Insulation Coatings Market Report

Published Date: 22 January 2026 | Report Code: insulation-coatings

Insulation Coatings Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Insulation Coatings market from 2023 to 2033, detailing market size, growth trends, key segments, regional insights, and leading companies shaping the industry landscape.

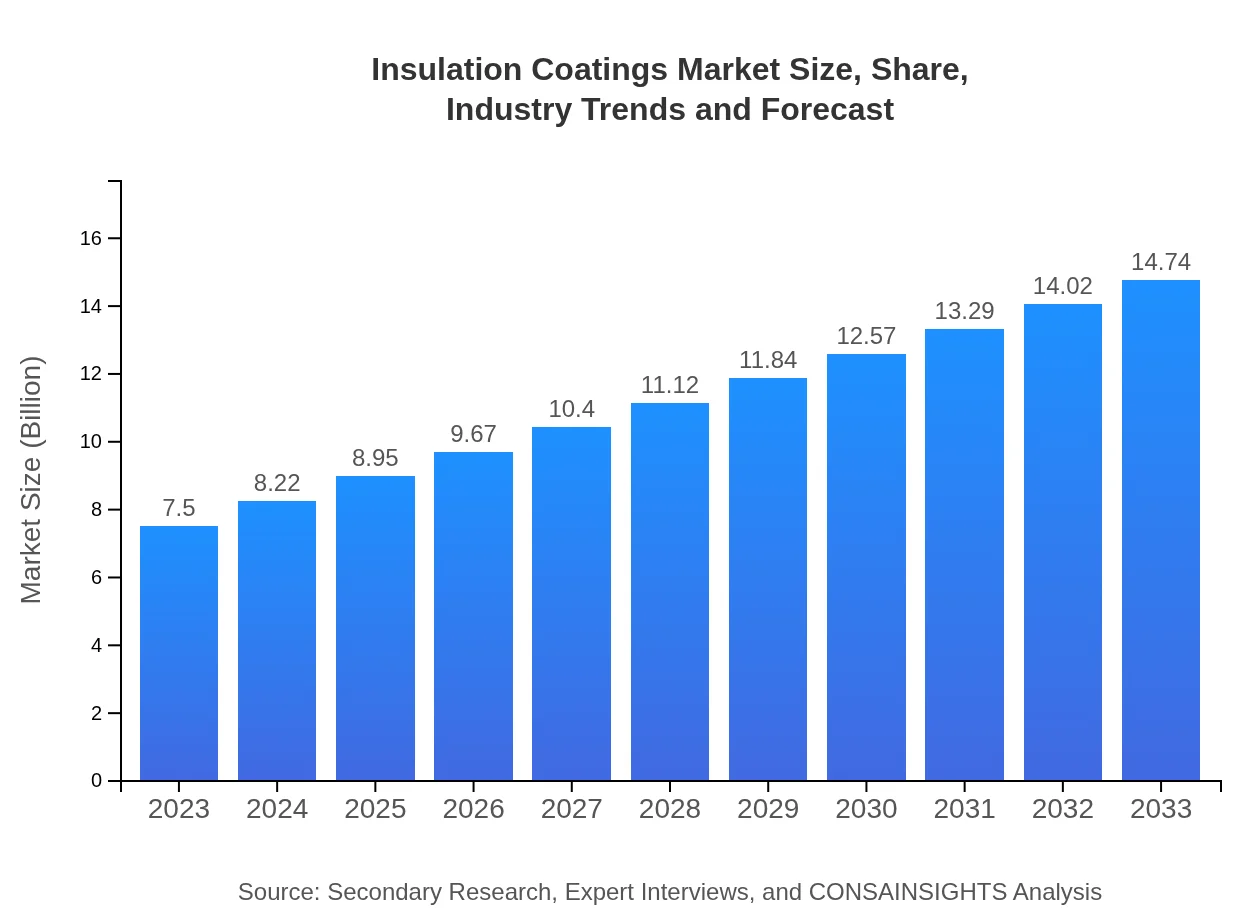

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $7.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $14.74 Billion |

| Top Companies | Sherwin-Williams, BASF, Axalta Coating Systems, 3M, RPM International |

| Last Modified Date | 22 January 2026 |

Insulation Coatings Market Overview

Customize Insulation Coatings Market Report market research report

- ✔ Get in-depth analysis of Insulation Coatings market size, growth, and forecasts.

