Iron Powder Market Report

Published Date: 02 February 2026 | Report Code: iron-powder

Iron Powder Market Size, Share, Industry Trends and Forecast to 2033

This report assesses the global Iron Powder market from 2023 to 2033, detailing insights into market size, trends, segmentation, industry forecast, and leading players. It provides a comprehensive overview of the competitive landscape and regional dynamics affecting market growth.

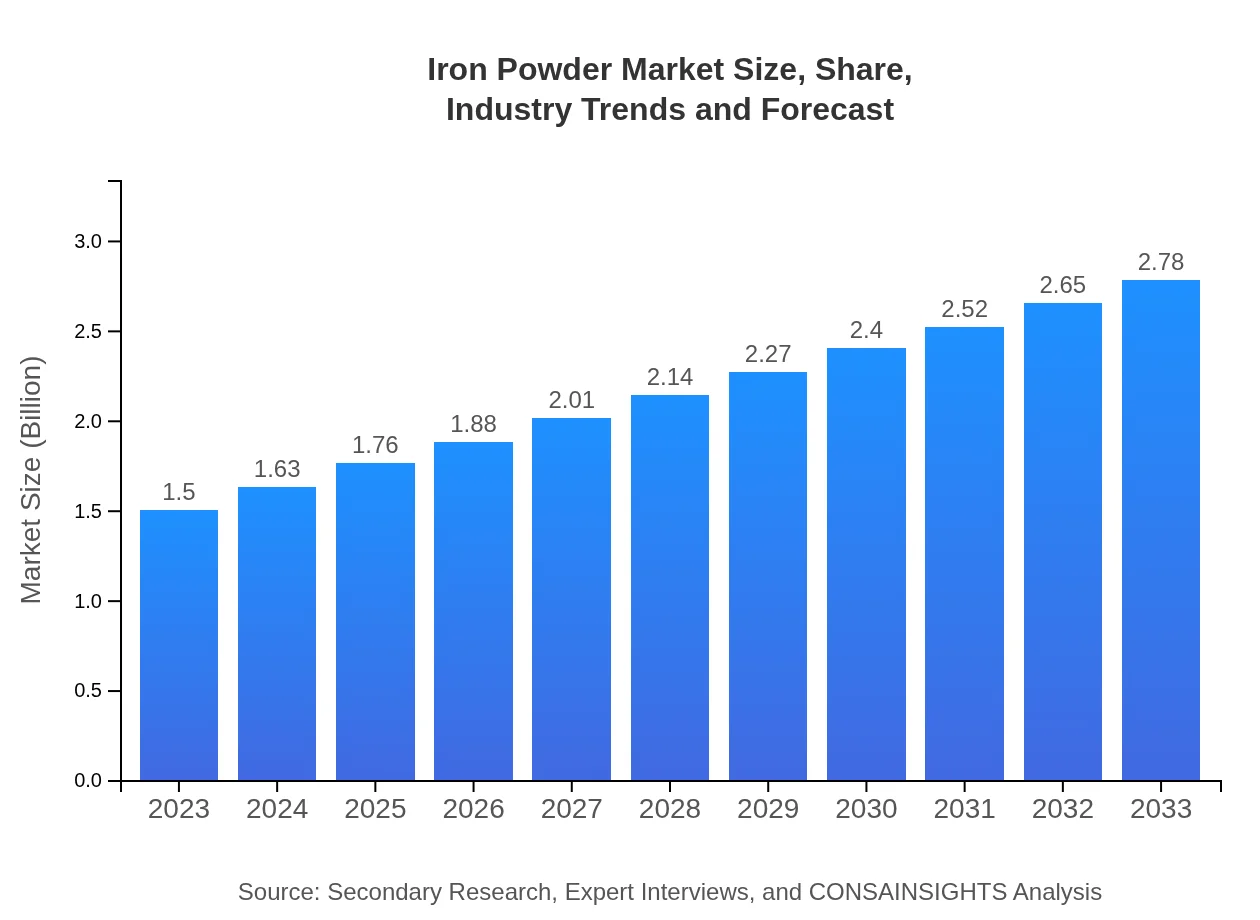

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $2.78 Billion |

| Top Companies | Hoeganaes Corporation, GKN Sinter Metals, Rio Tinto, Metallurgical Corporation of China |

| Last Modified Date | 02 February 2026 |

Iron Powder Market Overview

Customize Iron Powder Market Report market research report

- ✔ Get in-depth analysis of Iron Powder market size, growth, and forecasts.

