Ion Milling System Market Report

Published Date: 22 January 2026 | Report Code: ion-milling-system

Ion Milling System Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Ion Milling System market from 2023 to 2033, including market size, growth trends, regional insights, and leading companies. It aims to deliver valuable data for stakeholders to make informed decisions.

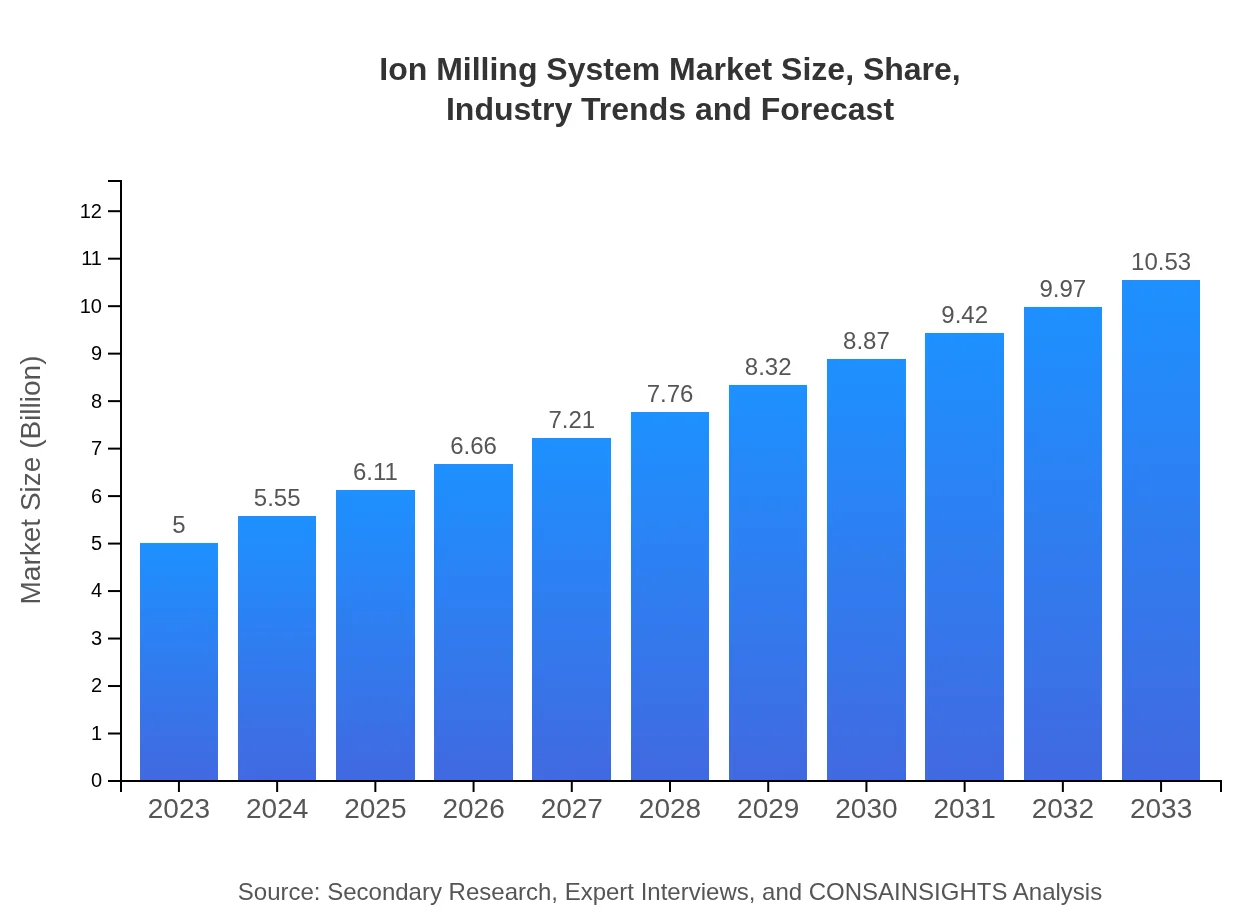

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Hitachi High-Technologies Corporation, AMETEK, Inc., Gatan, Inc. |

| Last Modified Date | 22 January 2026 |

Ion Milling System Market Overview

Customize Ion Milling System Market Report market research report

- ✔ Get in-depth analysis of Ion Milling System market size, growth, and forecasts.

