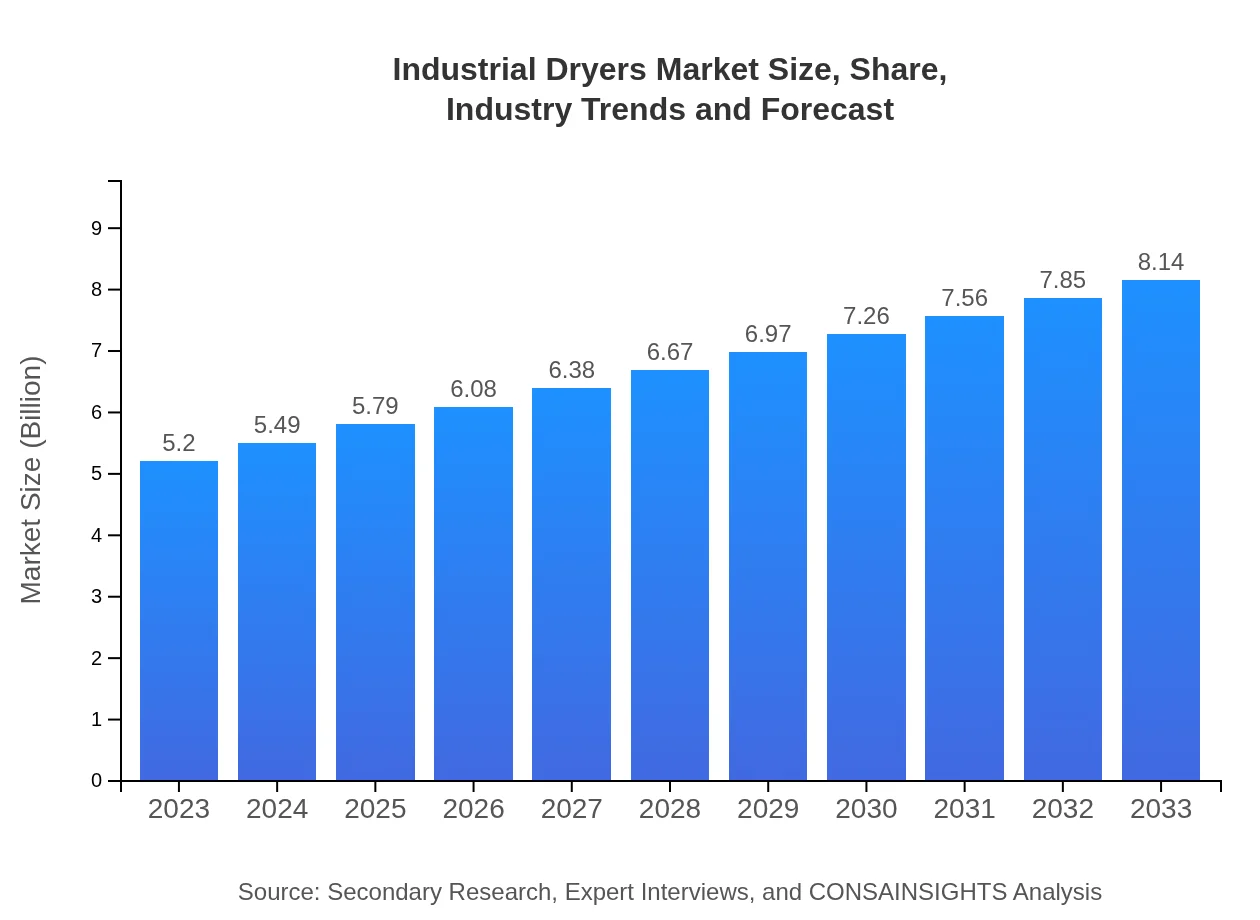

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.20 Billion |

| CAGR (2023-2033) | 4.5% |

| 2033 Market Size | $8.14 Billion |

| Top Companies | GEA Group AG, Bühler Group, Mäntysilta Group, Andritz AG |

| Last Modified Date | 22 January 2026 |

Industrial Dryers Market Overview

Customize Industrial Dryers Market Report market research report

- ✔ Get in-depth analysis of Industrial Dryers market size, growth, and forecasts.

