Industrial Tubes Market Report

Published Date: 22 January 2026 | Report Code: industrial-tubes

Industrial Tubes Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Industrial Tubes market, including current trends, regional insights, and a detailed forecast for the years 2023 to 2033, focusing on market dynamics, segmentation, and industry leaders.

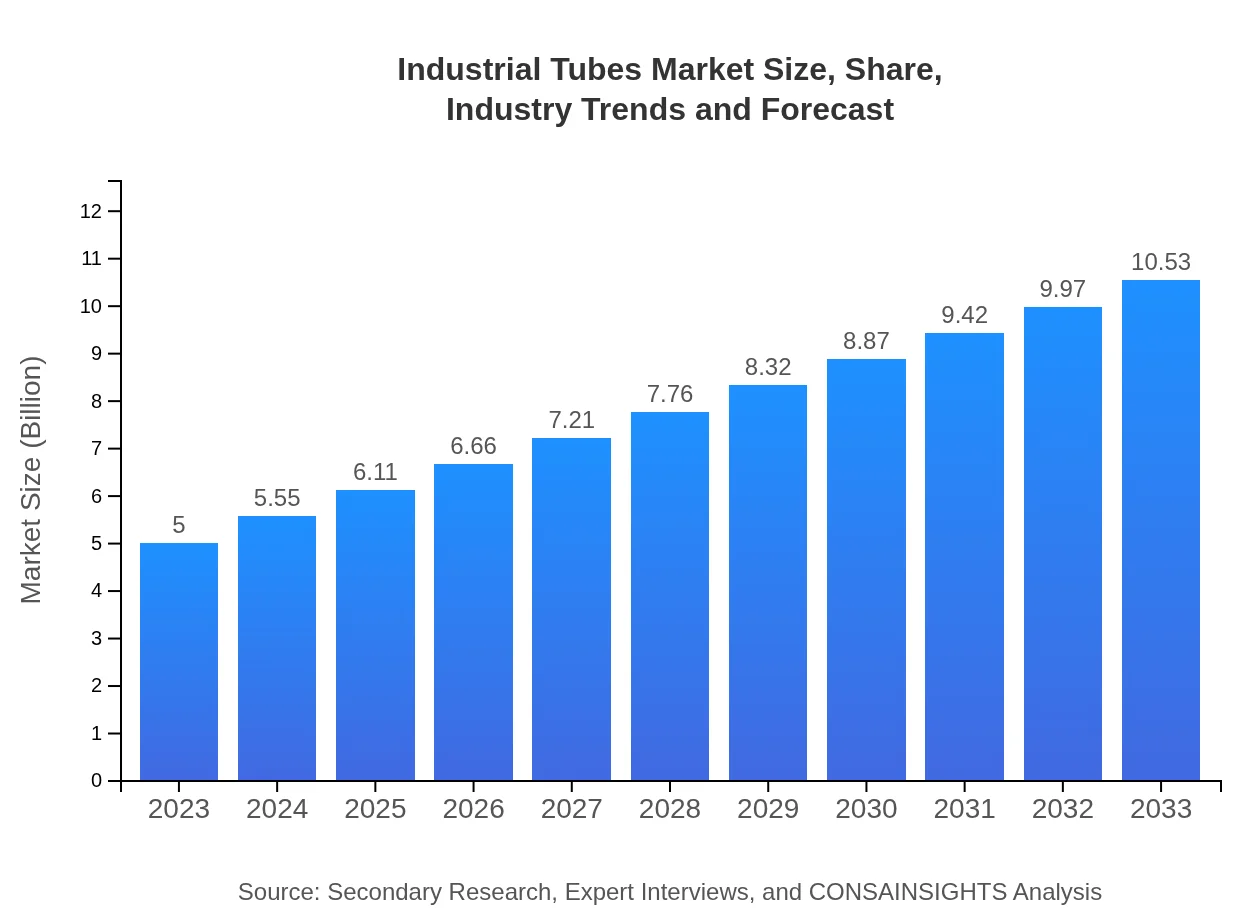

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Tenaris, Swagelok Company, Parker Hannifin |

| Last Modified Date | 22 January 2026 |

Industrial Tubes Market Overview

Customize Industrial Tubes Market Report market research report

- ✔ Get in-depth analysis of Industrial Tubes market size, growth, and forecasts.

