Industrial Plugs And Sockets Market Report

Published Date: 22 January 2026 | Report Code: industrial-plugs-and-sockets

Industrial Plugs And Sockets Market Size, Share, Industry Trends and Forecast to 2033

This report provides comprehensive insights into the Industrial Plugs and Sockets market, including detailed analysis and forecasts from 2023 to 2033. It highlights market size, growth trends, regional analysis, technological advancements, and key players shaping the industry.

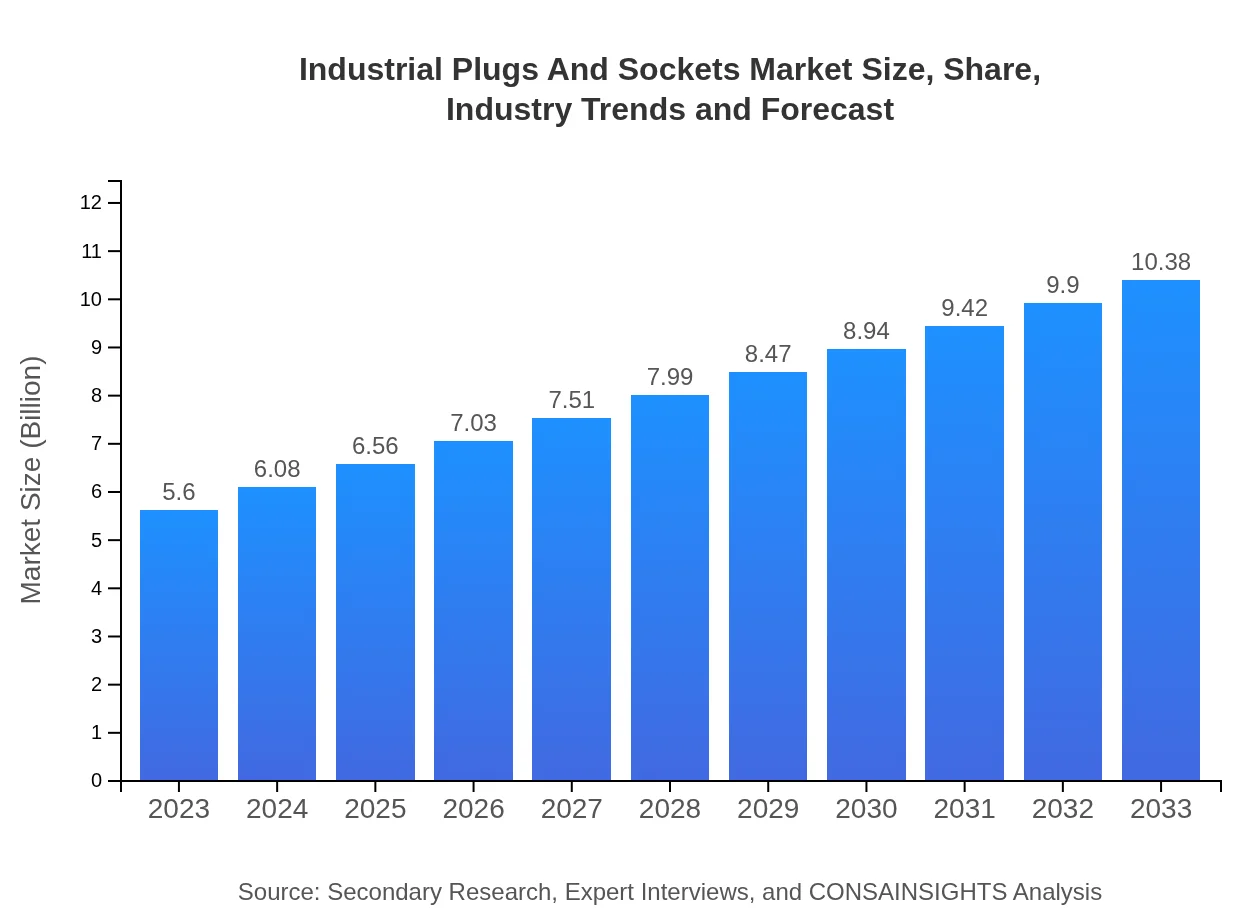

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $10.38 Billion |

| Top Companies | Schneider Electric, Siemens AG, Legrand, ABB, Phoenix Contact |

| Last Modified Date | 22 January 2026 |

Industrial Plugs And Sockets Market Overview

Customize Industrial Plugs And Sockets Market Report market research report

- ✔ Get in-depth analysis of Industrial Plugs And Sockets market size, growth, and forecasts.

