Industrial Gaskets Market Report

Published Date: 22 January 2026 | Report Code: industrial-gaskets

Industrial Gaskets Market Size, Share, Industry Trends and Forecast to 2033

This report examines the Industrial Gaskets market, providing insights into market size, segmentation, technological advancements, and regional analysis from 2023 to 2033.

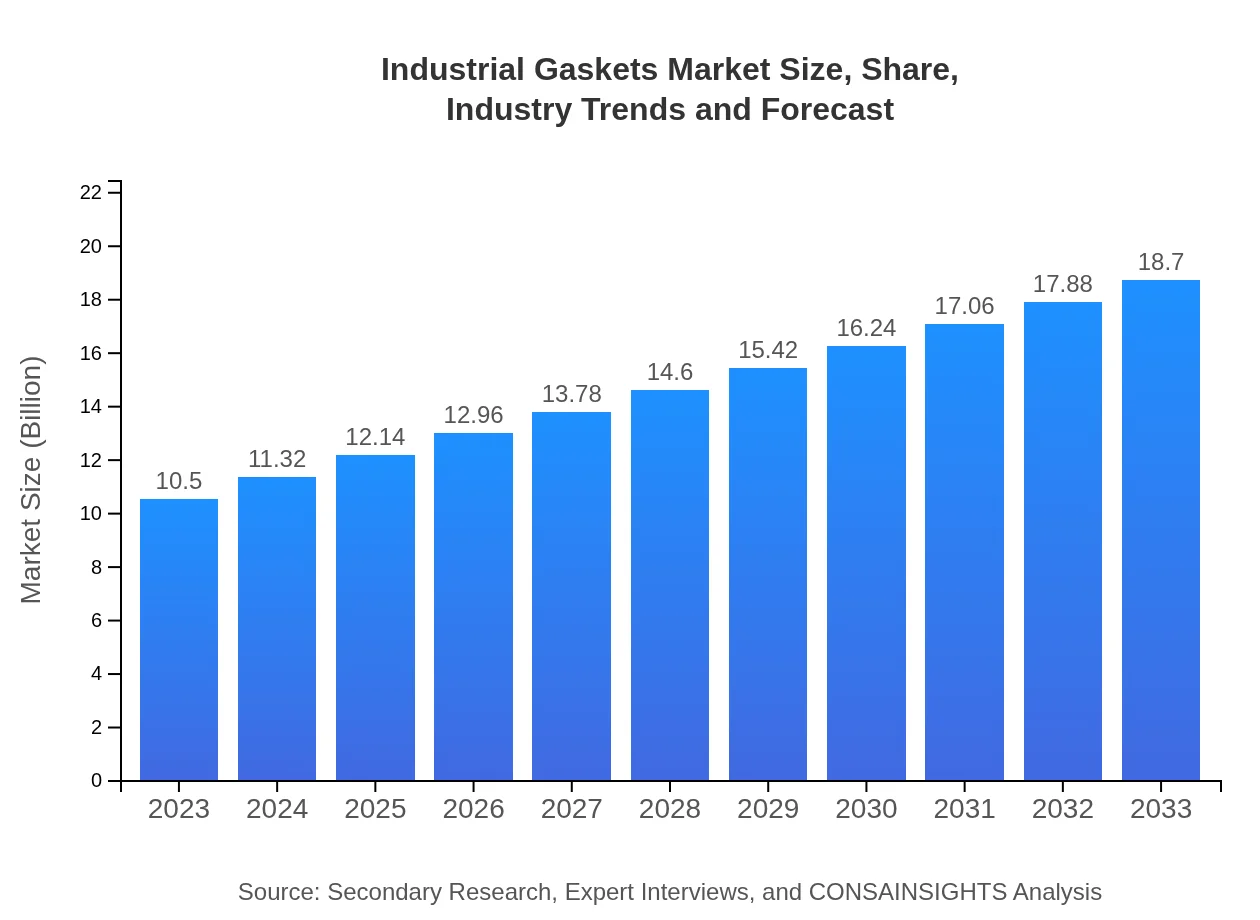

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $10.50 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $18.70 Billion |

| Top Companies | Garlock, Flexitallic, John Crane, Sealing Force |

| Last Modified Date | 22 January 2026 |

Industrial Gaskets Market Overview

Customize Industrial Gaskets Market Report market research report

- ✔ Get in-depth analysis of Industrial Gaskets market size, growth, and forecasts.

