Isostatic Pressing Market Report

Published Date: 22 January 2026 | Report Code: isostatic-pressing

Isostatic Pressing Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Isostatic Pressing market, including insights into market size, growth trends, and forecasts from 2023 to 2033. It covers key segments, regional performance, and industry leaders shaping the current landscape.

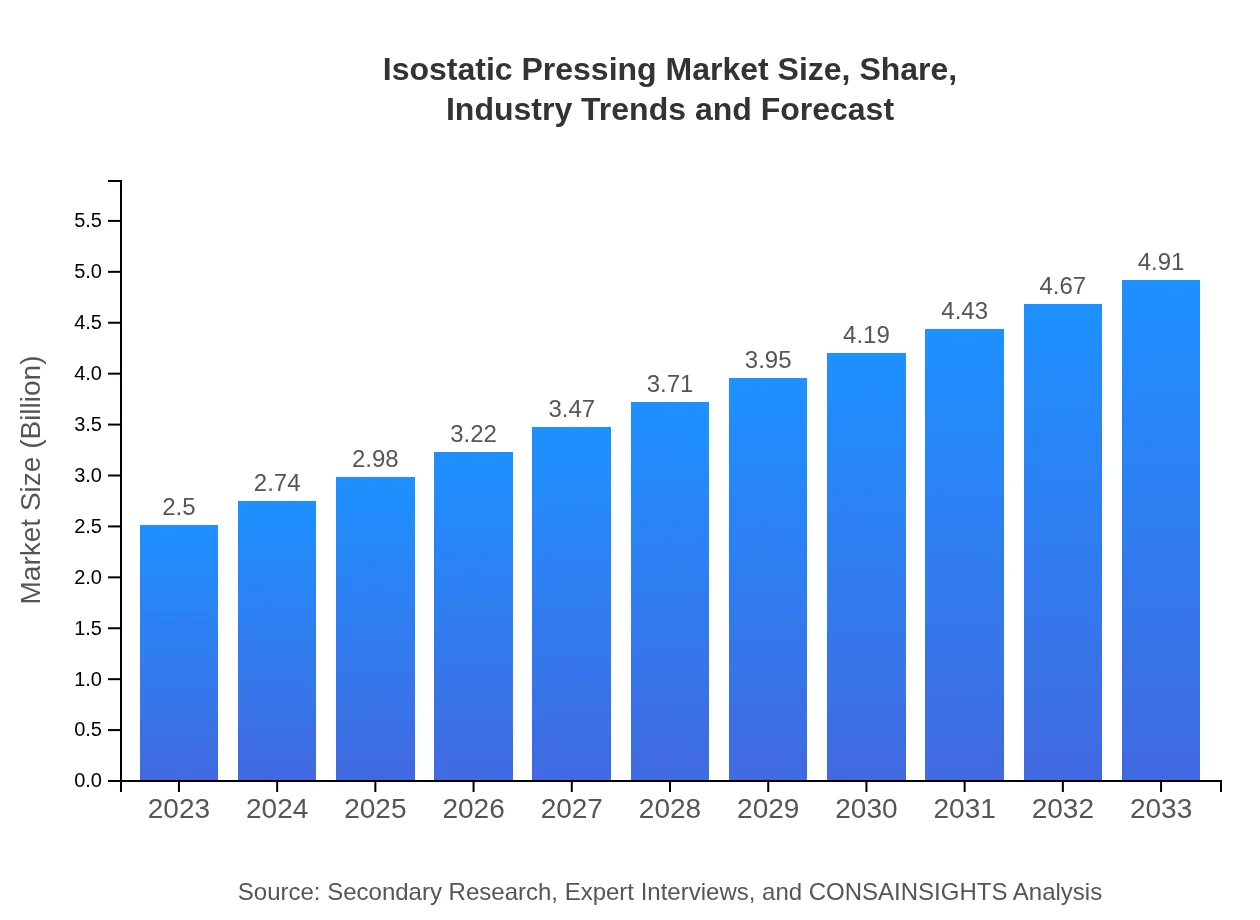

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.91 Billion |

| Top Companies | Bodycote plc, APC International, Ltd., Kryolan GmbH, MetalTech Ltd. |

| Last Modified Date | 22 January 2026 |

Isostatic Pressing Market Overview

Customize Isostatic Pressing Market Report market research report

- ✔ Get in-depth analysis of Isostatic Pressing market size, growth, and forecasts.