- ✔ Understand Industrial Dryers's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Dryers

What is the Market Size & CAGR of Industrial Dryers market in 2023?

Industrial Dryers Industry Analysis

Industrial Dryers Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Dryers Market Analysis Report by Region

Europe Industrial Dryers Market Report:

Europe's Industrial Dryers market, valued at $1.75 billion in 2023, is projected to reach $2.75 billion by 2033. Regulations concerning food safety and quality, alongside a heightened focus on sustainable production processes, are pivotal in shaping the market trajectory.Asia Pacific Industrial Dryers Market Report:

The Asia Pacific market for Industrial Dryers is valued at $0.87 billion in 2023, projected to reach $1.36 billion by 2033. This growth is attributable to rapid industrialization, particularly in countries like China and India, where the demand for efficient drying solutions in food processing and textile industries is rising.North America Industrial Dryers Market Report:

The North America market is estimated at $1.80 billion in 2023, with a forecasted increase to $2.82 billion by 2033. The demand for industrial dryers in the food and beverage segment, coupled with the increasing trend towards automation and energy efficiency, drives this market's expansion.South America Industrial Dryers Market Report:

In South America, the Industrial Dryers market is expected to grow from $0.36 billion in 2023 to $0.56 billion by 2033. Factors influencing this growth include increased investments in food processing infrastructure and the growing pharmaceutical sector, particularly in Brazil and Argentina.Middle East & Africa Industrial Dryers Market Report:

In the Middle East and Africa, the market is expected to grow from $0.42 billion in 2023 to $0.65 billion by 2033, driven by growing industrial activities and the need for advanced drying technologies in construction materials and food processing.Tell us your focus area and get a customized research report.

