Industrial Emission Control Systems Market Report

Published Date: 22 January 2026 | Report Code: industrial-emission-control-systems

Industrial Emission Control Systems Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Industrial Emission Control Systems market, evaluating market size, trends, technology impacts, regional insights, and forecasts from 2023 to 2033.

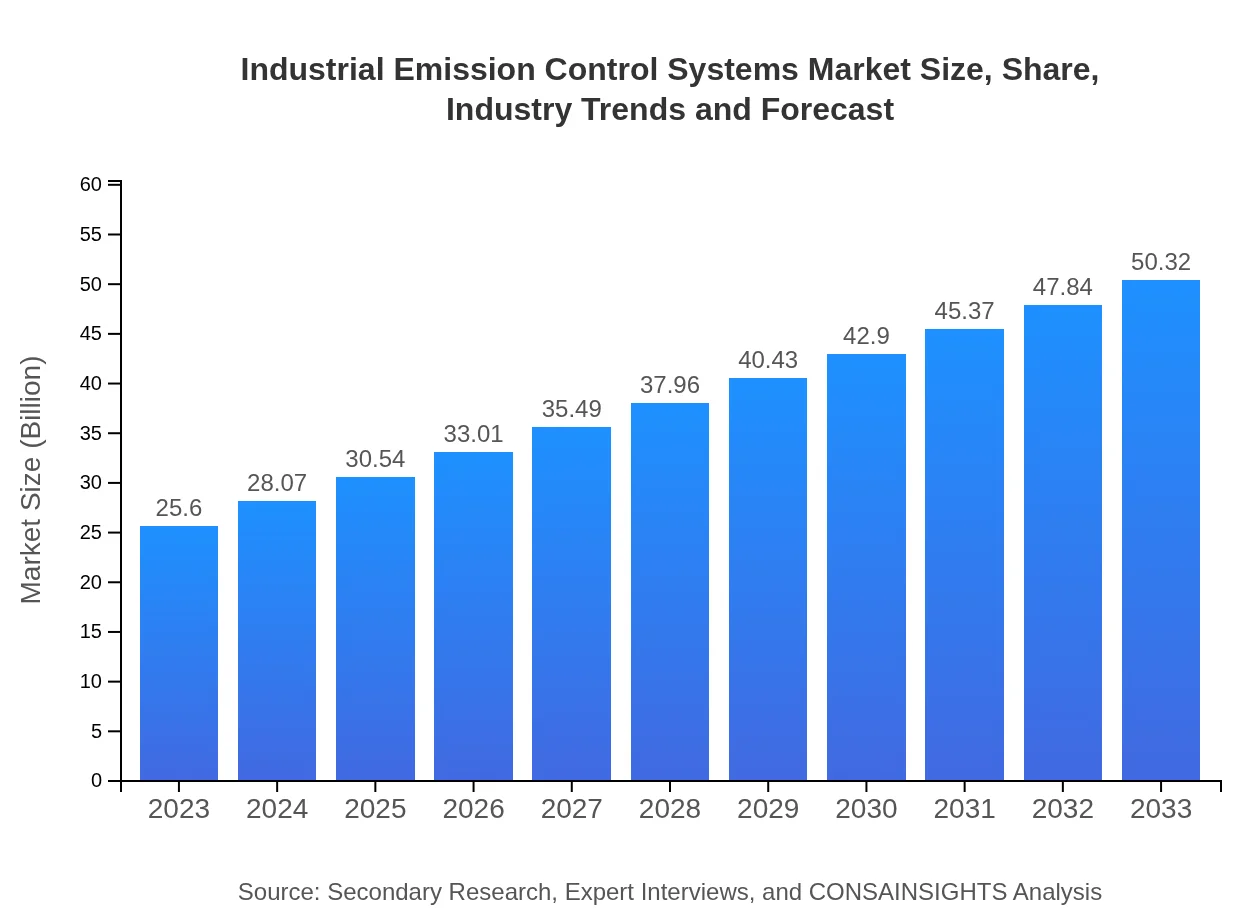

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $25.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $50.32 Billion |

| Top Companies | Emerson Electric Co., Parker Hannifin Corporation, Babcock & Wilcox Enterprises, Inc., GE (General Electric) Company, Siemens AG |

| Last Modified Date | 22 January 2026 |

Industrial Emission Control Systems Market Overview

Customize Industrial Emission Control Systems Market Report market research report

- ✔ Get in-depth analysis of Industrial Emission Control Systems market size, growth, and forecasts.