- ✔ Understand Iron Powder's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Iron Powder

What is the Market Size & CAGR of Iron Powder market in 2023?

Iron Powder Industry Analysis

Iron Powder Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Iron Powder Market Analysis Report by Region

Europe Iron Powder Market Report:

The European iron powder market size is anticipated to grow from $0.48 billion in 2023 to $0.89 billion by 2033, led by demand for high-purity iron powders used in electronics and industrial applications.Asia Pacific Iron Powder Market Report:

The Asia Pacific iron powder market is expected to grow from $0.31 billion in 2023 to $0.57 billion by 2033, with substantial contributions from automotive and industrial manufacturing sectors driving the demand.North America Iron Powder Market Report:

The North American market is forecasted to reach $0.90 billion by 2033, up from $0.49 billion in 2023, supported by advanced manufacturing capabilities and a growing focus on innovative applications.South America Iron Powder Market Report:

In South America, the market is projected to increase from $0.02 billion in 2023 to $0.04 billion in 2033, attributed to rising industrial activities despite challenges in economic conditions.Middle East & Africa Iron Powder Market Report:

The Middle East & Africa market is expected to rise from $0.21 billion in 2023 to $0.38 billion by 2033, with industrial applications in emerging economies contributing significantly to growth.Tell us your focus area and get a customized research report.