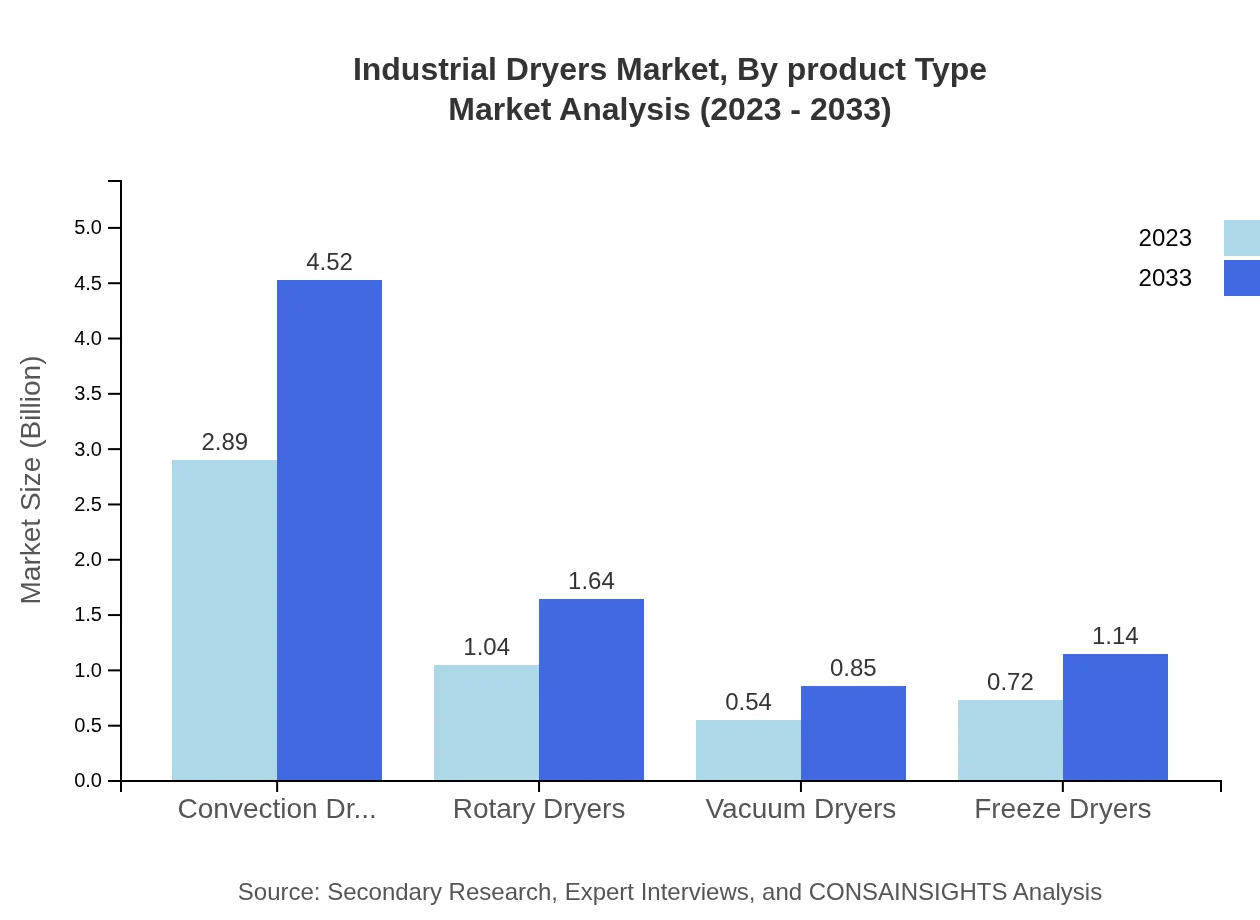

Industrial Dryers Market Analysis By Product Type

The Industrial Dryers market is segmented by product type into thermal dryers, solar dryers, microwave dryers, infrared dryers, rotary dryers, vacuum dryers, and freeze dryers. Thermal drying remains the most dominant segment due to its vast applications in food processing and pharmaceuticals, with a market size reaching $2.89 billion in 2023, expected to grow to $4.52 billion by 2033.

