Industrial Hose Market Report

Published Date: 22 January 2026 | Report Code: industrial-hose

Industrial Hose Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Industrial Hose market covering insights on market size, growth trends, regional performance, segment analysis, and forecasts from 2023 to 2033. It aims to equip stakeholders with critical information to make informed decisions.

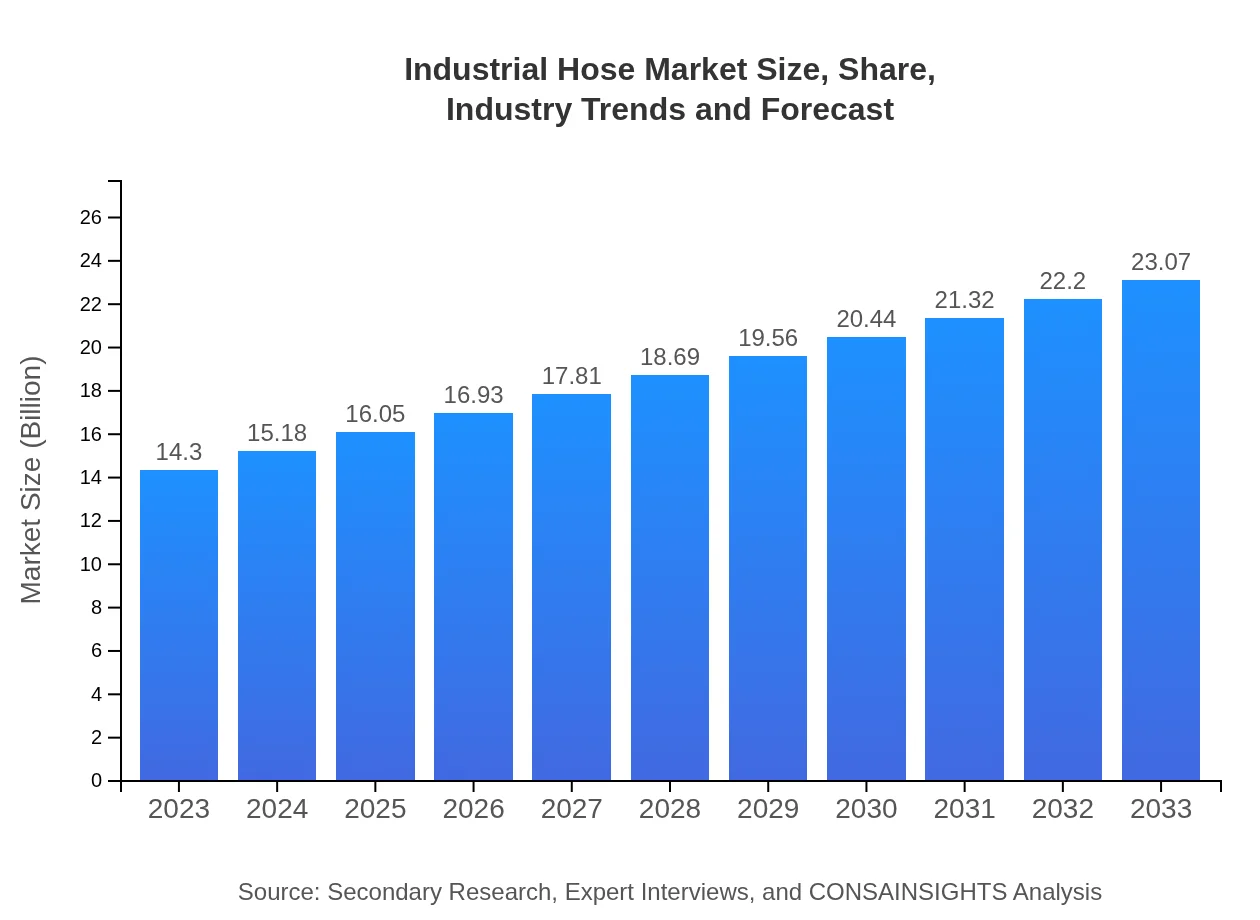

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $14.30 Billion |

| CAGR (2023-2033) | 4.8% |

| 2033 Market Size | $23.07 Billion |

| Top Companies | Parker Hannifin Corporation, Continental AG, Goodyear Tire & Rubber Company, Gates Corporation |

| Last Modified Date | 22 January 2026 |

Industrial Hose Market Overview

Customize Industrial Hose Market Report market research report

- ✔ Get in-depth analysis of Industrial Hose market size, growth, and forecasts.

