Insulated Concrete Form Market Report

Published Date: 22 January 2026 | Report Code: insulated-concrete-form

Insulated Concrete Form Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Insulated Concrete Form (ICF) market, examining key trends, market size, and growth forecasts from 2023 to 2033, as well as segment analysis and regional insights.

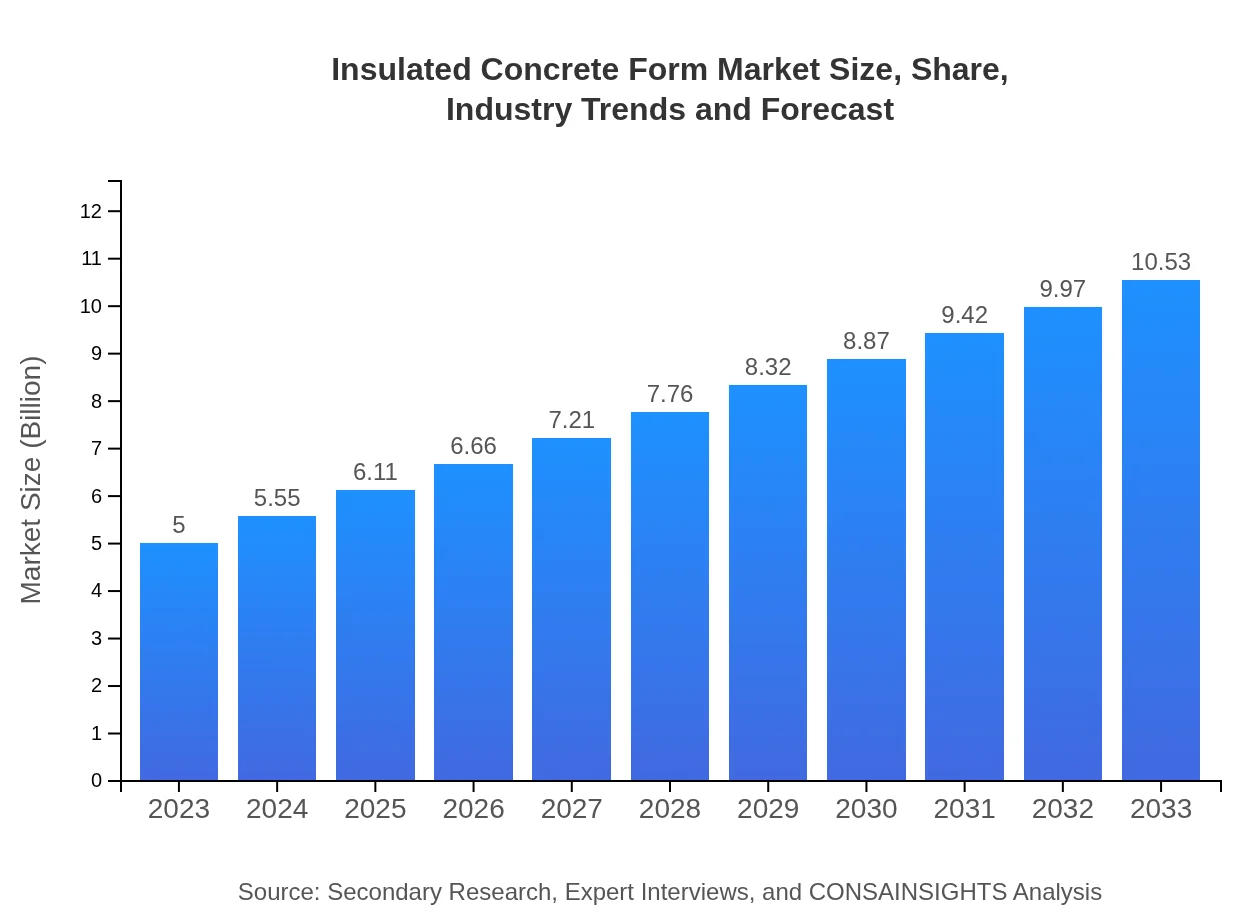

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Nudura, Amvic Building System, Logix Insulated Concrete Forms, ICF Tech |

| Last Modified Date | 22 January 2026 |

Insulated Concrete Form Market Overview

Customize Insulated Concrete Form Market Report market research report

- ✔ Get in-depth analysis of Insulated Concrete Form market size, growth, and forecasts.