- ✔ Understand Industrial Plugs And Sockets's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Plugs And Sockets

What is the Market Size & CAGR of Industrial Plugs And Sockets market in 2023?

Industrial Plugs And Sockets Industry Analysis

Industrial Plugs And Sockets Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Plugs And Sockets Market Analysis Report by Region

Europe Industrial Plugs And Sockets Market Report:

Europe's market, valued at $1.55 billion in 2023, is anticipated to reach $2.87 billion by 2033. Stringent safety regulations and the shift towards renewable energy sources are key drivers in this region.Asia Pacific Industrial Plugs And Sockets Market Report:

In 2023, the Asia Pacific region's market is valued at $1.11 billion, growing to $2.05 billion by 2033. The growth is primarily attributed to rapid industrialization, urbanization, and increased infrastructure projects. Countries like China and India are significant contributors to this growth due to their extensive manufacturing sectors.North America Industrial Plugs And Sockets Market Report:

North America, with a market value of $2.05 billion in 2023, is expected to grow to $3.81 billion by 2033. The expansion is driven by technological advancements, a strong manufacturing base, and the emphasis on smart grid infrastructure.South America Industrial Plugs And Sockets Market Report:

The market in South America is estimated at $0.38 billion in 2023, projected to reach $0.70 billion by 2033. Increased investment in mining and energy projects in nations like Brazil and Argentina is bolstering demand for industrial plugs and sockets.Middle East & Africa Industrial Plugs And Sockets Market Report:

In the Middle East and Africa, the market is valued at $0.51 billion in 2023 and expected to grow to $0.95 billion by 2033, supported by infrastructural developments and rising investments in energy sectors.Tell us your focus area and get a customized research report.