- ✔ Understand Industrial Hose's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Hose

What is the Market Size & CAGR of Industrial Hose market in 2023?

Industrial Hose Industry Analysis

Industrial Hose Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Hose Market Analysis Report by Region

Europe Industrial Hose Market Report:

The European market is forecasted to grow from $4.35 billion in 2023 to $7.03 billion by 2033. This growth will be supported by stringent regulations enforcing the use of high-quality hoses in various sectors, including food and beverage, pharmaceuticals, and chemicals.Asia Pacific Industrial Hose Market Report:

The Asia Pacific region is rapidly emerging as a leading market for Industrial Hoses, with a projected market size of $4.56 billion by 2033, up from $2.83 billion in 2023. This growth is fueled by expanding industrial sectors, urbanization, and increased construction activities in countries like China, India, and Japan.North America Industrial Hose Market Report:

North America is a significant market for Industrial Hose, projected to reach $7.68 billion by 2033, increasing from $4.76 billion in 2023. The demand is largely driven by the aging infrastructure requiring upgrades and a strong focus on safety in manufacturing processes.South America Industrial Hose Market Report:

In South America, the Industrial Hose market is expected to grow from $0.84 billion in 2023 to $1.35 billion in 2033. Key drivers include infrastructure projects and growing demand from the oil and gas sector, particularly in Brazil and Argentina, where natural resources play a critical economic role.Middle East & Africa Industrial Hose Market Report:

The Middle East and Africa market will see an increase from $1.52 billion in 2023 to an estimated $2.45 billion in 2033, driven by construction and oil extraction activities. Additionally, economic diversification efforts in Gulf countries contribute to the market's robustness.Tell us your focus area and get a customized research report.