- ✔ Understand Insulated Concrete Form's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Insulated Concrete Form

What is the Market Size & CAGR of Insulated Concrete Form market in 2023?

Insulated Concrete Form Industry Analysis

Insulated Concrete Form Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Insulated Concrete Form Market Analysis Report by Region

Europe Insulated Concrete Form Market Report:

The European market is forecasted to increase from $1.31 billion in 2023 to $2.77 billion by 2033. The region is witnessed stringent regulations concerning environmental sustainability and energy conservation, further fostering ICF adoption in construction practices across countries like Germany, France, and the UK.Asia Pacific Insulated Concrete Form Market Report:

The Asia Pacific region is projected to witness aggressive growth, with the market size growing from $0.99 billion in 2023 to $2.09 billion by 2033. Countries like China and India are investing heavily in infrastructure and residential projects, thus propelling the demand for Insulated Concrete Forms. The increasing preference for sustainable construction solutions in emerging economies has also augmented market growth.North America Insulated Concrete Form Market Report:

North America holds the largest market share, anticipated to grow significantly from $1.73 billion in 2023 to $3.64 billion by 2033. The presence of major construction companies and heightened focus on energy-efficient buildings drive the extensive adoption of ICF in both residential and commercial markets.South America Insulated Concrete Form Market Report:

In South America, the market is expected to grow from $0.44 billion in 2023 to $0.92 billion by 2033. Brazil and Argentina are the key players in the region, with rising urbanization and government initiatives favoring sustainable building solutions. This growth will be supported by increased investments in the construction sector as economies recover.Middle East & Africa Insulated Concrete Form Market Report:

The Middle East and Africa region is expected to expand from $0.52 billion in 2023 to approximately $1.10 billion by 2033. Growth in construction activities in Gulf countries, propelled by the 2022 World Expo in Dubai and other mega projects, is expected to significantly enhance the market prospects for insulated concrete forms.Tell us your focus area and get a customized research report.