- ✔ Understand Insulation Coatings's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Insulation Coatings

What is the Market Size & CAGR of Insulation Coatings market in 2023?

Insulation Coatings Industry Analysis

Insulation Coatings Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Insulation Coatings Market Analysis Report by Region

Europe Insulation Coatings Market Report:

Europe's Insulation Coatings market is set to grow from $2.49 billion in 2023 to $4.89 billion by 2033. The European market is heavily influenced by regulatory frameworks aimed at reducing energy consumption, alongside increasing investments in sustainable building technologies.Asia Pacific Insulation Coatings Market Report:

The Asia Pacific region is experiencing rapid urbanization and infrastructure development, contributing to a market size of approximately $1.43 billion in 2023, projected to reach $2.80 billion by 2033. Countries like China and India are crucial players, focusing on energy efficiency in construction, thereby driving demand for insulation coatings.North America Insulation Coatings Market Report:

North America holds a considerable market share, valued at approximately $2.46 billion in 2023, expected to grow to $4.83 billion by 2033. This growth is driven by the rising demand for energy-efficient products and stringent government regulations supporting insulation in both new and retrofitted buildings.South America Insulation Coatings Market Report:

In South America, the Insulation Coatings market is valued at around $0.29 billion in 2023, with forecasts predicting growth to $0.57 billion by 2033. The growth is supported by increasing investments in construction and a stronger focus on environmental regulations, although economic fluctuations may temper overall growth.Middle East & Africa Insulation Coatings Market Report:

The Middle East and Africa market for insulation coatings is projected to increase from $0.84 billion in 2023 to $1.65 billion by 2033. Growth is driven by infrastructural developments and heightened awareness regarding insulation performance in extreme climates.Tell us your focus area and get a customized research report.

