Laser Cutting Machines Market Report

Published Date: 31 January 2026 | Report Code: laser-cutting-machines

Laser Cutting Machines Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Laser Cutting Machines market, covering key insights, market size forecasts, trends, and regional performances from 2023 to 2033.

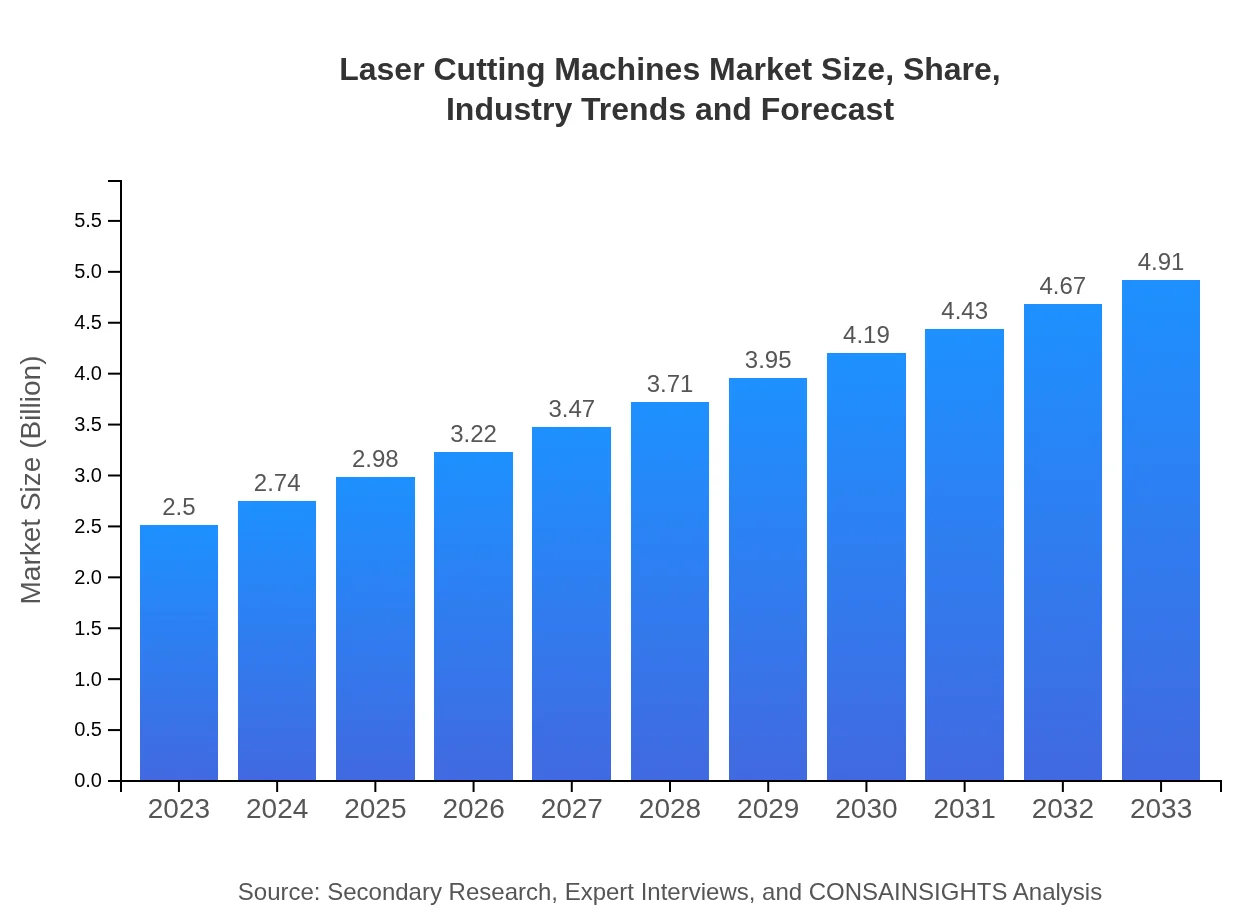

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.91 Billion |

| Top Companies | TRUMPF, Amada Co., Ltd., Bystronic AG, Mitsubishi Electric Corporation, LVD Group |

| Last Modified Date | 31 January 2026 |

Laser Cutting Machines Market Overview

Customize Laser Cutting Machines Market Report market research report

- ✔ Get in-depth analysis of Laser Cutting Machines market size, growth, and forecasts.