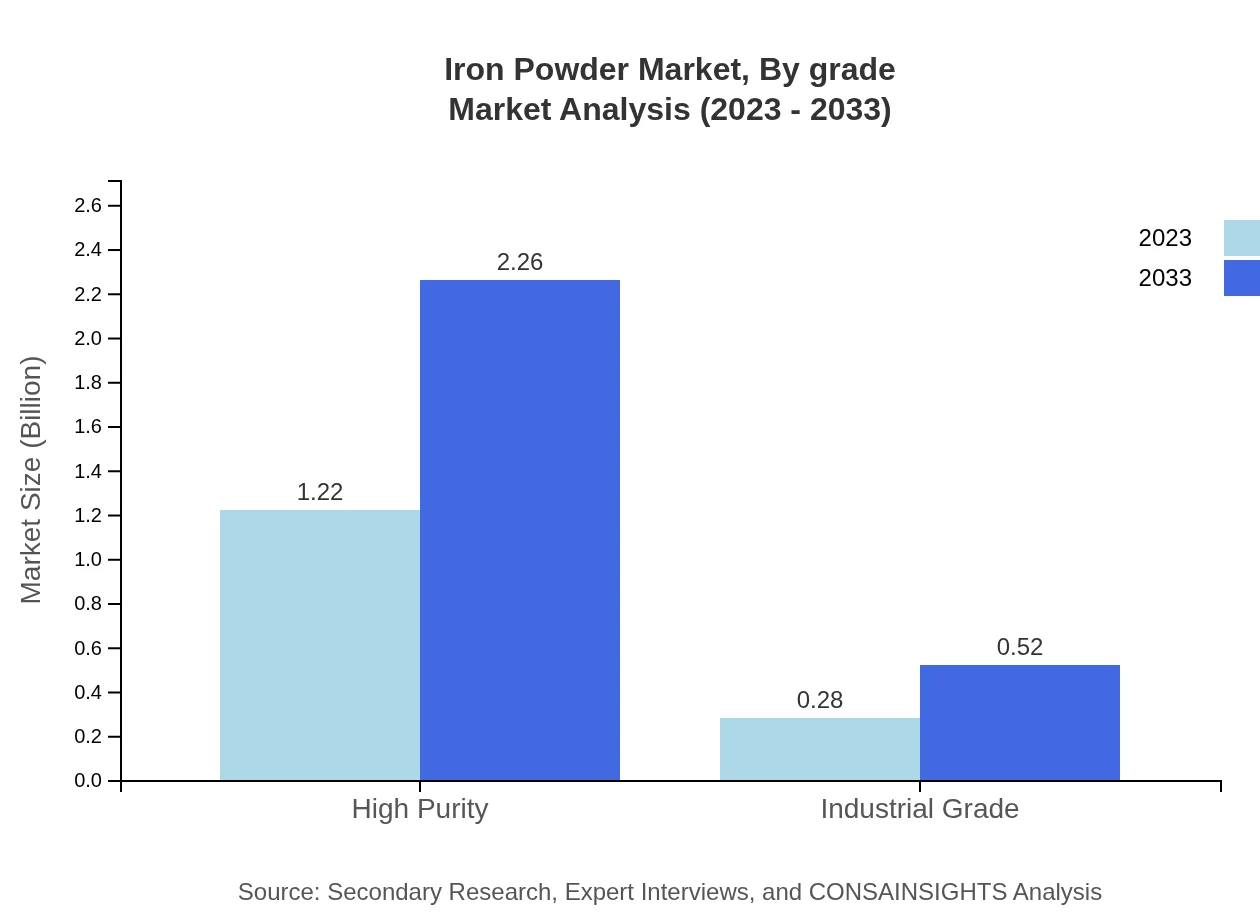

Iron Powder Market Analysis By Grade

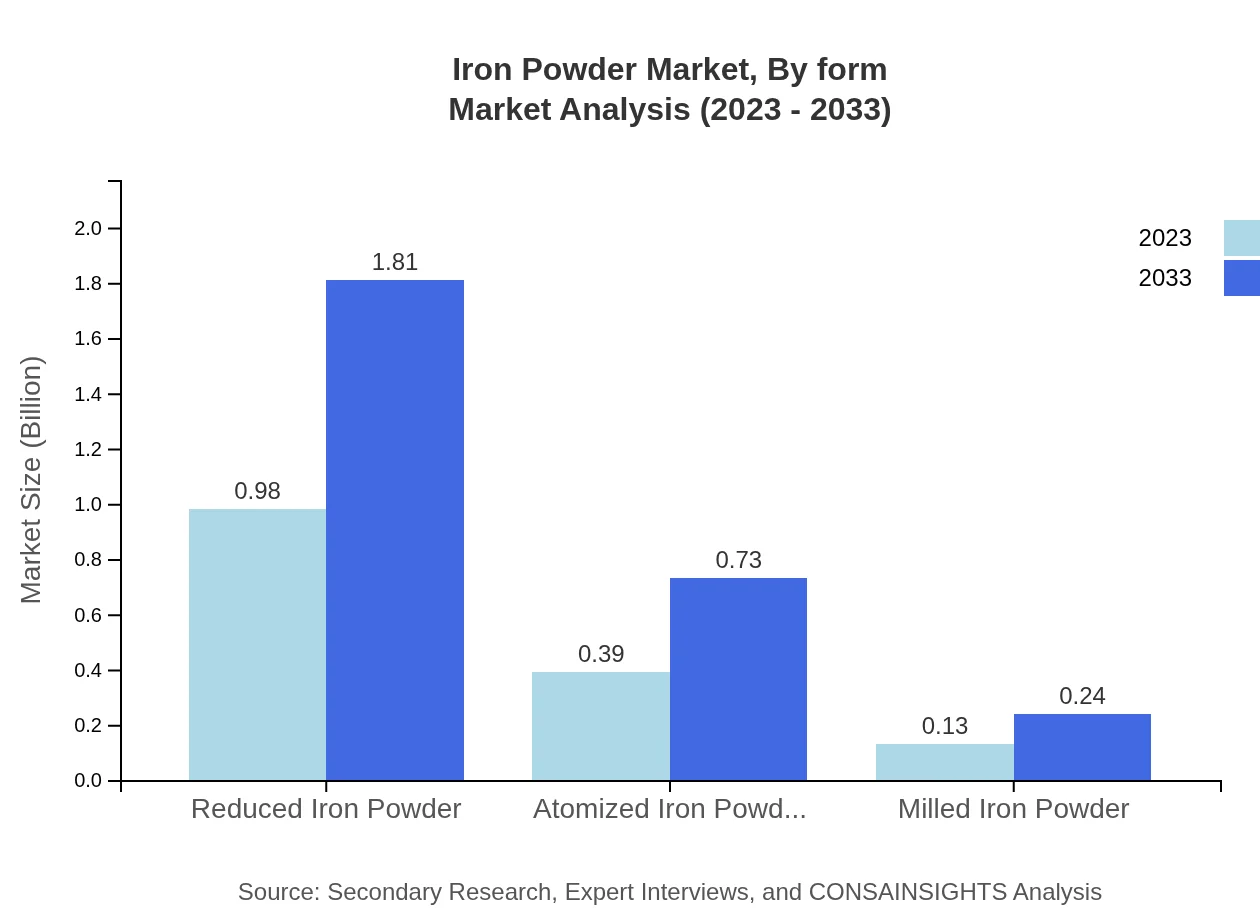

The market for reduced iron powder is projected to grow from $0.98 billion in 2023 to $1.81 billion by 2033, representing 65.29% of the market share. Atomized iron powder is also growing, expected to reach $0.73 billion by 2033, maintaining a 26.24% share of the market.

