Industrial Wireless Sensor Market Report

Published Date: 31 January 2026 | Report Code: industrial-wireless-sensor

Industrial Wireless Sensor Market Size, Share, Industry Trends and Forecast to 2033

This report offers comprehensive insights into the Industrial Wireless Sensor market, covering market size, CAGR, segmentation, regional performance, technology trends, and forecasts from 2023 to 2033.

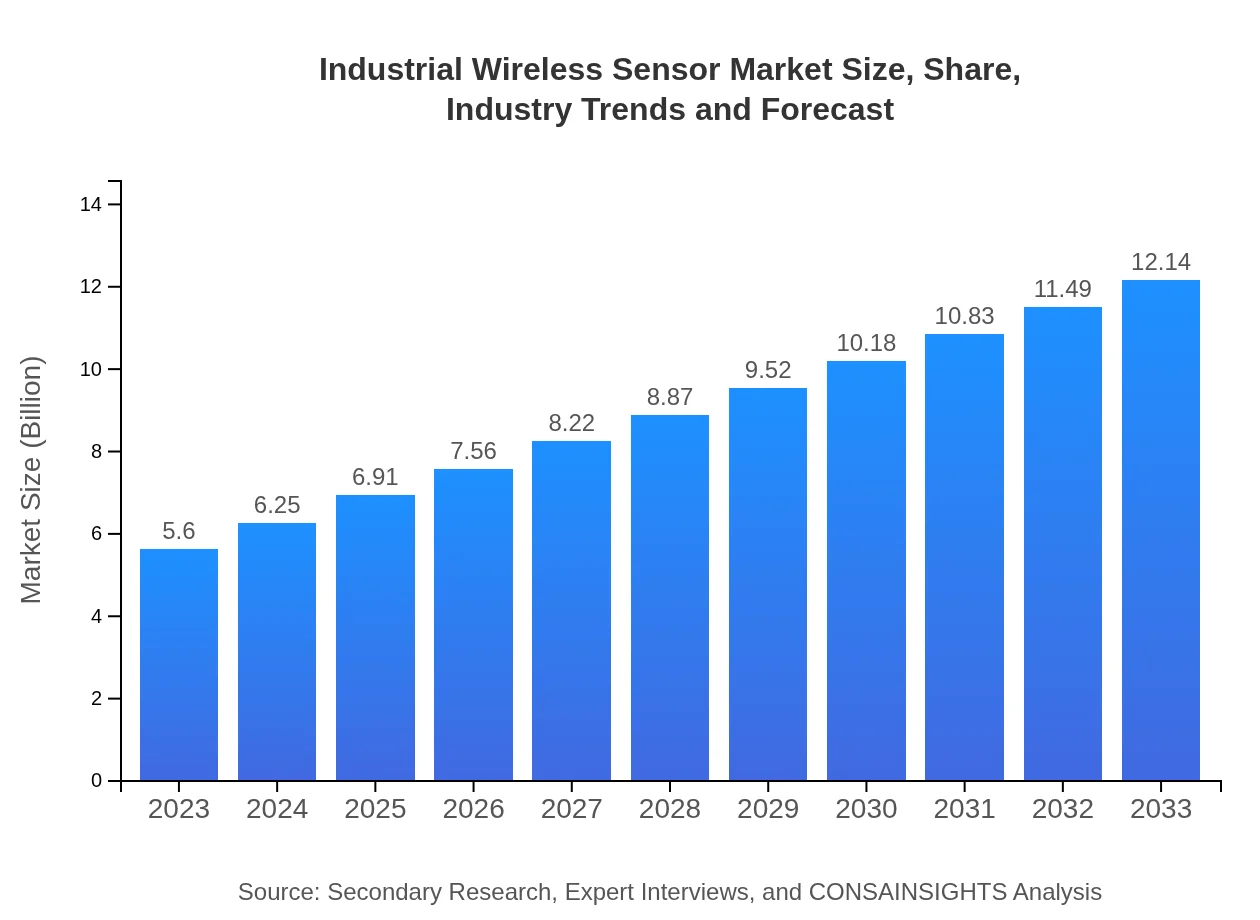

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $12.14 Billion |

| Top Companies | Honeywell International Inc., Siemens AG, Schneider Electric, Rockwell Automation |

| Last Modified Date | 31 January 2026 |

Industrial Wireless Sensor Market Overview

Customize Industrial Wireless Sensor Market Report market research report

- ✔ Get in-depth analysis of Industrial Wireless Sensor market size, growth, and forecasts.

