Iot In Manufacturing Market Report

Published Date: 31 January 2026 | Report Code: iot-in-manufacturing

Iot In Manufacturing Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the IoT in manufacturing sector, offering critical insights on market dynamics, trends, and forecasts for the period 2023-2033. It covers key areas including market size, segmentation, regional dynamics, and competitive landscape.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

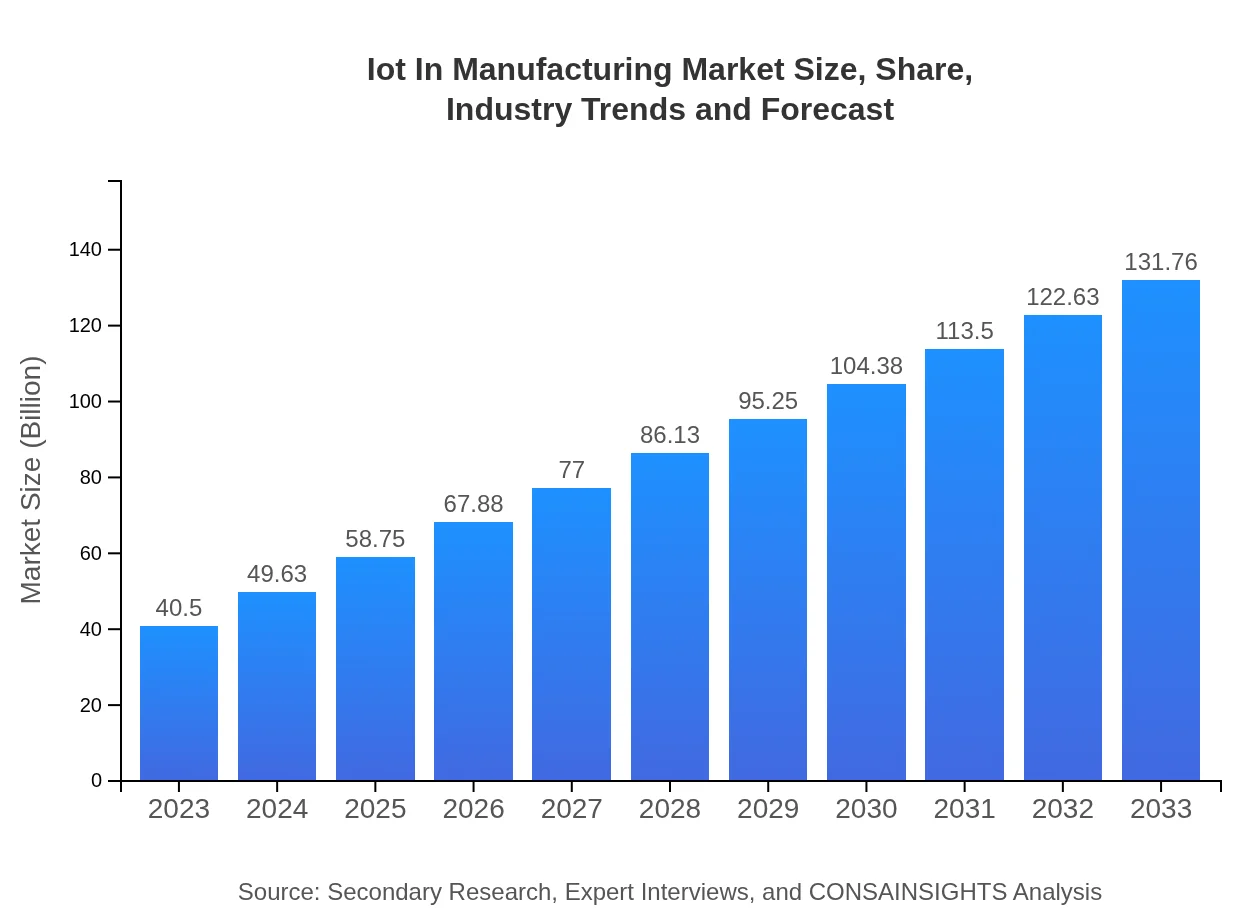

| 2023 Market Size | $40.50 Billion |

| CAGR (2023-2033) | 12% |

| 2033 Market Size | $131.76 Billion |

| Top Companies | Siemens AG, General Electric, Cisco Systems, IBM |

| Last Modified Date | 31 January 2026 |

IoT In Manufacturing Market Overview

Customize Iot In Manufacturing Market Report market research report

- ✔ Get in-depth analysis of Iot In Manufacturing market size, growth, and forecasts.