- ✔ Understand Isostatic Pressing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Isostatic Pressing

What is the Market Size & CAGR of Isostatic Pressing market in 2023?

Isostatic Pressing Industry Analysis

Isostatic Pressing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Isostatic Pressing Market Analysis Report by Region

Europe Isostatic Pressing Market Report:

Europe's market is expected to expand from $0.67 billion in 2023 to $1.31 billion in 2033, propelled by technology advancements and a strong focus on sustainable manufacturing processes. Countries like Germany and France are at the forefront.Asia Pacific Isostatic Pressing Market Report:

The Asia Pacific region is experiencing substantial growth, with a market size increasing from $0.53 billion in 2023 to $1.04 billion in 2033. Key drivers include rapid industrialization and a booming manufacturing sector, particularly in China and India, where demand for advanced materials is high.North America Isostatic Pressing Market Report:

North America holds a significant share of the global market, anticipated to increase from $0.91 billion in 2023 to $1.79 billion in 2033. The U.S. is a leader in aerospace and defense applications, driving demand for high-performance materials.South America Isostatic Pressing Market Report:

In South America, the market size is projected to grow from $0.19 billion in 2023 to $0.36 billion in 2033. Growth is supported by the increasing use of isostatic pressing in automotive and aerospace industries, although it remains slower compared to other regions due to infrastructural challenges.Middle East & Africa Isostatic Pressing Market Report:

The Middle East and Africa market is projected to grow from $0.20 billion in 2023 to $0.40 billion in 2033. Although it represents a smaller market, increasing investments in industrial capabilities contribute to steady growth.Tell us your focus area and get a customized research report.

