Intrinsically Safe Equipment Market Report

Published Date: 31 January 2026 | Report Code: intrinsically-safe-equipment

Intrinsically Safe Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the Intrinsically Safe Equipment market, providing in-depth insights, analysis, and forecasts for the period 2023 to 2033. Key market aspects, trends, and regional performance are highlighted to give a comprehensive understanding of the industry's future.

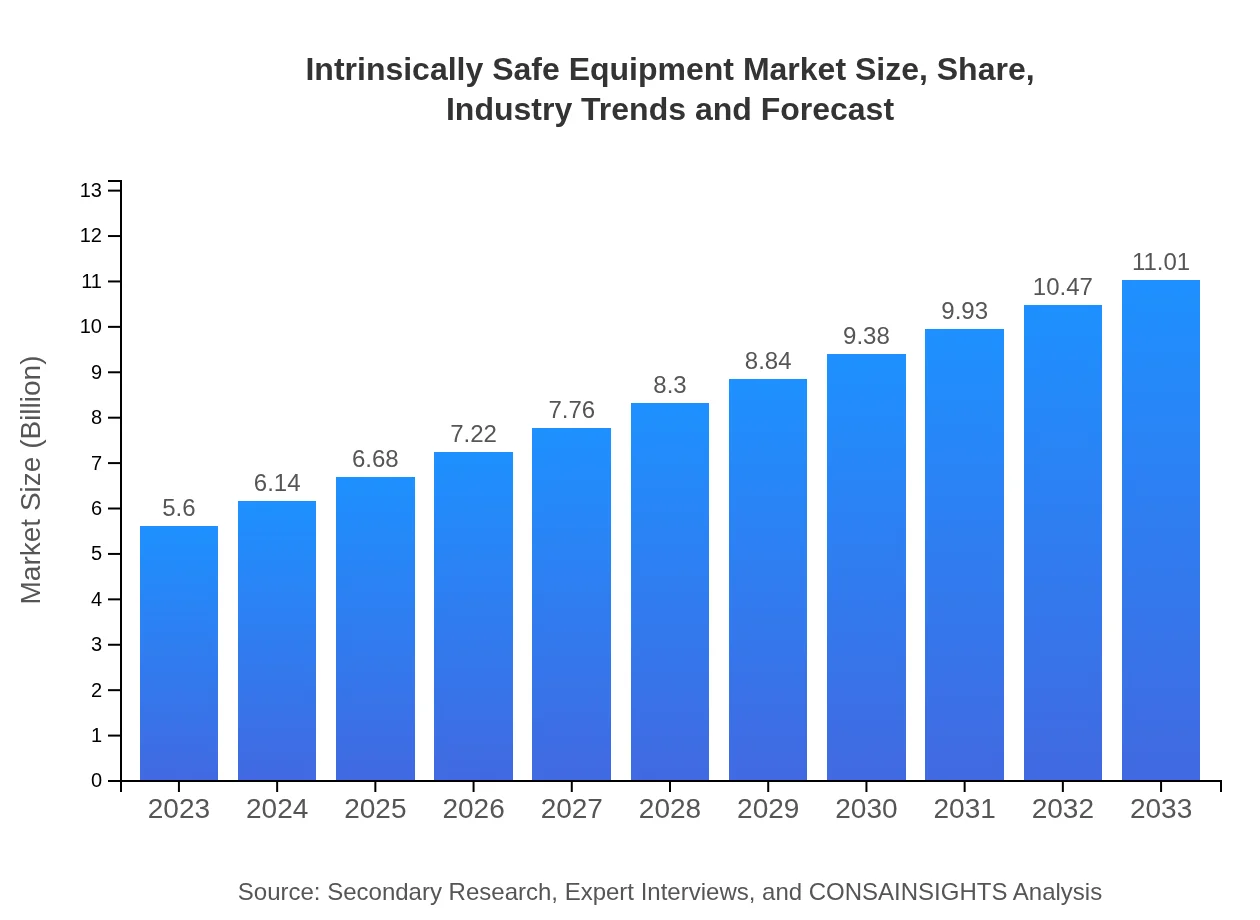

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $11.01 Billion |

| Top Companies | Emerson Electric Co., Rockwell Automation, Inc., Honeywell International Inc., Schneider Electric |

| Last Modified Date | 31 January 2026 |

Intrinsically Safe Equipment Market Overview

Customize Intrinsically Safe Equipment Market Report market research report

- ✔ Get in-depth analysis of Intrinsically Safe Equipment market size, growth, and forecasts.