- ✔ Understand Iot In Manufacturing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Iot In Manufacturing

What is the Market Size & CAGR of IoT In Manufacturing market in 2023?

IoT In Manufacturing Industry Analysis

IoT In Manufacturing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

IoT In Manufacturing Market Analysis Report by Region

Europe Iot In Manufacturing Market Report:

In Europe, the market is projected to grow from $12.55 billion in 2023 to $40.83 billion by 2033. European manufacturers are increasingly investing in IoT technologies to optimize production processes and improve efficiency. The emphasis on sustainability and regulatory compliance further boosts the market as organizations seek to enhance their operational capabilities.Asia Pacific Iot In Manufacturing Market Report:

In the Asia Pacific region, the market was valued at $7.76 billion in 2023 and is anticipated to expand to $25.24 billion by 2033. This growth is primarily driven by the rapid industrialization and technology adoption in countries like China and India. The increasing focus on smart manufacturing initiatives and government support for digital transformation are key factors propelling this market.North America Iot In Manufacturing Market Report:

North America is a leading region in the IoT in manufacturing market, with a value of $14.08 billion in 2023, expected to reach $45.80 billion by 2033. The region benefits from high technological adoption rates and the presence of major industry players. The focus on smart factories and automation solutions are driving tremendous growth in this segment.South America Iot In Manufacturing Market Report:

The South American IoT in manufacturing market was valued at $3.77 billion in 2023, projected to grow to $12.28 billion by 2033. South America is gradually embracing IoT technologies, with Brazil and Argentina leading the way. Development of infrastructure and government initiatives aimed at technological advancement will likely fuel this growth.Middle East & Africa Iot In Manufacturing Market Report:

In the Middle East and Africa region, the market is expected to grow from $2.34 billion in 2023 to $7.60 billion by 2033. There is a growing recognition of the need for digital transformation in manufacturing. Investments in infrastructure and technology adoption will be crucial for achieving growth in this region.Tell us your focus area and get a customized research report.

