Industrial Floor Coating Market Report

Published Date: 22 January 2026 | Report Code: industrial-floor-coating

Industrial Floor Coating Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Industrial Floor Coating market from 2023 to 2033, including insights on market size, growth forecasts, industry trends, segmentation, and competitive landscape.

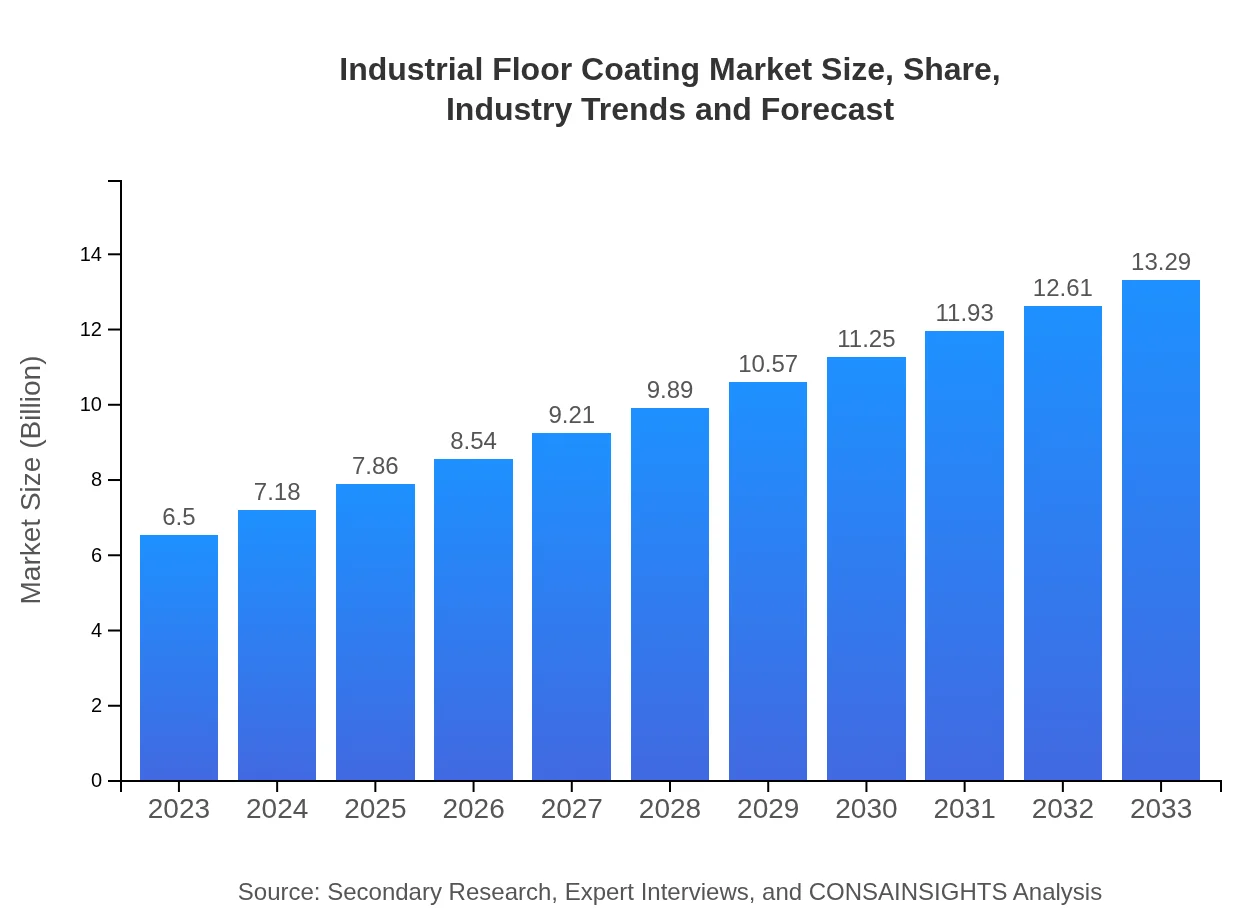

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $6.50 Billion |

| CAGR (2023-2033) | 7.2% |

| 2033 Market Size | $13.29 Billion |

| Top Companies | Sherwin-Williams, BASF SE, PPG Industries, RPM International |

| Last Modified Date | 22 January 2026 |

Industrial Floor Coating Market Overview

Customize Industrial Floor Coating Market Report market research report

- ✔ Get in-depth analysis of Industrial Floor Coating market size, growth, and forecasts.