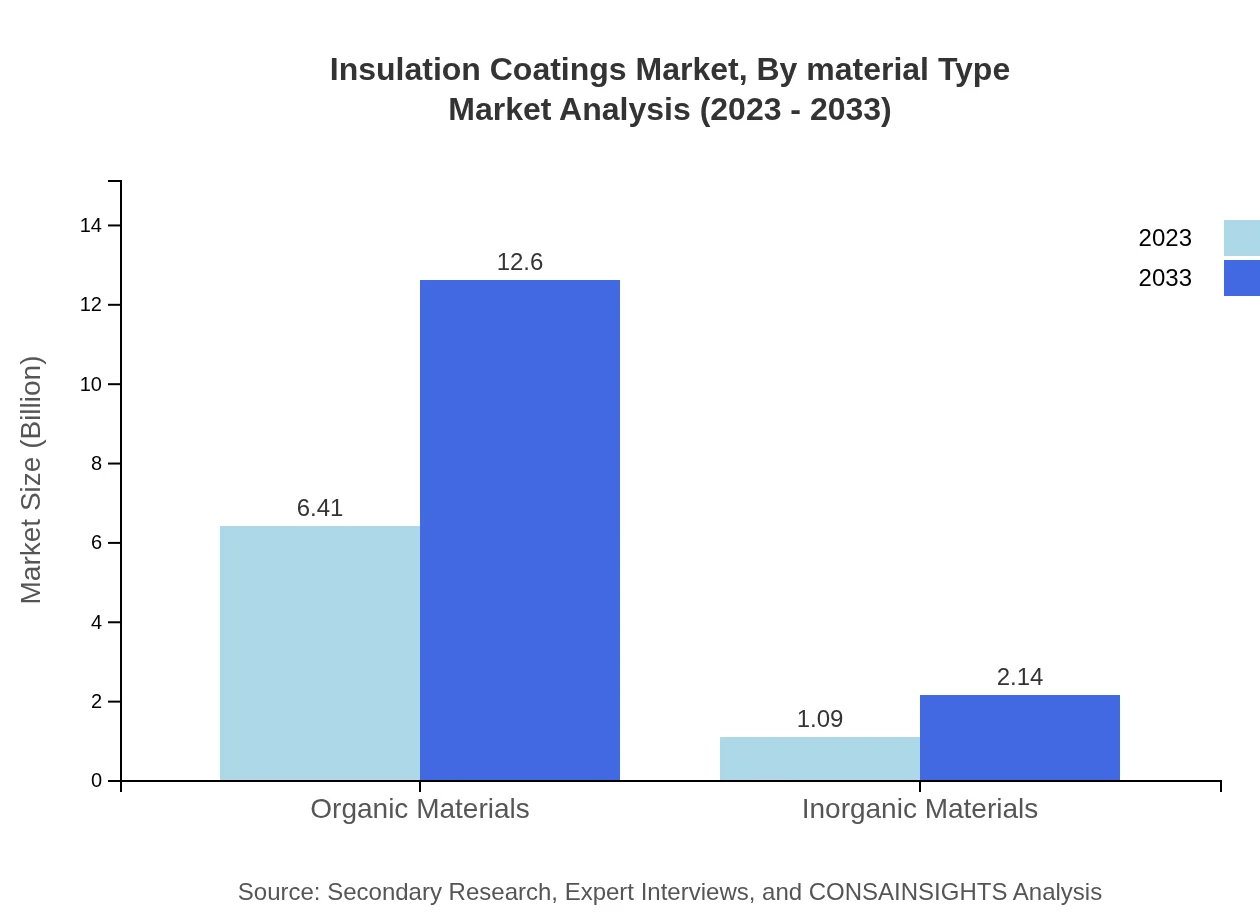

Insulation Coatings Market Analysis By Material Type

The Insulation Coatings market is divided into organic and inorganic materials, with organic materials dominating due to their superior insulation properties and flexibility. Organic-based coatings, including water-based and solvent-based products, accounted for 85.45% of the market in 2023, projected to sustain this share into 2033.