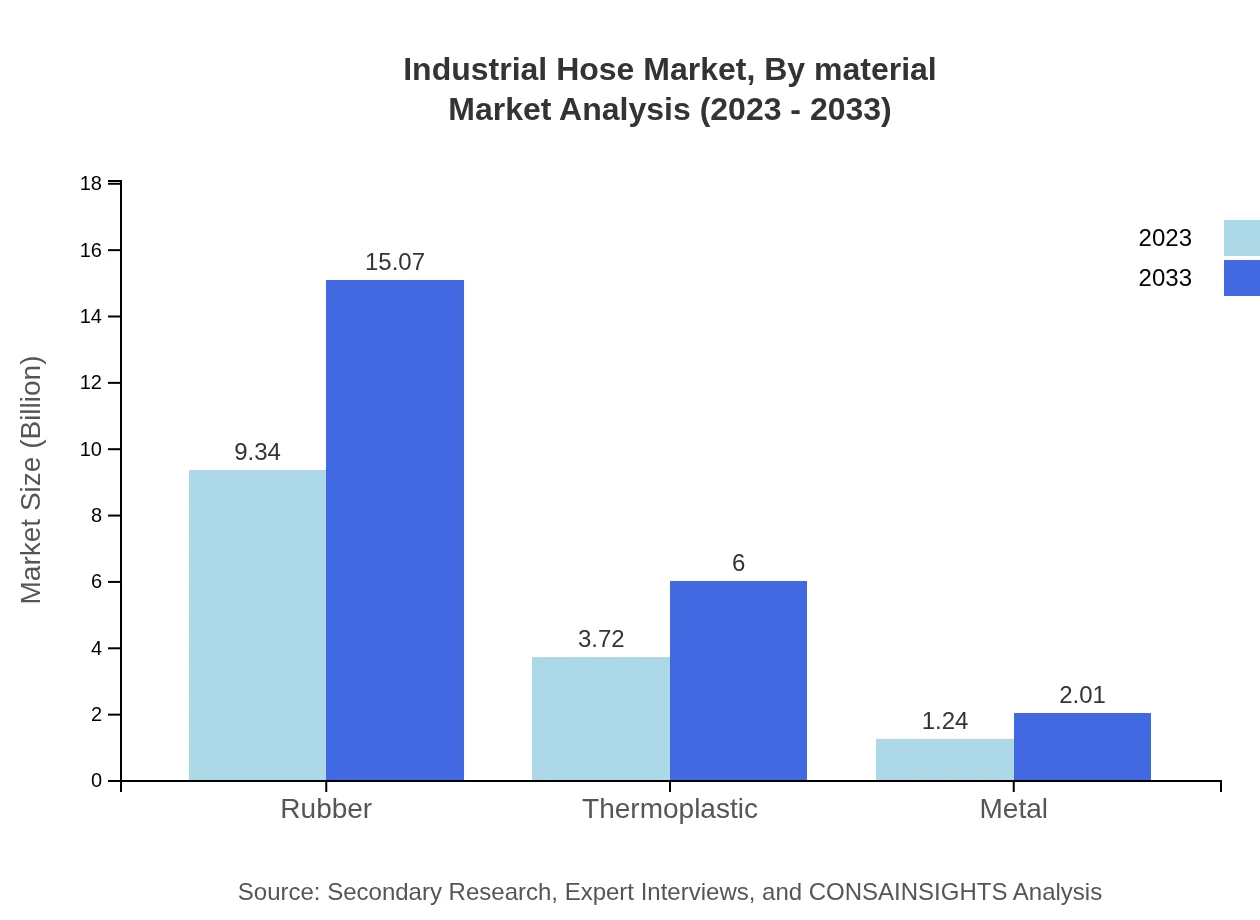

Industrial Hose Market Analysis By Material

The Industrial Hose market by material is dominated by rubber, accounting for approximately 65.32% of the market size in 2023, with a growth to $15.07 billion by 2033. Rubber hoses are preferred for their flexibility and durability. Thermoplastic hoses hold a substantial share at 25.99%, while metal hoses constitute around 8.69% due to their use in high-pressure applications.