- ✔ Understand Industrial Tubes's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Tubes

What is the Market Size & CAGR of Industrial Tubes market in 2023?

Industrial Tubes Industry Analysis

Industrial Tubes Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Tubes Market Analysis Report by Region

Europe Industrial Tubes Market Report:

In Europe, the market for Industrial Tubes is set to increase from USD 1.55 billion in 2023 to USD 3.26 billion by 2033. Key drivers include stringent regulations favoring the use of durable and recyclable materials, alongside significant growth in automotive and construction sectors.Asia Pacific Industrial Tubes Market Report:

In the Asia Pacific region, the Industrial Tubes market is anticipated to grow from USD 0.95 billion in 2023 to USD 2.00 billion by 2033, driven by rapid industrialization, increasing urbanization, and robust infrastructure developments in emerging economies like China and India.North America Industrial Tubes Market Report:

The North American market is projected to expand from USD 1.74 billion in 2023 to USD 3.66 billion by 2033. The region's growth is supported by advancements in manufacturing technologies and a thriving aerospace sector, leading to increased demand for high-performance industrial tubes.South America Industrial Tubes Market Report:

The South American industrial tubes market is expected to grow from USD 0.40 billion in 2023 to USD 0.85 billion by 2033. The growth is mainly attributed to increasing investments in the oil and gas sector and expanding construction activities within the region.Middle East & Africa Industrial Tubes Market Report:

The Industrial Tubes market in the Middle East and Africa is expected to grow from USD 0.36 billion in 2023 to USD 0.75 billion by 2033, driven by infrastructure developments and the growing oil and gas industry, requiring innovative tube solutions.Tell us your focus area and get a customized research report.