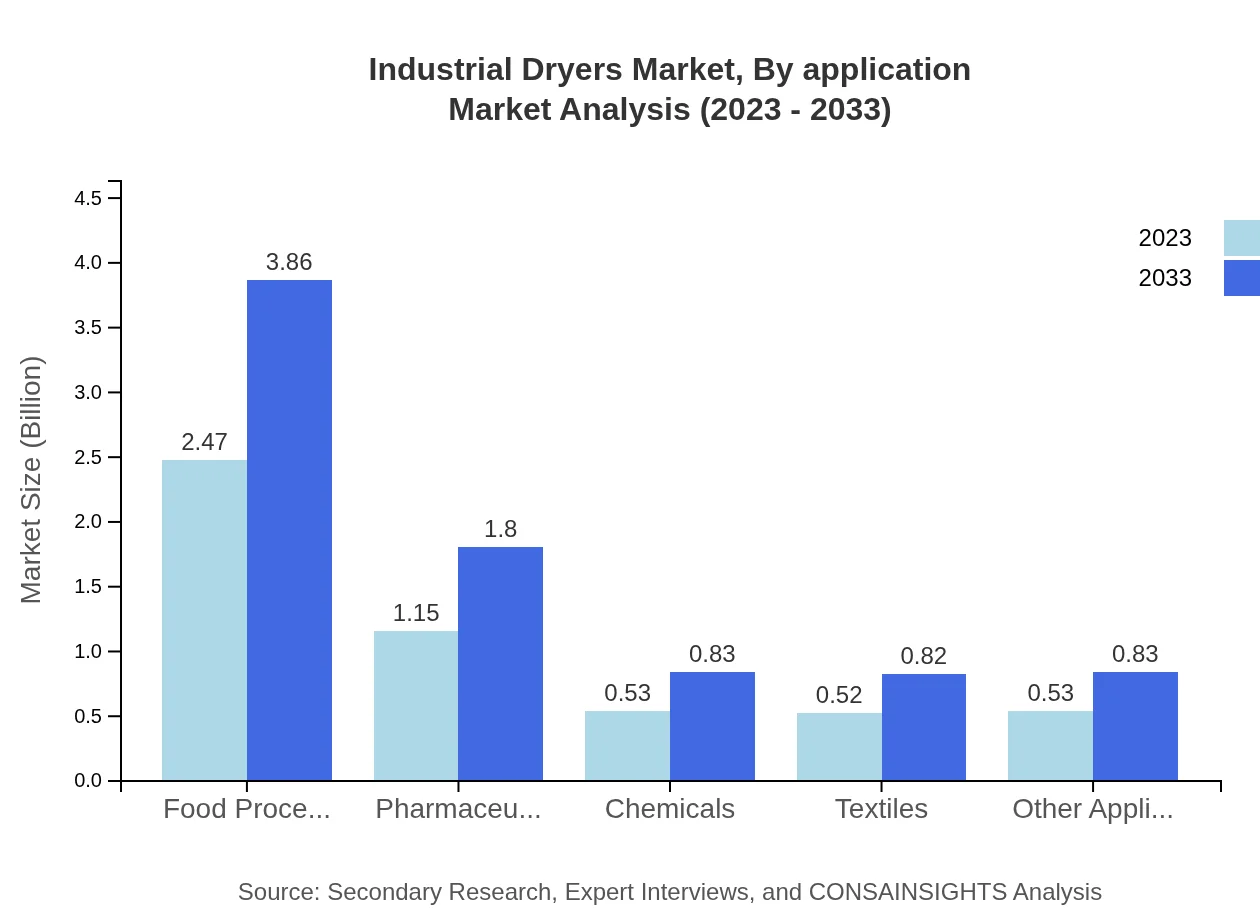

Industrial Dryers Market Analysis By Application

The market is segmented into applications such as food processing, pharmaceuticals, chemicals, textiles, and other applications. Food processing accounts for the major share at approximately 47.41% of the market in 2023, valued at $2.47 billion.