- ✔ Understand Ion Milling System's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Ion Milling System

What is the Market Size & CAGR of Ion Milling System market in 2023?

Ion Milling System Industry Analysis

Ion Milling System Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Ion Milling System Market Analysis Report by Region

Europe Ion Milling System Market Report:

Europe's Ion Milling System market is projected to expand from $1.31 billion in 2023 to $2.76 billion by 2033, translating to a CAGR of 7.7%. The region's focus on advanced technology in industrial applications and robust research frameworks supports market development.Asia Pacific Ion Milling System Market Report:

In the Asia Pacific region, the Ion Milling System market is projected to grow from $0.97 billion in 2023 to $2.03 billion by 2033, reflecting a compound annual growth rate (CAGR) of around 7.7%. The substantial growth in this region is driven by the rising semiconductor manufacturing activities and advancements in materials science research.North America Ion Milling System Market Report:

The North American market will experience significant growth, expected to rise from $1.94 billion in 2023 to $4.09 billion by 2033, reflecting a CAGR of 7.4%. This growth is propelled by the region’s strong emphasis on technological advancements and innovations in semiconductor and electronics manufacturing.South America Ion Milling System Market Report:

The South American Ion Milling System market is expected to grow from $0.39 billion in 2023 to $0.81 billion by 2033, with a CAGR of 7.6%. Investments in industrial capabilities and an increasing number of research initiatives are contributing factors to market growth in this region.Middle East & Africa Ion Milling System Market Report:

The Middle East and Africa market is expected to grow from $0.39 billion in 2023 to $0.83 billion by 2033, with a CAGR of 7.7%. Increased collaboration between global technology leaders and local firms aimed at enhancing research facilities may contribute to market growth.Tell us your focus area and get a customized research report.