- ✔ Understand Industrial Wireless Sensor's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Industrial Wireless Sensor

What is the Market Size & CAGR of Industrial Wireless Sensor market in 2023?

Industrial Wireless Sensor Industry Analysis

Industrial Wireless Sensor Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Industrial Wireless Sensor Market Analysis Report by Region

Europe Industrial Wireless Sensor Market Report:

Europe's market, valued at USD 1.42 billion in 2023, is forecasted to grow to USD 3.07 billion by 2033, benefiting from stringent regulations related to industry standards and an increasing move towards sustainability in industrial processes.Asia Pacific Industrial Wireless Sensor Market Report:

In the Asia Pacific, the market size was USD 1.09 billion in 2023, projected to reach USD 2.36 billion by 2033, spurred by rapid industrialization and the adoption of smart factory concepts, particularly in countries like China and India.North America Industrial Wireless Sensor Market Report:

North America leads the market with a size of USD 2.09 billion in 2023, anticipated to double to USD 4.53 billion by 2033 due to significant investments in smart manufacturing and technology upgrades in industrial operations.South America Industrial Wireless Sensor Market Report:

South America shows modest growth, with the market size at USD 0.29 billion in 2023, expected to rise to USD 0.64 billion by 2033, primarily in the oil & gas sector driven by need for enhanced safety and operational efficiency.Middle East & Africa Industrial Wireless Sensor Market Report:

The Middle East and Africa market stood at USD 0.71 billion in 2023 and is projected to grow to USD 1.54 billion by 2033, with rising investments in infrastructure development and industrial applications, particularly in oil-rich nations.Tell us your focus area and get a customized research report.