- ✔ Understand Industrial Gaskets's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Gaskets

What is the Market Size & CAGR of the Industrial Gaskets market in 2023?

Industrial Gaskets Industry Analysis

Industrial Gaskets Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Gaskets Market Analysis Report by Region

Europe Industrial Gaskets Market Report:

The European Industrial Gaskets market, projected to grow from 3.73 billion USD in 2023 to 6.64 billion USD by 2033, benefits from stringent regulations mandating leak prevention and safety. Industries in Germany and France are particularly invested in enhanced gasket technology, emphasizing compliance with environmental mandates.Asia Pacific Industrial Gaskets Market Report:

In the Asia-Pacific region, the Industrial Gaskets market is set to grow from 1.77 billion in 2023 to 3.16 billion by 2033. Rapid industrialization, coupled with a booming automotive market, is driving demand in countries like China and India. Additionally, growing investments in infrastructure projects will further enhance market opportunities.North America Industrial Gaskets Market Report:

In North America, the market is anticipated to increase from 3.51 billion USD in 2023 to 6.25 billion USD by 2033. The growth is buoyed by the United States' substantial investments in an aging infrastructure and the oil and gas sector's revival, creating sustained demand for industrial sealing solutions.South America Industrial Gaskets Market Report:

The South American market for Industrial Gaskets is estimated to grow from 0.84 billion USD in 2023 to 1.49 billion USD by 2033. However, economic fluctuations and political instability may pose challenges to consistent growth. The focus on improving manufacturing standards offers hope for a stabilized market growth period.Middle East & Africa Industrial Gaskets Market Report:

The Middle East and Africa region is expected to see growth from 0.65 billion USD in 2023 to 1.16 billion USD by 2033. This is driven by the oil and gas sector, which remains a significant part of the regional economy despite fluctuations in global oil prices.Tell us your focus area and get a customized research report.