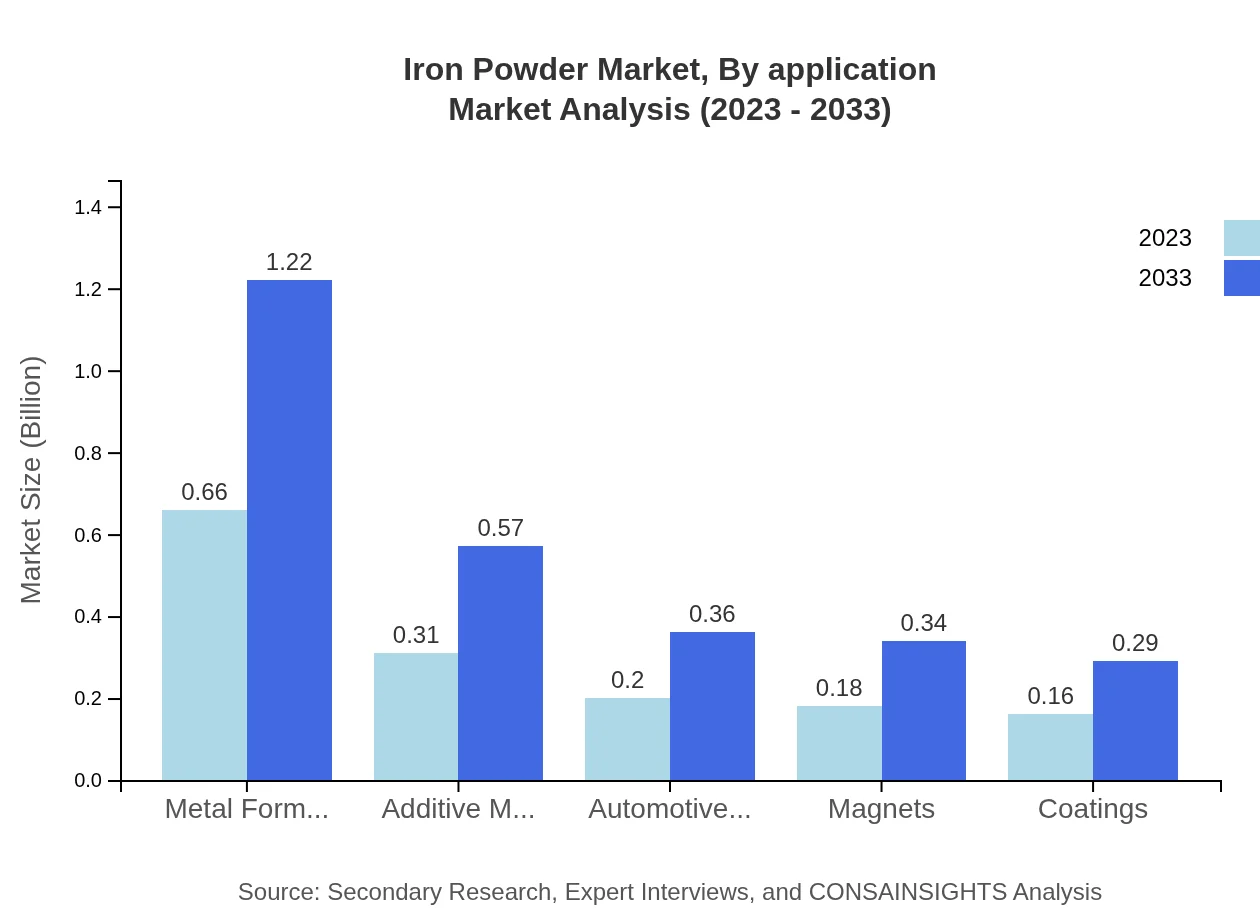

Iron Powder Market Analysis By Application

In terms of application, the metal forming sector holds a significant share, growing from $0.66 billion in 2023 to $1.22 billion by 2033. Meanwhile, automotive parts and electronics sectors are expected to reach $0.36 billion and $0.30 billion respectively by 2033.