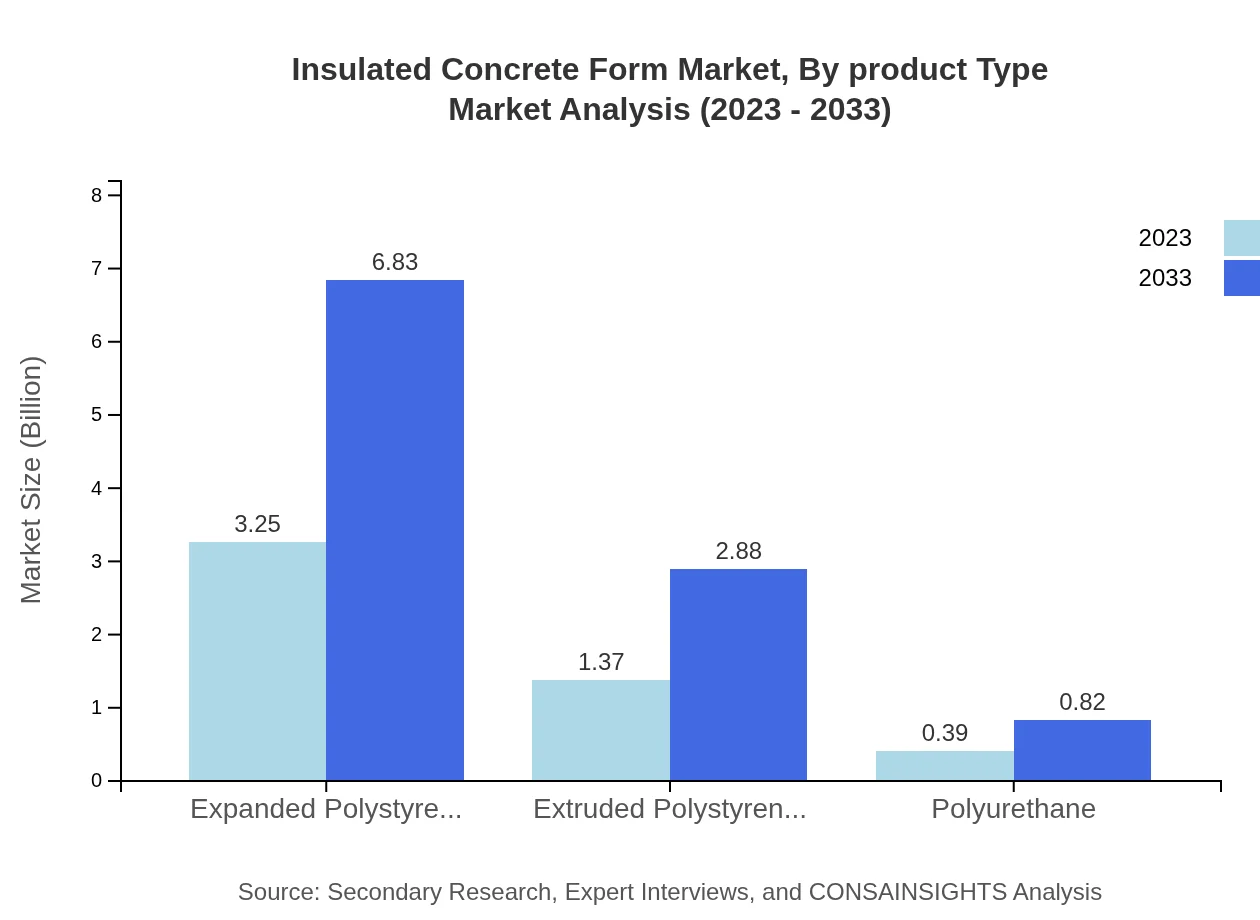

Insulated Concrete Form Market Analysis By Product Type

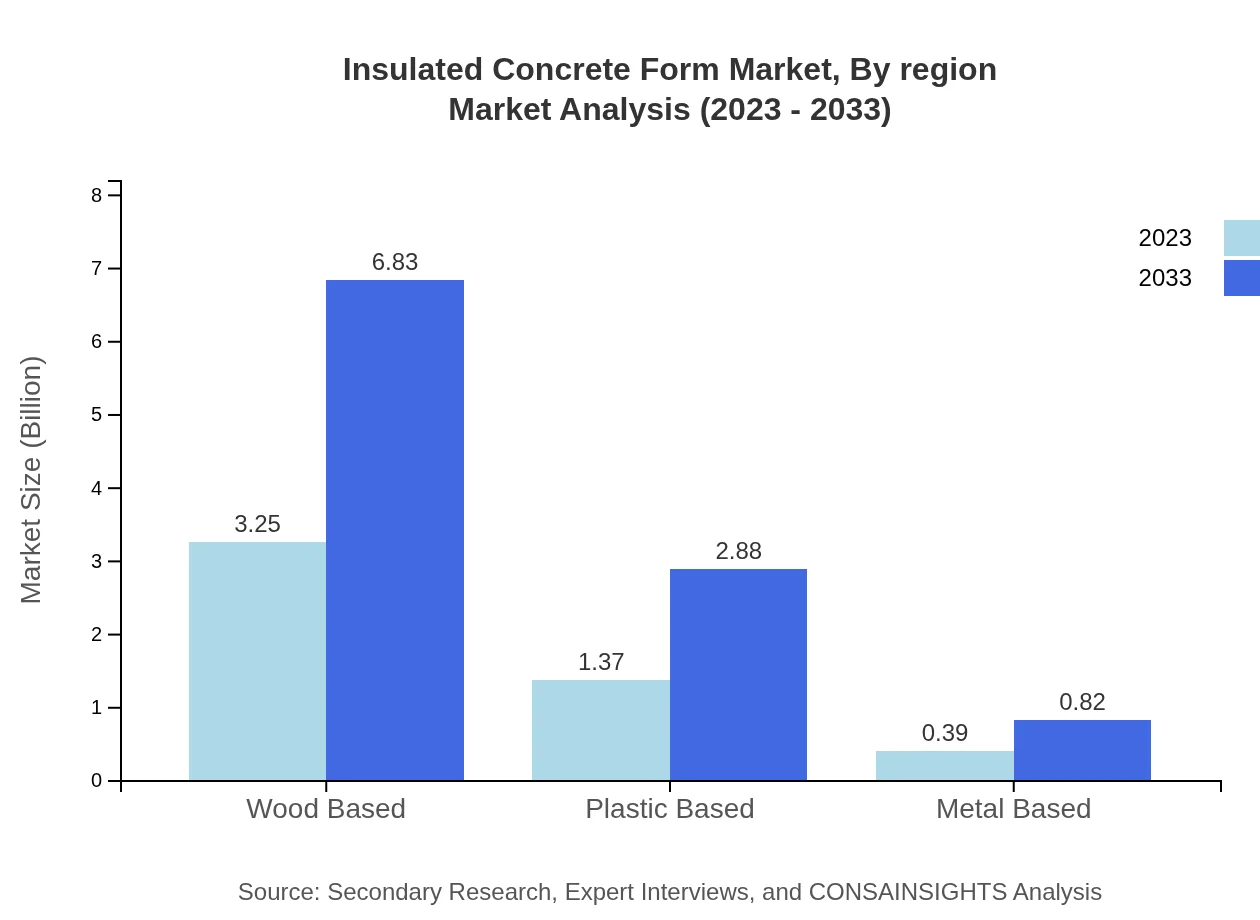

The market is predominantly driven by three main product types: Expanded Polystyrene (EPS), Extruded Polystyrene (XPS), and Polyurethane. In 2023, EPS holds the largest market share with a size of $3.25 billion and is projected to maintain this position through to 2033, reaching $6.83 billion. XPS and Polyurethane show substantial growth rates, with projections from $1.37 billion to $2.88 billion and $0.39 billion to $0.82 billion respectively, reflecting growing innovation and demand in custom insulation solutions.