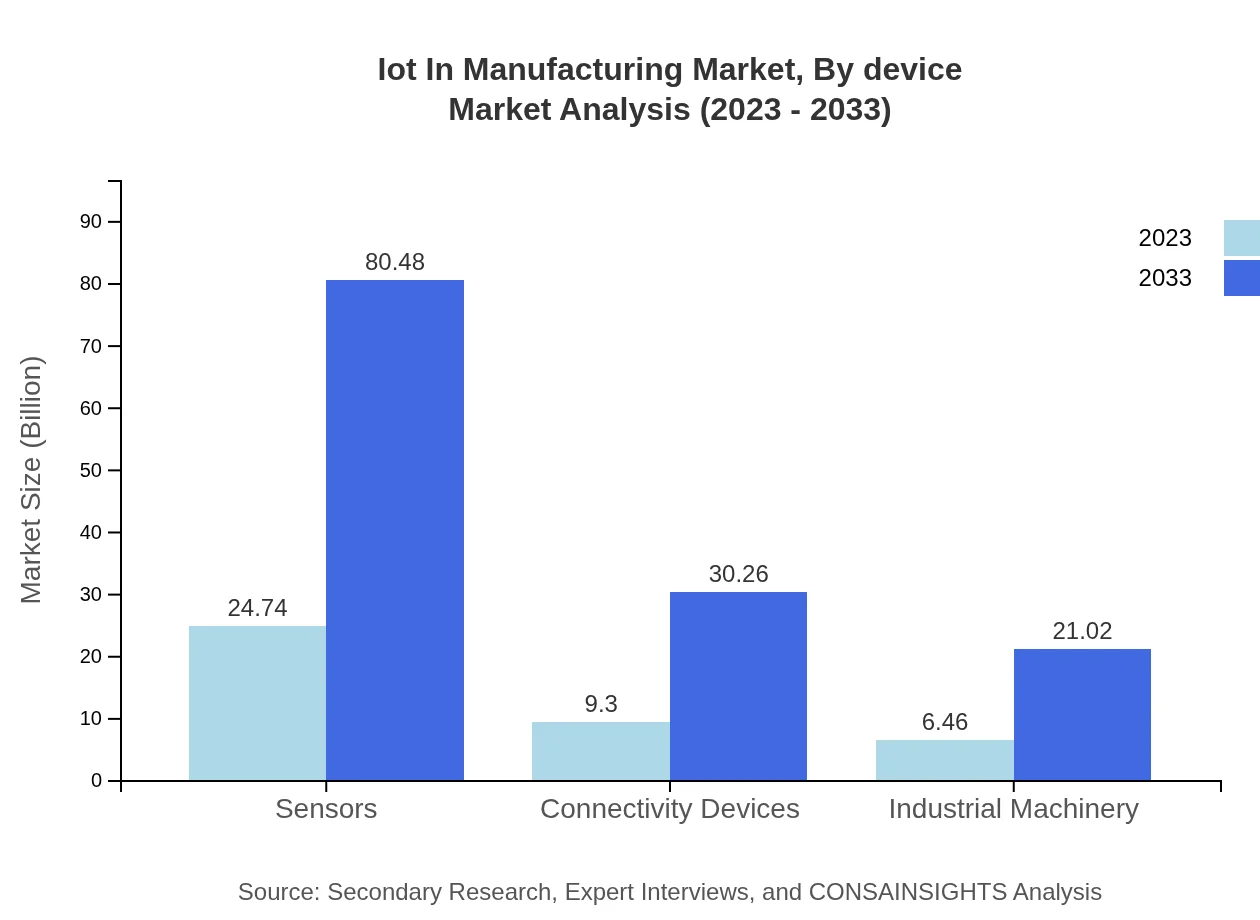

Iot In Manufacturing Market Analysis By Device

The IoT in manufacturing market is heavily driven by devices such as sensors and connectivity devices. Sensors are projected to reach $80.48 billion by 2033 from $24.74 billion in 2023, dominating with a market share of 61.08%. Connectivity devices also show significant growth, expected to grow from $9.30 billion in 2023 to $30.26 billion in 2033, holding a 22.97% market share.