- ✔ Understand Intrinsically Safe Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Intrinsically Safe Equipment

What is the Market Size & CAGR of Intrinsically Safe Equipment market in 2023?

Intrinsically Safe Equipment Industry Analysis

Intrinsically Safe Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Intrinsically Safe Equipment Market Analysis Report by Region

Europe Intrinsically Safe Equipment Market Report:

Europe’s Intrinsically Safe Equipment market is poised to rise from $1.53 billion in 2023 to $3.00 billion by 2033, bolstered by regulatory demands for safety in manufacturing and chemical industries, alongside technological advancements in safety equipment.Asia Pacific Intrinsically Safe Equipment Market Report:

In 2023, the Asia Pacific Intrinsically Safe Equipment market is valued at approximately $1.11 billion and expected to grow to $2.18 billion by 2033. Rapid industrialization and increased mining activities in countries like China and India are significant contributing factors.North America Intrinsically Safe Equipment Market Report:

North America’s market is estimated at $1.80 billion in 2023 and likely to increase to $3.54 billion by 2033, driven by stringent regulatory measures and significant investments in safety equipment amid growing industrial operations.South America Intrinsically Safe Equipment Market Report:

The South American market is projected to grow from $0.56 billion in 2023 to $1.09 billion in 2033. This growth is attributed to the expanding oil and gas sectors and a rising awareness of safety protocols within industries.Middle East & Africa Intrinsically Safe Equipment Market Report:

The Middle East and Africa market is expected to grow from $0.61 billion in 2023 to $1.19 billion by 2033. The region's increasing focus on oil, gas, and chemicals industries, alongside heightened safety regulations, drives this market forward.Tell us your focus area and get a customized research report.