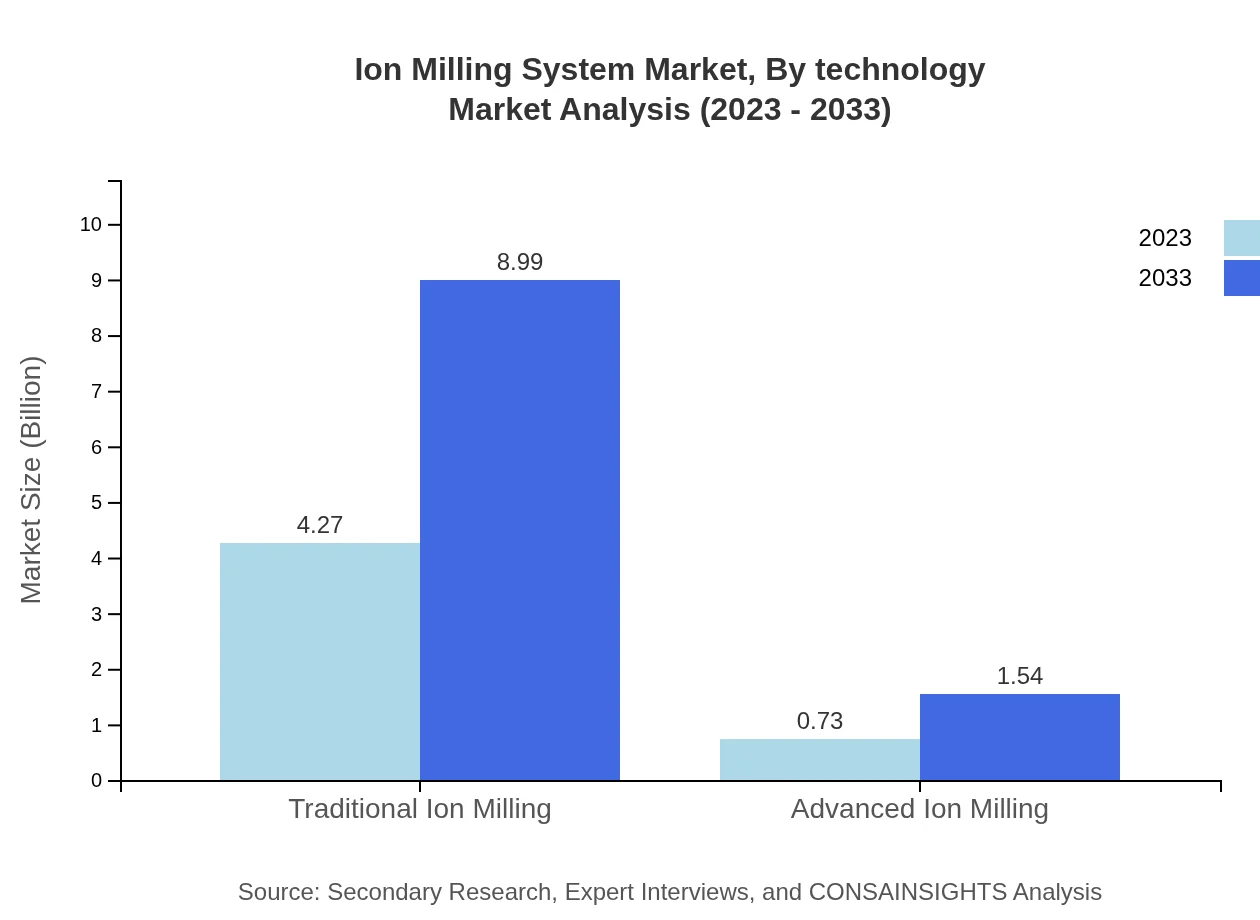

Ion Milling System Market Analysis By Technology

The segmentation based on technology distinguishes between Traditional Ion Milling and Advanced Ion Milling. In 2023, Traditional Ion Milling holds a significant market size of $4.27 billion, expected to increase to $8.99 billion by 2033, maintaining an 85.41% share of the market. In contrast, Advanced Ion Milling, while smaller, shows promising growth from a market size of $0.73 billion in 2023 to $1.54 billion in 2033, ultimately capturing a 14.59% market share.