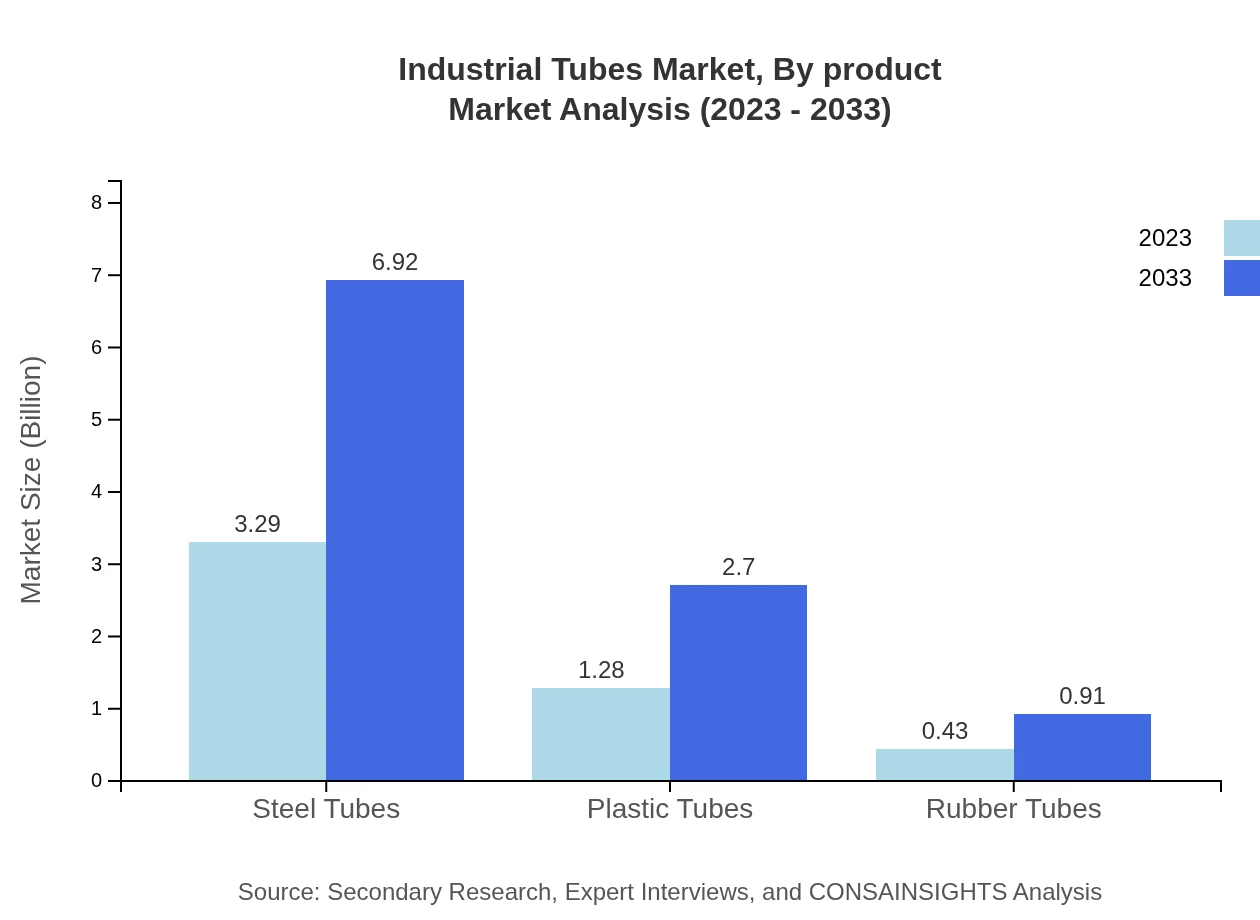

Industrial Tubes Market Analysis By Product

The market for industrial tubes by product type shows robust performance, particularly in steel tubes, which have a market value of USD 3.29 billion (65.76% market share) in 2023, increasing to USD 6.92 billion by 2033. Plastic tubes also show significant growth from USD 1.28 billion (25.61% share) to USD 2.70 billion, while rubber tubes are anticipated to grow from USD 0.43 billion (8.63% share) to USD 0.91 billion.