Iot In Manufacturing Market Analysis By Application

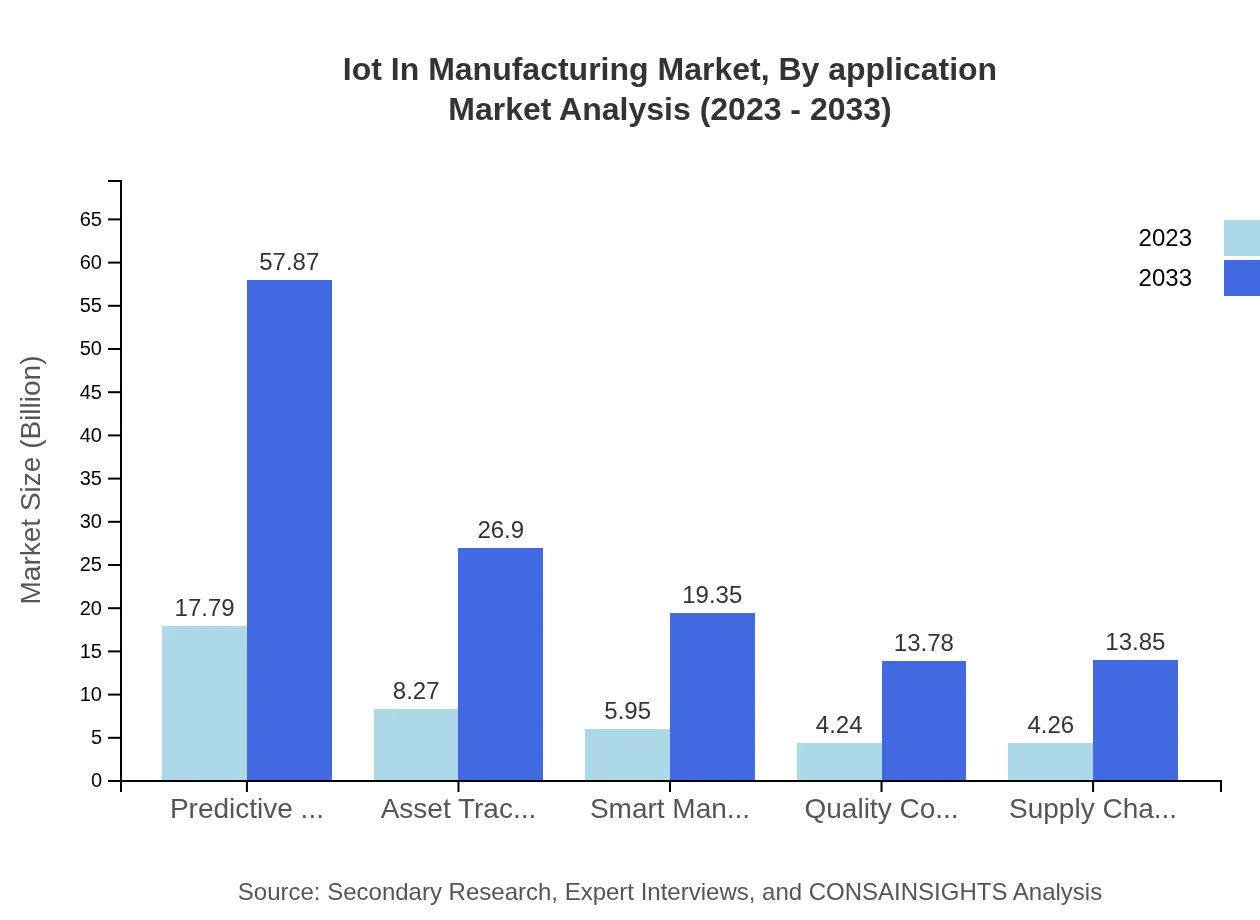

Applications like predictive maintenance will experience considerable growth from $17.79 billion in 2023 to $57.87 billion in 2033, achieving a market share of 43.92%. Asset tracking and smart manufacturing applications are also witnessing significant demand, as companies seek to enhance their operational performance and minimize downtime.