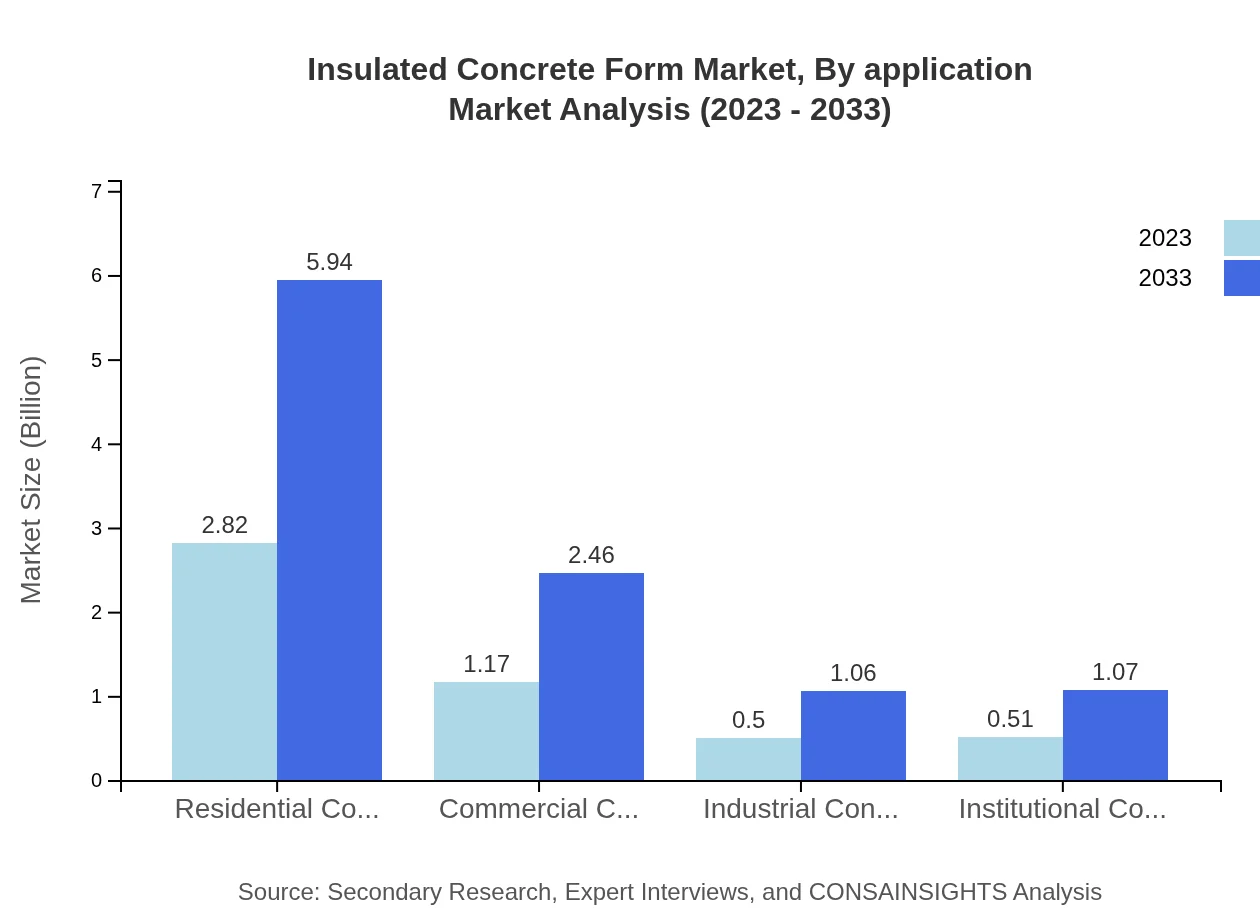

Insulated Concrete Form Market Analysis By Application

The application segment reveals residential construction as the leading segment, accounting for $2.82 billion in 2023 and growing to $5.94 billion by 2033. Commercial and industrial sectors follow, with notable growth characterized by increasing high-rise developments and infrastructure projects worldwide. Innovations in ICF technology increasingly allow multifunctionality in various applications, appealing to builders for diverse project requirements.