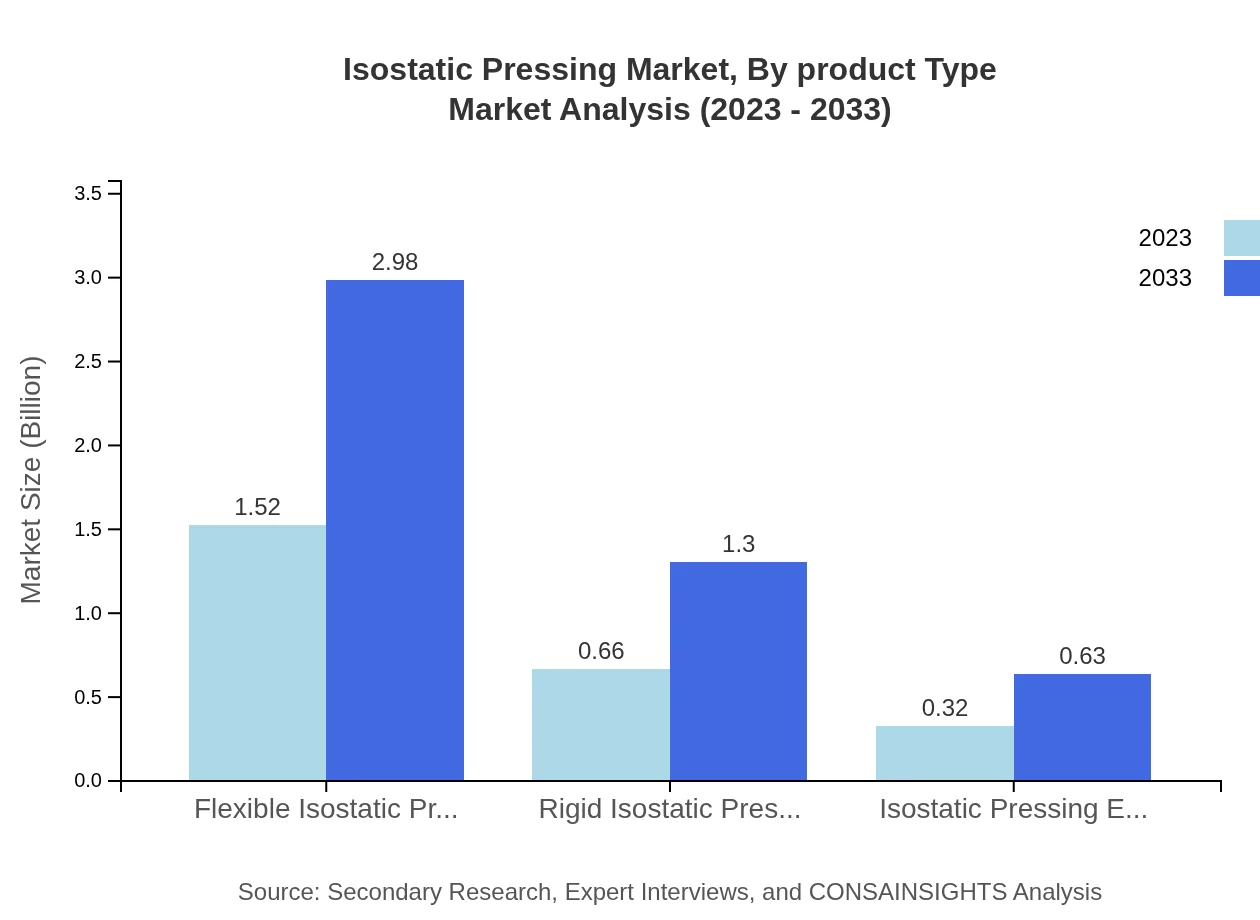

Isostatic Pressing Market Analysis By Product Type

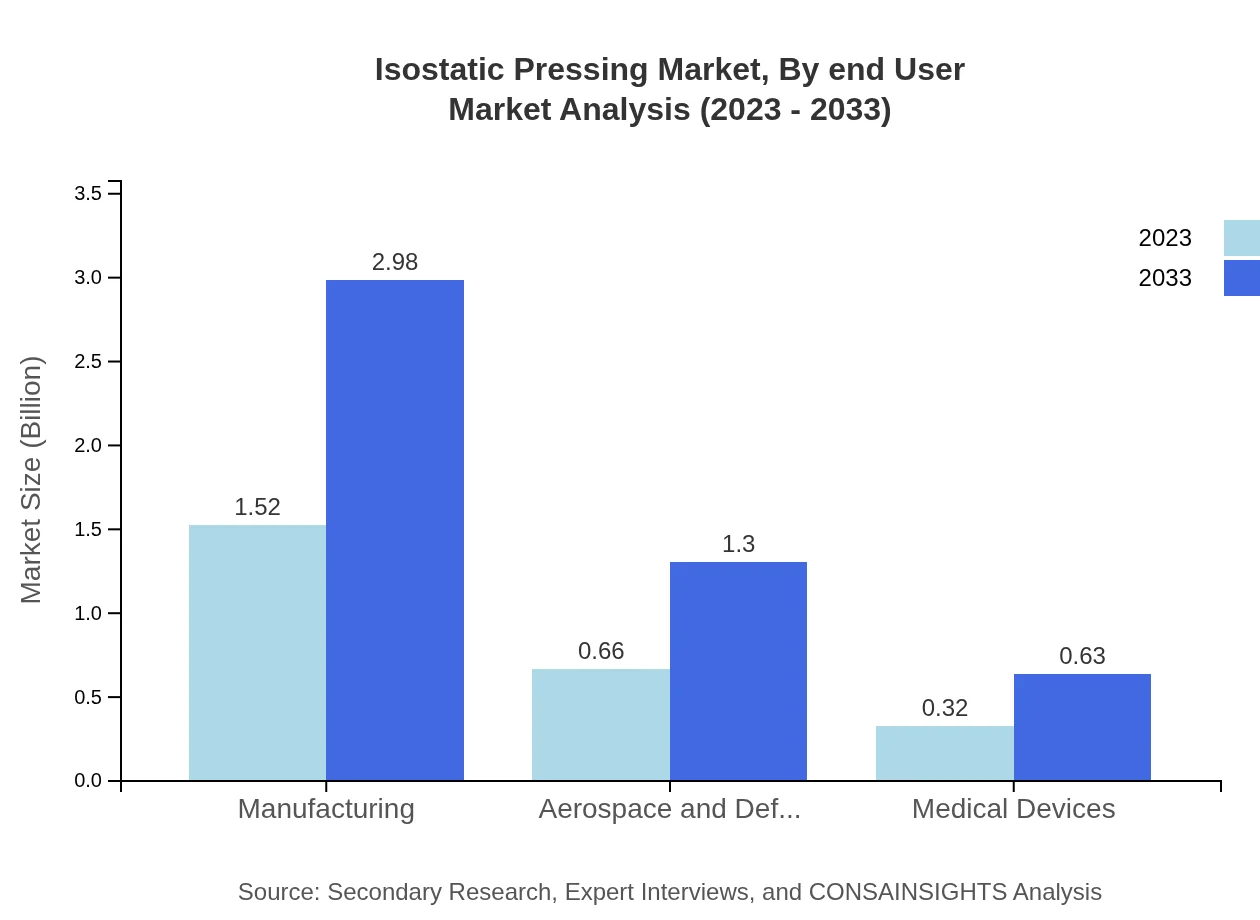

In 2023, manufacturing is the leading segment with a market size of $1.52 billion, projected to reach $2.98 billion by 2033, maintaining a share of 60.66%. Other notable segments include aerospace and defense, medical devices, and automotive, indicating diversified applications driving overall market growth.