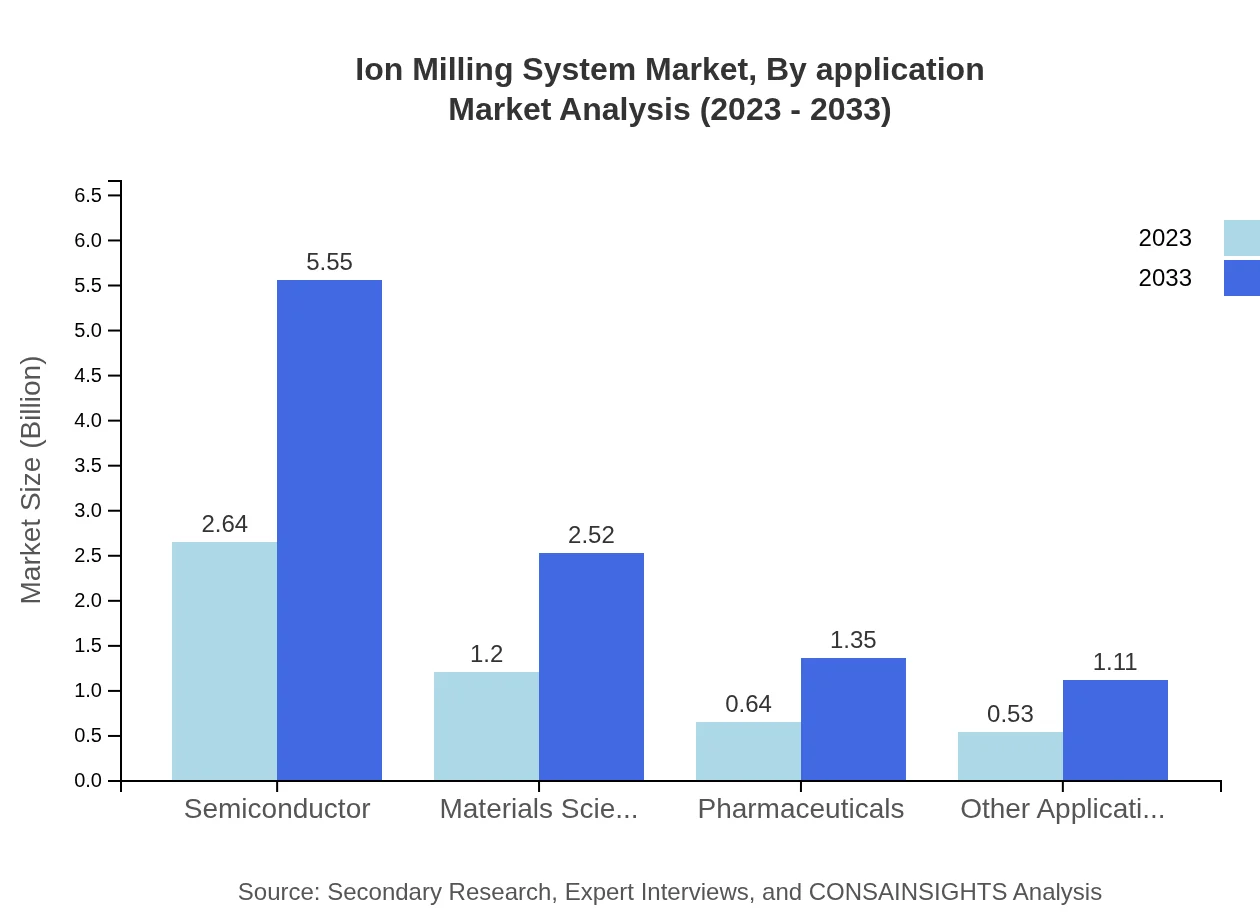

Ion Milling System Market Analysis By Application

The major applications , including Electronics, Semiconductor, Materials Science, and Pharmaceuticals, show substantial demand. Electronics remains dominant with a size of $2.64 billion in 2023, growing to $5.55 billion by 2033, holding a share of 52.71%. Research Institutes also exhibit strong growth potential from $1.20 billion to $2.52 billion in the same period, maintaining a 23.95% market share.