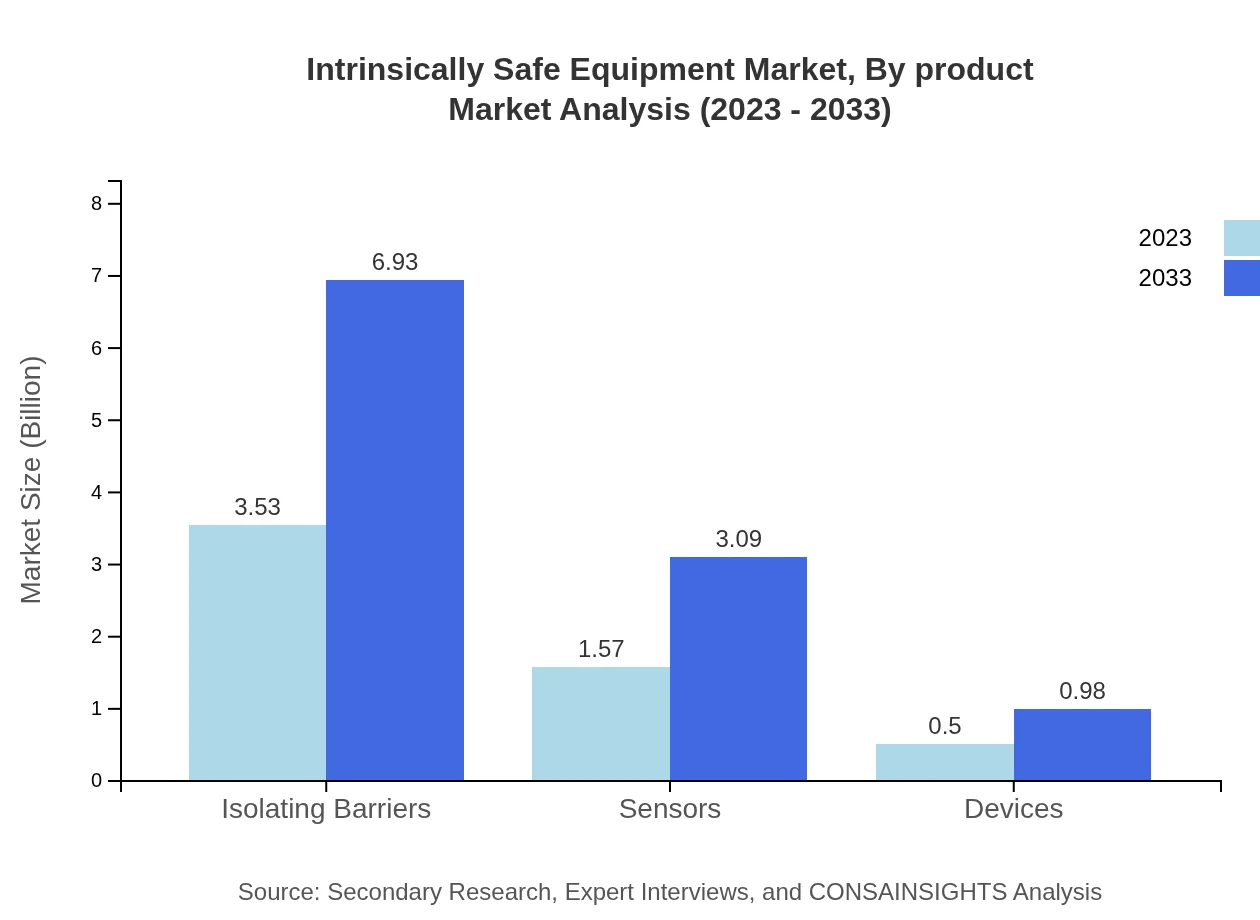

Intrinsically Safe Equipment Market Analysis By Product

The product segment of the intrinsically safe equipment market comprises isolating barriers, sensors, and various industrial devices. In 2023, isolating barriers lead the segment with a market of $3.53 billion, projected to grow to $6.93 billion by 2033, indicating a strong emphasis on protective safety measures. Sensors follow with a market worth $1.57 billion in 2023, expected to reach $3.09 billion by 2033, reflecting the demand for advanced monitoring systems.