- ✔ Understand Industrial Emission Control Systems's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Emission Control Systems

What is the Market Size & CAGR of Industrial Emission Control Systems market in 2023?

Industrial Emission Control Systems Industry Analysis

Industrial Emission Control Systems Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Emission Control Systems Market Analysis Report by Region

Europe Industrial Emission Control Systems Market Report:

The European market is projected to expand from $7.92 billion in 2023 to $15.56 billion by 2033, backed by aggressive policies focused on sustainability and emissions reduction. The adoption of innovative technologies and sustainability measures by European companies further fuels this growth.Asia Pacific Industrial Emission Control Systems Market Report:

In Asia Pacific, the market is projected to grow from $4.75 billion in 2023 to $9.34 billion by 2033, driven by rapid industrialization, increasing pollution levels, and stringent environmental regulations. Countries like China and India are leading contributors to this growth through strong investments in emission control technologies.North America Industrial Emission Control Systems Market Report:

North America has a robust market for Industrial Emission Control Systems, with estimates growing from $9.56 billion in 2023 to $18.79 billion by 2033. The region's strict regulatory environment and significant industrial activities in the U.S. and Canada push demand for advanced emission controlling solutions.South America Industrial Emission Control Systems Market Report:

The South American market is expected to increase from $1.12 billion in 2023 to $2.19 billion in 2033. Key drivers include rising environmental awareness and investments in renewable energy sources, paired with government initiatives aimed at reducing industrial emissions.Middle East & Africa Industrial Emission Control Systems Market Report:

In the Middle East and Africa, the market is projected to grow from $2.26 billion in 2023 to $4.43 billion by 2033. The market growth is primarily driven by increasing industrial activities and growing environmental awareness in countries within this region.Tell us your focus area and get a customized research report.