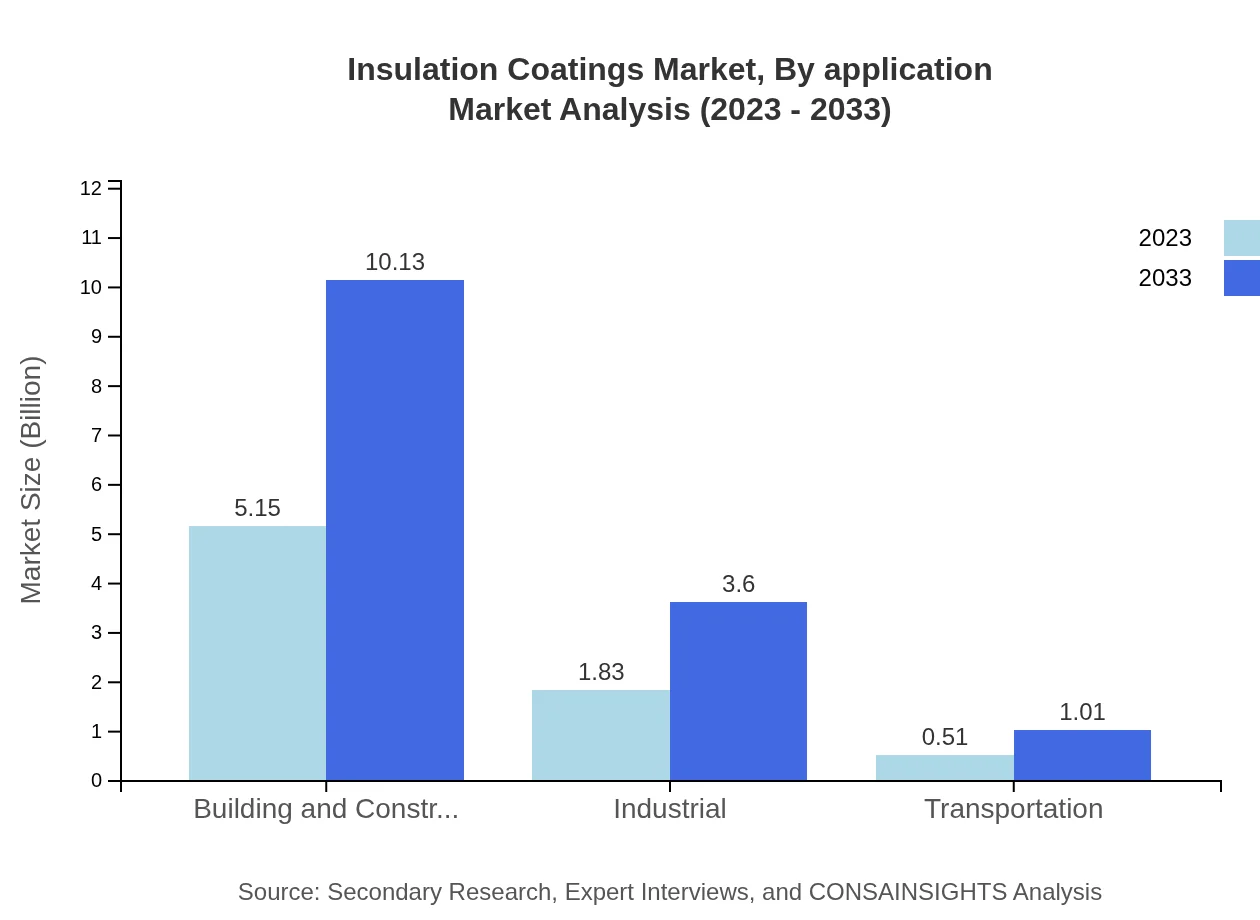

Insulation Coatings Market Analysis By Application

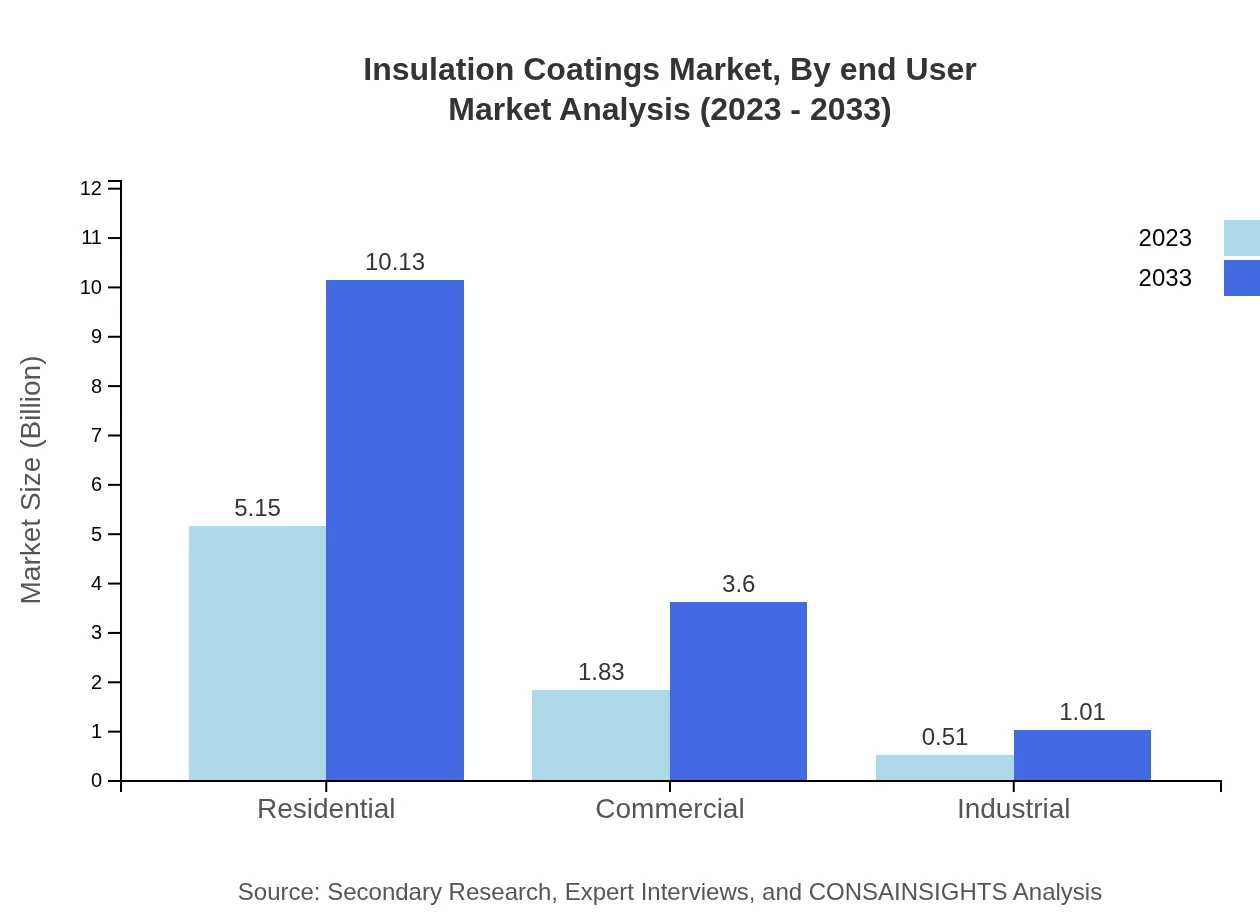

The primary applications of Insulation Coatings are in residential, commercial, and industrial sectors. The residential segment holds the largest market share, accounting for 68.71% in 2023 due to increased housing demands and refurbishment projects. Commercial applications are also on the rise, underpinning the market's growth trajectory.