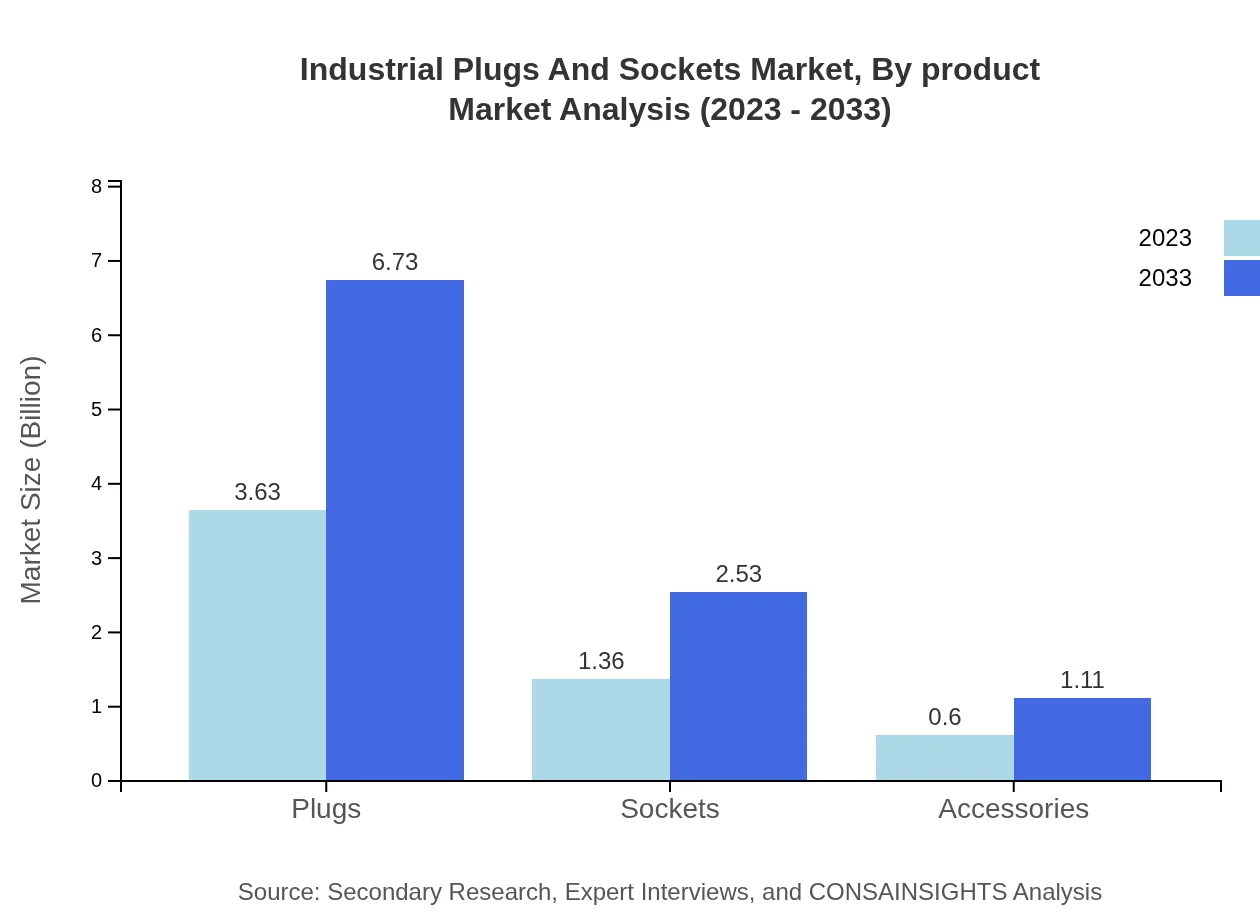

Industrial Plugs And Sockets Market Analysis By Product

The product segment includes Plugs, Sockets, and Accessories, with a predominant share held by plugs, valued at $3.63 billion in 2023 and expected to rise to $6.73 billion by 2033. Sockets follow at $1.36 billion, growing to $2.53 billion. Accessories account for a smaller share, growing from $0.60 billion to $1.11 billion, reflecting ongoing integration of accessory products in electrical installations.