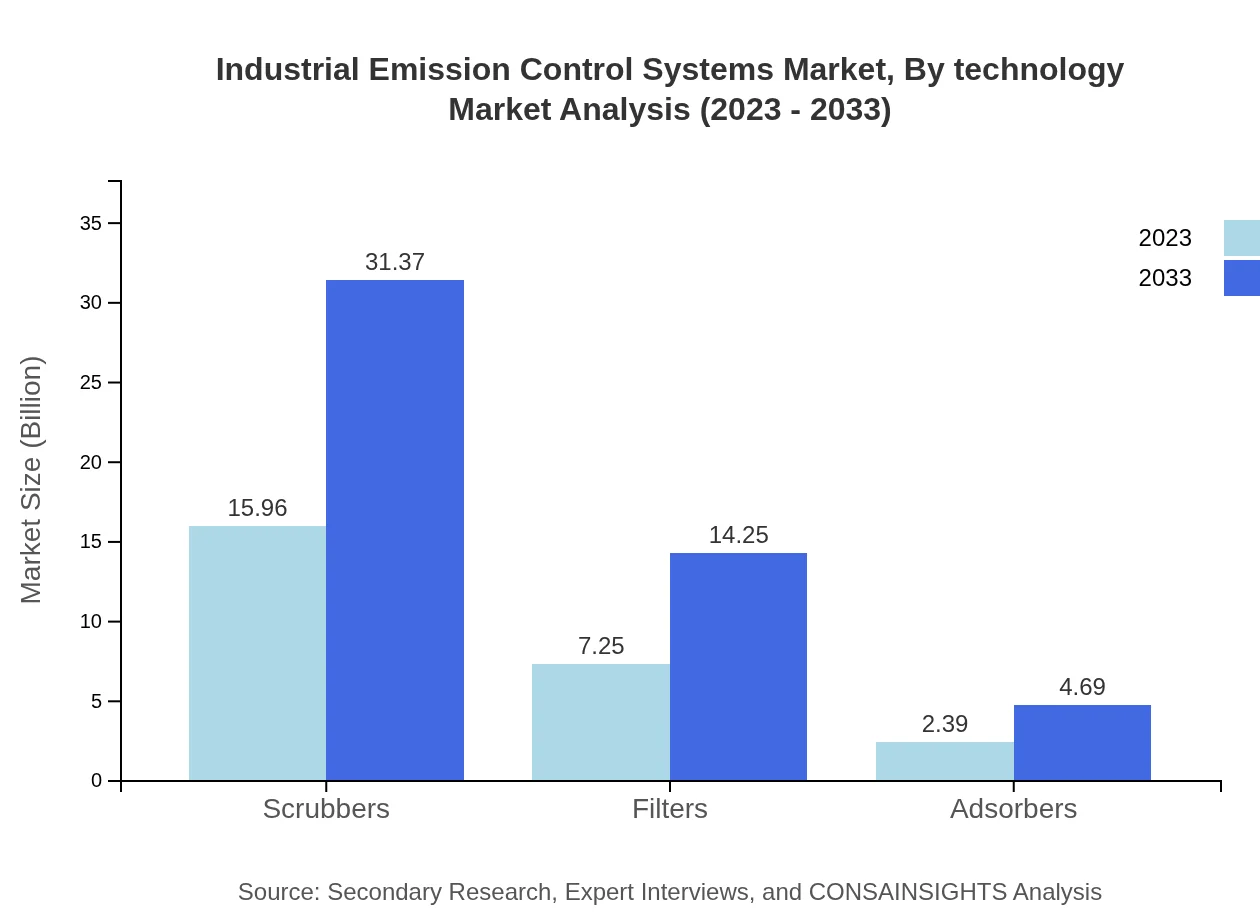

Industrial Emission Control Systems Market Analysis By Technology

The technology segment of the IECS market includes scrubbers, filters, and adsorbers. Scrubbers account for the largest market share, estimated at $15.96 billion in 2023 and projected to reach $31.37 billion by 2033. Filters follow with a market size of $7.25 billion in 2023, growing to $14.25 billion, while adsorbers are expected to rise from $2.39 billion to $4.69 billion over the same period. This indicates a strong reliance on these technologies for efficient emission control.