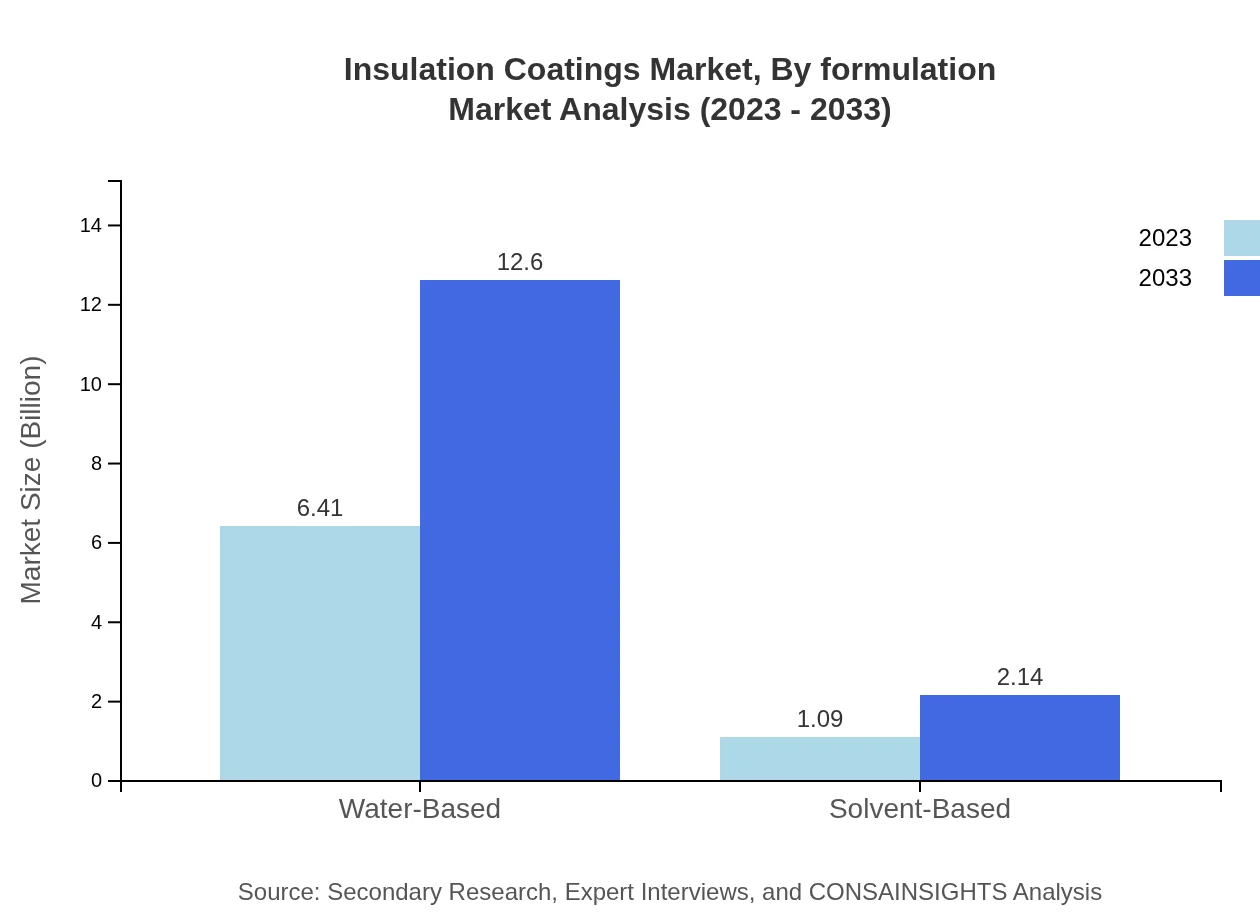

Insulation Coatings Market Analysis By Formulation

Formulations are classified mainly into water-based and solvent-based categories. Water-based insulation coatings dominate the market due to their eco-friendliness and compliance with stringent regulations. In 2023, water-based products contributed to 85.45% of the market share while solvent-based coatings covered the remaining 14.55%.

Insulation Coatings Market Analysis By End User

The end-user industries include residential, commercial, and industrial. The residential sector remains the largest consumer of insulation coatings, followed closely by the industrial segment, which is experiencing growing demand for energy-efficient solutions as industries seek to cut operational costs.