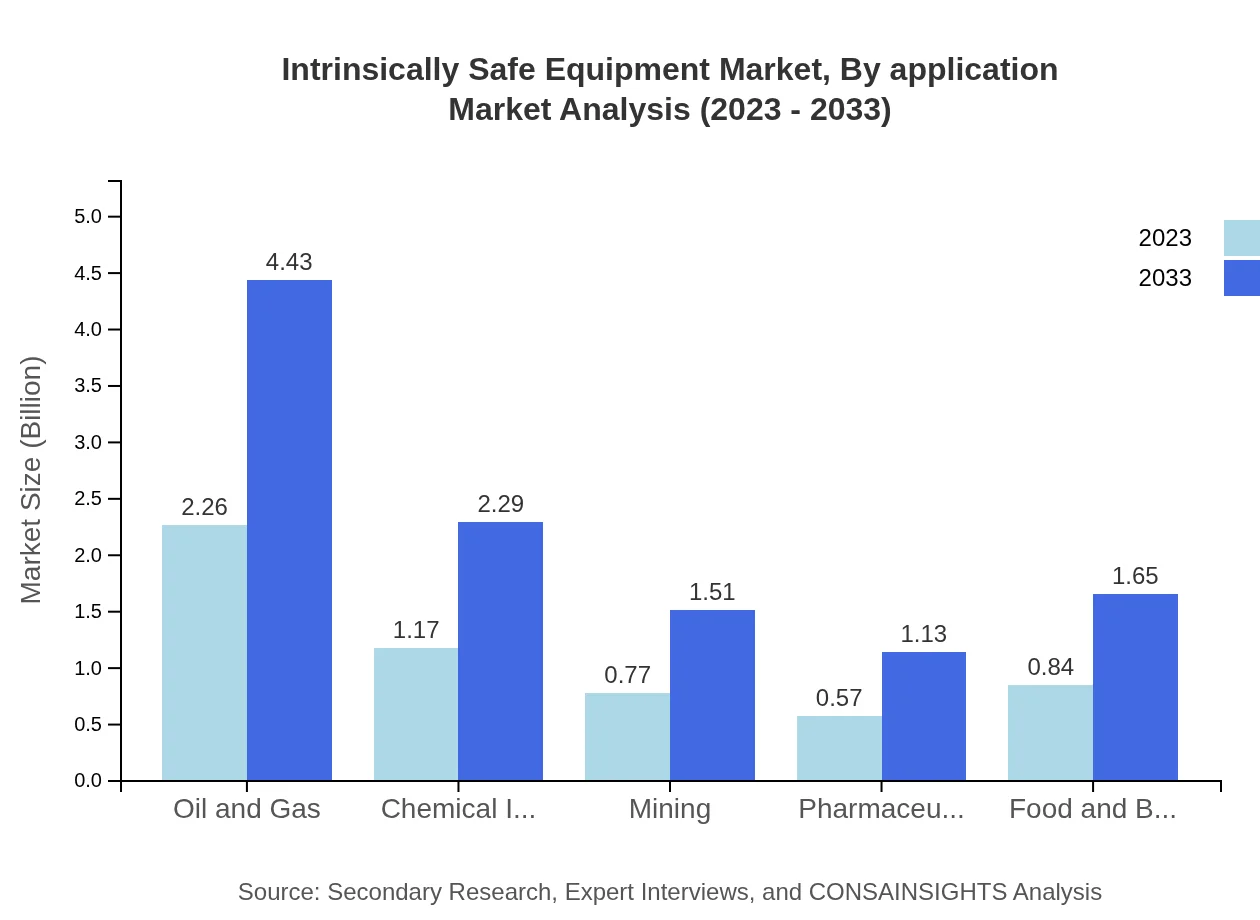

Intrinsically Safe Equipment Market Analysis By Application

Applications of intrinsically safe equipment span across sectors like oil and gas, mining, chemicals, and pharmaceuticals. The oil and gas segment is anticipated to maintain its dominance with a market growth from $2.26 billion in 2023 to $4.43 billion in 2033, showcasing the necessity for stringent safety measures in high-risk operating environments.