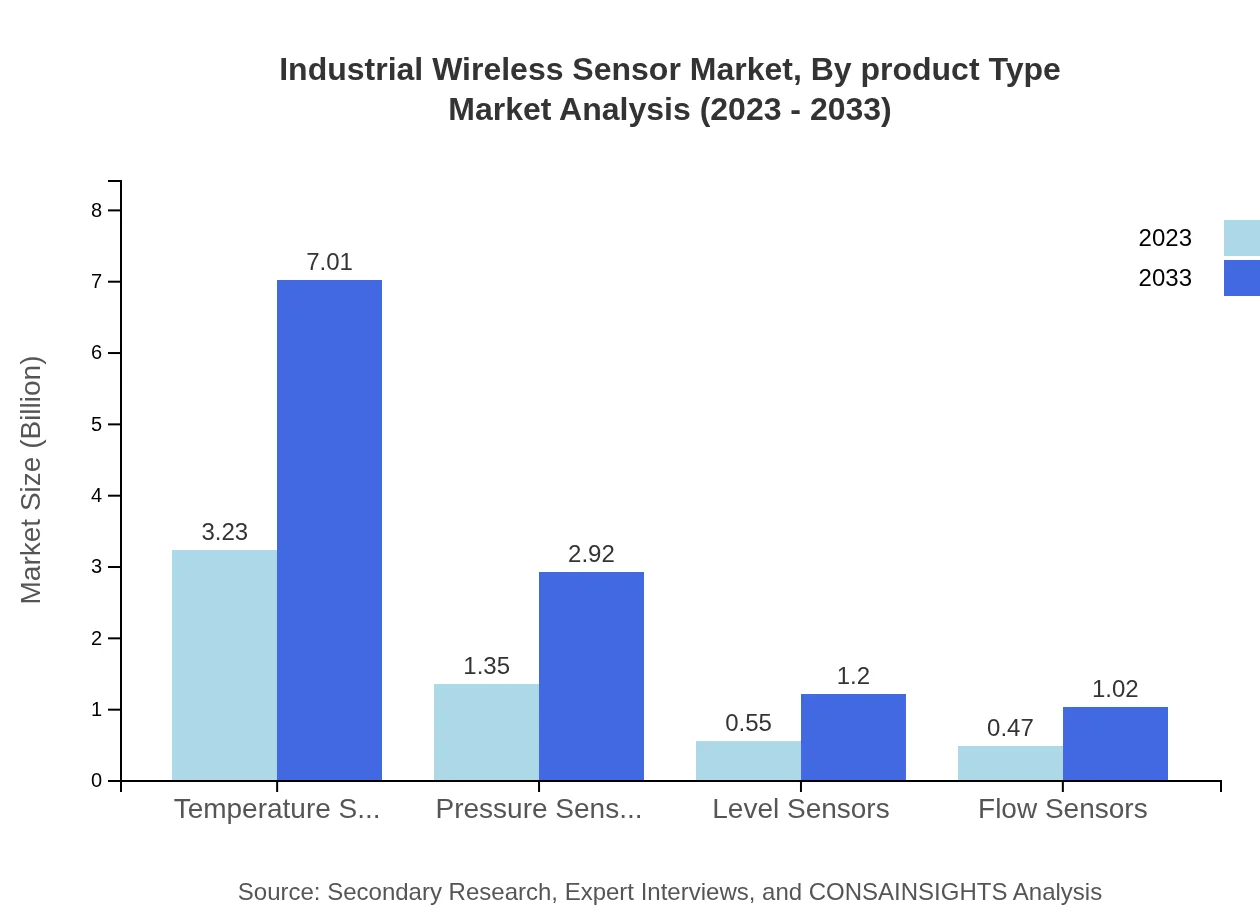

Industrial Wireless Sensor Market Analysis By Product Type

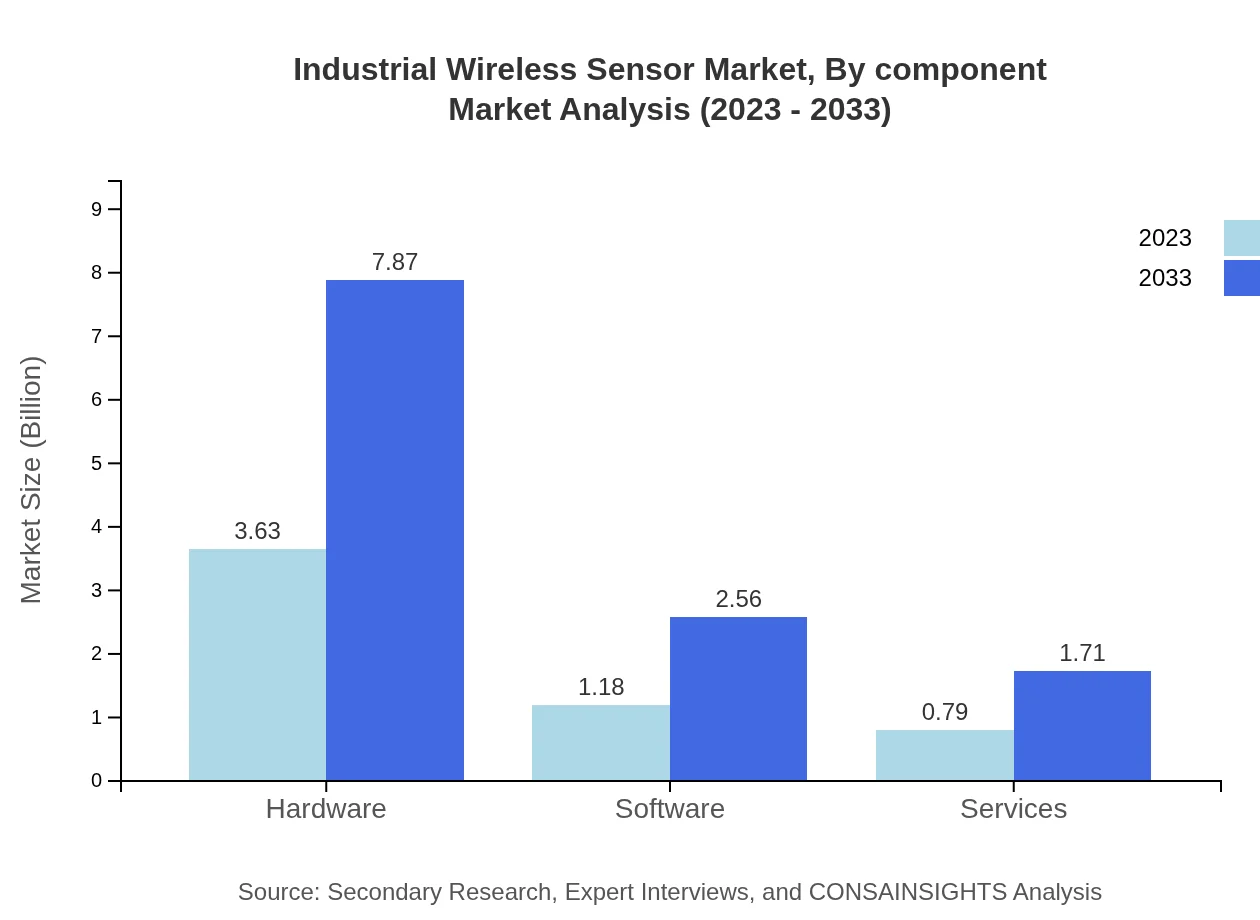

The product-type segmentation illustrates hardware dominating the market at USD 3.63 billion in 2023 and expected to reach USD 7.87 billion by 2033, driven by continuous R&D and increased demand for accurate data transmission. Software makes a vital contribution with anticipated growth from USD 1.18 billion to USD 2.56 billion and services showing a growth trajectory from USD 0.79 billion to USD 1.71 billion during the same period.