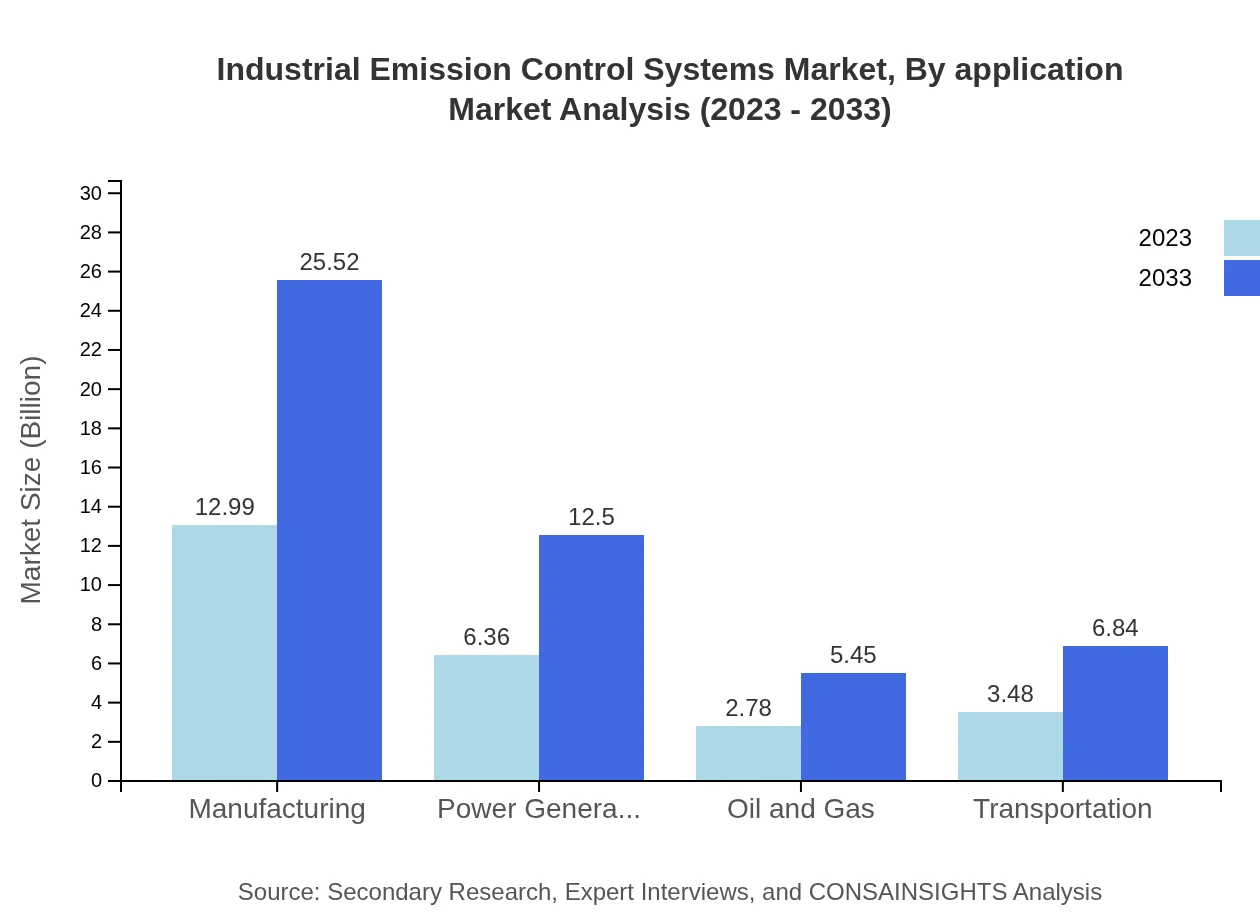

Industrial Emission Control Systems Market Analysis By Application

The application segment covers critical industries such as construction, metals and mining, pulp and paper, manufacturing, power generation, and oil and gas. Construction and manufacturing lead this segment with significant shares—construction's market size is projected to grow from $15.96 billion to $31.37 billion, while manufacturing's share is expected to grow from $12.99 billion to $25.52 billion by 2033.