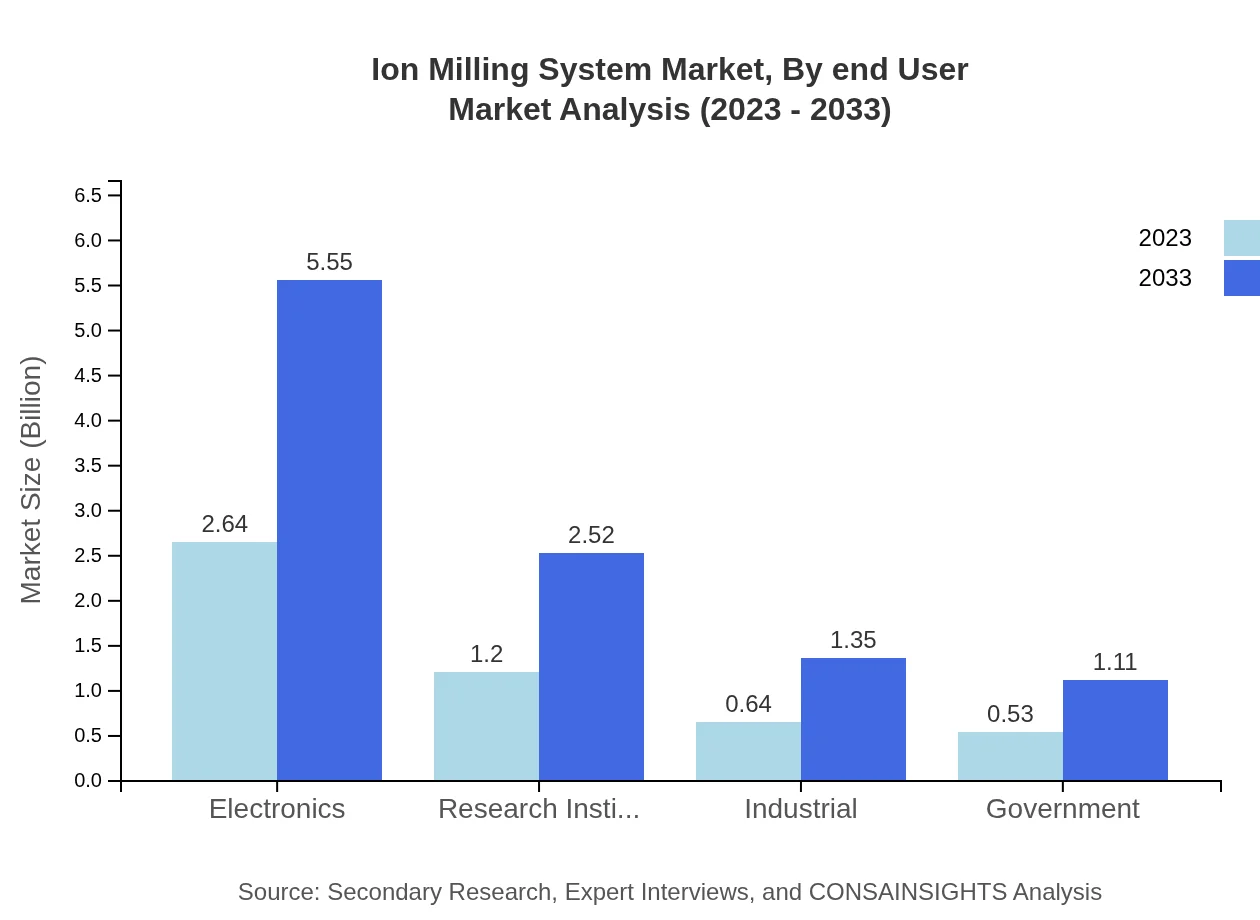

Ion Milling System Market Analysis By End User

The end-user segmentation reveals significant contributions from government and industrial sectors. As of 2023, the Government sector contributes $0.53 billion, expected to rise to $1.11 billion by 2033. Meanwhile, the Industrial sector rises from $0.64 billion to $1.35 billion, demonstrating the ongoing need for precision manufacturing across various applications.