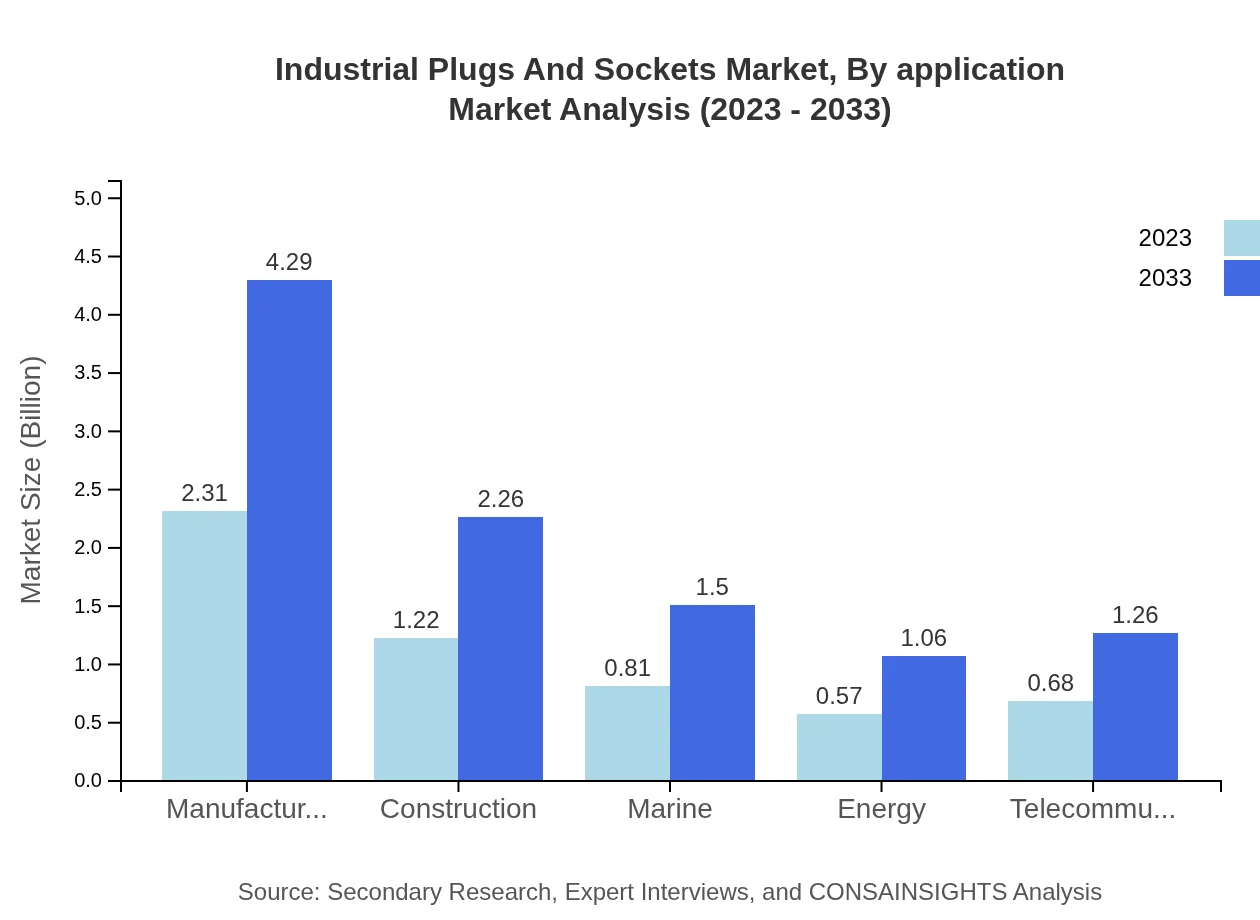

Industrial Plugs And Sockets Market Analysis By Application

The application segmentation outlines significant sectors such as Oil and Gas, Manufacturing, and Construction, with Manufacturing representing the largest share at $2.31 billion in 2023, projected to grow to $4.29 billion. The Food and Beverage sector is also noteworthy, growing from $1.22 billion to $2.26 billion, depicting a strong demand for specialized connectors to ensure safety and compliance.