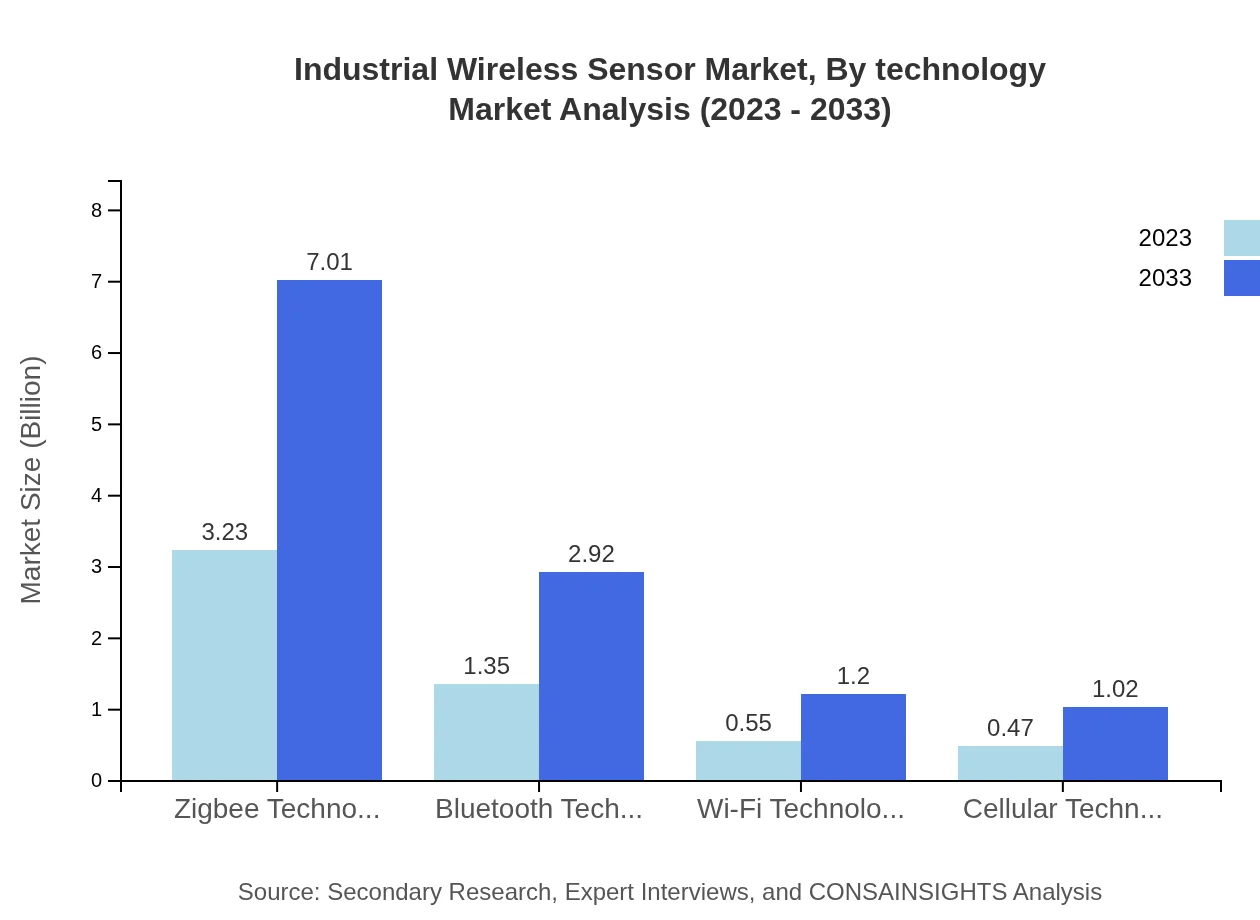

Industrial Wireless Sensor Market Analysis By Technology

Technological segmentation highlights Zigbee technology as market leader, forecasted to grow from USD 3.23 billion in 2023 to USD 7.01 billion by 2033, maintaining a share of 57.71%. Bluetooth technology is also gaining traction, expanding from USD 1.35 billion to USD 2.92 billion while Wi-Fi and Cellular technology markets are set to grow significantly due to their expanding applications in IoT setups.