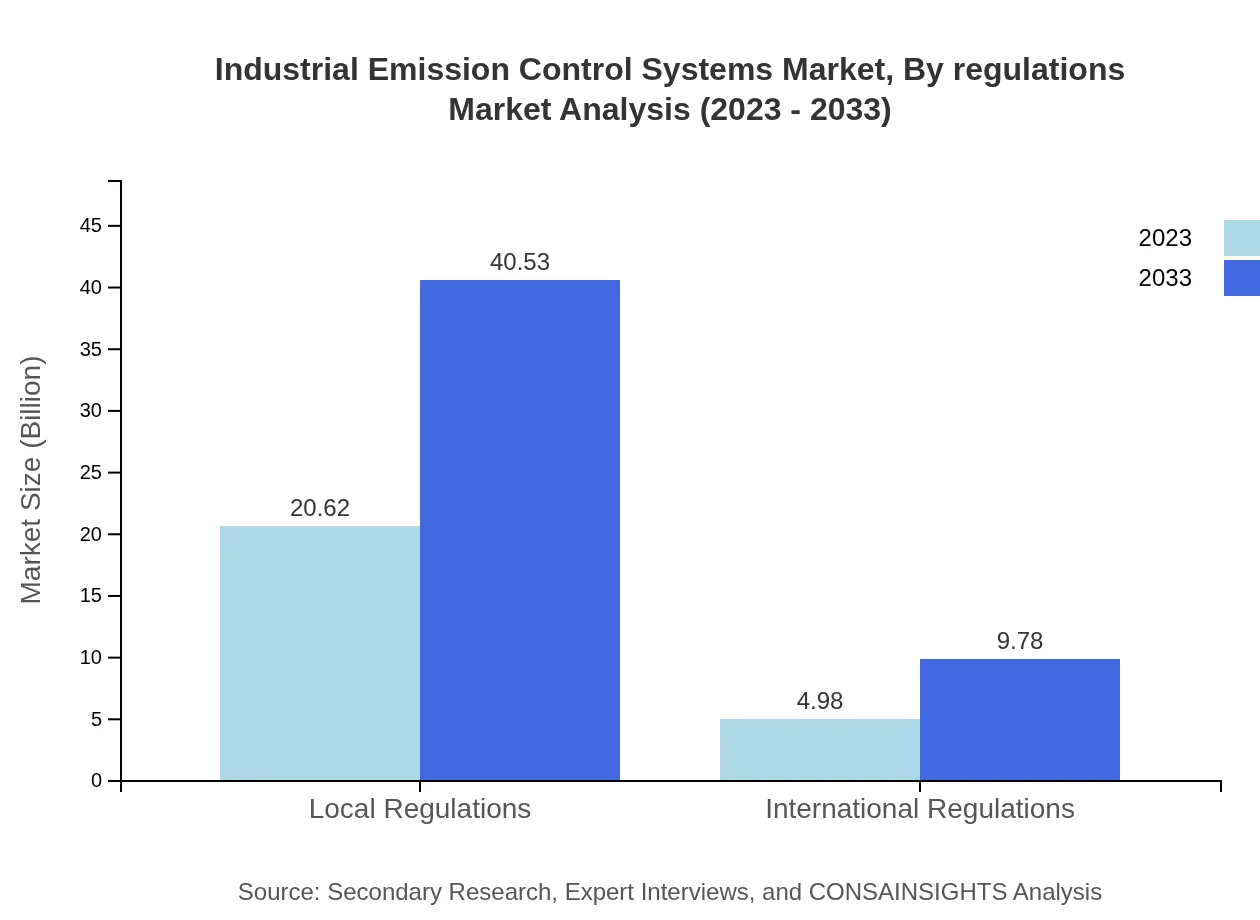

Industrial Emission Control Systems Market Analysis By Regulations

Regulatory influences are crucial, with local regulations projected to dominate the market, with a size increasing from $20.62 billion in 2023 to $40.53 billion by 2033. International regulations are also significant, expected to grow from $4.98 billion to $9.78 billion during the same period, reflecting the global push for stricter emissions standards.