- ✔ Understand Laser Cutting Machines's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Laser Cutting Machines

What is the Market Size & CAGR of Laser Cutting Machines market in 2033?

Laser Cutting Machines Industry Analysis

Laser Cutting Machines Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Laser Cutting Machines Market Analysis Report by Region

Europe Laser Cutting Machines Market Report:

Europe's laser cutting machines market is expected to grow from $0.77 billion in 2023 to $1.52 billion by 2033. The region is characterized by high demand for precision engineering and automation in manufacturing. Countries like Germany and the UK are leading the way in adopting cutting-edge technology, thus amplifying the growth prospects of laser cutting machines.Asia Pacific Laser Cutting Machines Market Report:

The Asia Pacific region is set to experience significant growth, with the market anticipated to reach approximately $0.94 billion by 2033, up from $0.48 billion in 2023. The surge in industrialization, particularly in countries like China and India, is a primary driver of this growth. Increased investments in manufacturing and metal processing industries, coupled with technological advancements, further bolster the demand for laser cutting machines in this region.North America Laser Cutting Machines Market Report:

North America is projected to see the market grow from $0.87 billion in 2023 to $1.71 billion by 2033. The demand is driven by advancements in automation and a strong manufacturing base, particularly in the automotive and aerospace sectors. The region's focus on adopting advanced technologies, coupled with the presence of major manufacturers, contributes to the robust growth of the laser cutting machines market.South America Laser Cutting Machines Market Report:

In South America, the market for laser cutting machines is expected to grow from $0.03 billion in 2023 to $0.07 billion by 2033. The region is witnessing a gradual industrial transformation, with emerging economies investing in modern manufacturing technologies. Although the market size is smaller compared to other regions, the potential for growth exists as industries increasingly recognize the advantages of laser cutting technologies.Middle East & Africa Laser Cutting Machines Market Report:

The Middle East and Africa region is witnessing a growth in the laser cutting machines market, expected to expand from $0.34 billion in 2023 to $0.67 billion by 2033. Factors driving this include rising investments in infrastructure and manufacturing sectors, along with increasing adoption of advanced manufacturing technologies in the region.Tell us your focus area and get a customized research report.