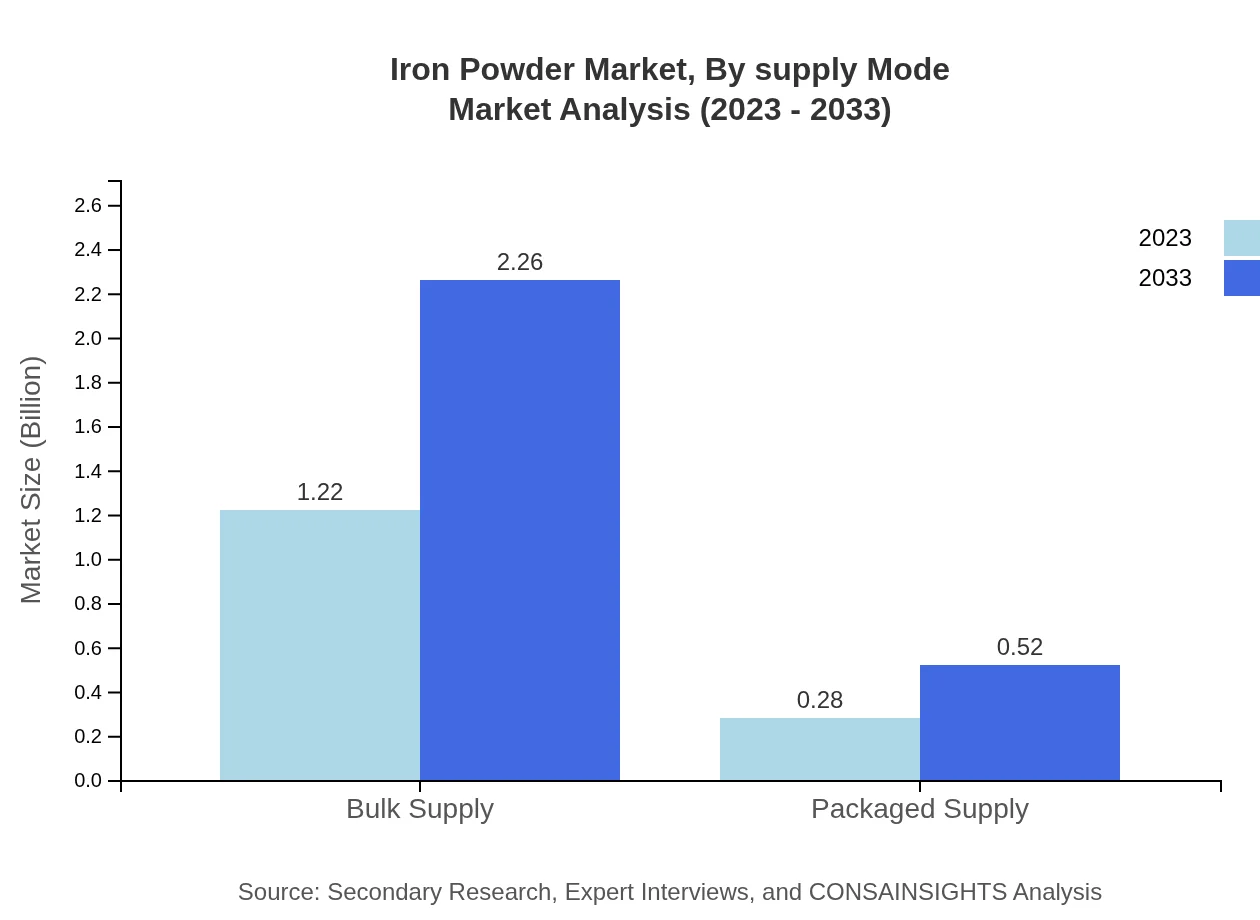

Iron Powder Market Analysis By Form

The bulk supply format dominates the market with an expected increase from $1.22 billion in 2023 to $2.26 billion by 2033, representing 81.26% of the market share, while packaged supply is projected to grow from $0.28 billion to $0.52 billion.