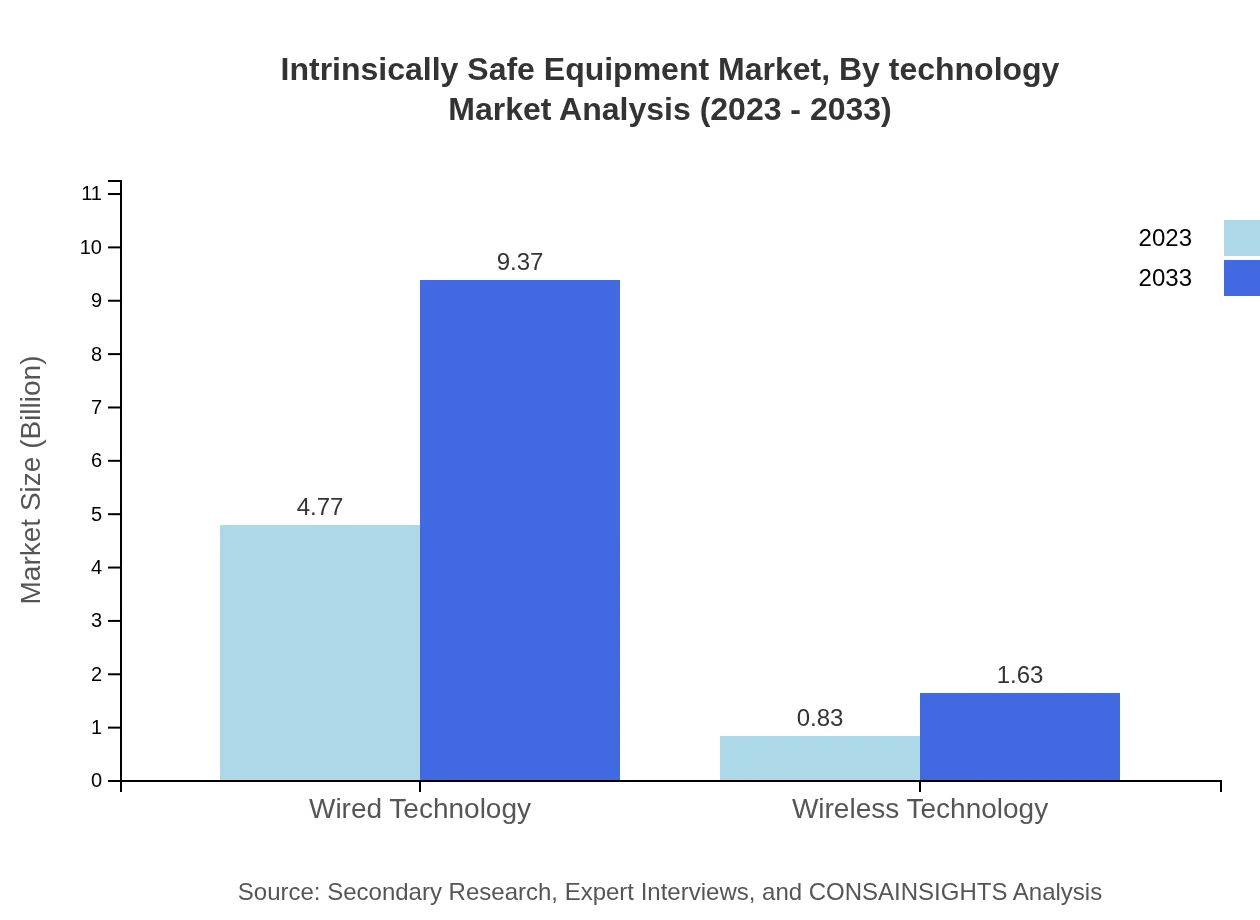

Intrinsically Safe Equipment Market Analysis By Technology

The market is segmented into wired and wireless technologies. Wired technology dominates with a market size of $4.77 billion in 2023, projected to see growth to $9.37 billion by 2033. Conversely, the wireless segment is estimated to grow from $0.83 billion in 2023 to $1.63 billion by 2033, driven by advancements in wireless communication and monitoring technologies.