Iot In Manufacturing Market Analysis By Deployment Type

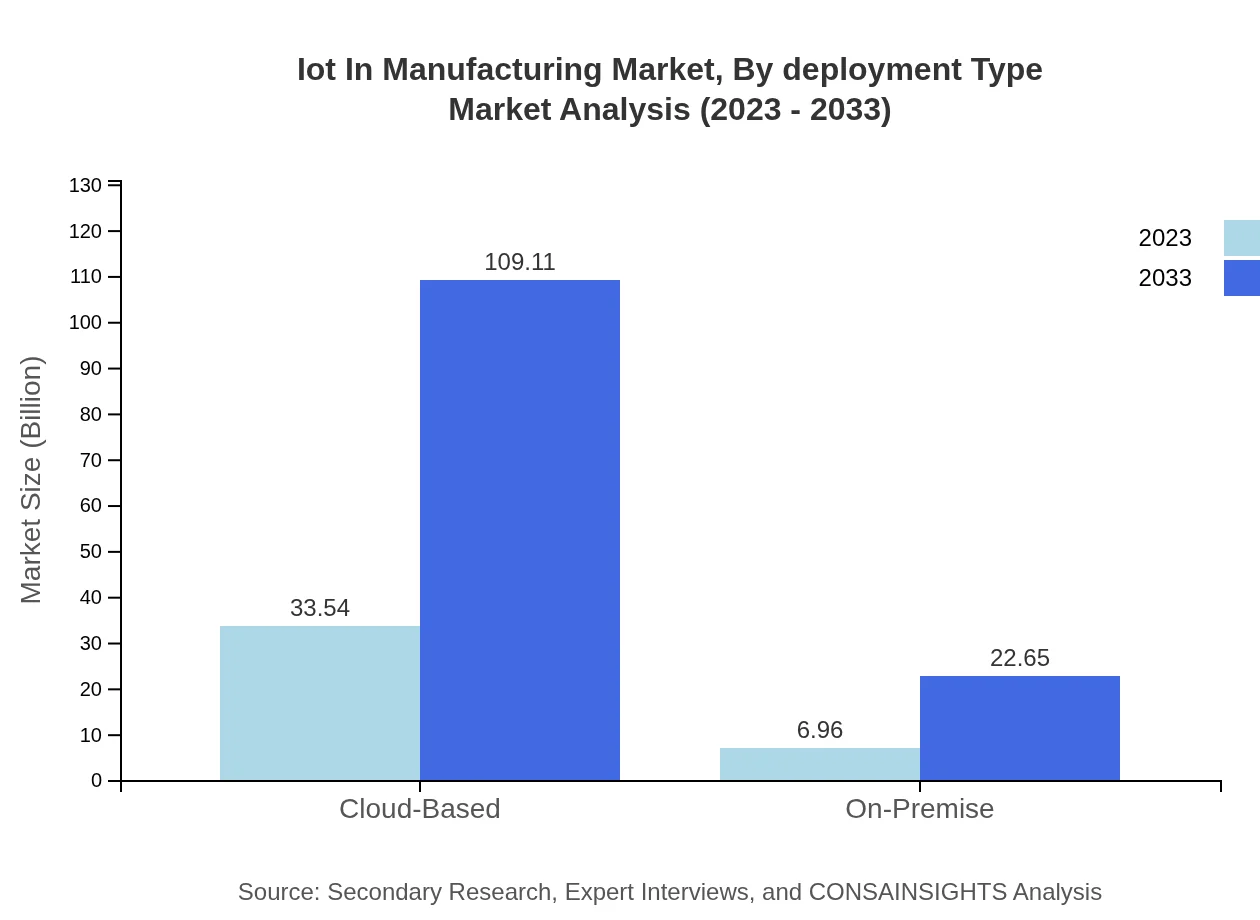

The market is seeing a notable preference for Cloud-Based solutions, projected to reach $109.11 billion by 2033 from $33.54 billion in 2023, capturing an overwhelming market share of 82.81%. On-Premise models will also grow but at a slower pace, expected to rise to $22.65 billion by 2033.