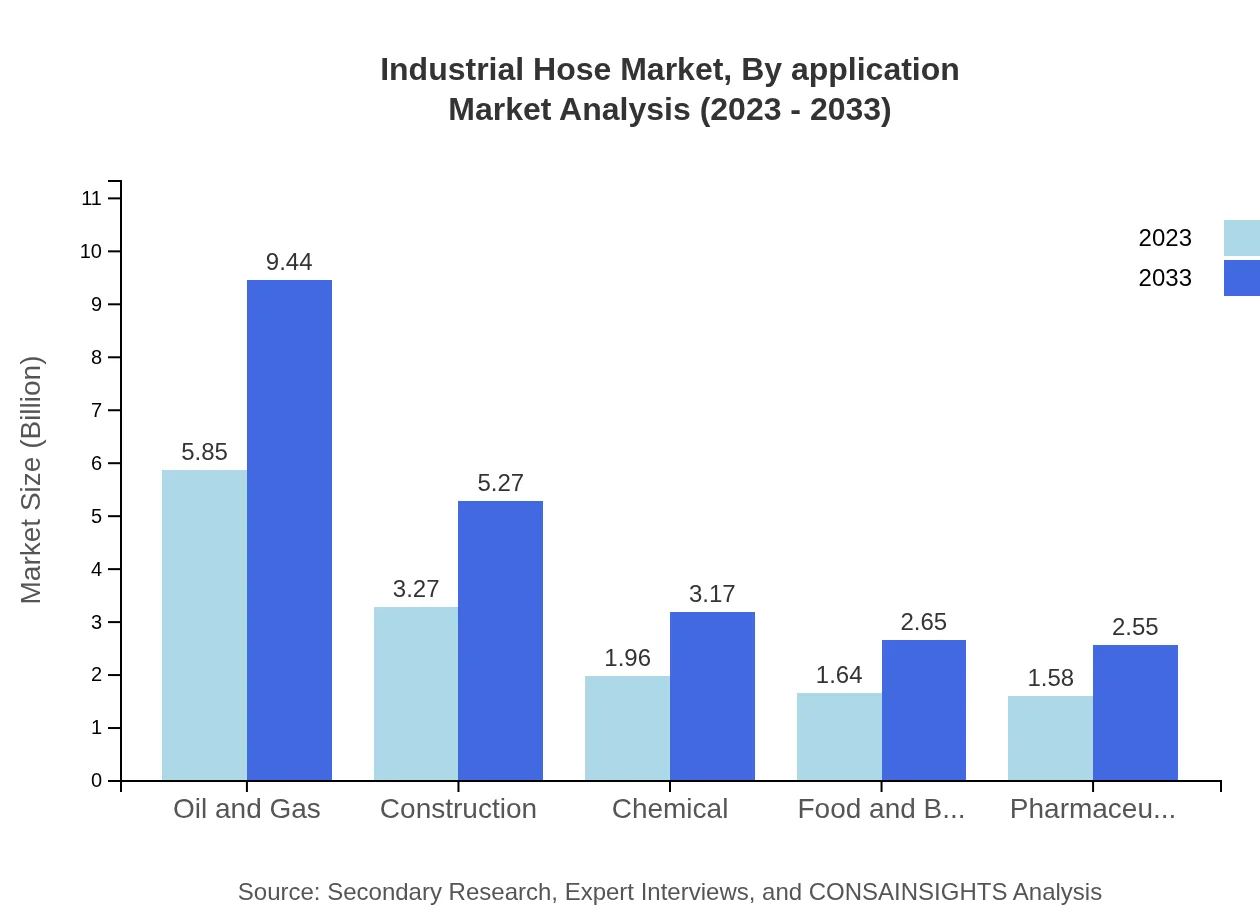

Industrial Hose Market Analysis By Application

By application, the Industrial Hose market is primarily driven by the oil and gas sector, representing a share of 40.92% in 2023, with a market increase to $9.44 billion by 2033. Other significant applications include the manufacturing sector (40.92%), construction (22.84%), and agriculture, contributing substantially to the overall market growth.