- ✔ Understand Industrial Floor Coating's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Floor Coating

What is the Market Size & CAGR of Industrial Floor Coating market in 2023?

Industrial Floor Coating Industry Analysis

Industrial Floor Coating Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Floor Coating Market Analysis Report by Region

Europe Industrial Floor Coating Market Report:

Europe’s Industrial Floor Coating market, valued at $1.85 billion in 2023, is expected to grow to $3.79 billion by 2033. Increasing regulations on emissions and a push for sustainable construction practices are influencing this growth, with manufacturers introducing eco-friendly coating options.Asia Pacific Industrial Floor Coating Market Report:

In the Asia Pacific region, the Industrial Floor Coating market is valued at $1.29 billion in 2023, projected to reach $2.63 billion by 2033, due to rising urbanization and increased industrial activities. The demand for durable flooring solutions in manufacturing and logistics is anticipated to drive growth significantly.North America Industrial Floor Coating Market Report:

North America represents a major segment, with the market size at $2.30 billion in 2023, expanding to $4.70 billion by 2033. The growth here is fueled by a strong emphasis on safety standards and demand for resilient flooring in key industries like pharmaceuticals and food and beverage.South America Industrial Floor Coating Market Report:

The South American market is currently valued at $0.24 billion in 2023, with an expectation to grow to $0.50 billion by 2033. Growth in this region will be driven by infrastructure improvements and a growing awareness of the benefits of quality industrial flooring solutions.Middle East & Africa Industrial Floor Coating Market Report:

The Middle East and Africa market has a value of $0.82 billion in 2023, predicted to rise to $1.67 billion by 2033. The region's growth trajectory is supported by infrastructural developments driven by economic diversification strategies.Tell us your focus area and get a customized research report.