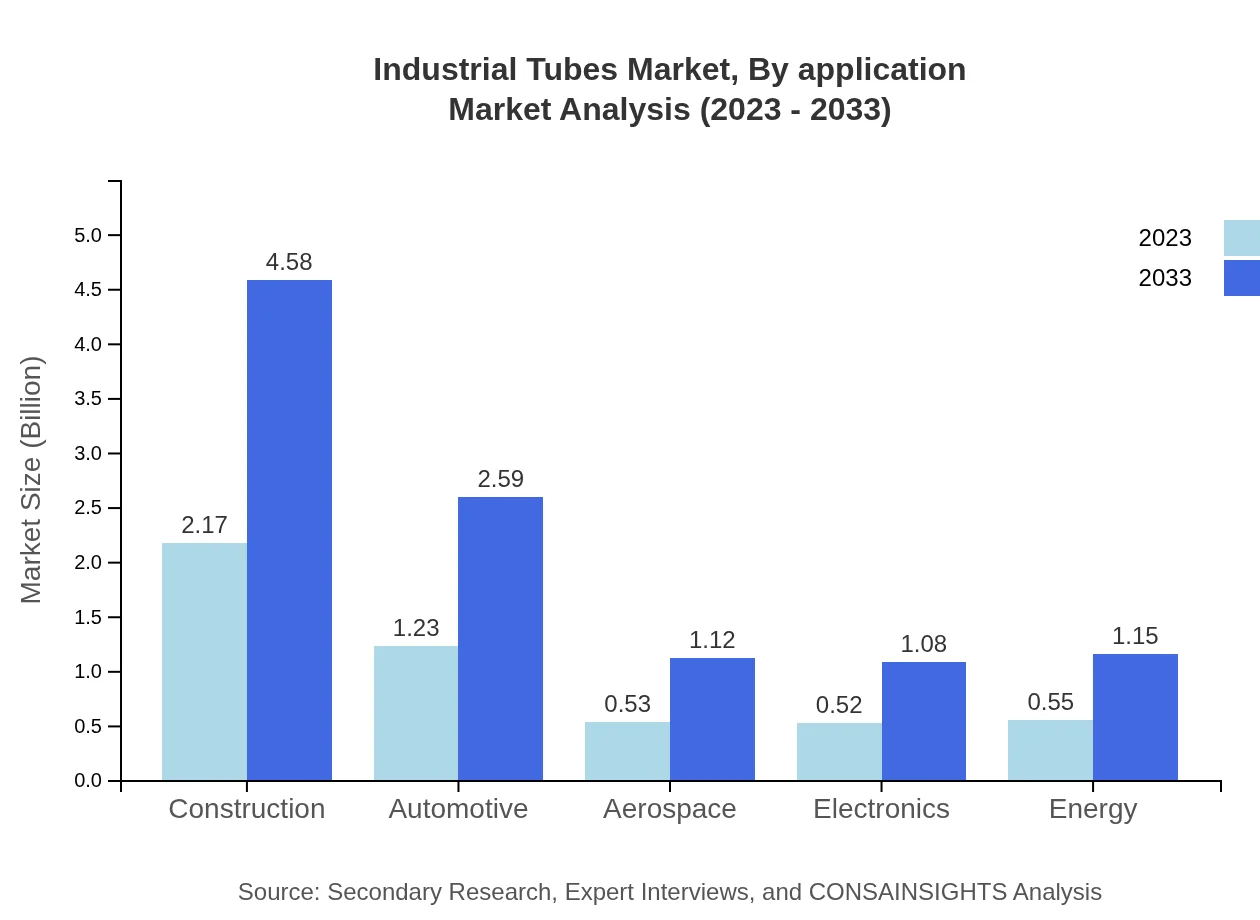

Industrial Tubes Market Analysis By Application

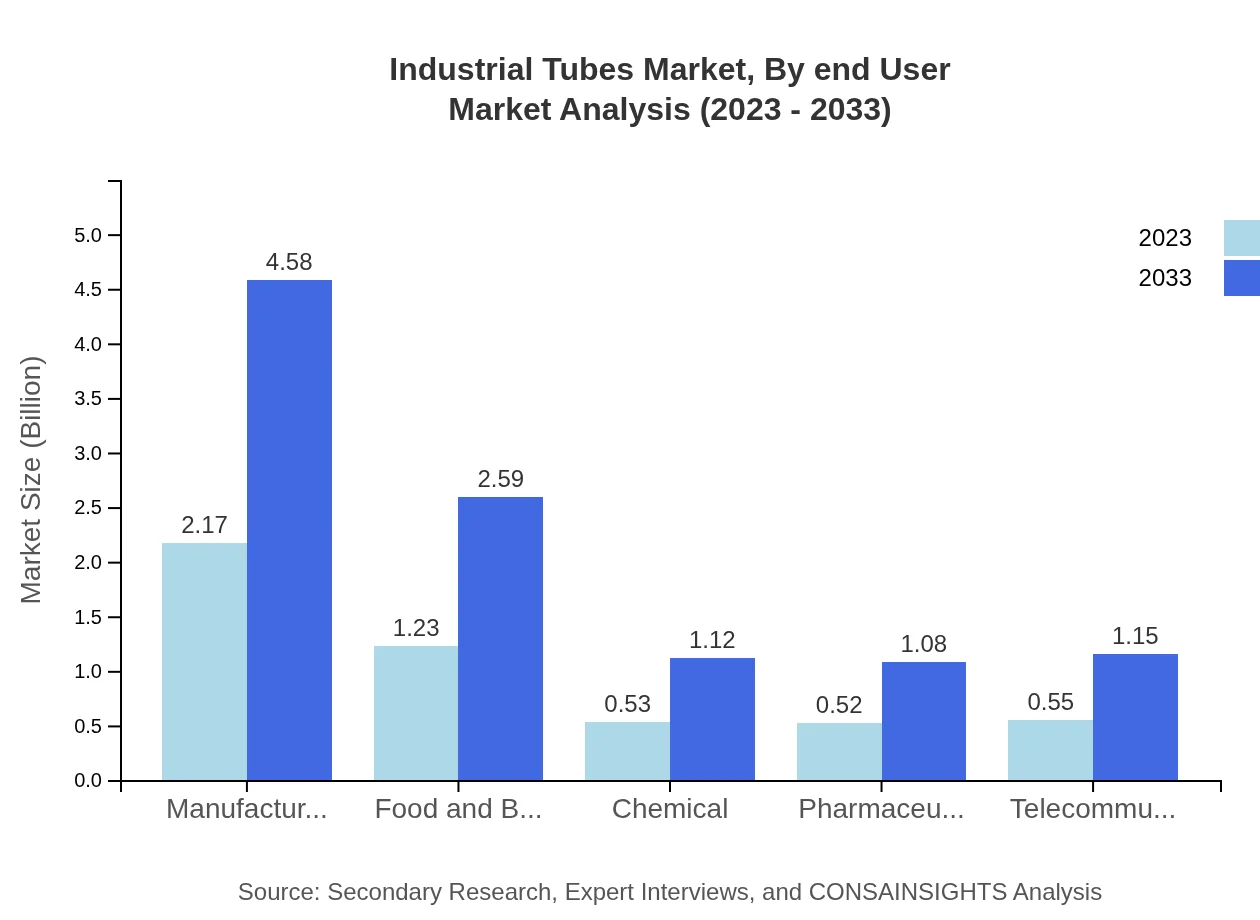

In terms of applications, the manufacturing sector leads with a market size of USD 2.17 billion in 2023, growing to USD 4.58 billion (43.48% share) by 2033. The food and beverage industry also demonstrates strong demand, increasing from USD 1.23 billion (24.64% share) to USD 2.59 billion. Other key applications include chemical, pharmaceutical, and telecommunications, each valuable segments contributing to the market's expansion.