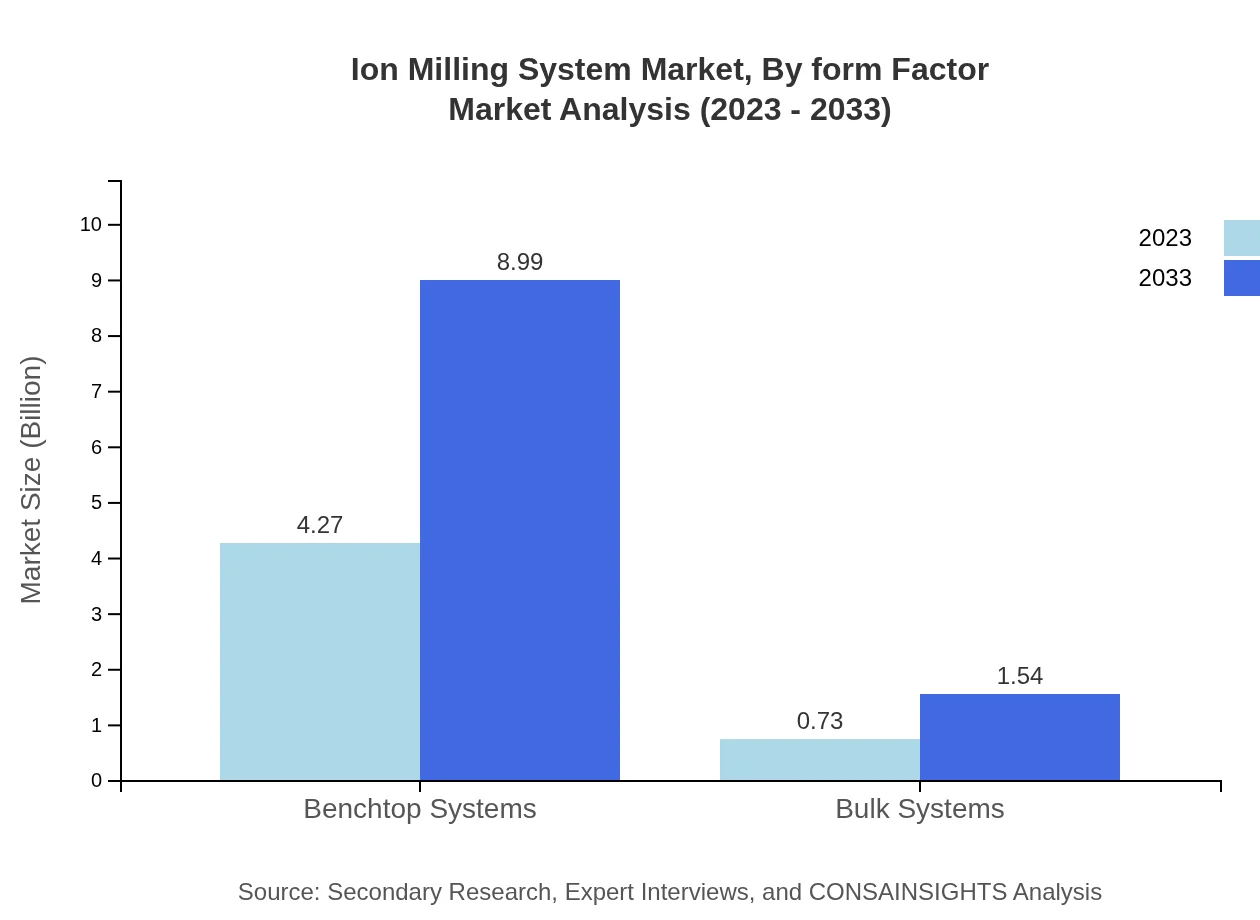

Ion Milling System Market Analysis By Form Factor

Form factor segmentation shows Benchtop Systems leading the market with a size of $4.27 billion in 2023 and projected to grow to $8.99 billion by 2033, holding 85.41% of the market. Bulk Systems are smaller, with a size of $0.73 billion in 2023, rising to $1.54 billion by 2033, capturing 14.59% market share.

Ion Milling System Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Ion Milling System Industry

Hitachi High-Technologies Corporation:

Hitachi High-Technologies offers a range of ion milling technologies ideal for semiconductor applications, focusing on precision and efficiency in material processing.AMETEK, Inc.:

AMETEK is a leading global manufacturer of electronic instruments and electromechanical devices with advanced ion milling technologies widely used in research and industrial applications.Gatan, Inc.:

Gatan specializes in innovative microscopy solutions, including ion milling systems designed to enhance analytical capabilities in high-resolution imaging.We're grateful to work with incredible clients.

FAQs

What is the market size of ion Milling System?

The global market size of the ion-milling-system is projected to reach approximately $5 billion by 2033, with a compound annual growth rate (CAGR) of 7.5% between 2023 and 2033, indicating significant growth potential.

What are the key market players or companies in the ion Milling System industry?

Key players in the ion-milling-system industry include major equipment manufacturers and technology providers that focus on semiconductor fabrication, materials research, and scientific instruments, contributing significantly to the industry's growth and innovation.

What are the primary factors driving the growth in the ion Milling System industry?

Growth in the ion-milling-system industry is driven by increasing demand in semiconductor applications, advancements in materials science, and the rising need for precision in microfabrication technologies across various sectors, leading to higher investment and R&D.

Which region is the fastest Growing in the ion Milling System?

The Asia Pacific region is the fastest-growing market for ion-milling-systems, with projections of growth from $0.97 billion in 2023 to $2.03 billion by 2033, showcasing substantial opportunities driven by semiconductor manufacturing and R&D activities.

Does ConsaInsights provide customized market report data for the ion Milling System industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the ion-milling-system industry, enabling businesses to receive insights and analytics according to their unique operational models and market challenges.

What deliverables can I expect from this ion Milling System market research project?

Expect detailed market analysis, including data on market size, segmentation, competitive landscape, regional trends, and forecasts, along with actionable insights to guide strategic decisions in the ion-milling-system sector.

What are the market trends of ion Milling System?

Key trends in the ion-milling-system market include a gradual shift towards advanced materials processing, increased integration of automation in manufacturing, and the growing importance of sustainable practices in equipment design and production.