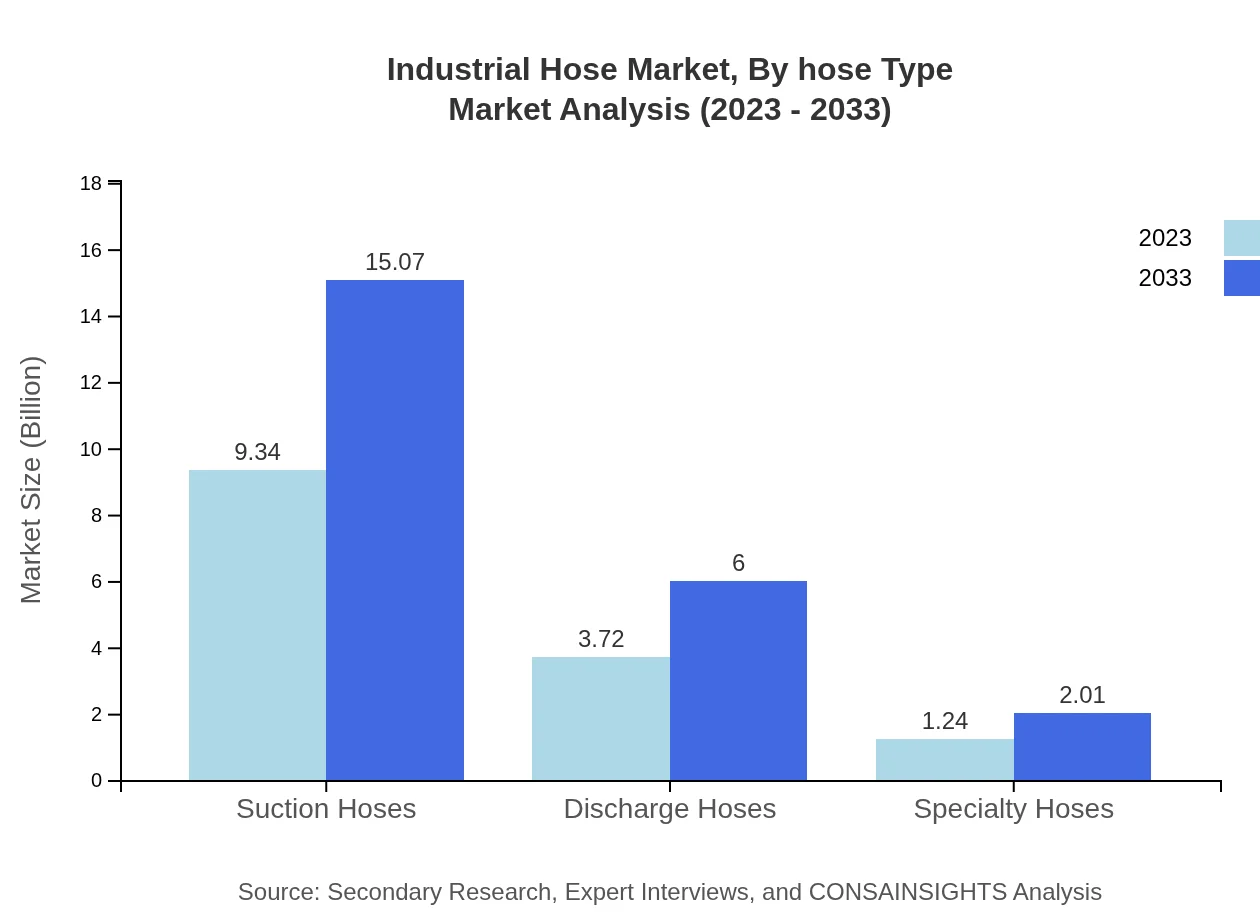

Industrial Hose Market Analysis By Hose Type

Market segmentation by hose type reveals suction hoses leading with a significant market share of 65.32% in 2023, anticipated to reach $15.07 billion by 2033. Discharge hoses follow closely at 25.99%, with growing demand for specialty hoses across diverse applications.