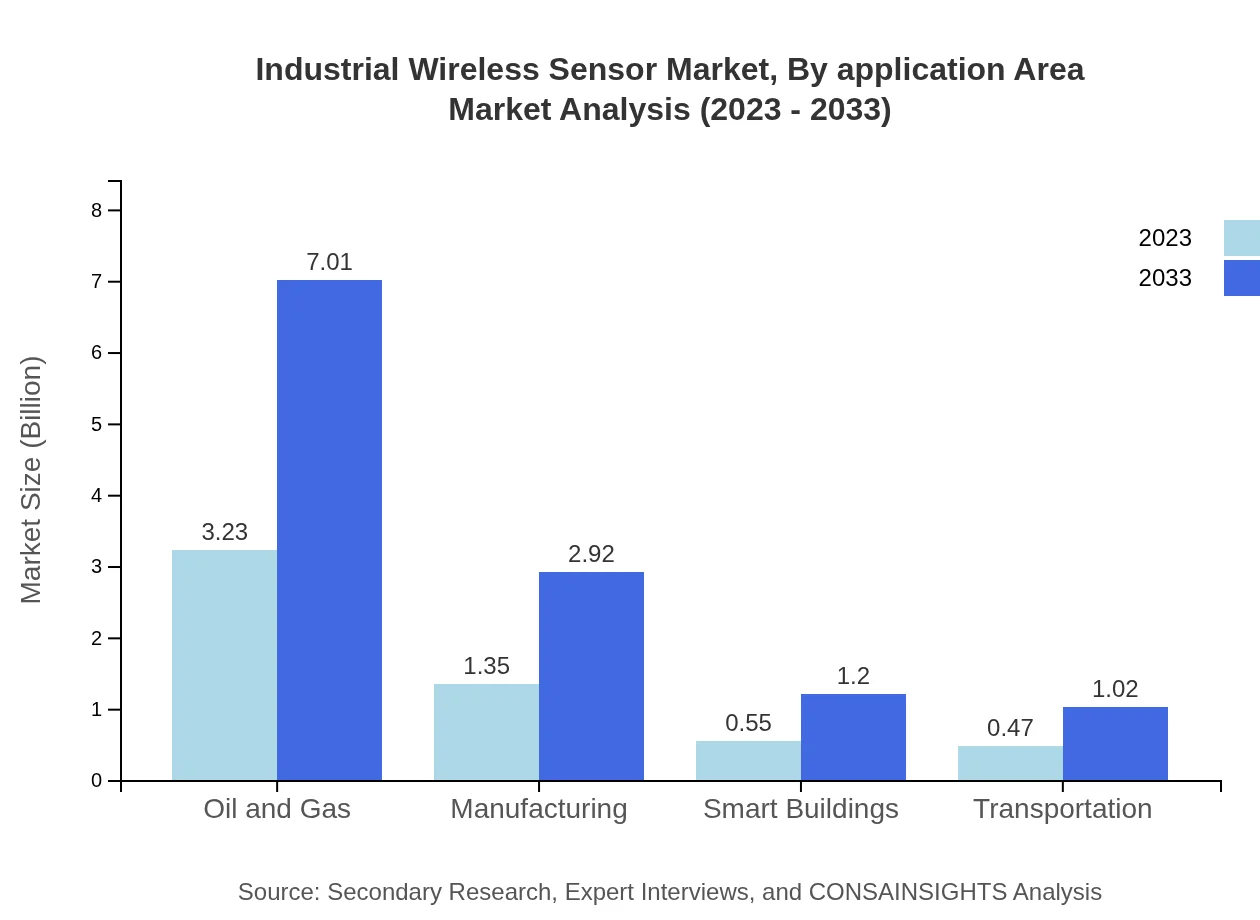

Industrial Wireless Sensor Market Analysis By Application Area

In application areas, oil and gas hold the largest share, with a valuation from USD 3.23 billion in 2023 to USD 7.01 billion by 2033, which underscores the critical nature of wireless sensors in ensuring safety and operational efficiency. Manufacturing follows, expanding from USD 1.35 billion to USD 2.92 billion, while sectors such as smart buildings are on a rise owing to increasing urbanization.

Industrial Wireless Sensor Market Analysis By Component

Component analysis reinforces hardware's dominance with significant growth from USD 3.63 billion to USD 7.87 billion by 2033. The software segment will also see robust growth as industries increasingly rely on sophisticated analytical tools for data interpretation and actionable insights, moving from USD 1.18 billion to USD 2.56 billion during the same timeframe.

Industrial Wireless Sensor Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Industrial Wireless Sensor Industry

Honeywell International Inc.:

A leader in industrial technologies, Honeywell focuses on advanced automation and control systems, providing state-of-the-art wireless sensors for various industrial applications.Siemens AG:

Siemens is prominent for its contributions to digital industries, with an extensive range of wireless sensors integrated into industrial applications to enhance efficiency and safety.Schneider Electric:

Specializes in energy management and automation solutions, offering innovative wireless sensor technologies facilitating better performance in industrial environments.Rockwell Automation:

Renowned for its digital transformation solutions, Rockwell emphasizes connectivity and data-driven insights through its wireless sensor offerings in manufacturing.We're grateful to work with incredible clients.

FAQs

What is the market size of industrial Wireless Sensor?

The global industrial wireless sensor market is projected to grow from USD 5.6 billion in 2023, with a CAGR of 7.8%, indicating robust expansion driven by technological advancements and increased adoption in various industries.

What are the key market players or companies in this industrial Wireless Sensor industry?

Key players in the industrial wireless sensor market include Siemens, Honeywell, Bosch, ABB, and Emerson Electric, known for their innovative solutions and extensive portfolios in wireless sensor technologies across various applications.

What are the primary factors driving the growth in the industrial Wireless Sensor industry?

Growth drivers in the industrial wireless sensor market include rising demand for automation, increased focus on IoT integration, and the need for real-time monitoring, which enhance operational efficiency and reduce downtime across sectors.

Which region is the fastest Growing in the industrial Wireless Sensor?

Asia Pacific is expected to be the fastest-growing region in the industrial wireless sensor market, expanding from USD 1.09 billion in 2023 to USD 2.36 billion by 2033, fueled by industrial growth and smart manufacturing initiatives.

Does ConsaInsights provide customized market report data for the industrial Wireless Sensor industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the industrial wireless sensor industry, enabling clients to obtain precise insights and forecasts relevant to their business strategies.

What deliverables can I expect from this industrial Wireless Sensor market research project?

Deliverables from the industrial wireless sensor market research include comprehensive reports on market trends, growth drivers, competitive analysis, and forecasts segmented by region, technology, and application, providing actionable insights.

What are the market trends of industrial Wireless Sensor?

Market trends in the industrial wireless sensor sector highlight an increasing shift toward IoT applications, enhanced wireless communication technologies, and growing investments in smart infrastructure, indicating a dynamic phase of transformation ahead.