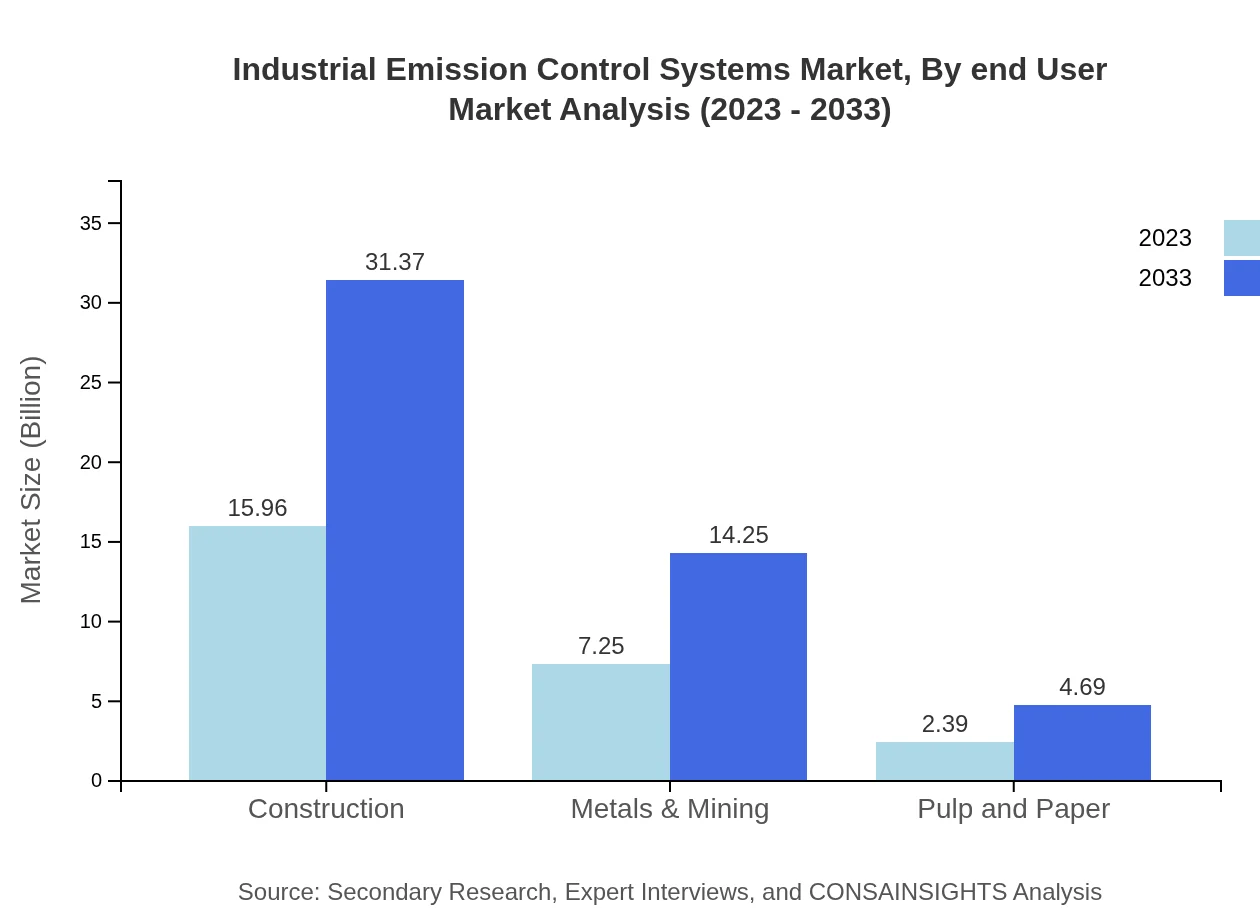

Industrial Emission Control Systems Market Analysis By End User

End-user industries include construction, manufacturing, oil and gas, and transportation, with notable demands originating from manufacturing and construction. The construction industry's market share is estimated at 62.35% in 2023, with steady growth projected through 2033. Meanwhile, manufacturing holds a critical share of 50.73%, supporting ongoing demand for emission controls amid evolving standards.