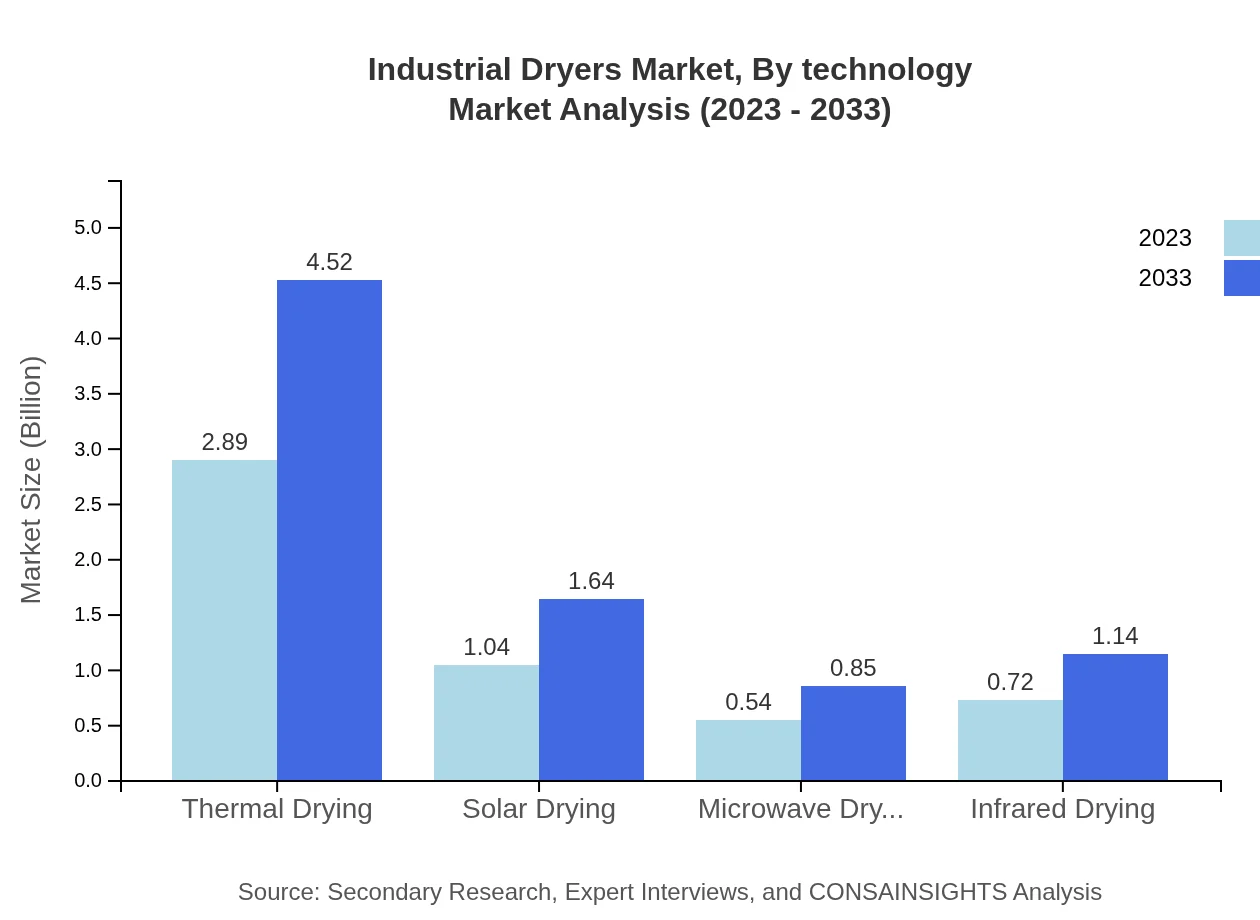

Industrial Dryers Market Analysis By Technology

Technological advancements in drying methods are pivotal for enhancing efficiency. Convection drying techniques dominate the market, yet emerging methods like microwave and infrared drying gain traction due to their energy efficiency and product quality benefits.