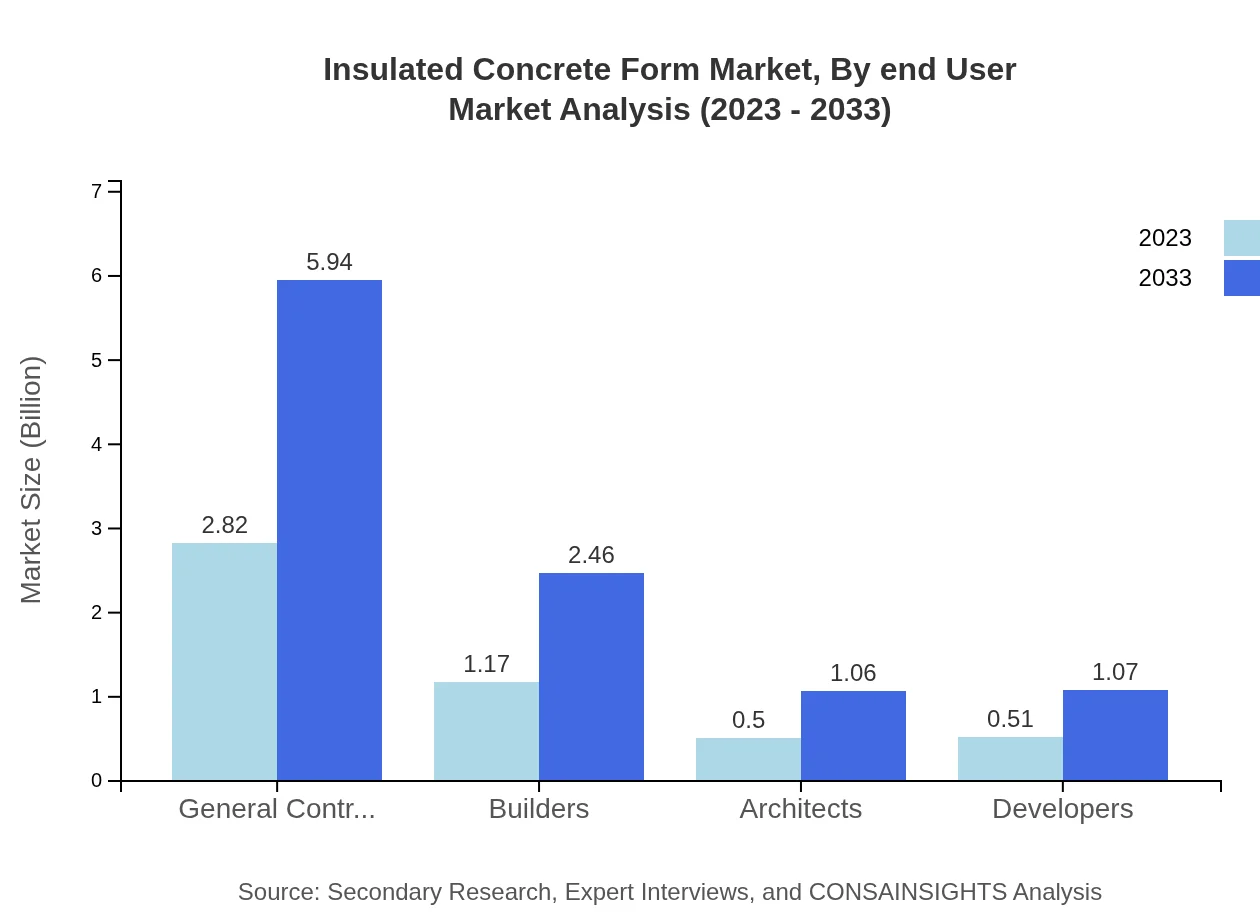

Insulated Concrete Form Market Analysis By End User

General contractors dominate the end-user segment, accounting for a significant market share with $2.82 billion in 2023 and projected to reach $5.94 billion by 2033. Builders, architects, and developers remain essential players in the segment as they rubberstamp the increasing adoption of ICF in their projects across various sectors, notably in residential and commercial buildings.