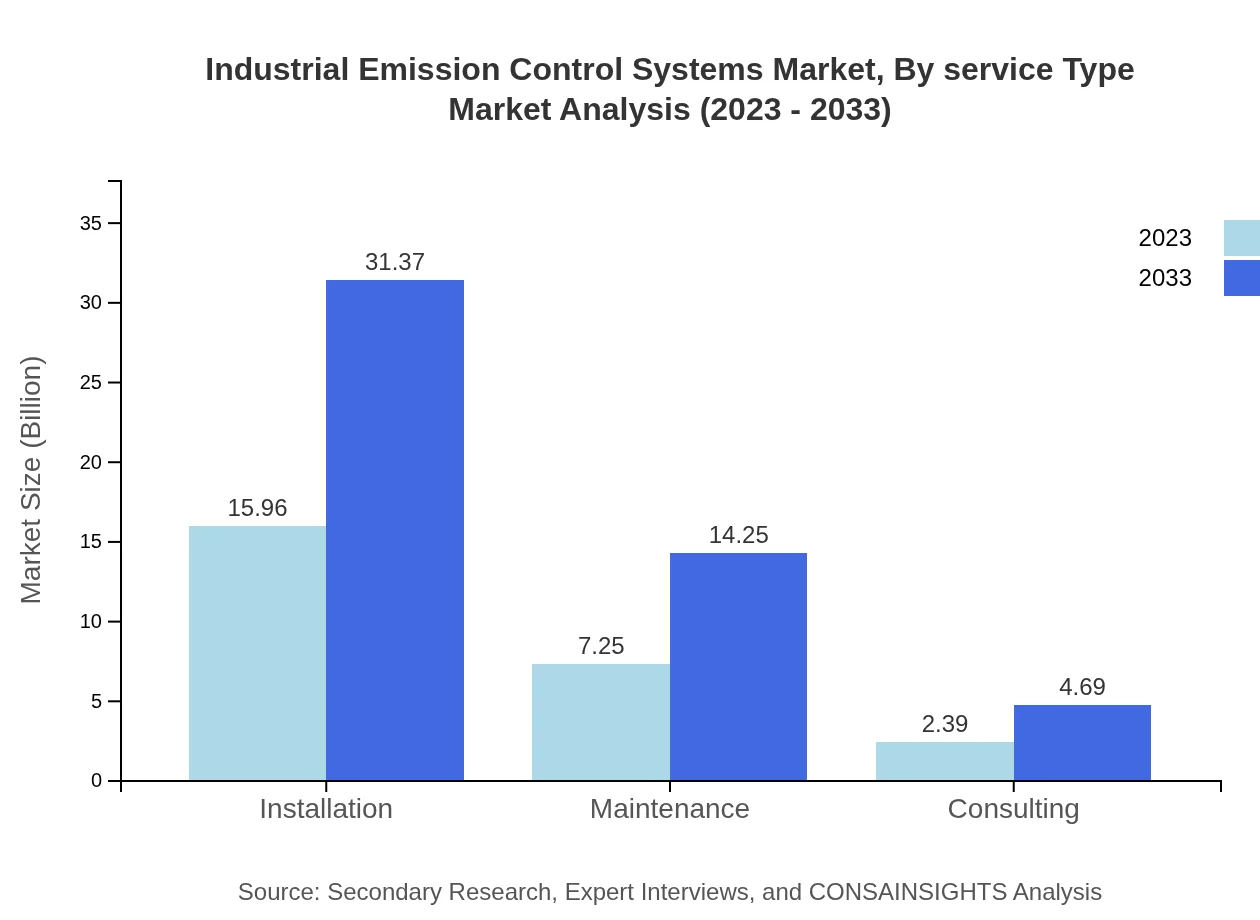

Industrial Emission Control Systems Market Analysis By Service Type

Service types encompassing installation, maintenance, and consulting are instrumental in the IECS market. Installation services are dominant, representing a share of 62.35% in 2023, followed by maintenance services at 28.33%. These services are crucial for ensuring optimal operation and compliance of emission control systems across industries.

Industrial Emission Control Systems Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Emission Control Systems Industry

Emerson Electric Co.:

Emerson leads in providing innovative solutions for emission control across various industries, focusing on automation and efficiency.Parker Hannifin Corporation:

Parker Hannifin specializes in filtration systems and is recognized for its contributions to reducing industrial emissions through state-of-the-art technology.Babcock & Wilcox Enterprises, Inc.:

Babcock & Wilcox is a renowned provider of energy and environmental technologies, delivering advanced emission control systems for power generation.GE (General Electric) Company:

General Electric plays a pivotal role in the IECS market, emphasizing innovative solutions to enhance efficiency and compliance in emission control.Siemens AG:

Siemens is a leader in electrical and automation systems, offering extensive solutions designed to help industries manage their emissions effectively.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial Emission Control Systems?

The industrial emission control systems market is valued at approximately $25.6 billion in 2023, with a projected compound annual growth rate (CAGR) of 6.8%, indicating significant growth potential over the forecast period.

What are the key market players or companies in this industrial Emission Control Systems industry?

Key players in the industrial emission control systems market include Honeywell International, Siemens AG, and General Electric. These companies lead with innovative technologies and extensive portfolios in compliance solutions for various industrial sectors.

What are the primary factors driving the growth in the industrial Emission Control Systems industry?

Growth in the industrial emission control systems market is primarily driven by stringent environmental regulations, increasing awareness of air pollution, and advancements in technology that enhance filter and scrubber efficacy. Demand for cleaner production processes also significantly impacts market expansion.

Which region is the fastest Growing in the industrial Emission Control Systems?

The fastest-growing region in the industrial emission control systems market is Europe, projected to grow from $7.92 billion in 2023 to $15.56 billion by 2033. Other regions like North America and Asia Pacific also show robust growth trajectories.

Does Consainsights provide customized market report data for the industrial Emission Control Systems industry?

Yes, Consainsights offers customized market report data tailored to specific needs within the industrial emission control systems industry. Clients can request detailed analyses based on geographic, demographic, and technological segments.

What deliverables can I expect from this industrial Emission Control Systems market research project?

Expect comprehensive deliverables including market size estimates, growth forecasts, segment analysis across various dimensions, competitive landscape assessments, and insights into regional trends and consumer behavior within the industrial emission control systems market.

What are the market trends of industrial Emission Control Systems?

Current trends include increasing adoption of advanced filtration technologies, growing integration of IoT for monitoring emissions, and a shift towards sustainable practices in manufacturing. More companies are implementing green technologies to comply with regulations and optimize efficiency.