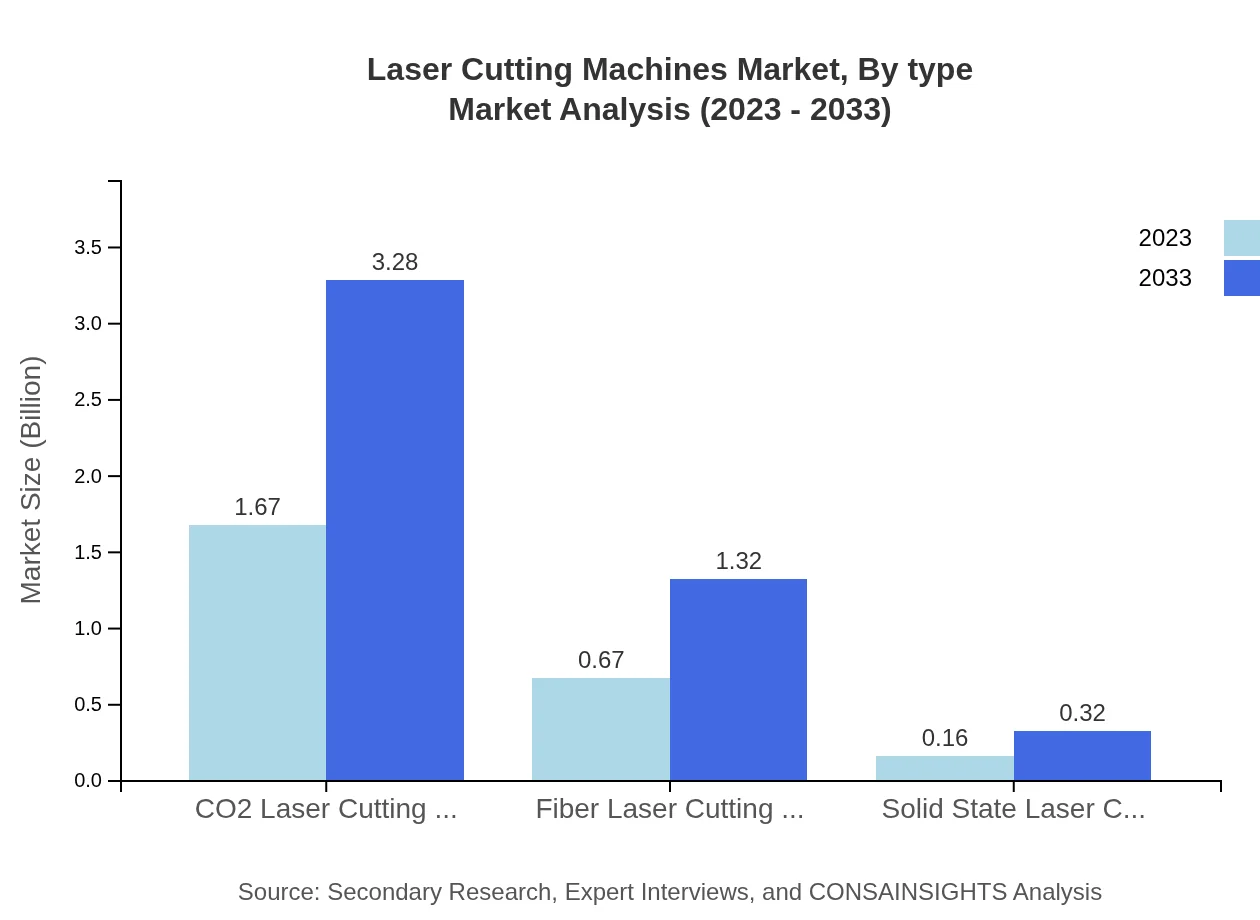

Laser Cutting Machines Market Analysis By Type

The Laser Cutting Machines market is significantly categorized into three main types: CO2 laser cutting machines, fiber laser cutting machines, and solid-state laser cutting machines. In 2023, CO2 laser cutting machines are expected to dominate the market with a size of $1.67 billion, accounting for 66.74% of the share. Fiber laser cutting machines will also see growth, reaching $0.67 billion in the same year with a 26.78% market share. Solid-state machines, while smaller, are expected to grow in relevance as industries seek tailored solutions.