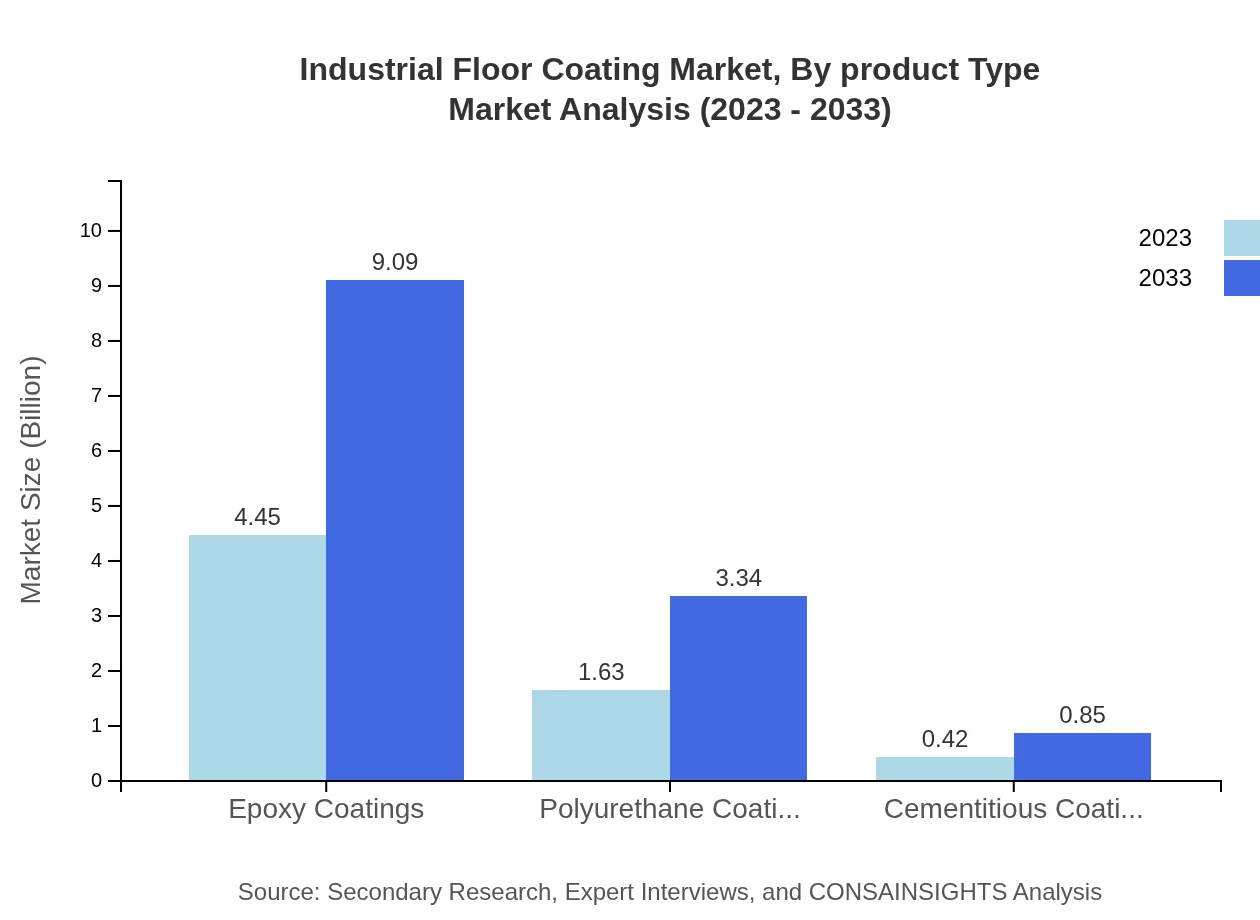

Industrial Floor Coating Market Analysis By Product Type

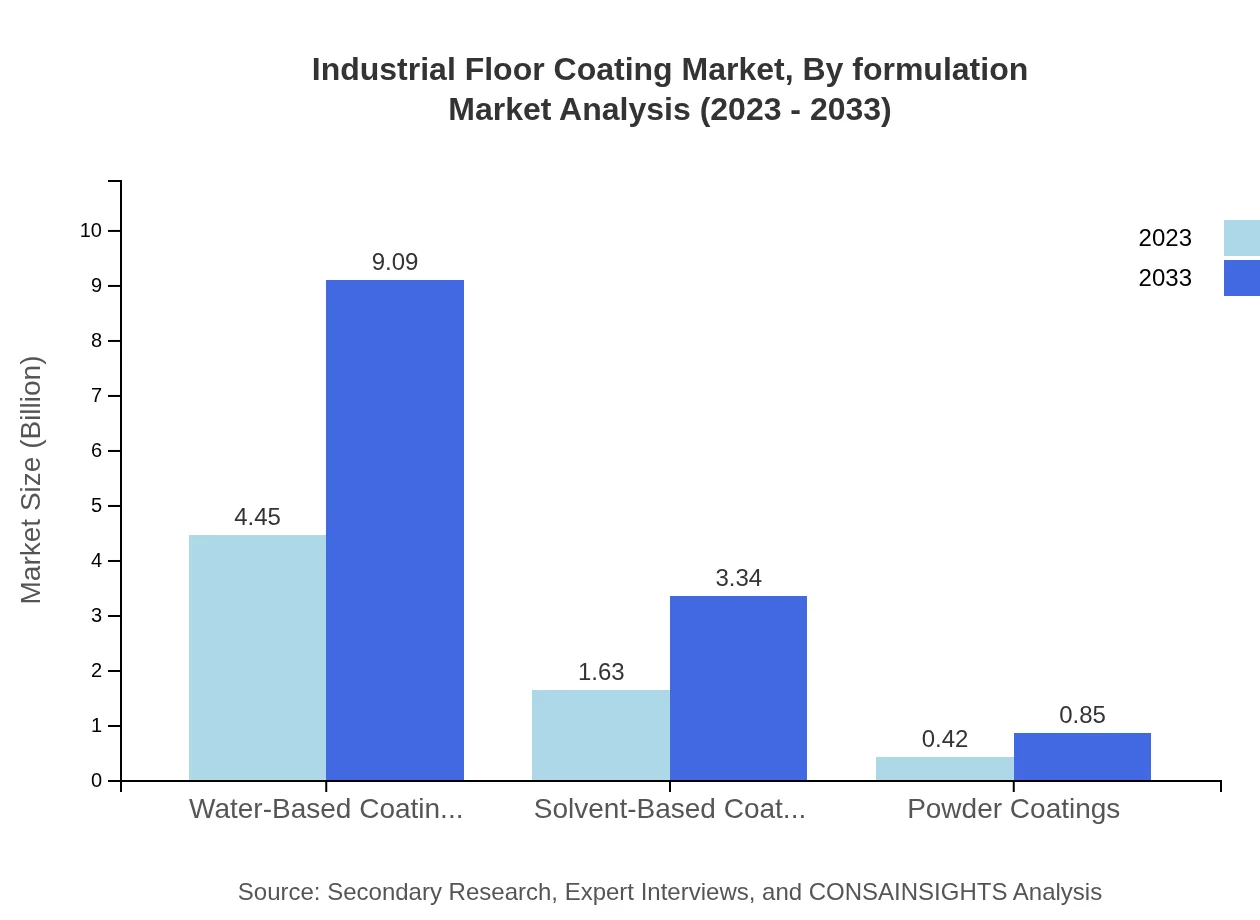

In 2023, water-based coatings dominate the market with a size of $4.45 billion, representing a 68.42% share, and are expected to grow to $9.09 billion by 2033. Epoxy coatings also hold a substantial share at 68.42%, while solvent-based coatings capture 25.15% of the market.