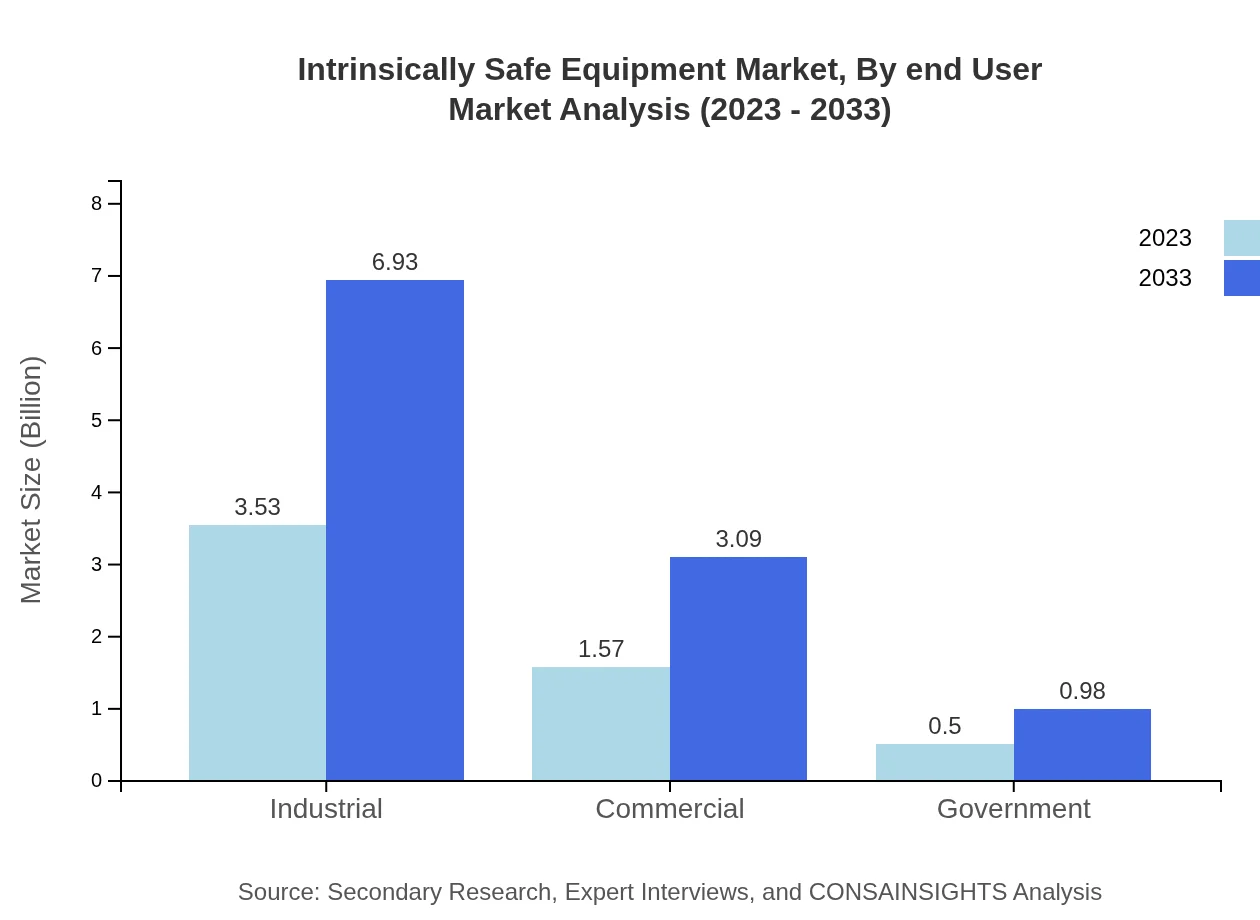

Intrinsically Safe Equipment Market Analysis By End User

End-user industries for intrinsically safe equipment include industrial, commercial, and government sectors. The industrial segment leads with $3.53 billion in 2023, and is forecasted to reach $6.93 billion by 2033, reflecting the sector's growing need for safety compliance amid expanding industrial activities.