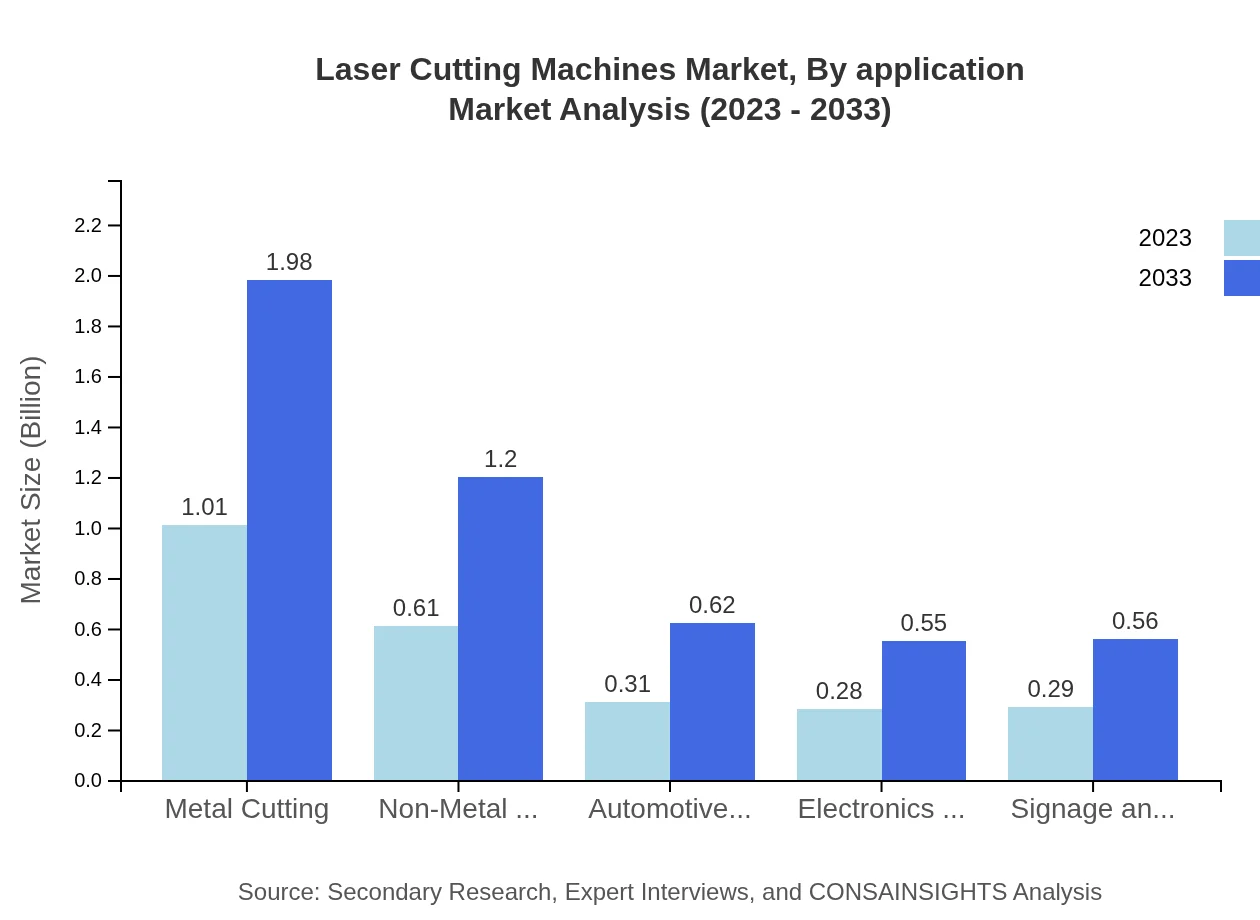

Laser Cutting Machines Market Analysis By Application

Applications of laser cutting machines span across various sectors including manufacturing, construction, aerospace, and electronics. In 2023, manufacturing holds a major share of 40.38% with an estimated market size of $1.01 billion, while construction accounts for 24.44%. This trend is projected to continue as industries strive for efficiency and precision in their operations.