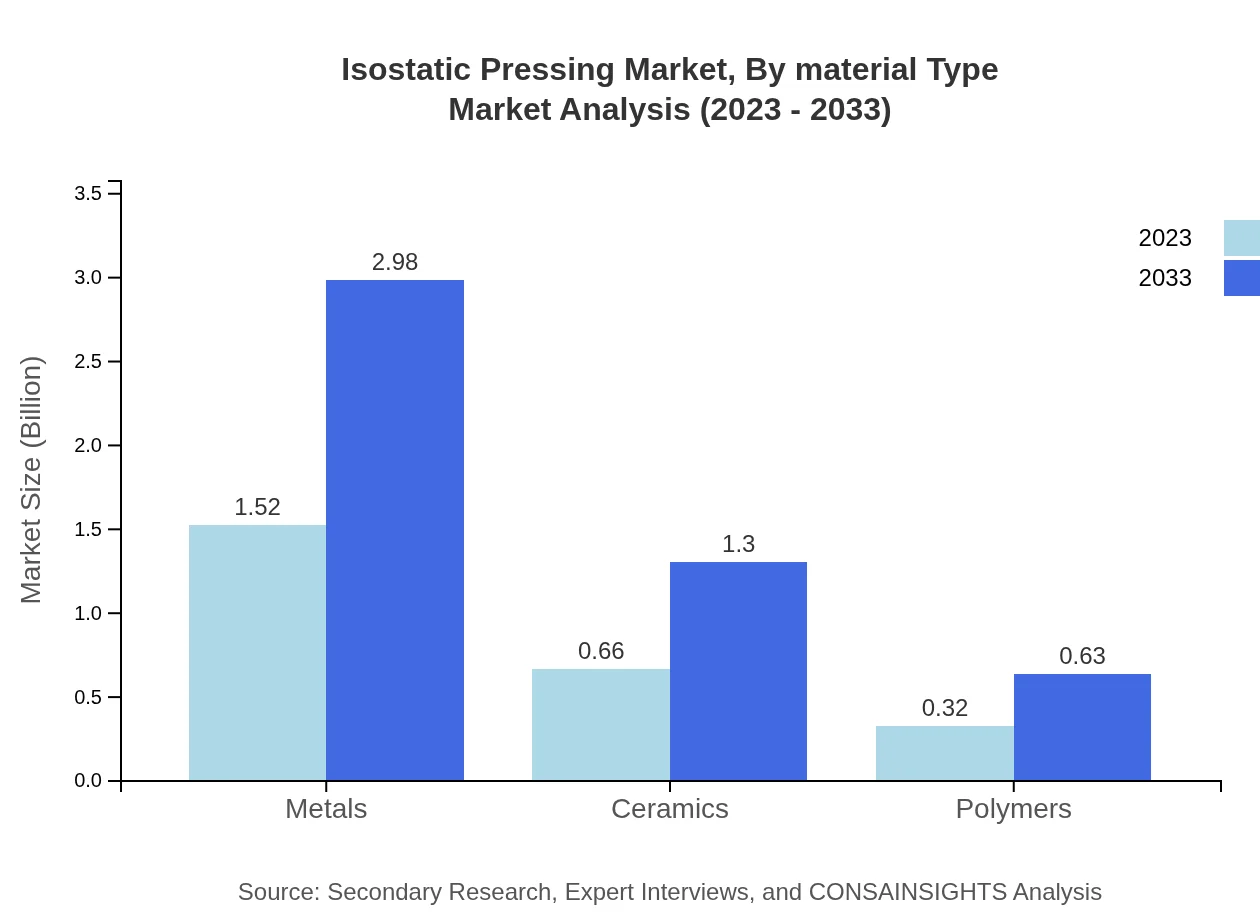

Isostatic Pressing Market Analysis By Material Type

The metals segment leads the market with a size of $1.52 billion in 2023, reaching $2.98 billion by 2033. Ceramics and polymers also contribute significantly, reflecting a balanced demand across different materials in various applications.