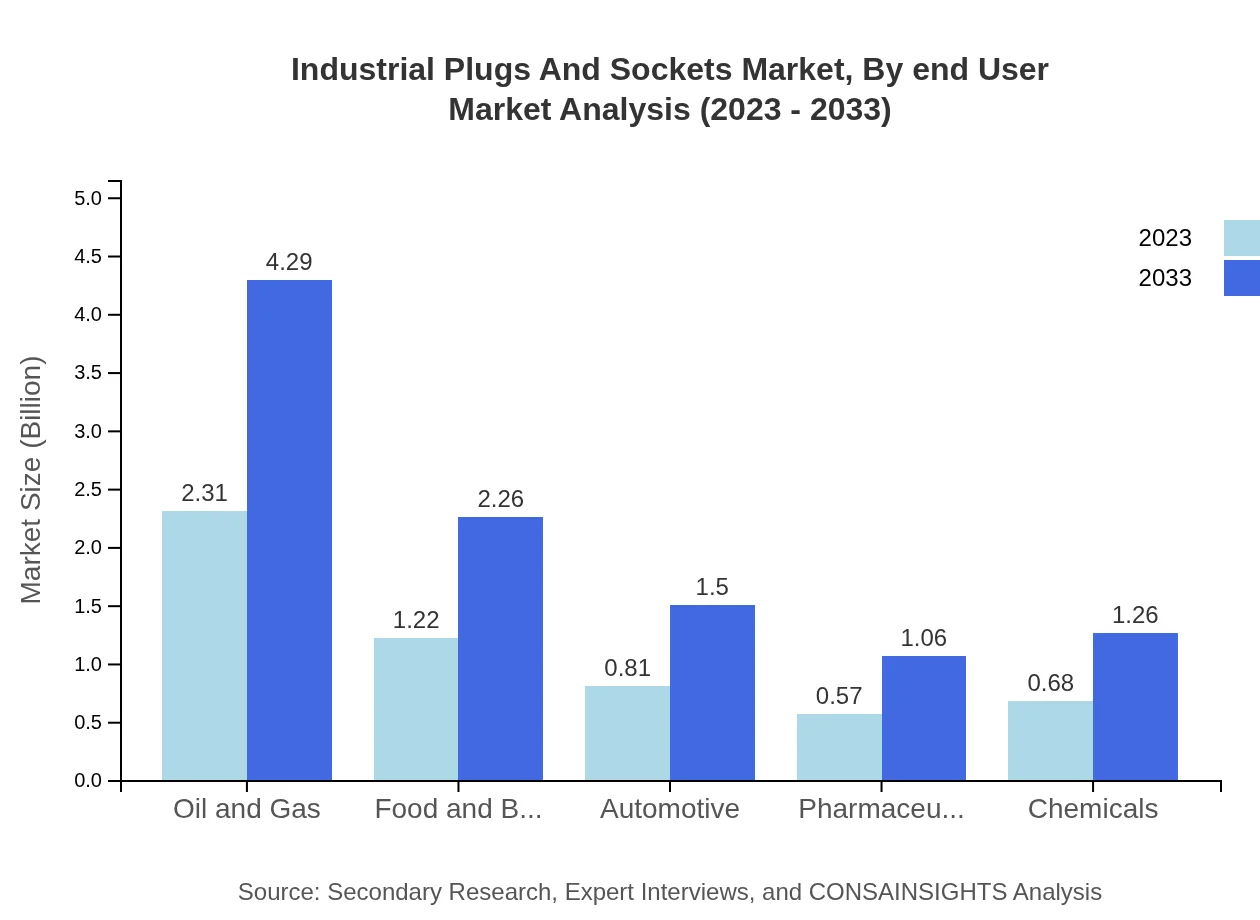

Industrial Plugs And Sockets Market Analysis By End User

Industries such as Manufacturing, Construction, and Energy represent major end-users. Manufacturing holds a dominant share at $2.31 billion, and is projected to expand in alignment with industrial growth. The Energy sector is also forecasted to grow significantly, particularly as investments in sustainable energy solutions increase.