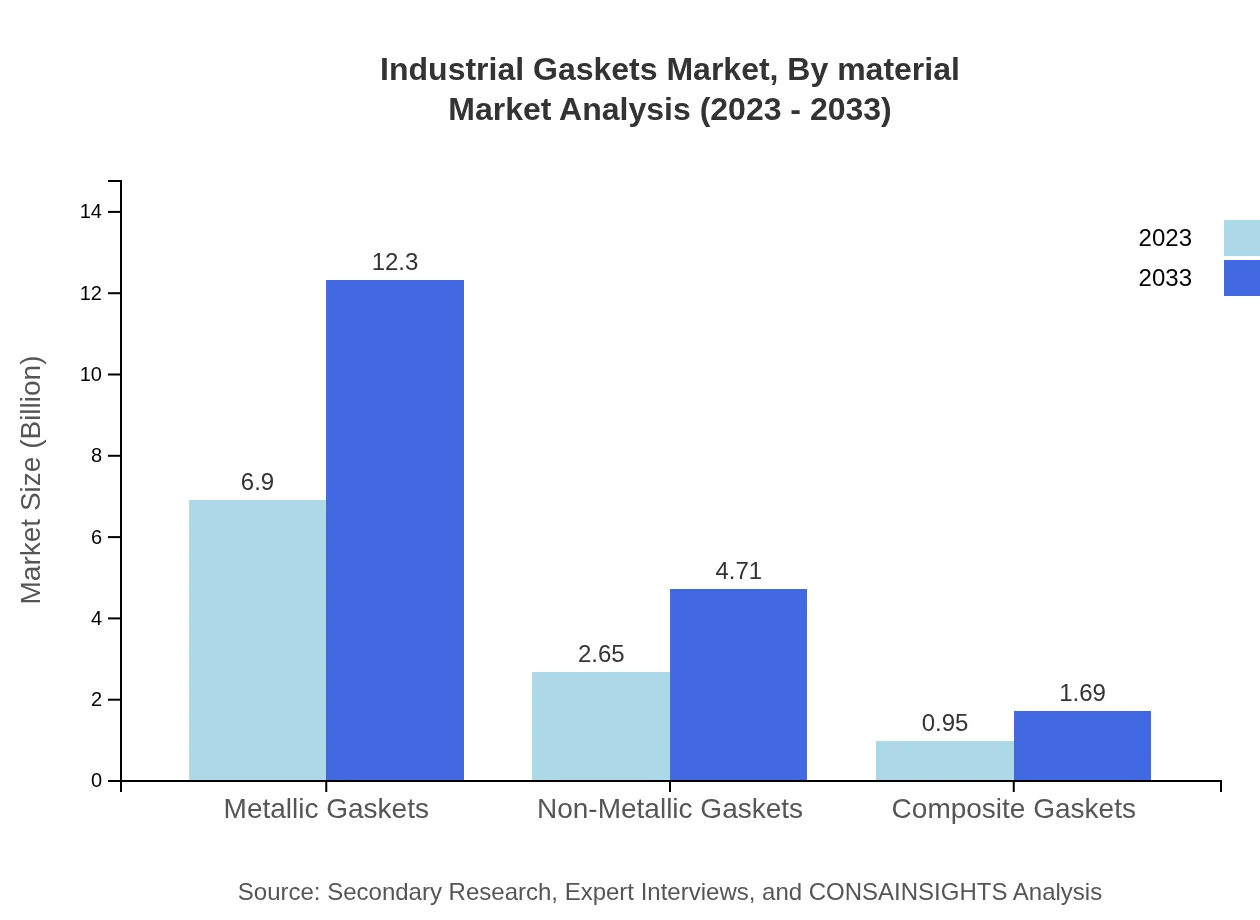

Industrial Gaskets Market Analysis By Material

The material segment of Industrial Gaskets is dominated by Metallic Gaskets which hold a market size of 6.90 billion USD in 2023, expected to grow to 12.30 billion USD by 2033, accounting for 65.76% market share. Non-Metallic Gaskets follow with a size of 2.65 billion USD in 2023, growing to 4.71 billion USD in 2033, at 25.21% market share. Composite Gaskets represent a smaller segment, with anticipated growth from 0.95 billion USD to 1.69 billion USD.