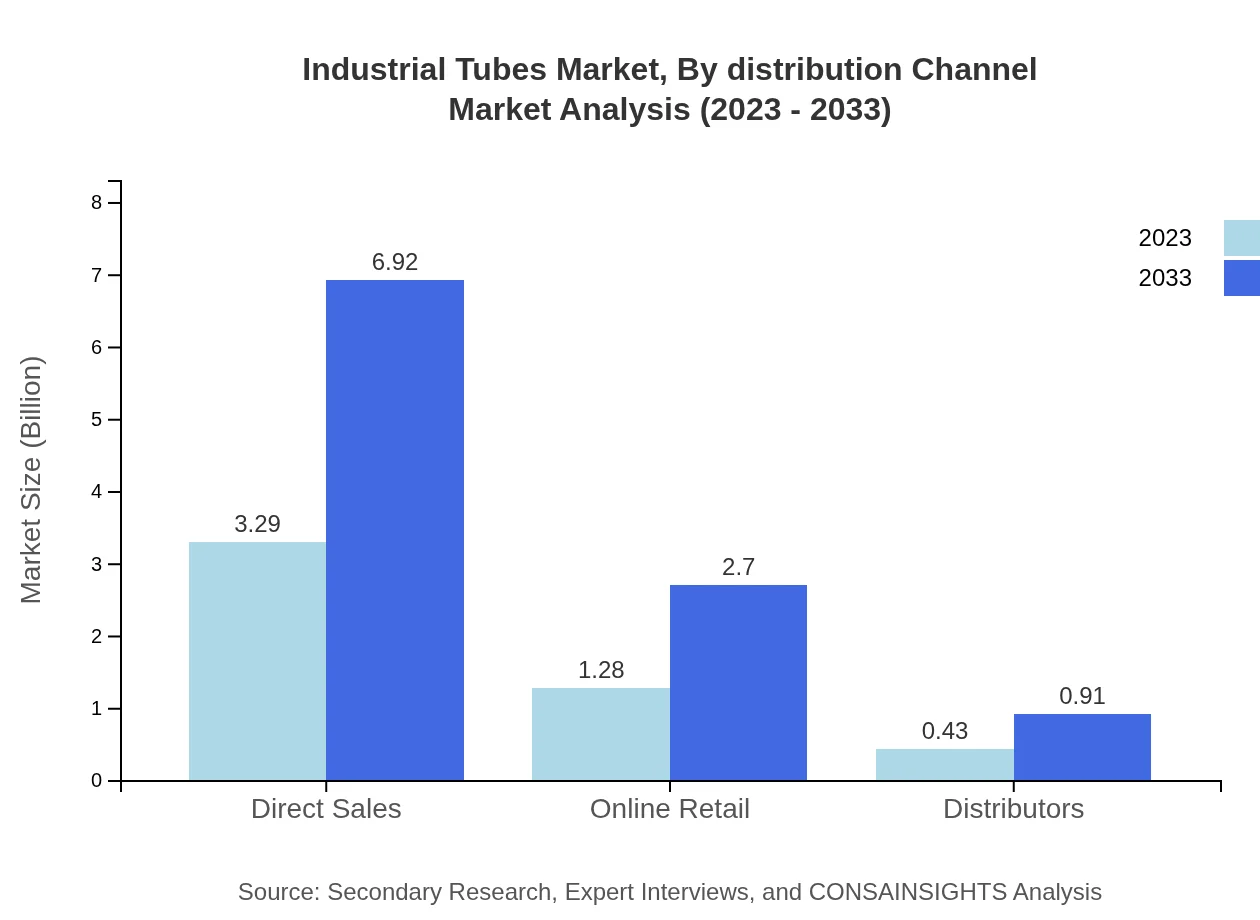

Industrial Tubes Market Analysis By Distribution Channel

The distribution channel analysis reveals direct sales as the largest segment, achieving a size of USD 3.29 billion (65.76% share) in 2023, expected to grow to USD 6.92 billion by 2033. Online retail is emerging as a significant channel, projected to increase from USD 1.28 billion to USD 2.70 billion (25.61% share). Distributors contribute smaller, yet important amounts growing from USD 0.43 billion to USD 0.91 billion.

Industrial Tubes Market Analysis By End User

The automotive industry comprises a notable segment of the Industrial Tubes market with a size of USD 1.23 billion in 2023, expanding to USD 2.59 billion by 2033 (24.64% share). Other end-users such as aerospace, electronics, and energy are expected to see similar growth with diverse applications necessitating high-quality tubing solutions.