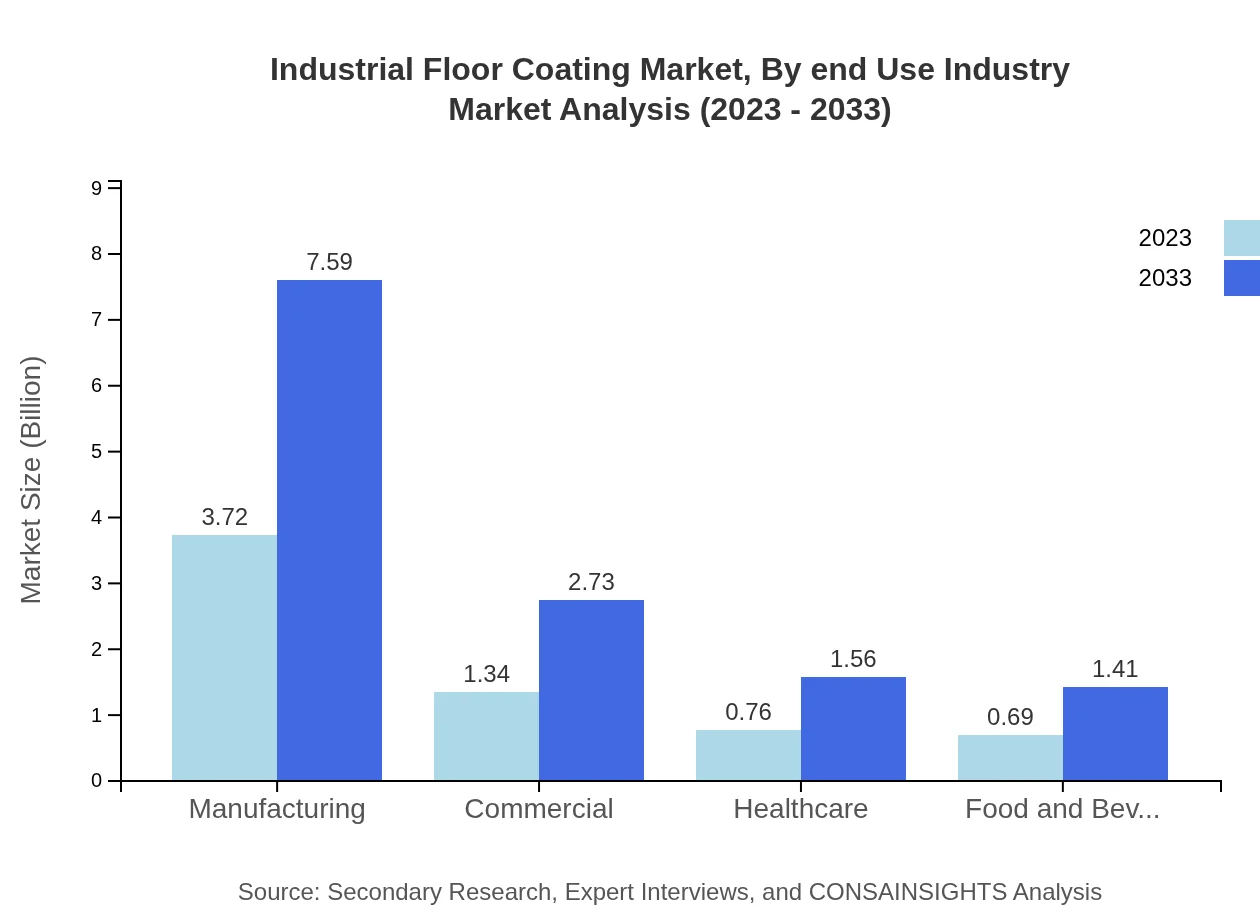

Industrial Floor Coating Market Analysis By End Use Industry

Manufacturing accounts for over 57% of the market in 2023, emphasizing the significance of durable flooring. This sector is expected to grow from $3.72 billion to $7.59 billion by 2033. The commercial segment holds 20.54% market share, while healthcare represents 11.72%.