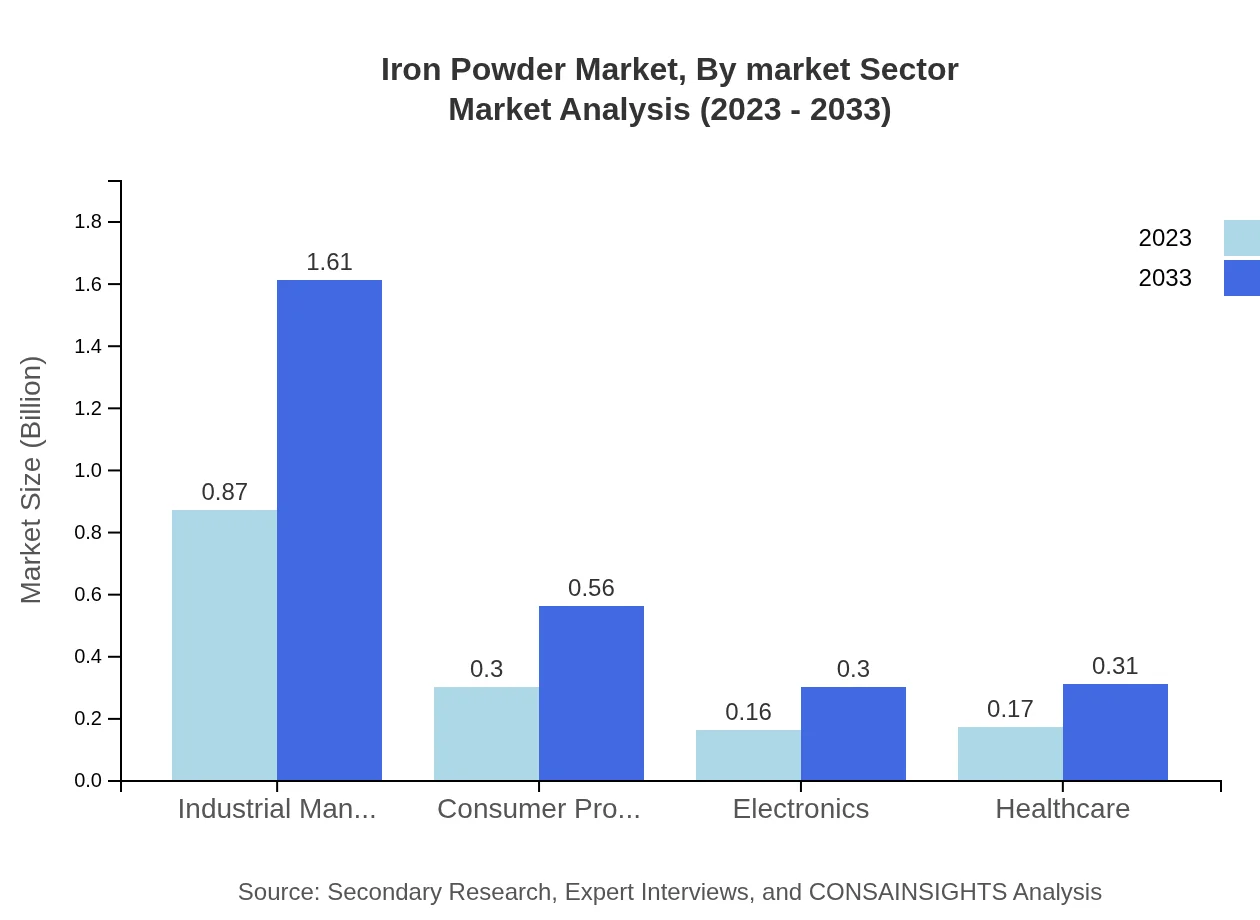

Iron Powder Market Analysis By Market Sector

The industrial manufacturing sector constitutes the largest segment, expanding from $0.87 billion in 2023 to $1.61 billion by 2033, accounted for 58.1% of the market share, thereby indicating a steady demand from manufacturing activities.

Iron Powder Market Analysis By Supply Mode

The market for bulk supply is projected to dominate the iron powder market structure, indicating strength in the supply chain efficiencies and economies of scale from manufacturers.

Iron Powder Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Iron Powder Industry

Hoeganaes Corporation:

Hoeganaes is a leading global producer of iron powder, providing innovative and high-quality products for various applications in the automotive and industrial sectors.GKN Sinter Metals:

A prominent player in the iron powder market, GKN specializes in sintered products and offers a broad range of iron powders, catering to technology-driven industries and changing customer needs.Rio Tinto:

Rio Tinto is a major player in the raw material supply chain and produces a variety of iron products, including powders for industrial applications, ensuring sustainable practices.Metallurgical Corporation of China:

With a stronghold in metal manufacturing, the Metallurgical Corporation of China produces iron powders that find extensive applications in multiple sectors, supporting domestic and international demands.We're grateful to work with incredible clients.

FAQs

What is the market size of the iron powder?

The global iron powder market is valued at $1.5 billion in 2023 and is expected to grow at a CAGR of 6.2% over the next decade. This growth reflects increasing applications across various industries, thereby driving demand for iron powder.

What are the key market players or companies in the iron powder industry?

Key players in the iron powder market include companies such as Hoeganaes Corporation, GKN Sinter Metals, and Rio Tinto. These firms play a significant role in shaping the industry through innovative product offerings and strategic partnerships.

What are the primary factors driving the growth in the iron powder industry?

Growth in the iron powder industry is primarily driven by increasing demand in sectors such as automotive, electronics, and additive manufacturing. Innovative applications, particularly in 3D printing and metal forming, are also crucial to market expansion.

Which region is the fastest Growing in the iron powder market?

The Asia Pacific region is the fastest-growing market for iron powder, with a projected increase from $0.31 billion in 2023 to $0.57 billion by 2033. This growth is fueled by rapid industrialization and expanding manufacturing capabilities in countries like China and India.

Does ConsaInsights provide customized market report data for the iron powder industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs in the iron powder industry. This allows clients to gain insights that are vital for strategic planning and decision-making.

What deliverables can I expect from this iron powder market research project?

Deliverables from the iron powder market research project typically include comprehensive market analysis, regional insights, competitive landscape evaluation, and segmented market data, enabling informed business decisions for stakeholders.

What are the market trends of the iron powder?

Current trends in the iron powder market include a shift towards sustainable manufacturing and increased usage in high-purity applications. Innovations in production technologies are also enhancing efficiency and product performance across industry verticals.