Industrial Tubes Market Analysis By Material

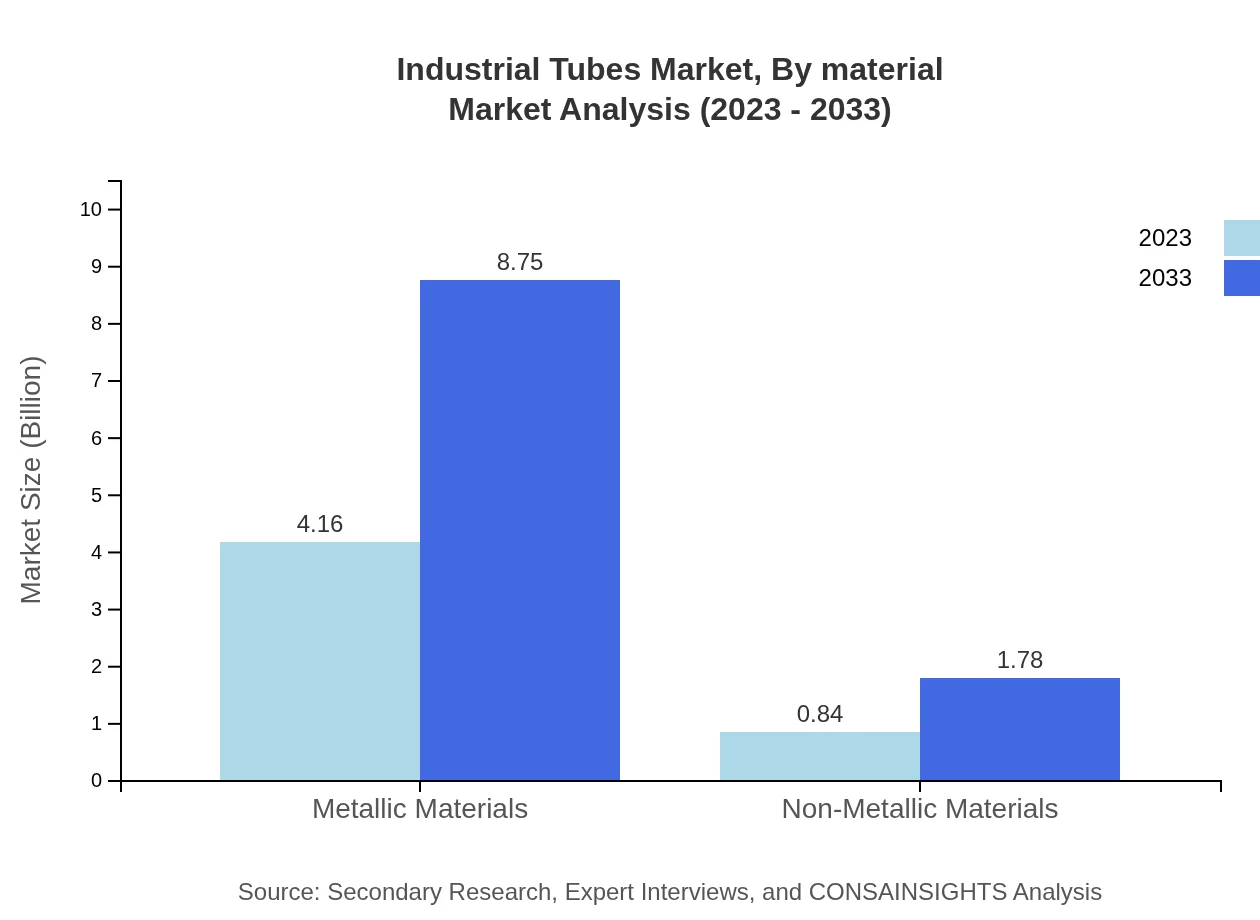

Materials in the Industrial Tubes market are primarily categorized into metallic and non-metallic. Metallic materials dominate the market with USD 4.16 billion (83.11% share) in 2023 and are projected to grow to USD 8.75 billion by 2033. Non-metallic materials, currently at USD 0.84 billion (16.89% share), are also expected to see growth, reaching USD 1.78 billion due to diversification in applications.

Industrial Tubes Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Tubes Industry

Tenaris:

Tenaris is a leading provider of steel tubes and related services for the world’s energy industry and other industrial applications, focusing on innovative manufacturing processes and sustainability.Swagelok Company:

Swagelok Company specializes in the manufacturing of fluid and gas systems components for various industries, ensuring high quality and performance in their industrial tube offerings.Parker Hannifin:

Parker Hannifin is a global leader in motion and control technologies, delivering a wide range of tube products widely used across numerous sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial Tubes?

The global industrial tubes market is estimated to be around $5 billion in 2023 and is projected to grow at a CAGR of 7.5%, reaching significant growth by 2033.

What are the key market players or companies in the industrial Tubes industry?

Key players in the industrial tubes market include major companies with strong manufacturing capabilities and distribution networks, ensuring a competitive landscape that fosters innovation and industry collaboration.

What are the primary factors driving the growth in the industrial Tubes industry?

The industrial tubes industry's growth is propelled by rising demand in key sectors like manufacturing, construction, and energy, along with technological advancements that enhance product performance and application versatility.

Which region is the fastest Growing in the industrial Tubes?

The Asia Pacific region is the fastest-growing market for industrial tubes, expected to expand from $0.95 billion in 2023 to $2.00 billion by 2033, showcasing significant growth opportunities.

Does ConsaInsights provide customized market report data for the industrial Tubes industry?

Yes, ConsaInsights offers customized market report data that can be tailored to specific needs, providing insights that align with unique business goals in the industrial tubes market.

What deliverables can I expect from this industrial Tubes market research project?

From the industrial tubes market research project, you can expect comprehensive reports, analytical insights, market forecasts, segmentation data, and strategy recommendations tailored to your needs.

What are the market trends of industrial Tubes?

Current trends in the industrial tubes market include increasing use of advanced materials, rising sustainability initiatives, and digital transformation in manufacturing processes, shaping the future of the industry.