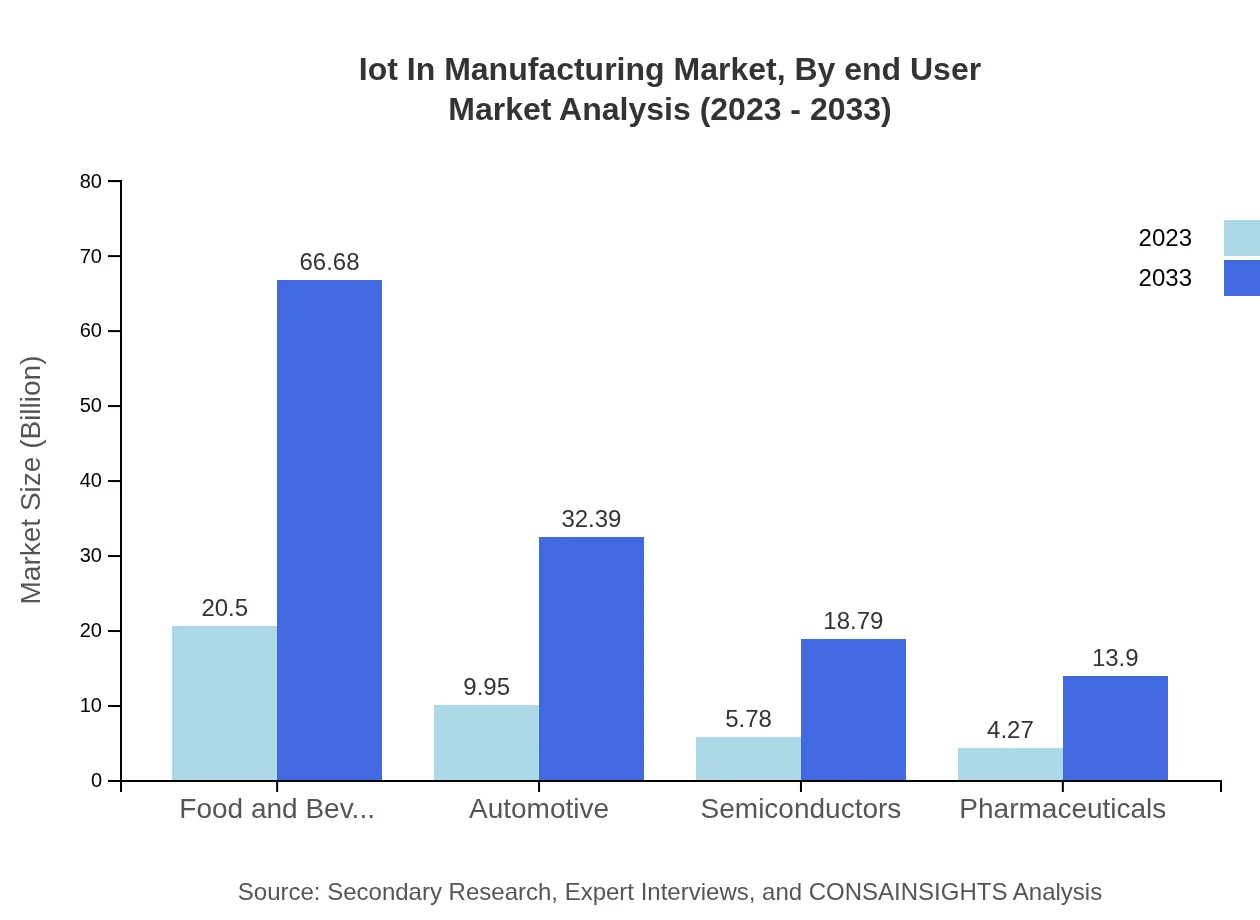

Iot In Manufacturing Market Analysis By End User

The end-user segments, such as food and beverage and automotive, are central to the market's growth. The food and beverage sector is projected to grow from $20.50 billion in 2023 to $66.68 billion in 2033. Similarly, the automotive industry will expand from $9.95 billion to $32.39 billion during the same period.