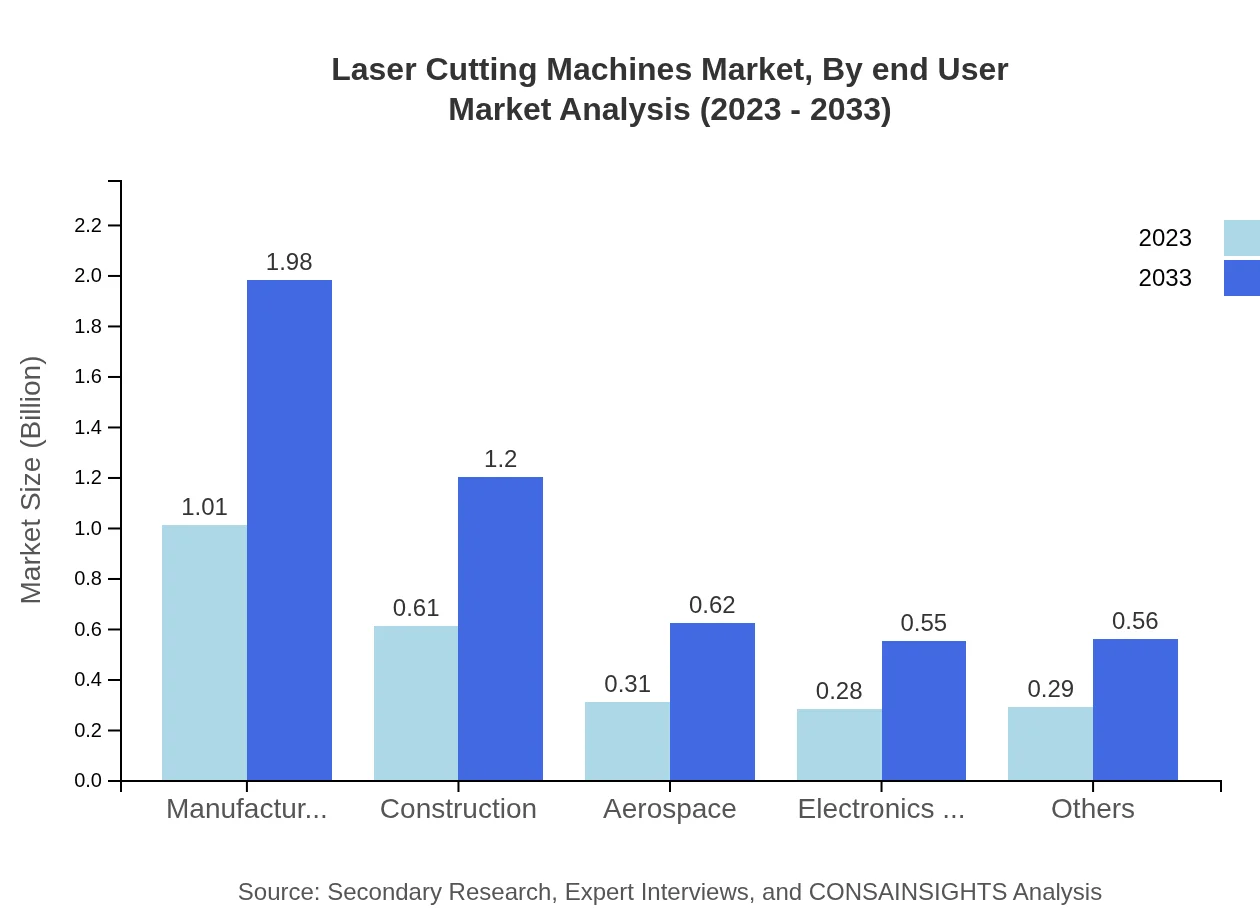

Laser Cutting Machines Market Analysis By End User

The end-user industries of laser cutting machines include Aerospace, Electronics, Automotive, and more. The manufacturing and automotive sectors represent significant demand, with aerospace also showing robust growth. For instance, aerospace applications currently represent 12.58% of market share, underscoring the importance of laser cutting in high-precision fields like aerospace engineering.