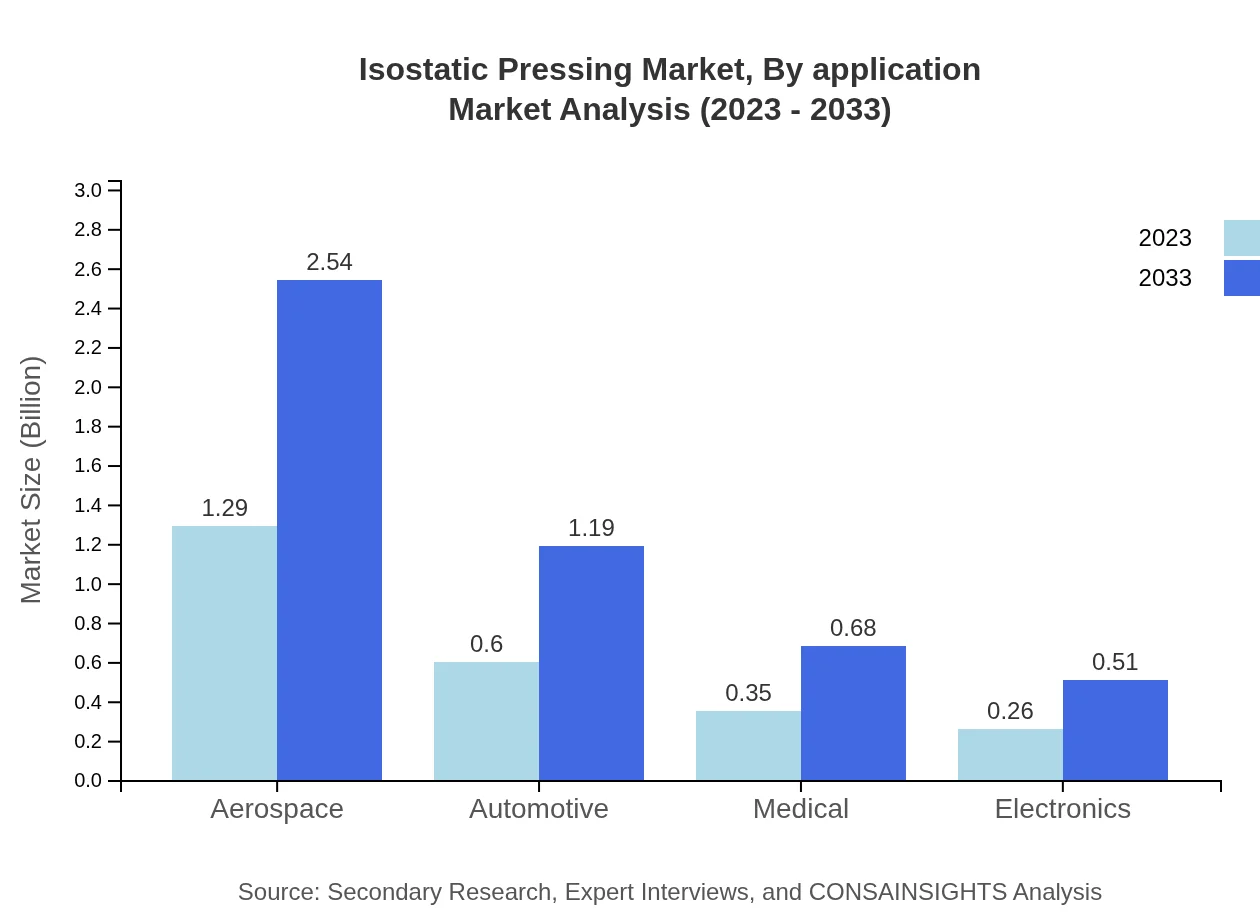

Isostatic Pressing Market Analysis By Application

Aerospace, the largest application area, is projected to grow from $1.29 billion in 2023 to $2.54 billion by 2033. The automotive and medical applications follow, showcasing the versatility of isostatic pressing across critical industries.

Isostatic Pressing Market Analysis By End User

Key end-user industries include aerospace, automotive, medical devices, and electronics. The aerospace sector takes the lead, owing to a surge in demand for light-weight, durable materials for various applications.