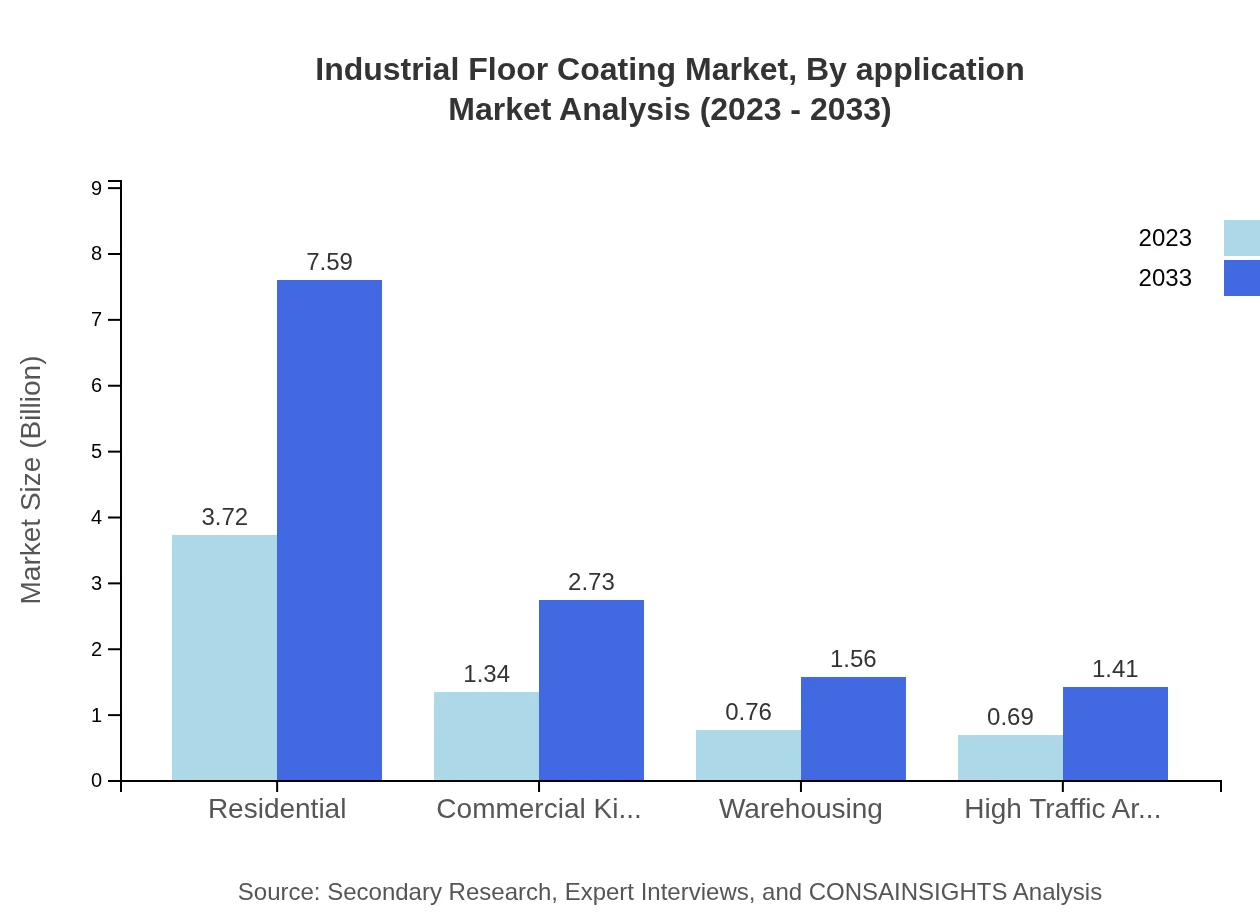

Industrial Floor Coating Market Analysis By Application

High traffic areas represent a critical application segment, currently at $0.69 billion in 2023 and expected to reach $1.41 billion by 2033. The food and beverage sector is also significant, indicating strong growth in the coming years.

Industrial Floor Coating Market Analysis By Formulation

The formulation of coatings significantly impacts performance. Water-based formulations dominate with 68.42% market share, while solvent-based options follow at 25.15%. Innovations in formulations are leading to improved environmental compliance and performance metrics.

Industrial Floor Coating Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Floor Coating Industry

Sherwin-Williams:

A leader in the coatings industry, Sherwin-Williams offers a vast range of industrial floor coating solutions known for their durability and sustainability.BASF SE:

BASF SE is a prominent global player known for its advanced chemical solutions, including innovative floor coating products that enhance the performance of industrial surfaces.PPG Industries:

PPG is a major competitor in the coatings market, providing a variety of floor coatings suitable for diverse applications, known for their quality and extensive R&D efforts.RPM International:

RPM International specializes in high-performance coatings and offers a comprehensive suite of industrial flooring solutions.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial Floor Coating?

The global industrial floor coating market is valued at approximately $6.5 billion in 2023, with an expected compound annual growth rate (CAGR) of 7.2%, projecting significant growth in the upcoming years.

What are the key market players or companies in this industrial Floor Coating industry?

Prominent companies in the industrial floor coating market include Sherwin-Williams, PPG Industries, RPM International, and BASF, which contribute significantly to market share and innovations in product offerings.

What are the primary factors driving the growth in the industrial Floor Coating industry?

Key growth factors include the increasing demand for durable flooring solutions in industries, advancements in coating technologies, and the rising focus on aesthetic value and sustainability in industrial spaces.

Which region is the fastest Growing in the industrial Floor Coating?

The Asia-Pacific region is the fastest-growing market for industrial floor coatings, projected to increase from $1.29 billion in 2023 to $2.63 billion by 2033, driven by industrial expansion and infrastructure development.

Does ConsaInsights provide customized market report data for the industrial Floor Coating industry?

Yes, ConsaInsights offers tailored market report data for the industrial floor coating industry, allowing clients to gain insights specific to their needs and focus areas.

What deliverables can I expect from this industrial Floor Coating market research project?

Deliverables for the industrial floor coating market research project include detailed market analysis, regional breakdowns, competitive landscape overview, and forecasts segmented by application and product type.

What are the market trends of industrial Floor Coating?

Current market trends for industrial floor coatings include a shift towards eco-friendly options, increased use of advanced coatings like epoxy and polyurethane, and a rising demand in sectors such as healthcare and manufacturing.