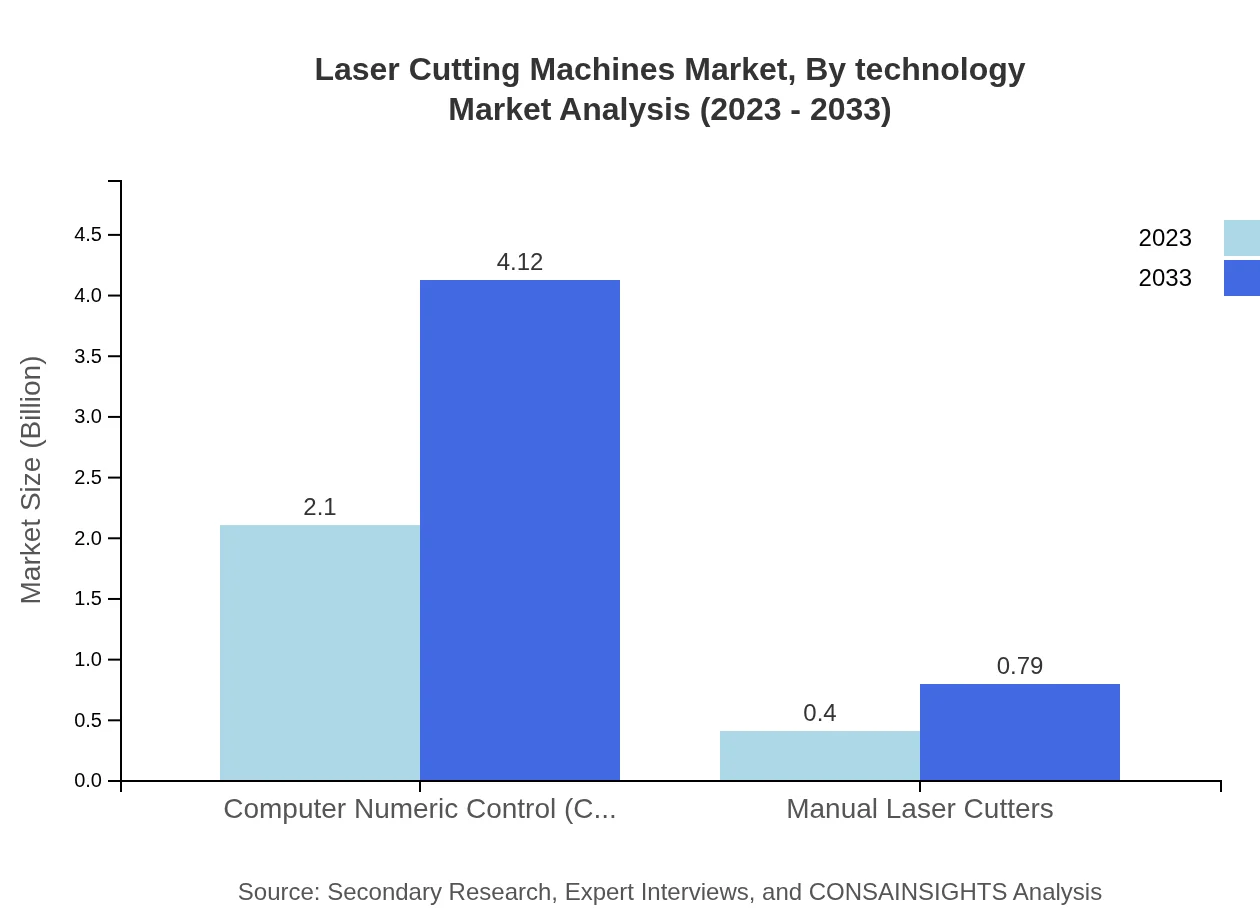

Laser Cutting Machines Market Analysis By Technology

The market is dominated by Computer Numeric Control (CNC) laser technology, which comprises 83.95% share in 2023, thanks to its precision and automation capabilities. Manual laser cutters make up a smaller share at 16.05%, but they cater to niche markets that require flexibility and user control. The trend is leaning heavily towards CNC as companies prioritize efficiency.