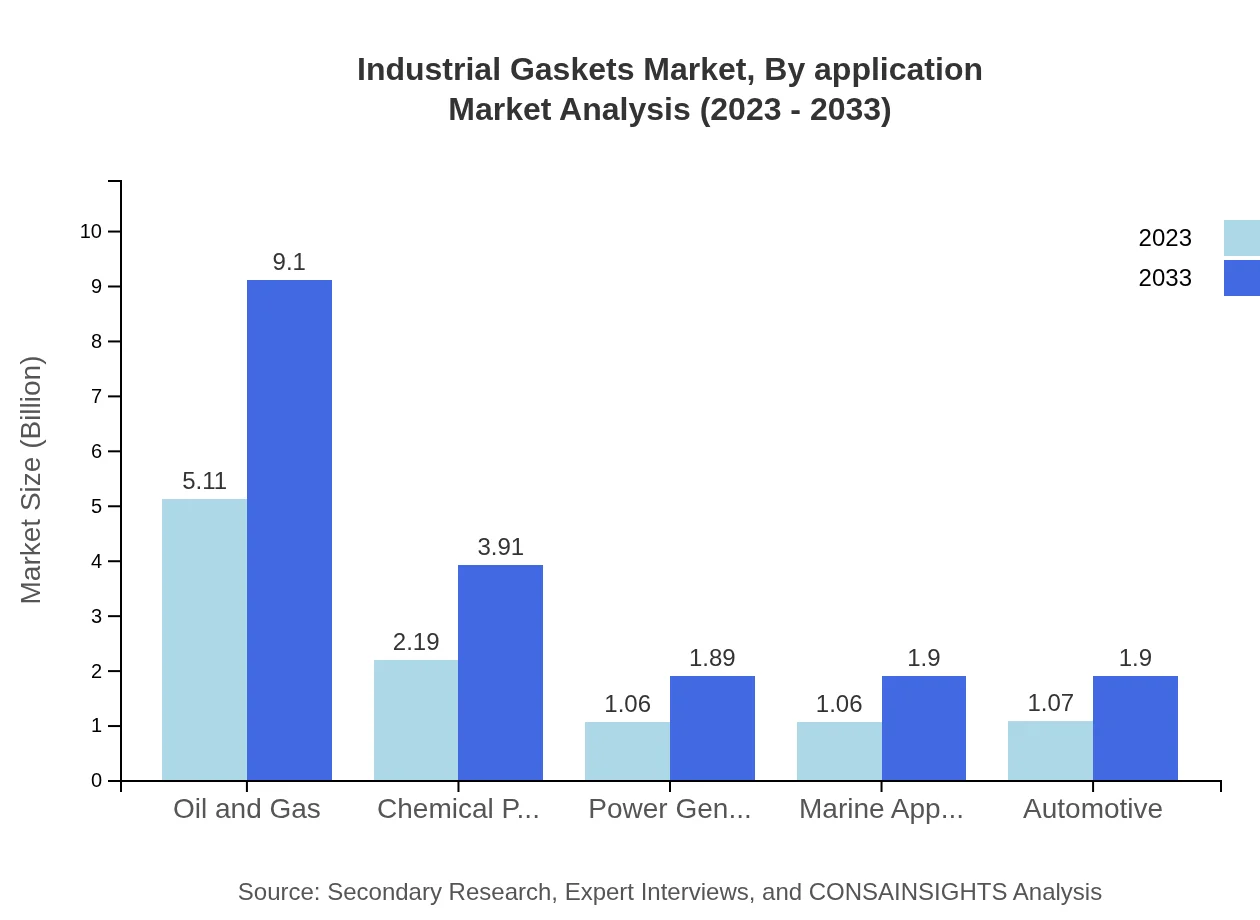

Industrial Gaskets Market Analysis By Application

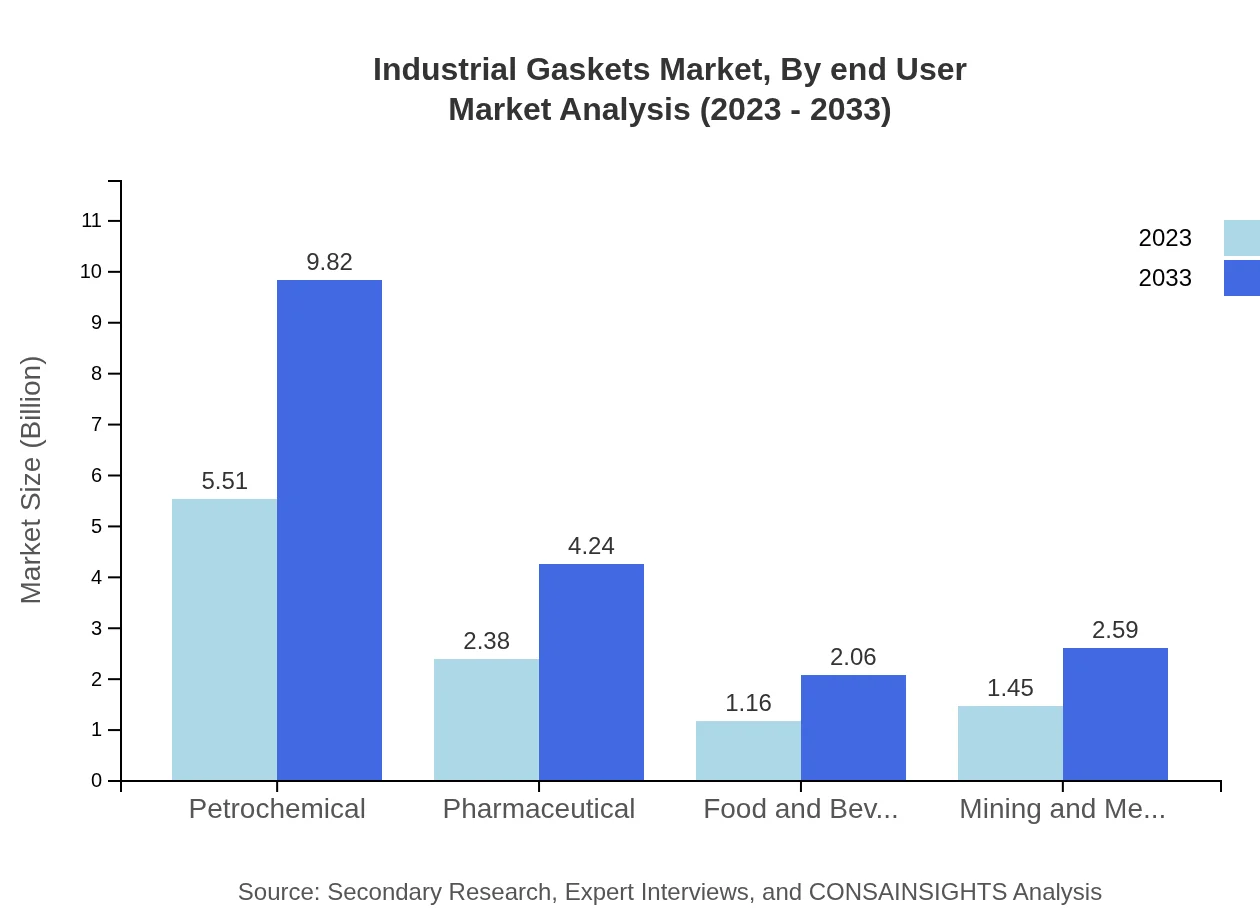

In terms of application, the Petrochemical industry remains the largest end-user, capturing a market size of 5.51 billion USD in 2023 and projected to expand to 9.82 billion USD by 2033, reflecting a 52.49% market share. The Pharmaceutical and Oil & Gas sectors follow, with sizes of 2.38 billion USD and 5.11 billion USD respectively, highlighting their significant contributions to the overall growth of the market.