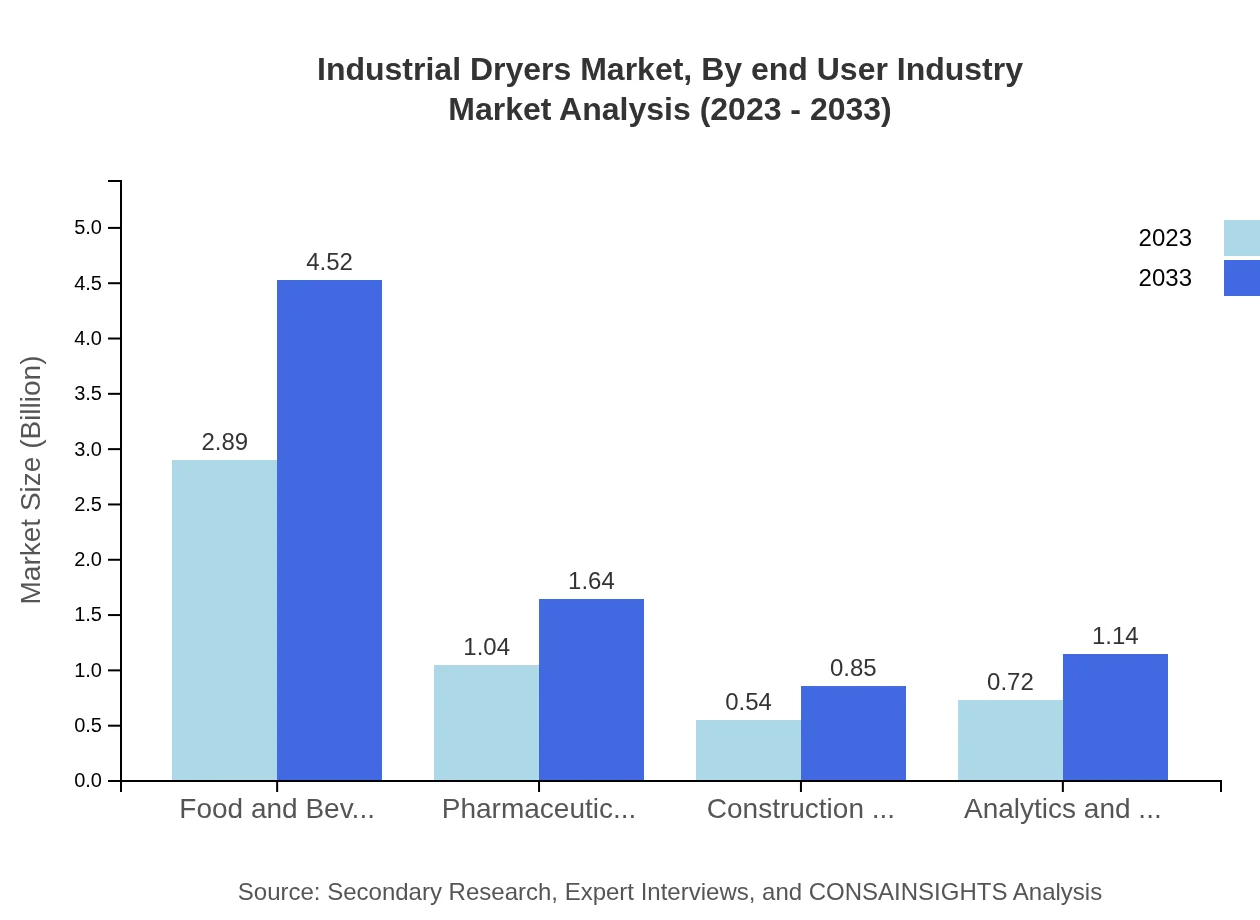

Industrial Dryers Market Analysis By End User Industry

Key end-user industries include food and beverages, pharmaceuticals, chemicals, and textiles. The food and beverages sector leads the market, highlighting the essential role of dryers in maintaining product quality and safety standards across various applications.

Industrial Dryers Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Dryers Industry

GEA Group AG:

A leading provider of process technology and equipment, GEA specializes in the food processing industry, providing highly efficient drying solutions.Bühler Group:

Bühler Group excels in providing innovative process technologies and equipment, particularly for the food and feed sectors, focusing on sustainability and energy efficiency.Mäntysilta Group:

Mäntysilta specializes in drying equipment for the wood and other industries, known for its commitment to quality and technological innovations.Andritz AG:

Andritz provides a comprehensive range of drying technologies and solutions, particularly catering to the pulp and paper, wood, and food industries.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial Dryers?

The industrial dryers market is projected to reach a size of approximately $5.2 billion by 2033, with a compound annual growth rate (CAGR) of 4.5%. This growth reflects increasing demand across various industries.

What are the key market players or companies in this industrial Dryers industry?

Key players in the industrial dryers market include leading manufacturers known for innovative technologies and solutions. These companies often focus on enhancing energy efficiency while improving product quality and meeting diverse industry needs.

What are the primary factors driving the growth in the industrial Dryers industry?

Growth in the industrial dryers industry is primarily driven by technological advancements, the increase in food processing needs, and rising demand in pharmaceutical manufacturing. Environmental concerns also push for energy-efficient drying solutions.

Which region is the fastest Growing in the industrial Dryers?

The fastest-growing region in the industrial dryers market is projected to be Europe, expanding from $1.75 billion in 2023 to $2.75 billion by 2033. Other notable regions include North America and Asia Pacific due to industrial expansion.

Does ConsaInsights provide customized market report data for the industrial Dryers industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the industrial dryers industry. Clients can request tailored insights based on sectors, technology types, and geographical focuses.

What deliverables can I expect from this industrial Dryers market research project?

From the industrial dryers market research project, expect comprehensive reports featuring market size, growth forecasts, segment analysis, regional trends, and in-depth competitive landscape assessments tailored to strategic decision-making.

What are the market trends of industrial Dryers?

Key trends in the industrial dryers market include increasing use of energy-efficient drying technologies, growth in renewable energy applications, and rising integration of automation in manufacturing processes, enhancing productivity and sustainability.