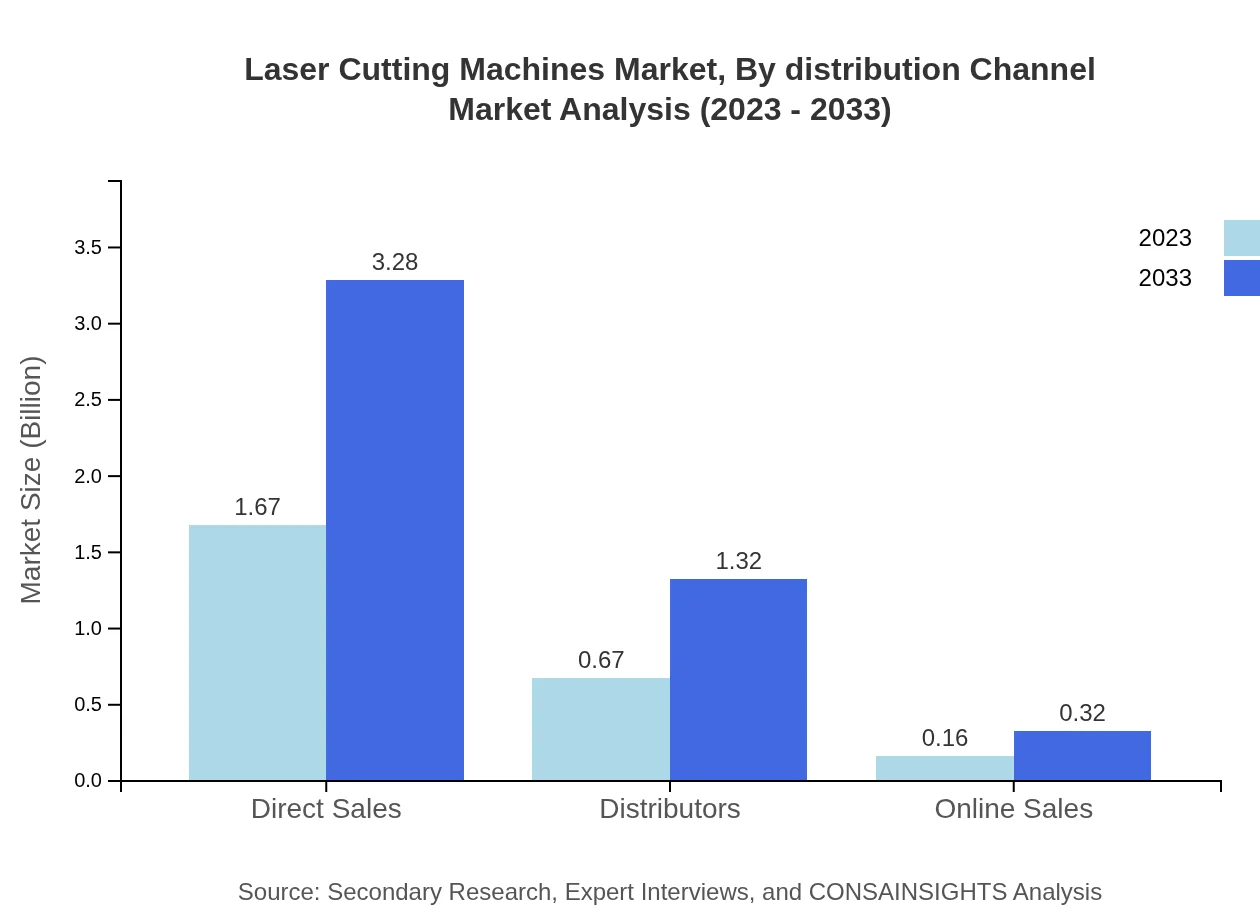

Laser Cutting Machines Market Analysis By Distribution Channel

Distribution channels for laser cutting machines include direct sales, distributors, and online sales. Direct sales lead the market with 66.74% in 2023, reflecting a strong presence of manufacturers engaging directly with customers. Distributors also hold a significant portion of the market (26.78%), facilitating access to local markets, while online sales remain a smaller but growing channel as digital adoption in procurement increases.

Laser Cutting Machines Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Laser Cutting Machines Industry

TRUMPF:

A leading provider of laser technology, specializing in manufacturing high-quality laser cutting machines and systems for various applications.Amada Co., Ltd.:

A prominent player in the metalworking industry, known for its advanced laser cutting machines that cater to multiple sectors including automotive and aerospace.Bystronic AG:

This company focuses on providing innovative solutions in laser cutting and bending machinery, delivering enhanced efficiency and precision.Mitsubishi Electric Corporation:

Mitsubishi offers advanced laser cutting machines with a commitment to quality and technological innovation across industries.LVD Group:

Known for its expertise in sheet metal working, LVD manufactures a range of laser cutting machines aimed at improving productivity.We're grateful to work with incredible clients.

FAQs

What is the market size of laser Cutting Machines?

The global laser cutting machines market is projected to reach $2.5 billion by 2033, growing at a CAGR of 6.8%. This robust growth reflects the increasing demand for precision cutting across various industries.

What are the key market players or companies in the laser Cutting Machines industry?

Prominent players in the laser cutting machines market include Trumpf GmbH, Coherent Inc., and Amada Co., Ltd. These companies are recognized for their innovative technologies and expansive product lines that cater to diverse industrial applications.

What are the primary factors driving the growth in the laser cutting machines industry?

Key growth drivers include advancements in laser technology, increased demand for automation in manufacturing processes, and the growing preference for precision cutting in industries such as aerospace, automotive, and electronics.

Which region is the fastest Growing in the laser Cutting Machines market?

The Asia Pacific region is expected to be the fastest-growing market, with its size increasing from $0.48 billion in 2023 to $0.94 billion by 2033. This growth is fueled by rising industrialization and investments in technology.

Does ConsInsights provide customized market report data for the laser Cutting Machines industry?

Yes, ConsInsights offers customized market report data tailored to specific needs within the laser cutting machines industry, ensuring clients receive the most relevant insights for informed decision-making.

What deliverables can I expect from this laser Cutting Machines market research project?

Clients can expect comprehensive deliverables including detailed market analysis, segmentation data, competitive landscape insights, and actionable recommendations tailored to specific requirements in the laser cutting machines market.

What are the market trends of laser Cutting Machines?

Current trends include the increasing adoption of fiber laser cutting technologies, a shift towards automation, and the rising use of laser cutting in non-metal applications, indicating a diversification in market demands.