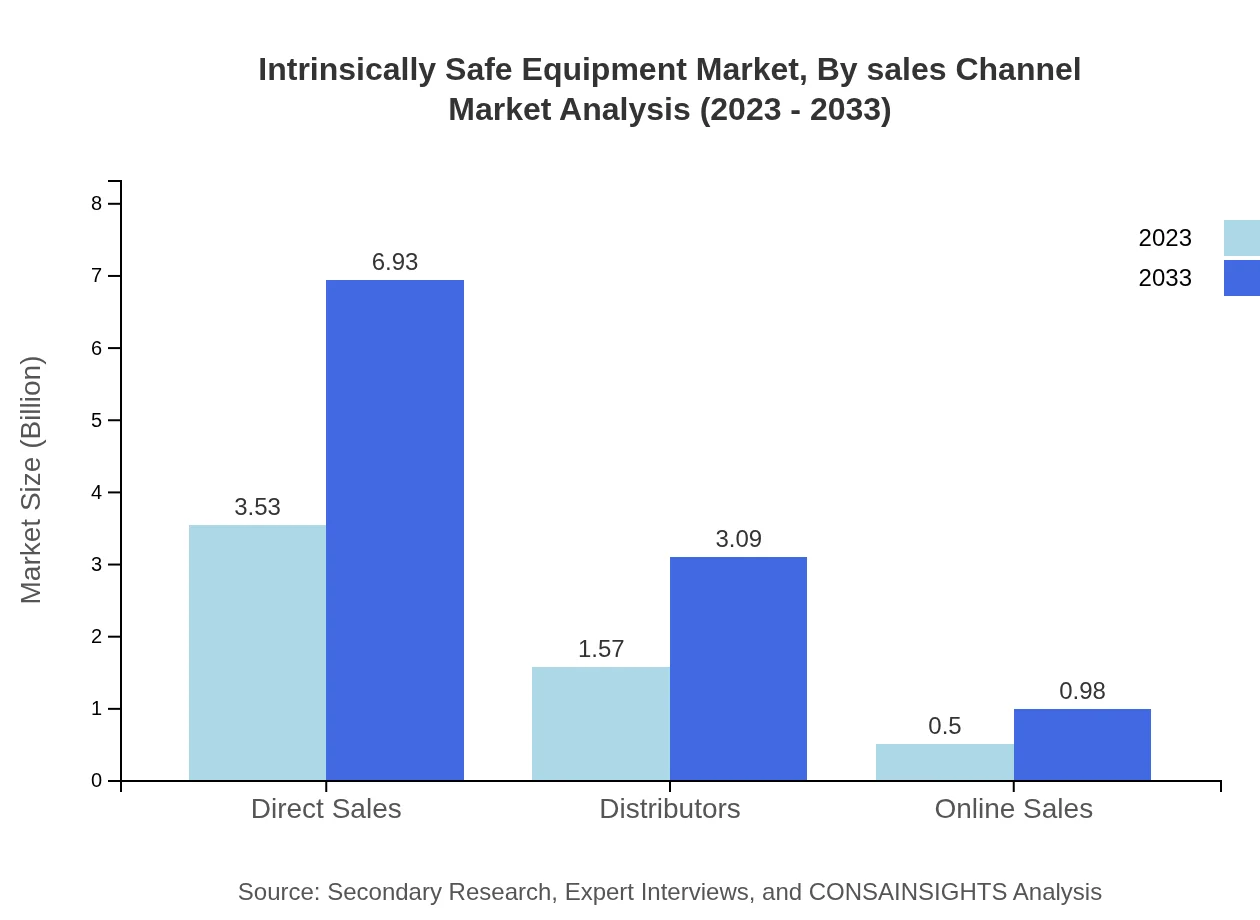

Intrinsically Safe Equipment Market Analysis By Sales Channel

Sales channels for intrinsically safe equipment include direct sales, distributors, and online sales. Direct sales dominate the market, accounting for $3.53 billion in 2023 and expected to grow to $6.93 billion by 2033. Distributors and online sales channels are also gaining traction, with substantial market shares driven by increasing safety awareness.

Intrinsically Safe Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Intrinsically Safe Equipment Industry

Emerson Electric Co.:

A global leader in automation and safety solutions, Emerson offers a wide range of intrinsically safe products aimed at enhancing safety standards within hazardous environments.Rockwell Automation, Inc.:

As a prominent technology provider, Rockwell Automation focuses on safety and efficiency in industrial processes, including a suite of intrinsically safe device solutions.Honeywell International Inc.:

Honeywell is a major player in the market, providing various intrinsically safe equipment tailored for industries with stringent safety compliance requirements.Schneider Electric:

A leading company in energy management and safety solutions, Schneider Electric produces a range of intrinsically safe equipment to ensure safe operational environments.We're grateful to work with incredible clients.

FAQs

What is the market size of intrinsically Safe Equipment?

The intrinsically safe equipment market is valued at approximately $5.6 billion in 2023, and is projected to grow at a CAGR of 6.8% over the next decade, reflecting increasing industrial safety regulations and technological advancements.

What are the key market players or companies in this intrinsically Safe Equipment industry?

Key players in the intrinsically safe equipment market include companies like ABB Ltd., Siemens AG, Schneider Electric, Pepperl+Fuchs, and Extronics Ltd. These companies lead in technology innovation and market share.

What are the primary factors driving the growth in the intrinsically Safe Equipment industry?

Growth is primarily driven by increasing safety regulations, rising awareness of workplace safety, advancements in technology, and growing industrial applications, particularly in sectors like oil and gas, chemicals, and pharmaceuticals.

Which region is the fastest Growing in the intrinsically Safe Equipment?

The Asia Pacific region is the fastest-growing market, expected to expand from $1.11 billion in 2023 to $2.18 billion by 2033, driven by industrial growth and stringent safety regulations.

Does ConsaInsights provide customized market report data for the intrinsically Safe Equipment industry?

Yes, ConsaInsights offers tailored market report data for the intrinsically safe equipment industry, allowing clients to receive insights and analysis specific to their needs and market conditions.

What deliverables can I expect from this intrinsically Safe Equipment market research project?

Deliverables include comprehensive market analysis reports, trend analysis, competitive landscape insights, regional market data, and tailored recommendations aimed at enhancing strategic decision-making.

What are the market trends of intrinsically Safe Equipment?

Current trends include a rise in wireless technology adoption, integration of IoT solutions, increasing demand for advanced sensor technologies, and a shift towards sustainable industrial practices.