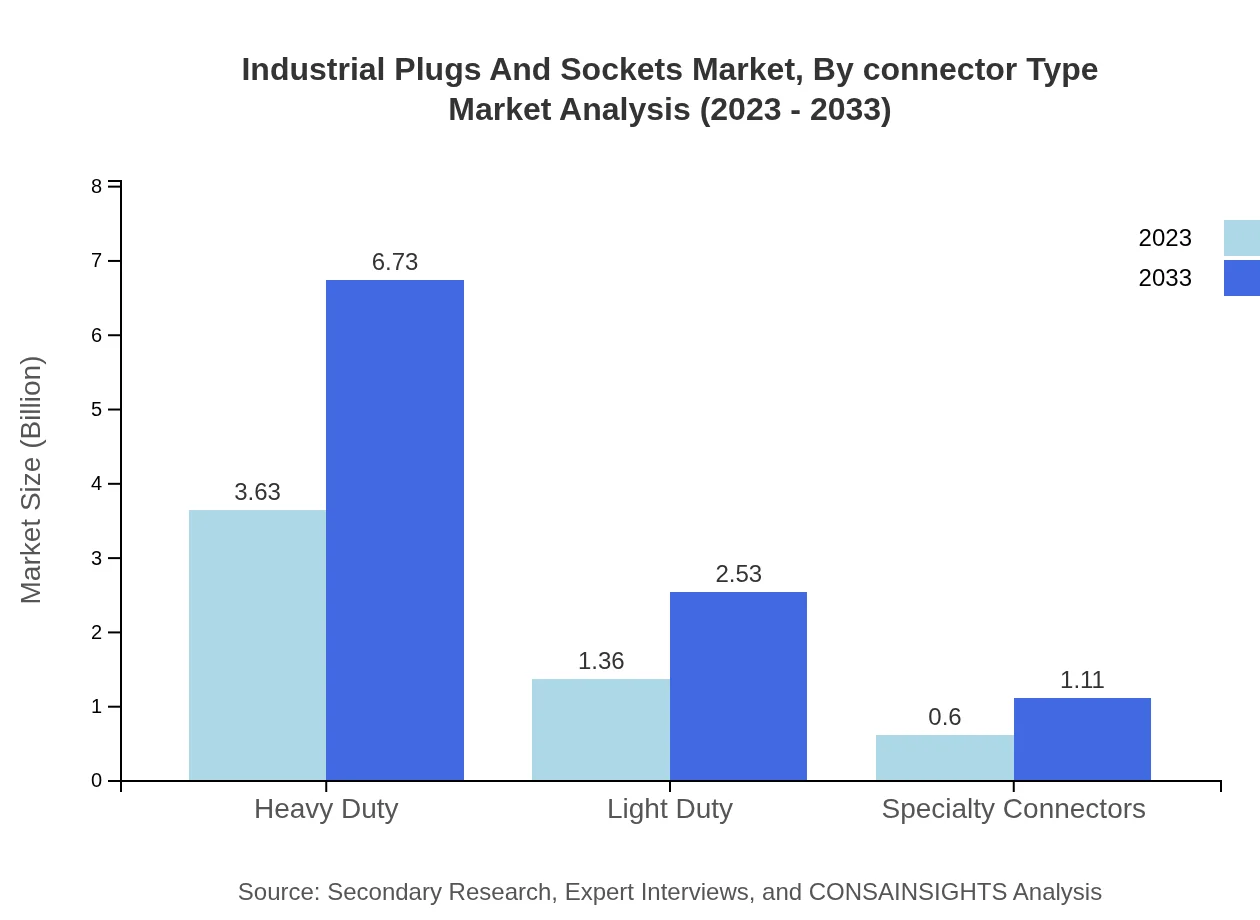

Industrial Plugs And Sockets Market Analysis By Connector Type

This segment shows growth across Heavy Duty and Specialty Connectors. Heavy Duty connectors dominate with $3.63 billion, driven by their suitability for harsh environments. Light Duty connectors also exhibit resilience in less demanding applications, projected to grow from $1.36 billion to $2.53 billion.