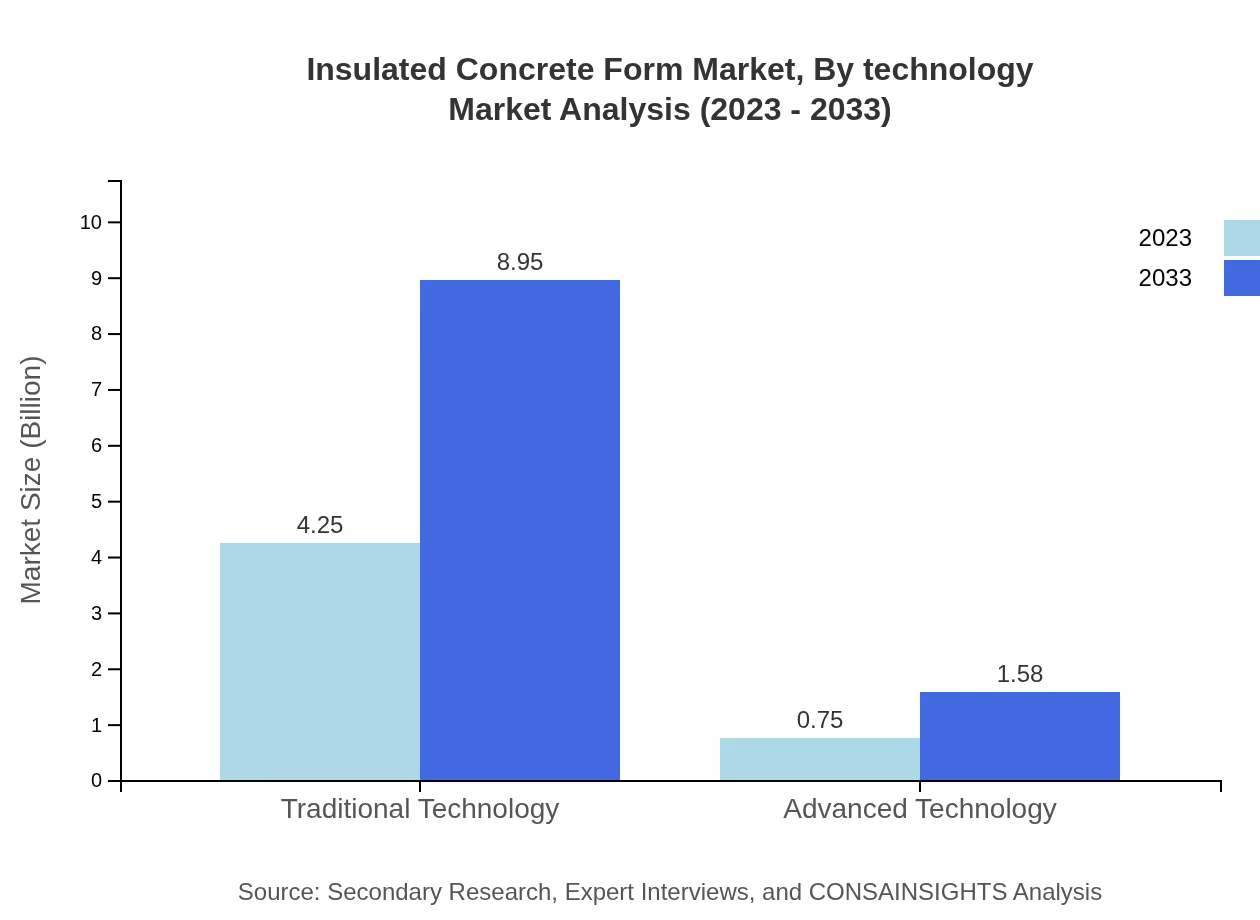

Insulated Concrete Form Market Analysis By Technology

The technology landscape in the ICF market is bifurcated into traditional and advanced technology. Traditional technology currently holds a dominating market share of $4.25 billion, projected to grow to $8.95 billion by 2033. However, advanced technology, representing approximately $0.75 billion in 2023, is expected to rapidly evolve, emphasizing innovation and efficiency in building design.

Insulated Concrete Form Market Analysis By Region

The ICF market structure by material types indicates an overwhelming preference for Expanded Polystyrene (EPS), which currently enjoys a market size of $3.25 billion in 2023, holding a dominant share of 64.9%. Extruded Polystyrene (XPS) accounts for 27.35% share, valued at $1.37 billion, while Polyurethane forms a smaller yet significant segment, providing HVAC solutions and specialized applications within the insulation framework.

Insulated Concrete Form Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Insulated Concrete Form Industry

Nudura:

Nudura is a leading manufacturer of insulated concrete forms, providing high-quality solutions for residential and commercial construction. Known for its innovative designs and commitment to sustainability, Nudura offers products that significantly reduce energy consumption and construction waste.Amvic Building System:

Amvic specializes in Insulated Concrete Form technology, providing a diverse range of energy-efficient building solutions. The company supports builders with training, resources, and innovative products designed to enhance construction speeds while lowering overall costs.Logix Insulated Concrete Forms:

Logix is renowned for its state-of-the-art ICF technology, delivering reliable solutions that cater to both residential and commercial markets. Their products are recognized for strength and energy efficiency, aligning with modern construction demands.ICF Tech:

With a focus on sustainable building practices, ICF Tech offers comprehensive ICF systems designed for diverse construction needs. The company emphasizes innovation and efficiency, contributing to its growing market share.We're grateful to work with incredible clients.

FAQs

What is the market size of insulated concrete form?

The global insulated concrete form market is valued at approximately $5 billion in 2023, with a projected compound annual growth rate (CAGR) of 7.5% through to 2033.

What are the key market players or companies in the insulated concrete form industry?

Key players in the insulated concrete form market include major manufacturers and suppliers who provide innovative building solutions and technologies, contributing significantly to market expansion and development.

What are the primary factors driving the growth in the insulated concrete form industry?

Growth factors include increasing demand for energy-efficient building materials, sustainability trends, and advances in construction technology that enhance performance and durability.

Which region is the fastest Growing in insulated concrete form?

North America is the fastest-growing region, with market size expected to grow from $1.73 billion in 2023 to $3.64 billion by 2033, reflecting a robust demand for efficient construction solutions.

Does ConsaInsights provide customized market report data for the insulated concrete form industry?

Yes, ConsaInsights offers customized market report data tailored to specific client needs, ensuring insights are relevant to individual business strategies and market dynamics.

What deliverables can I expect from this insulated concrete form market research project?

Expect comprehensive reports, detailed data analysis, market forecasts, segmentation insights, and strategic recommendations that empower informed decision-making in your business.

What are the market trends of insulated concrete form?

Current trends include increasing adoption of environmentally friendly products, innovations in insulation materials, and a shift toward modular construction techniques.