Isostatic Pressing Market Analysis By Dispensation

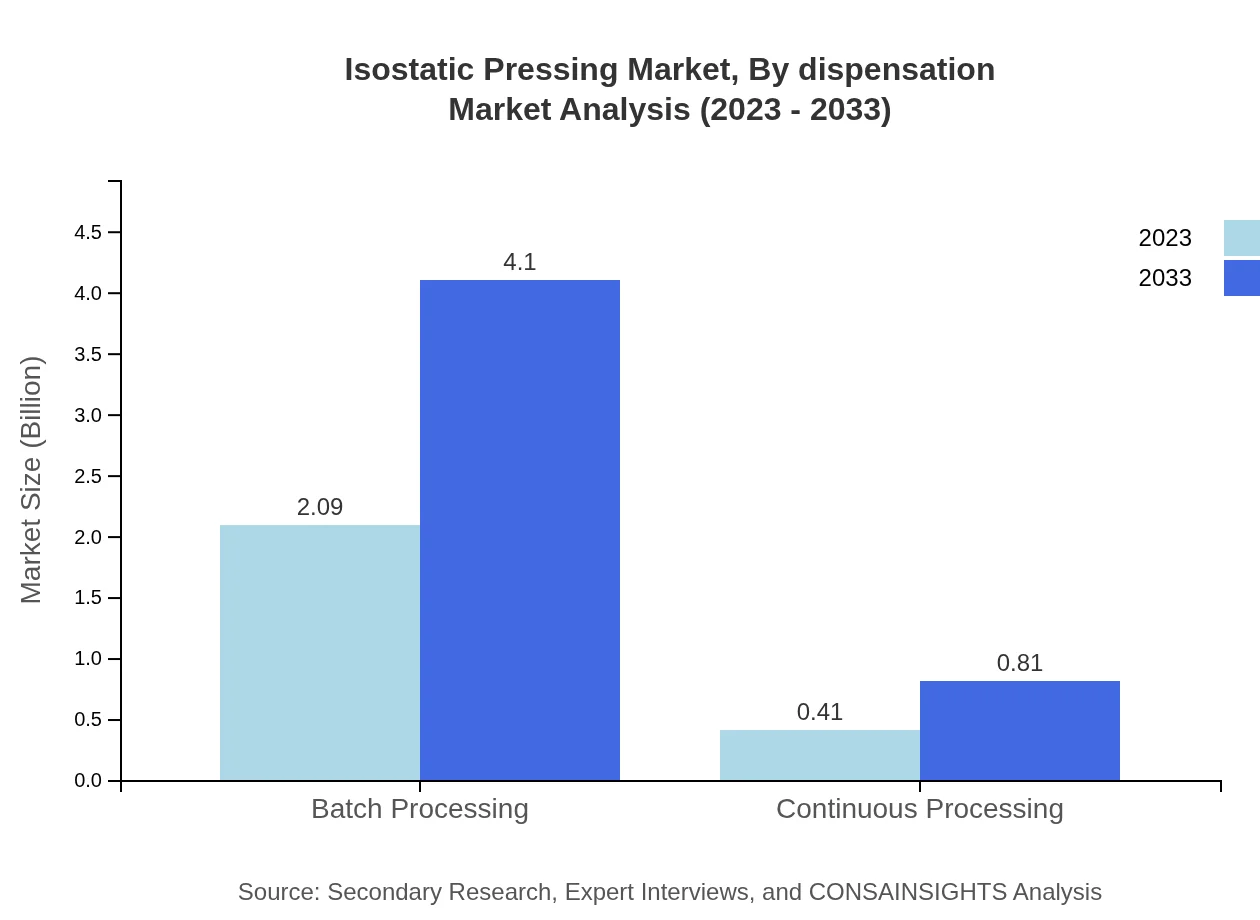

Batch processing dominates the market, accounting for 83.5% in 2023 with a size of $2.09 billion, projected to grow to $4.10 billion by 2033. Continuous processing, while smaller, is expected to grow steadily, reflecting changing industry requirements.

Isostatic Pressing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Isostatic Pressing Industry

Bodycote plc:

A leading global provider of heat treatment and specialized thermal processing services, Bodycote utilizes isostatic pressing to enhance material properties.APC International, Ltd.:

Specializes in advanced ceramics and offers services in isostatic pressing, contributing to innovations in manufacturing processes.Kryolan GmbH:

Known for high-performance materials and isostatic pressing solutions tailored for aerospace and automotive applications.MetalTech Ltd.:

A key player in the fabrication of parts using isostatic pressing for the automotive and energy sectors, driving quality enhancements.We're grateful to work with incredible clients.

FAQs

What is the market size of isostatic Pressing?

The isostatic pressing market is currently valued at approximately $2.5 billion, with a compound annual growth rate (CAGR) of 6.8% projected through 2033. This growth is driven by the increasing demand for advanced manufacturing processes across various industries.

What are the key market players or companies in the isostatic Pressing industry?

Key players in the isostatic pressing market include companies like Bodycote plc, Frederick T. E. Yates & Sons, and Vickers Engineering. These companies are involved in the development and innovation of isostatic pressing technologies and equipment.

What are the primary factors driving the growth in the isostatic Pressing industry?

The main factors propelling growth in the isostatic pressing industry include rising demand for lightweight materials in aerospace and automotive sectors, advancements in manufacturing technology, and an increased focus on cost-efficient production processes.

Which region is the fastest Growing in the isostatic Pressing?

Asia Pacific is the fastest-growing region in the isostatic pressing market, projected to grow from $0.53 billion in 2023 to $1.04 billion by 2033, driven by increasing industrialization and manufacturing activities.

Does ConsaInsights provide customized market report data for the isostatic Pressing industry?

Yes, ConsaInsights offers customized market report data for the isostatic pressing industry, allowing clients to obtain tailored insights and analyses according to their specific needs and interests within the market.

What deliverables can I expect from this isostatic Pressing market research project?

Deliverables from the isostatic pressing market research project include comprehensive market analysis reports, regional insights, competitive landscape assessments, and forecasts for market growth and trends over the next decade.

What are the market trends of isostatic Pressing?

Current trends in the isostatic pressing market include increasing adoption of flexible isostatic pressing techniques, advancements in high-performance materials, and a growing emphasis on sustainability in manufacturing processes.