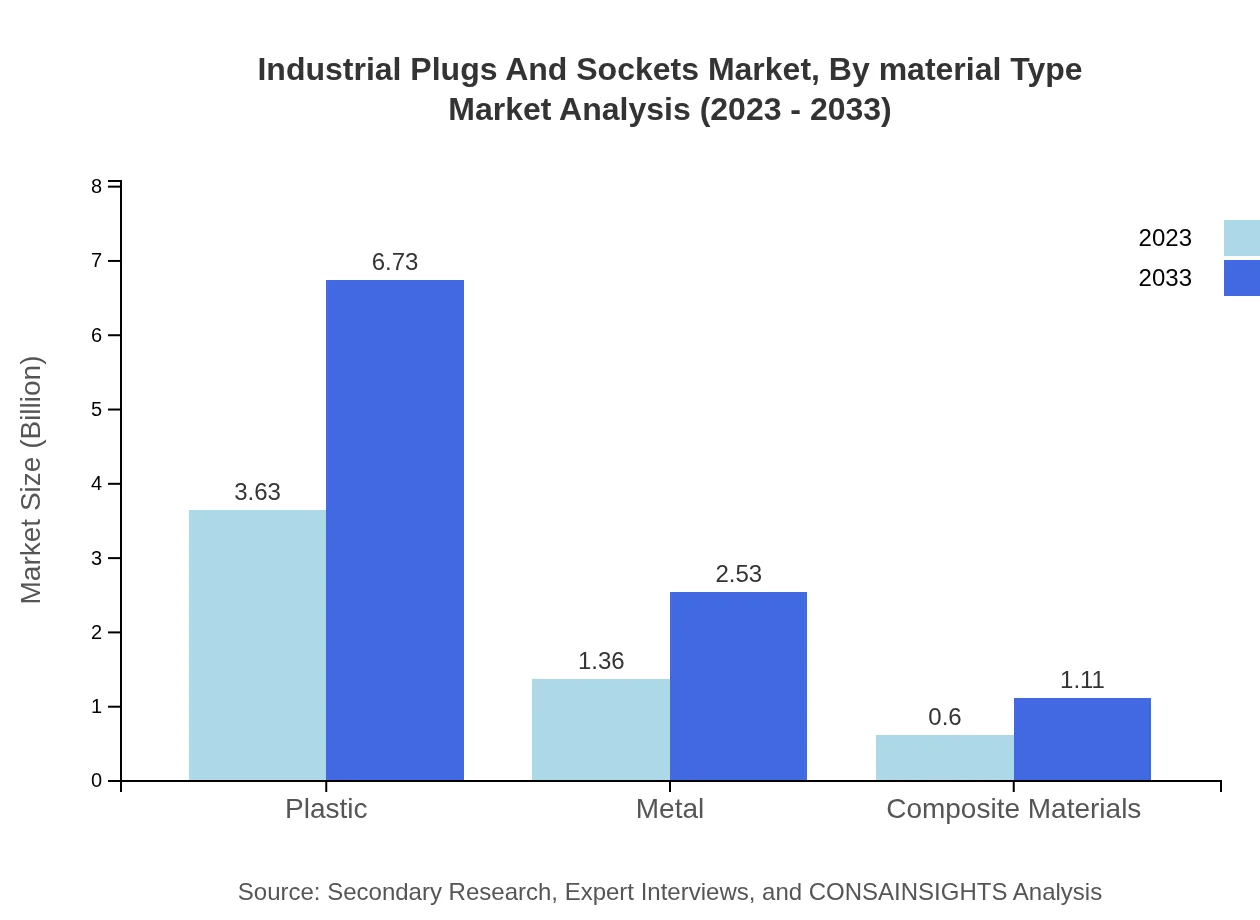

Industrial Plugs And Sockets Market Analysis By Material Type

Material segmentation highlights Plastic, Metal, and Composite Materials. Plastic connectors dominate due to their lightweight nature, valued at $3.63 billion in 2023, while metal connectors follow at $1.36 billion. Composite Materials have a smaller yet growing segment, capitalizing on their durability in industrial applications.

Industrial Plugs And Sockets Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Plugs And Sockets Industry

Schneider Electric:

A global leader in energy management and automation, Schneider Electric offers a range of innovative industrial plugs and sockets designed for safety and efficiency.Siemens AG:

Siemens is renowned for its advanced industrial equipment, including robust connector systems that promote seamless connectivity and durability.Legrand:

Legrand specializes in electrical and digital building infrastructures, providing a variety of industrial plugs and sockets focused on energy efficiency.ABB:

ABB provides high-quality industrial electrical components, with a significant focus on sustainability and innovation in their plug and socket solutions.Phoenix Contact:

Recognized for high-performance connection technology, Phoenix Contact offers a wide range of industrial plugs and sockets tailored for various applications.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial Plugs And Sockets?

The global market size for industrial plugs and sockets is projected to reach approximately $5.6 billion by 2033, expanding at a CAGR of 6.2%. This growth is driven by increasing industrial automation and infrastructure development.

What are the key market players or companies in the industrial Plugs And Sockets industry?

Key players in the industrial plugs and sockets market include established manufacturers and suppliers who lead with technology advancements. Notable companies focus on high-quality standards and safety features to gain competitive advantages.

What are the primary factors driving the growth in the industrial Plugs And Sockets industry?

Growth is propelled by rising demand in manufacturing and construction sectors, technological innovations, and increased focus on safety and efficiency in electrical connections. Moreover, the expansion of renewable energy projects fuels market demand.

Which region is the fastest Growing in the industrial Plugs And Sockets?

The Asia Pacific region is currently the fastest-growing market for industrial plugs and sockets, expected to grow from $1.11 billion in 2023 to $2.05 billion by 2033. This is due to rapid industrialization and infrastructural development.

Does ConsaInsights provide customized market report data for the industrial Plugs And Sockets industry?

Yes, ConsaInsights offers customized market report data to address the specific needs of clients in the industrial plugs and sockets industry, ensuring insights are tailored to unique business requirements.

What deliverables can I expect from this industrial Plugs And Sockets market research project?

Deliverables include comprehensive market analysis, growth forecasts, segmentation data, competitor analysis, and detailed insights on regional trends. Customized reports will align with stakeholders' strategic objectives.

What are the market trends of industrial Plugs And Sockets?

Key market trends include a shift towards eco-friendly materials, increasing smart technology integration, and greater emphasis on compatibility across different industries. Additionally, the demand for heavy-duty connections is on the rise.