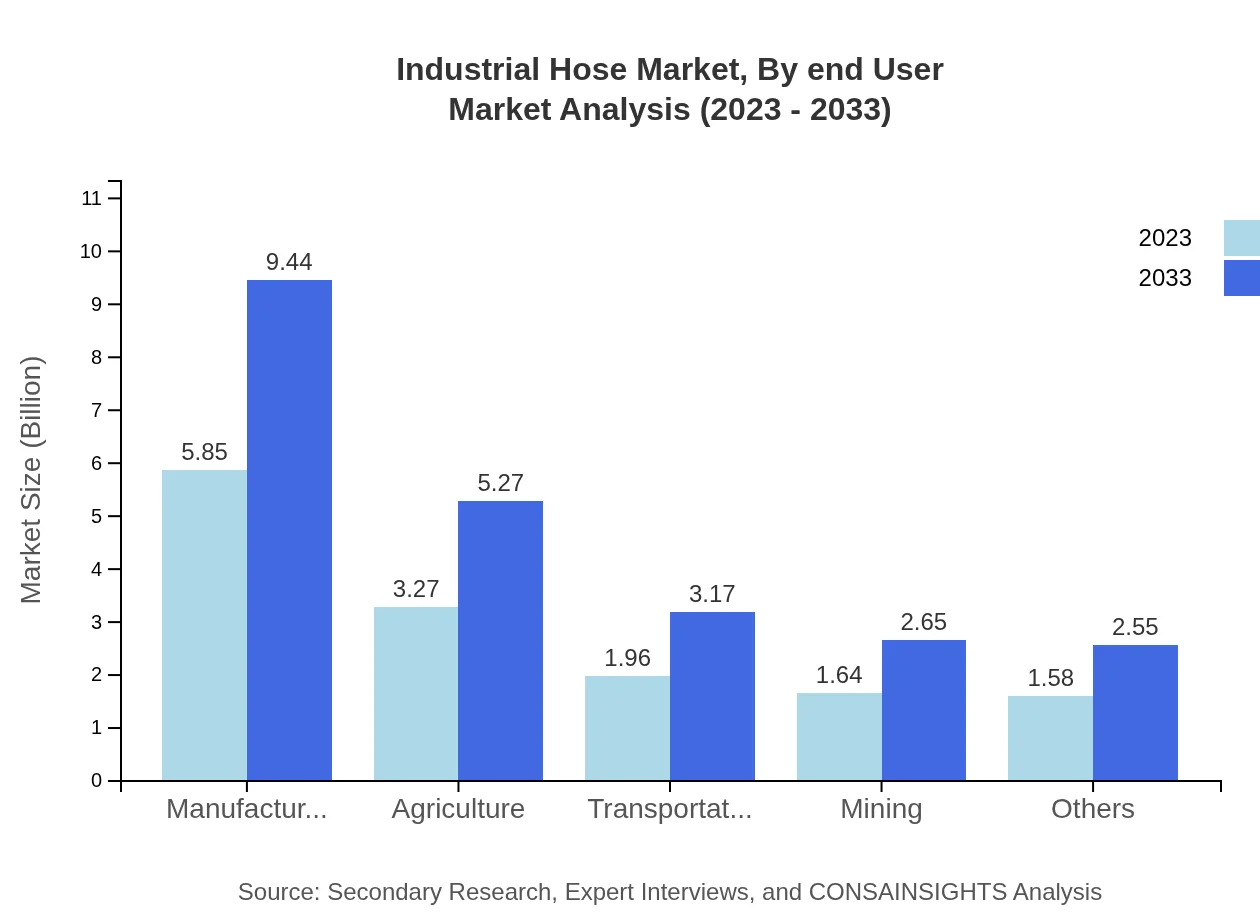

Industrial Hose Market Analysis By End User

The end-user analysis indicates that the manufacturing sector leads in demand for industrial hoses, accounting for nearly 40.92% of the market share in 2023, with a potential increase to $9.44 billion by 2033. Other notable segments include construction, agriculture, and pharmaceuticals, all showing stable growth patterns.

Industrial Hose Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Hose Industry

Parker Hannifin Corporation:

Parker Hannifin is a leading global manufacturer of motion and control technologies, offering a broad range of industrial hoses and fittings for various applications with a strong emphasis on innovation and quality.Continental AG:

Continental is renowned for its diverse industrial solutions, including advanced hose systems that ensure reliability and efficiency in various industries such as automotive, construction, and agriculture.Goodyear Tire & Rubber Company:

Goodyear specializes in high-performance hose solutions, providing products tailored to the demands of sectors like oil and gas, construction, and transportation.Gates Corporation:

Gates is a prominent player in the fluid power and power transmission industries, known for its innovation in industrial hoses that cater to dynamic and challenging environments.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial Hose?

The global industrial hose market is projected to reach approximately $14.3 billion by 2033, expanding at a CAGR of 4.8% from its 2023 value. This growth indicates a steady demand across various sectors utilizing industrial hoses.

What are the key market players or companies in this industrial Hose industry?

Key players in the industrial hose market include manufacturers known for their innovative products and wide distribution networks, ensuring they capture substantial market shares across global regions. They often engage in strategic partnerships and mergers to enhance their market presence.

What are the primary factors driving the growth in the industrial Hose industry?

Growth in the industrial hose market is primarily driven by increasing industrialization and construction activities, alongside a rising demand for durable hoses in transportation, agriculture, and oil & gas industries, further enhancing their importance in various applications.

Which region is the fastest Growing in the industrial Hose?

Asia Pacific is set to emerge as the fastest-growing region in the industrial hose market, with the size anticipated to grow from $2.83 billion in 2023 to $4.56 billion by 2033, driven by rapid industrialization and infrastructure developments.

Does ConsaInsights provide customized market report data for the industrial Hose industry?

Yes, ConsaInsights offers customized market report data tailored to specific requirements within the industrial hose industry, ensuring clients receive insights that align with their strategic goals and market challenges.

What deliverables can I expect from this industrial Hose market research project?

Clients can expect comprehensive deliverables, including detailed market reports, segmentation analysis, competitive landscape assessments, and actionable insights, all tailored to different stakeholders within the industrial hose market.

What are the market trends of industrial Hose?

Current trends in the industrial hose market include increasing preferences for lightweight and flexible materials, advancements in hose technology for better endurance, and a shift towards environmentally-friendly materials, aligning with global sustainability efforts.