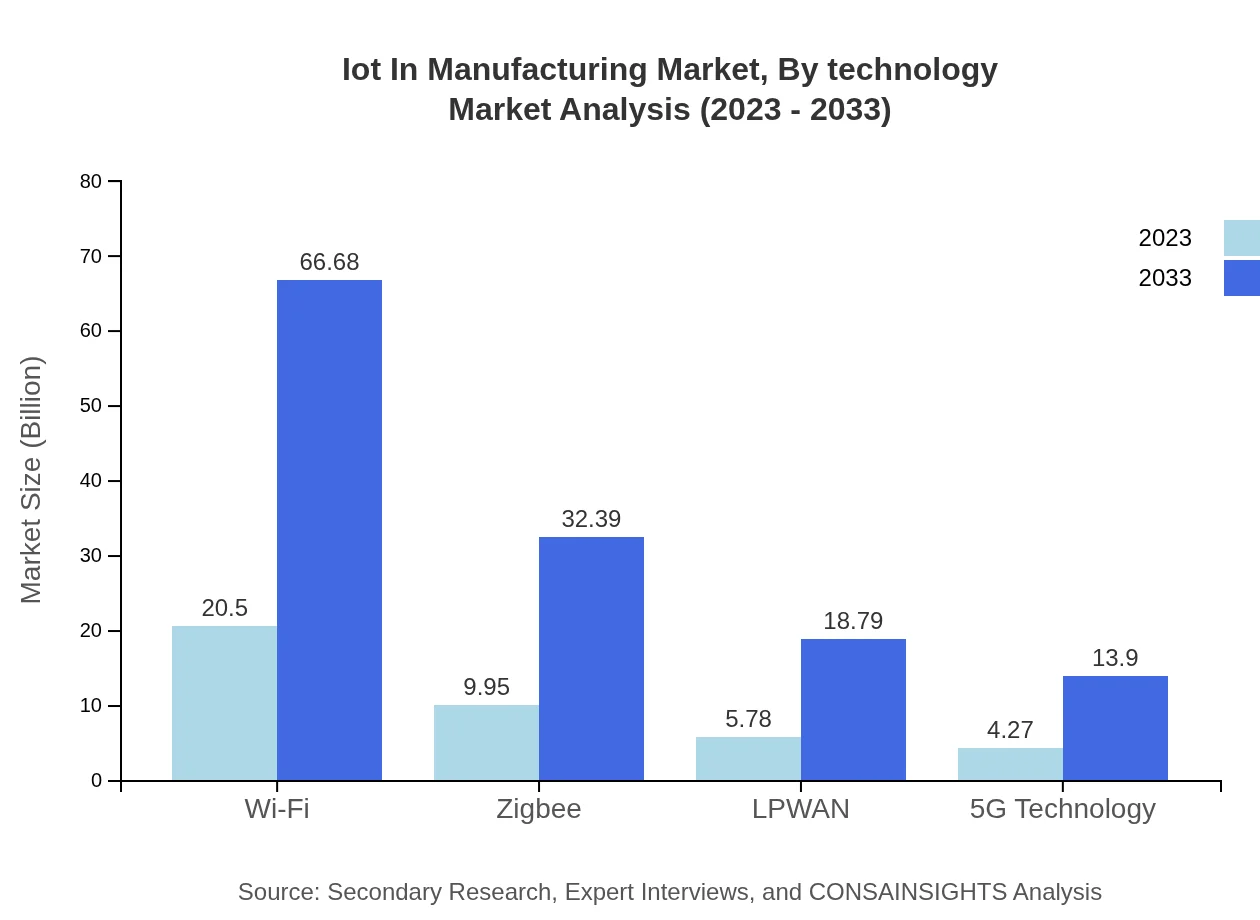

Iot In Manufacturing Market Analysis By Technology

Technologies such as Wi-Fi, Zigbee, and 5G are pivotal in shaping the IoT landscape in manufacturing. Wi-Fi is anticipated to reach $66.68 billion by 2033, while Zigbee and 5G technologies are also expected to grow significantly, driven by the demand for faster and more reliable connectivity in manufacturing operations.

IoT In Manufacturing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in IoT In Manufacturing Industry

Siemens AG:

Siemens AG is a global leader in automation and digitalization in manufacturing. Their IoT platform, MindSphere, offers unparalleled connectivity capabilities, enabling manufacturers to utilize data-driven insights for optimized performance.General Electric:

General Electric is a pioneer in IoT for the manufacturing industry through its Predix platform, which provides advanced analytics, enabling real-time insights into operational performance.Cisco Systems:

Cisco Systems plays a crucial role in the IoT ecosystem through its networking solutions and services that ensure secure and reliable connectivity for manufacturing operations.IBM:

IBM is renowned for its contributions to IoT with the IBM Watson IoT platform, which offers robust analytics and AI-driven insights to enhance manufacturing processes.We're grateful to work with incredible clients.

FAQs

What is the market size of IoT in manufacturing?

The IoT in manufacturing market is valued at approximately $40.5 billion in 2023, with a projected CAGR of 12%. It is expected to expand significantly over the next decade, reaching substantial growth by 2033.

What are the key market players or companies in the IoT in manufacturing industry?

Key players in the IoT manufacturing sector include Siemens AG, GE Digital, PTC Inc., Schneider Electric, and Honeywell, among others. These companies are instrumental in propelling innovation and deploying IoT solutions in manufacturing processes.

What are the primary factors driving the growth in the IoT in manufacturing industry?

Growth is primarily driven by increasing automation in factories, the need for real-time data analytics, operational efficiency improvements, supply chain optimization, and the integration of AI with IoT technologies to enhance production outcomes.

Which region is the fastest Growing in the IoT in manufacturing?

The fastest-growing region in the IoT in manufacturing market is Asia Pacific, expected to grow from $7.76 billion in 2023 to $25.24 billion by 2033, highlighting its rapid industrial development and technology adoption.

Does ConsaInsights provide customized market report data for the IoT in manufacturing industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs in the IoT in manufacturing industry, enabling businesses to access detailed insights and data that suit their strategic goals.

What deliverables can I expect from this IoT in manufacturing market research project?

Deliverables typically include comprehensive market analysis reports, segment evaluations, market forecasts up to 2033, competitive landscape insights, and tailored recommendations based on the latest trends and data.

What are the market trends of IoT in manufacturing?

Trends include growing investments in predictive maintenance, increased adoption of smart manufacturing techniques, expansion of cloud-based technologies, and enhanced use of sensors and connectivity solutions to optimize production efficiency.