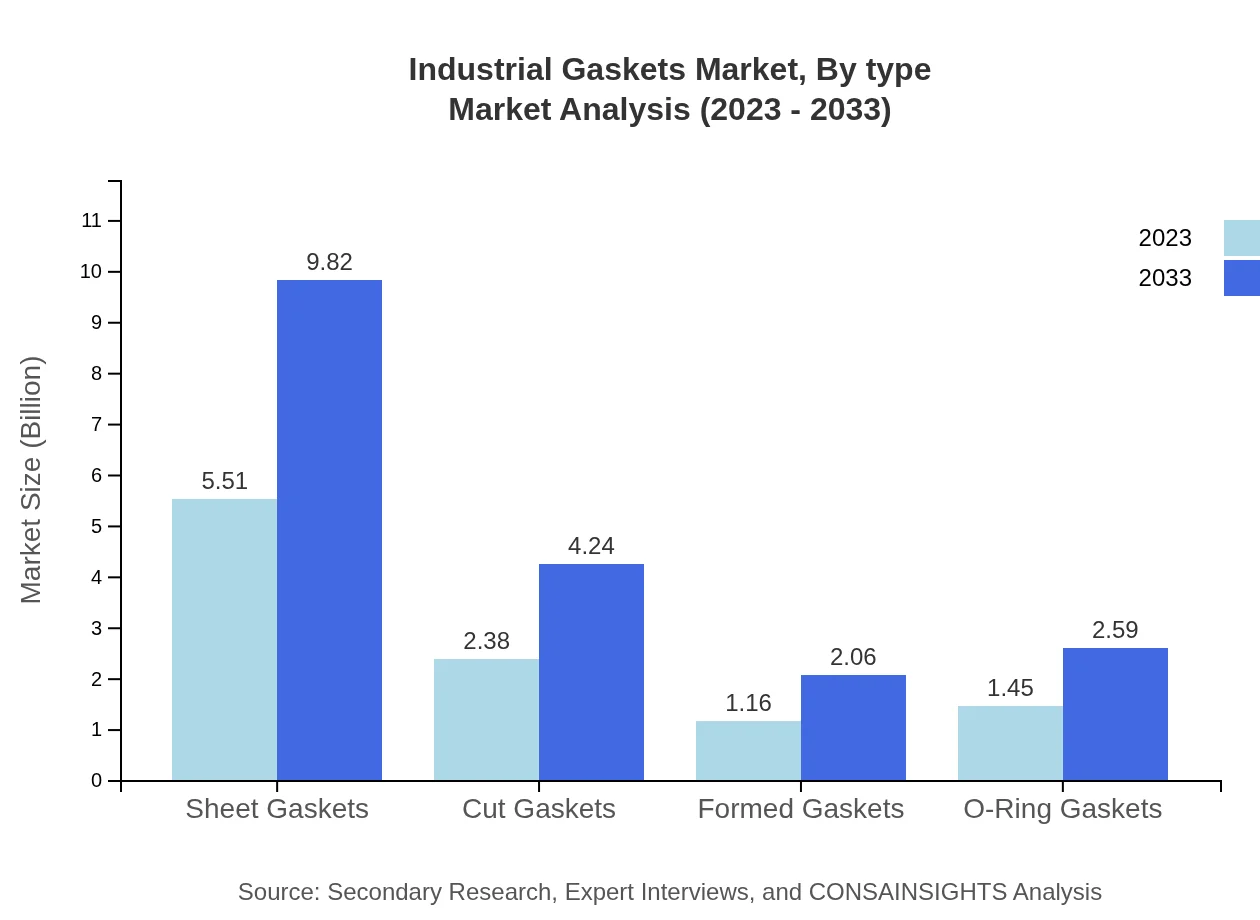

Industrial Gaskets Market Analysis By Type

By product type, Sheet Gaskets have a dominant market share starting at 5.51 billion USD in 2023 and increasing to 9.82 billion USD in 2033 at 52.49%. Cut Gaskets follow with market sizes of 2.38 billion USD and 4.24 billion USD respectively, while Formed Gaskets capture a share of 11.03% in 2023. O-Ring Gaskets and Composite Gaskets also play important roles within this structured market.

Industrial Gaskets Market Analysis By End User

The end-user segment highlights strong reliance on the Industrial Gaskets within the Oil and Gas, Chemical Processing, and Power Generation industries. The Oil and Gas sector is expected to show robust growth from 5.11 billion USD to 9.10 billion USD, representing a significant portion of market activity at 48.68% share.

Industrial Gaskets Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in the Industrial Gaskets Industry

Garlock:

Garlock is a prominent player in the gasket manufacturing sector, known for its innovative sealing solutions and commitment to safety and reliability across various industries.Flexitallic:

Flexitallic specializes in the development of high-performance gaskets made from advanced materials, catering to demanding applications in the oil and gas, chemical, and power generation sectors.John Crane:

John Crane offers a comprehensive range of sealing solutions, including gaskets, with a focus on sustainability and high-performance applications in critical environments.Sealing Force:

Sealing Force, with its extensive line of industrial gaskets, emphasizes customized solutions tailored to specific client needs across multiple industries.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial gaskets?

The global industrial gaskets market is valued at approximately $10.5 billion in 2023, and it is projected to grow at a CAGR of 5.8%, reaching significant market size by 2033.

What are the key market players or companies in this industrial gaskets industry?

Key players in the industrial gaskets market include prominent manufacturers and suppliers, although specific company names have not been identified in the provided research. These entities significantly influence market dynamics.

What are the primary factors driving the growth in the industrial gaskets industry?

The growth in the industrial gaskets industry is driven by increasing demand across diverse sectors like oil & gas, automotive, and pharmaceuticals, emphasizing the need for enhanced sealing solutions and durability.

Which region is the fastest Growing in the industrial gaskets?

The Asia-Pacific region demonstrates the fastest growth in the industrial gaskets market, with market size projected to rise from $1.77 billion in 2023 to $3.16 billion in 2033, showcasing a significant CAGR.

Does ConsaInsights provide customized market report data for the industrial gaskets industry?

Yes, ConsaInsights offers customized market report data tailored to client specifications, ensuring detailed insights for businesses operating within the industrial gaskets sector.

What deliverables can I expect from this industrial gaskets market research project?

Expect comprehensive reports detailing market size, regional analysis, segmentation data, competitor analysis, and future market forecasts, providing a robust tool for strategic decision-making.

What are the market trends of industrial gaskets?

Current trends in the industrial gaskets market include a shift towards advanced materials for better performance, increasing automation in production, and growing environmental regulations pushing for sustainable solutions.