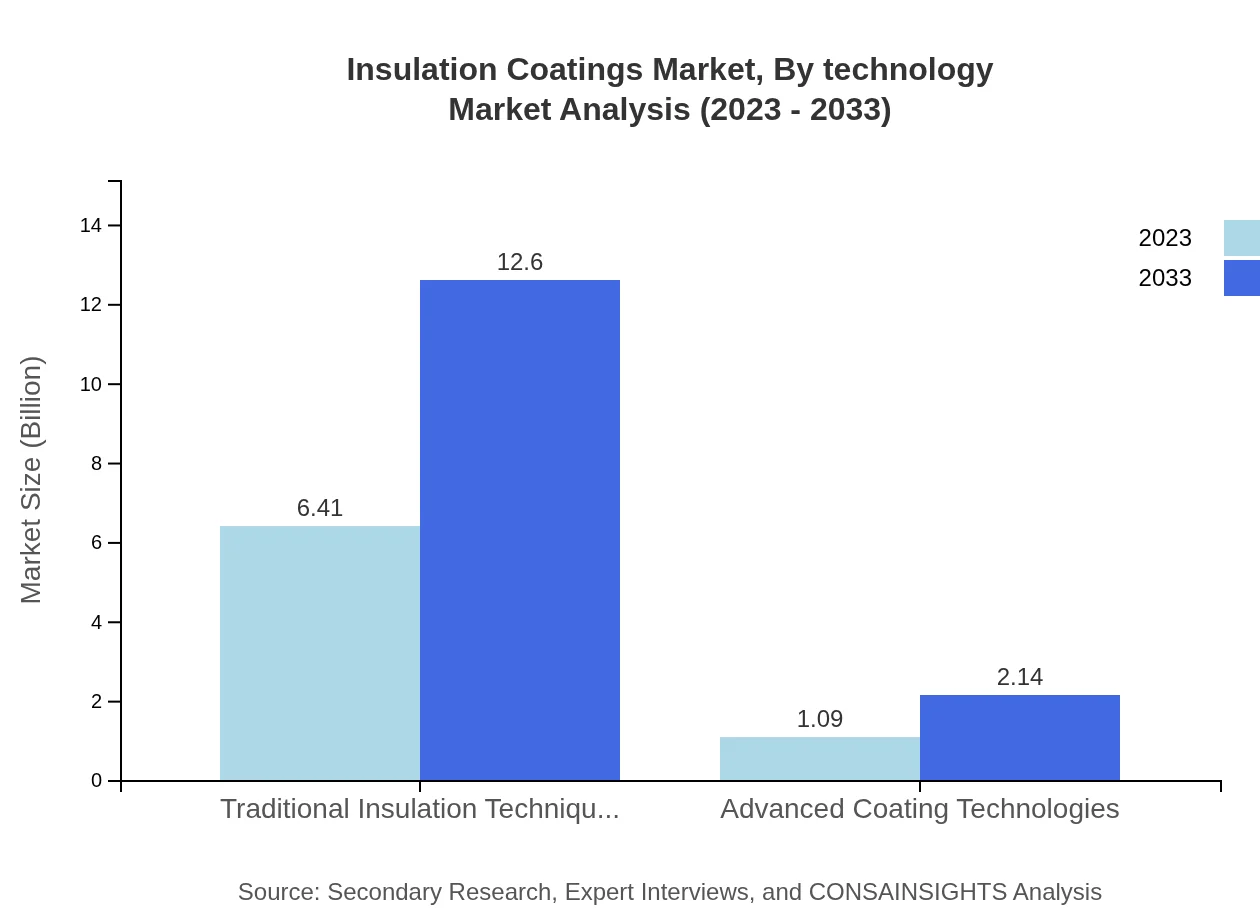

Insulation Coatings Market Analysis By Technology

Technological advancements in insulation coatings focus on developing innovative, energy-efficient products and formulations. Advanced coating technologies, such as nanotechnology and bio-based materials, are emerging as key trends. These innovations enhance thermal insulation performance and comply with environmental regulations.

Insulation Coatings Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Insulation Coatings Industry

Sherwin-Williams:

Sherwin-Williams is a leading manufacturer of high-performance coatings and provides a range of insulation coatings designed for energy efficiency and environmental safety.BASF:

BASF is a global leader in chemical manufacturing, enhancing the insulation coatings market with innovative solutions that improve building efficiency and sustainability.Axalta Coating Systems:

Axalta specializes in coatings technology and provides various insulation solutions that meet stringent industry standards while ensuring optimal performance.3M:

3M offers a diverse portfolio of insulation coating products, including advanced materials developed for various industrial and commercial applications.RPM International:

RPM International is a major player with a wide range of insulation coatings that cater to both protective and aesthetic requirements in the construction industry.We're grateful to work with incredible clients.

FAQs

What is the market size of insulation Coatings?

The insulation-coatings market is valued at $7.5 billion in 2023, with a projected CAGR of 6.8% from 2023 to 2033, indicating significant growth opportunities in this sector over the next decade.

What are the key market players or companies in this insulation Coatings industry?

The insulation-coatings market includes leading companies such as 3M, BASF, AkzoNobel, PPG Industries, and Arkema, which drive innovation and expand their market presence globally.

What are the primary factors driving the growth in the insulation Coatings industry?

Key growth drivers include increasing energy efficiency regulations, growing demand from the building and construction sector, and advancements in coating technologies that improve thermal performance and sustainability.

Which region is the fastest Growing in the insulation Coatings?

The Asia Pacific region is expected to exhibit the fastest growth in the insulation-coatings market, rising from $1.43 billion in 2023 to $2.80 billion in 2033, propelled by urbanization and infrastructure development.

Does ConsaInsights provide customized market report data for the insulation Coatings industry?

Yes, ConsaInsights offers tailored market report data for the insulation-coatings industry, allowing clients to obtain specific insights that suit their business needs and market objectives.

What deliverables can I expect from this insulation Coatings market research project?

Expected deliverables include comprehensive market analysis reports, trend assessments, competitive landscape reviews, and exclusive data on market segments, regions, and future projections.

What are the market trends of insulation Coatings?

Current trends in insulation-coatings include a shift towards sustainable materials, increased adoption of advanced coating technologies, and growing investments in energy-efficient building solutions, highlighting the sector's innovative trajectory.